Engine block drain plugs

#16

Three Wheelin'

Originally Posted by marton

about

I heard about doing this when you change the oil but it is new to me to do it when changing coolant - strange idea

Marton

HTML Code:

it talks about getting the engine up to temp before flushing/draining/refilling

Marton

Tony had a write up about this. The heating up part is just for the flushing product - I suspect you want it to circulate the chemicals throughout, and the flush that out as well. Hard to do without getting the car up to temp.

http://members.rennlist.com/v1uhoh/coolant.htm

#17

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I think that it will burp faster if you start warm, and there's always some chance that the engine heat will expand the block away from the bolts enough to make a difference.. NOT! Unless the engine is up to full operating temp, the thermostat is going to be in bypass mode. Coolant that how will burn you, as will all those hot parts you feel your way through to get the wrenches on the bolts. Bottom line: room temp is plenty warm.

Weapon of choice here is a 6-pt socket with a long breaker handle on it. IIRC, I used a short extension on one side but not the other. The long handle saves knuckles and makes the bolts seem to come out easier. Drain the radiator first, and you'll only have a gallon or two to manage at the block drain plugs. Make sure all the other drains are closed and the filler cap is tight on the reservoir tank before you pop the bottom drains, and do them one at a time. Keeping the rest of the system closed in will slow the flow out through the drains. It may save a nasty head wound when you don't try to jump out of the way under the car.

The threads are 8mm (13mm bolt head) IIRC, so the torque needed is not much at all. That 13-16 lbs/ft suggestion is right on. I dabbed a little Hylomar on the upper threads and never-seeze on the end threads. One or both of those products are keeping the coolant in, and hopefully the never-seeze will allow the bolts to come out easily next time the coolant change is due.

Weapon of choice here is a 6-pt socket with a long breaker handle on it. IIRC, I used a short extension on one side but not the other. The long handle saves knuckles and makes the bolts seem to come out easier. Drain the radiator first, and you'll only have a gallon or two to manage at the block drain plugs. Make sure all the other drains are closed and the filler cap is tight on the reservoir tank before you pop the bottom drains, and do them one at a time. Keeping the rest of the system closed in will slow the flow out through the drains. It may save a nasty head wound when you don't try to jump out of the way under the car.

The threads are 8mm (13mm bolt head) IIRC, so the torque needed is not much at all. That 13-16 lbs/ft suggestion is right on. I dabbed a little Hylomar on the upper threads and never-seeze on the end threads. One or both of those products are keeping the coolant in, and hopefully the never-seeze will allow the bolts to come out easily next time the coolant change is due.

#18

Rennlist Member

Originally Posted by fabric

WSM says 33-36 ft-lbs for the block plugs - just did this last weekend. Rad drain plug is 13-17 ft-lbs.

Roger is right - trying to avoid and then contain the escaping coolant is probably the roughest part.

Roger is right - trying to avoid and then contain the escaping coolant is probably the roughest part.

And BTW Marc, the first time I removed my drain plugs I used a craftsman flare nut wrench and had no issues. The things are damn sturdy -- makes me wonder, were you using HF tools?

#19

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Originally Posted by ROG100

And do not forget to wear your swimming trunks - my most hated job on the 928.

Friend of mine was helping me work on the 81 a while back. I cracked them loose then sent him under the car to pull the plug and keep the drain pan lined up.

You stay nice and dry this way!

#20

Addict

Rennlist Member

Rennlist Member

I agree,

A messy ARSS job!! IICRC, I think I broke mine loose and let them dribble for a while after the coolant started coming out. Get a nice large pan. Doesn't need to be deep, just wide as coolant seems to go everywhere!!

I used new crush washers last time but they kept weeping. I ended up using just a little teflon tape and it cured the problem.

Have fun!

A messy ARSS job!! IICRC, I think I broke mine loose and let them dribble for a while after the coolant started coming out. Get a nice large pan. Doesn't need to be deep, just wide as coolant seems to go everywhere!!

