Torque tube bearings

#1

Three Wheelin'

Thread Starter

Join Date: Sep 2003

Location: SF Bay Area

Posts: 1,526

Likes: 0

Received 0 Likes

on

0 Posts

Ok, I searched the forum and still did not get an answer to this question.

One of the posts directed me to a 944 site. The picture of the 944 torque has four bearings.

Now I am really curious. The 928 auto has either two or three bearings and the five speed has three bearings.

So why does the 944 have four bearing. The 944 has less horse power. Would it make sense to put four bearings in a 928 tube?

There are two questions here.

1. If I put a third bearing in a four speed auto tube, what is the placement of the four bearings?

2. The early four speed torque shafts were thinner. Is there any disadvantage to putting a thinner shaft on a 32 valve engine. The car is an 85.

3. Does the position of the harmonic damper have anything to do with vibrations? Can it be adjusted to eliminate vibrations?

I am about to put this thing back together and I sure do not want any vibration when I am done. This is the last time I am pulling an automatic transmission.

Thanks much

Dan the Pod Guy

One of the posts directed me to a 944 site. The picture of the 944 torque has four bearings.

Now I am really curious. The 928 auto has either two or three bearings and the five speed has three bearings.

So why does the 944 have four bearing. The 944 has less horse power. Would it make sense to put four bearings in a 928 tube?

There are two questions here.

1. If I put a third bearing in a four speed auto tube, what is the placement of the four bearings?

2. The early four speed torque shafts were thinner. Is there any disadvantage to putting a thinner shaft on a 32 valve engine. The car is an 85.

3. Does the position of the harmonic damper have anything to do with vibrations? Can it be adjusted to eliminate vibrations?

I am about to put this thing back together and I sure do not want any vibration when I am done. This is the last time I am pulling an automatic transmission.

Thanks much

Dan the Pod Guy

#2

Hi Dan,

The 944 torque tubes (TTs) are longer than either the 928 auto or the five speed TT. Porsche used four bearings in the 944 TT to better support the longer driveshaft.

The more bearings you use the flatter the driveshaft will remain under operation. This is a good thing. At least three evenly spaced will work fine. Getting them to stay put will be the trick because...

The current bearing carriers are getting old and the rubber surround is shrinking a bit. This will lead to the bearing carrier traveling up and down the torque tube from where they are intially set.

I have personally had the harmonic dampner at the rear of most torque tubes come apart due to the rubber fracturing and then the heavy dampner travels and usually ends up against the transmission torque converter housing at the end of TT. This causes some noise and the heavy dampner slides up and down the TT under acceleration and braking. These were left out of certain sporting models of the 928 and I personally will leave mine out when I rebuild my TT. Did so with the 1986.5 track car and no dramatic increase in felt vibrations within the cabin area with either the auto or later when I converted it to a 5 speed.

HTH,

Constantine

The 944 torque tubes (TTs) are longer than either the 928 auto or the five speed TT. Porsche used four bearings in the 944 TT to better support the longer driveshaft.

The more bearings you use the flatter the driveshaft will remain under operation. This is a good thing. At least three evenly spaced will work fine. Getting them to stay put will be the trick because...

The current bearing carriers are getting old and the rubber surround is shrinking a bit. This will lead to the bearing carrier traveling up and down the torque tube from where they are intially set.

I have personally had the harmonic dampner at the rear of most torque tubes come apart due to the rubber fracturing and then the heavy dampner travels and usually ends up against the transmission torque converter housing at the end of TT. This causes some noise and the heavy dampner slides up and down the TT under acceleration and braking. These were left out of certain sporting models of the 928 and I personally will leave mine out when I rebuild my TT. Did so with the 1986.5 track car and no dramatic increase in felt vibrations within the cabin area with either the auto or later when I converted it to a 5 speed.

HTH,

Constantine

#3

Addict

Rennlist Member

Rennlist Member

Originally Posted by Podguy

So why does the 944 have four bearing. The 944 has less horse power.

Would it make sense to put four bearings in a 928 tube?

1. If I put a third bearing in a four speed auto tube, what is the placement of the four bearings?

2. The early four speed torque shafts were thinner. Is there any disadvantage to putting a thinner shaft on a 32 valve engine. The car is an 85.

3. Does the position of the harmonic damper have anything to do with vibrations? Can it be adjusted to eliminate vibrations?

https://rennlist.com/forums/928-forum/178818-torque-tube-rebuild-pictures-and-tools.html#post4173970

Then again early cars and Club Sport do not have entire damper. It was put in for specific purpose but at least manual cars can live without it.

This is the last time I am pulling an automatic transmission.

#4

Addict

Rennlist Member

Rennlist Member

Can't add a lot to what erkka has already said other than

In my humble opinion the vibration damper is to damp comfort related vibrations not to damp the kind of vibrations that damage drivetrain components. Unless you can fabricate/have made new rubber seting rings that will reliably hold the damper in place there is the danger that it will become a slide hammer and slowly hammer the bearings forward every time you brake. Pinning the damper to the shaft sides would negate the benefit of having it there in the first place.

The thicker drive shaft used with the later S4 Auto and GTS brings more problems - they always snap at the neck down to the splines where they are the same diameter as the earlier S4 version.

I'ld stick with three bearings - Porsche used two or three for a reason - not 4. The introduction of a fourth bearing would introduce a whole new set of natural frequencies into the drive train that could do more harm than good.

