Drive oil pump with back side of belt?

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

If the gear were machined, removing the teeth?

I'm still thinking about a VVTS for my 86, and I need more belt length to give a 6-10░ range. (I'm changing the timing by varying the length of the belt on each side of the crank pulley.)

This is what I tried on my '81. I would be using a more sophisticated linkage for the '86.

thread

If I could run the oil pump with a smooth pulley, it would help me two ways. There would be more belt wrap on the crank pulley, and give me more belt length for advance/retarding the valve timing.

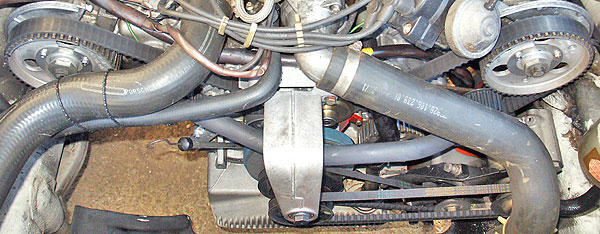

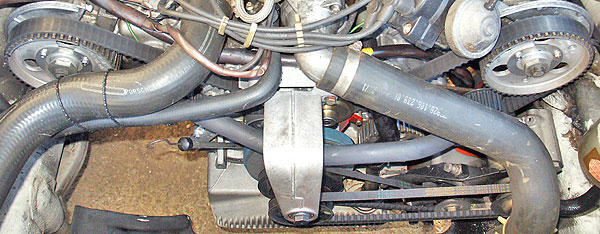

I'd have to remove the rear cover, but it looks like there's room. (Photo of DaveK9's '85 engine.)

I looked for a longer belt, but the 928 tooth profile and spacing is unique. It has specs more like a chain.

I'm still thinking about a VVTS for my 86, and I need more belt length to give a 6-10░ range. (I'm changing the timing by varying the length of the belt on each side of the crank pulley.)

This is what I tried on my '81. I would be using a more sophisticated linkage for the '86.

thread

If I could run the oil pump with a smooth pulley, it would help me two ways. There would be more belt wrap on the crank pulley, and give me more belt length for advance/retarding the valve timing.

I'd have to remove the rear cover, but it looks like there's room. (Photo of DaveK9's '85 engine.)

I looked for a longer belt, but the 928 tooth profile and spacing is unique. It has specs more like a chain.

#3

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Ken,

It looks like the design calls for about 1/2 of each gear to make contact with the belt (never noticed that before) do you think there's an advantage to having more contact?

How about if you went with some other way to drive the oil pump (maybe electric, or driven off a different belt?) so you could have the timing belt come off the crank and go straight up to the DS sprocket? I know the PS bracket goes on there, but maybe there's a way.

Wouldn't using the top make the pump turn the wrong way?

It looks like the design calls for about 1/2 of each gear to make contact with the belt (never noticed that before) do you think there's an advantage to having more contact?

How about if you went with some other way to drive the oil pump (maybe electric, or driven off a different belt?) so you could have the timing belt come off the crank and go straight up to the DS sprocket? I know the PS bracket goes on there, but maybe there's a way.

Wouldn't using the top make the pump turn the wrong way?

#4

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Duh.

I had thought to make an extension on the oil pump shaft, to space it out where the multi-rib alternator belt could drive it.

I wonder how many HP it takes to drive the pump? An electric motor would have advantages...

I wonder how many HP it takes to drive the pump? An electric motor would have advantages...

#5

Rennlist Member

The water pump discharges ~1/2 bar vs the minimum of 5 bar for the oil pump at rpm >2000. The coolant system can tolerate some considerable variation in flow ( centrifrugal pump) wheras the oil system ( constant vol gear pump) cannot, for the latter regulates excess flow via the pressure regulating check valve.

Thinking out loud about it .... there appears to be good reason for a geared drive ....

.... there appears to be good reason for a geared drive ....

Thinking out loud about it

.... there appears to be good reason for a geared drive ....

.... there appears to be good reason for a geared drive ....

#6

Burning Brakes

Trending Topics

#8

Inventor

Rennlist Member

Rennlist Member

Thread Starter

All good reasons not to do it! Besides the fact that it would go the wrong way.

I guess I'm back to using (making) an electric water pump. Without the fan bracket mount in the way, there would be plenty of belt.

I guess I'm back to using (making) an electric water pump. Without the fan bracket mount in the way, there would be plenty of belt.

#10

Rennlist Member

Here is the pump that I am running on my intercooler....without the mounting "pipes". This one is for a big block chevrolet.

http://store.summitracing.com/partde...5&autoview=sku

Regards,

Ken

http://store.summitracing.com/partde...5&autoview=sku

Regards,

Ken