In my humble opinion the vibration damper is to damp comfort related vibrations not to damp the kind of vibrations that damage drivetrain components. Unless you can fabricate/have made new rubber seting rings that will reliably hold the damper in place there is the danger that it will become a slide hammer and slowly hammer the bearings forward every time you brake. Pinning the damper to the shaft sides would negate the benefit of having it there in the first place.

The thicker drive shaft used with the later S4 Auto and GTS brings more problems - they always snap at the neck down to the splines where they are the same diameter as the earlier S4 version.

I'ld stick with three bearings - Porsche used two or three for a reason - not 4. The introduction of a fourth bearing would introduce a whole new set of natural frequencies into the drive train that could do more harm than good.

#5

Addict

Rennlist Member

Rennlist Member

Originally Posted by jon928se

Unless you can fabricate/have made new rubber seting rings that will reliably hold the damper in place there is the danger that it will become a slide hammer and slowly hammer the bearings forward every time you brake. Pinning the damper to the shaft sides would negate the benefit of having it there in the first place.

#7

Hi Jon,

Does your statement below come from personal experience? If not, how did you deduce adding a fourth bearing will introduce new, possibly harmful, frequencies?

Kind regards,

Constantine

I'ld stick with three bearings - Porsche used two or three for a reason - not 4. The introduction of a fourth bearing would introduce a whole new set of natural frequencies into the drive train that could do more harm than good.[/QUOTE]

Does your statement below come from personal experience? If not, how did you deduce adding a fourth bearing will introduce new, possibly harmful, frequencies?

Kind regards,

Constantine

I'ld stick with three bearings - Porsche used two or three for a reason - not 4. The introduction of a fourth bearing would introduce a whole new set of natural frequencies into the drive train that could do more harm than good.[/QUOTE]

Trending Topics

#8

Addict

Rennlist Member

Rennlist Member

Hi Constantine

Not from personal experience - just a gut reaction to not changing the length/natural frequency from what is known to work, and currently is not thought to cause problems (that I am aware of)

Also if there is any discrepancy in the alignment of the flywheel and gearbox, reducing the unsupported length of the shaft will mean the shaft has to bend over a shorter distance to take out the misalignment which means higher bending moments / stresses thus potentially reduced fatigue life.

Not from personal experience - just a gut reaction to not changing the length/natural frequency from what is known to work, and currently is not thought to cause problems (that I am aware of)

Also if there is any discrepancy in the alignment of the flywheel and gearbox, reducing the unsupported length of the shaft will mean the shaft has to bend over a shorter distance to take out the misalignment which means higher bending moments / stresses thus potentially reduced fatigue life.

#10

Addict

Rennlist Member

Rennlist Member

Originally Posted by FlyingDog

Did manual shafts change in diameter at some point, or just automatics?

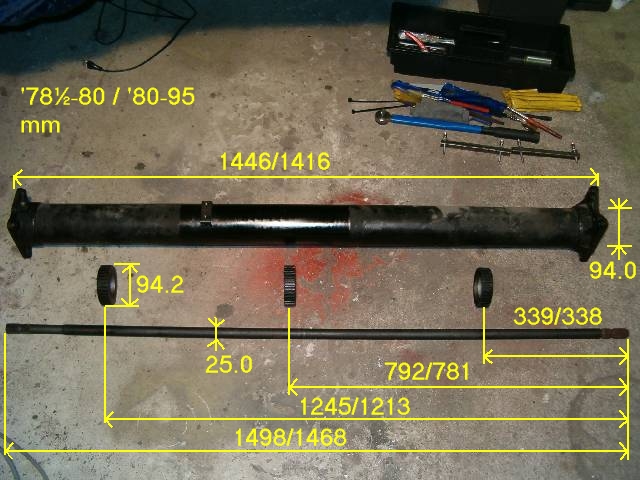

There three different lenghts of manual shafts, early '78, later '78-early '80 and later '80-95. Neither of the changes is done at same time as model year change.

There are two different lenght manual outer tubes, '78-early '80 and later '80-95.

There are two different versions of early tube. Those that where selector arm support is bolted into body and those tubes that have mounting point for support on top of tube. This change was done at beginning of '80 MY.

So in all there are four different versions of manual TT.

Early '78 shaft use different lenght clutch shaft and diffrent lenght front clamp. AFAIK early clutch shaft is no longer available meaning also TT needs to be changed if shaft needs change. These early short shafts were used up to VIN 753 ROW, 54 US and 9522 Japanise model. This also gives insight on production number relations little after production had started. ROW model was much more common in production line in those early days.

#11

Originally Posted by FlyingDog

Has anybody tried installing a custom hollow drive shaft in the torque tube?

#12

Is it someone that know the SKF number of the bearings inside the torque tube for 928 S4 -90 automatic. I am also interested if someone have the possition of the bearings in the torque tube.

Thanks!

Henrik

Thanks!

Henrik

#13

Addict

Rennlist Member

Rennlist Member

NSK No. is 6006ZZCM NS7S

SKF No. is 6006-2Z/C5 HT51

You'll probably find you can't get SKF in the C5 version like the rest of us you'll end up with C3.

SKF No. is 6006-2Z/C5 HT51

You'll probably find you can't get SKF in the C5 version like the rest of us you'll end up with C3.

#15

Three Wheelin'

Thread Starter

Join Date: Sep 2003

Location: SF Bay Area

Posts: 1,526

Likes: 0

Received 0 Likes

on

0 Posts

Try these people. They were a big help to me.

http://www.bearingplace.com/manufactures/ina.html

Dan the Pod Guy

http://www.bearingplace.com/manufactures/ina.html

Dan the Pod Guy