I used new crush washers last time but they kept weeping. I ended up using just a little teflon tape and it cured the problem.

Have fun!

#21

Drifting

Join Date: Nov 2001

Location: zürich, switzerland

Posts: 2,233

Likes: 0

Received 0 Likes

on

0 Posts

chuck wrote

"I ended up using just a little teflon tape .."

forgot that, I used some teflon tape on mine; they stay nice and water tight and are also easy to get out next time.

marton

"I ended up using just a little teflon tape .."

forgot that, I used some teflon tape on mine; they stay nice and water tight and are also easy to get out next time.

marton

#22

Three Wheelin'

Originally Posted by SharkSkin

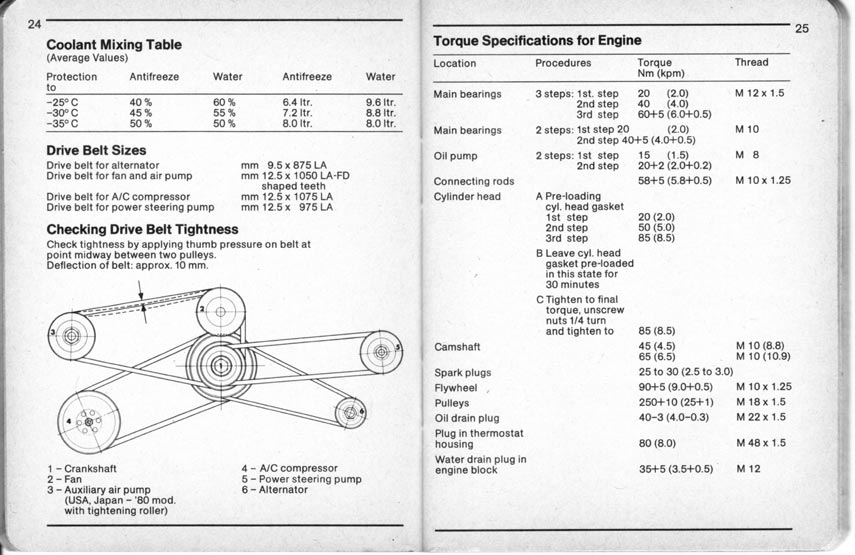

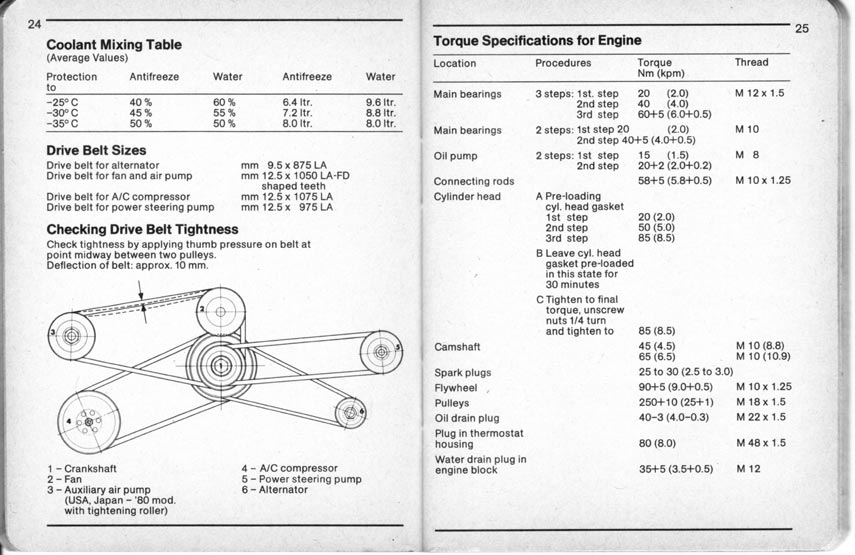

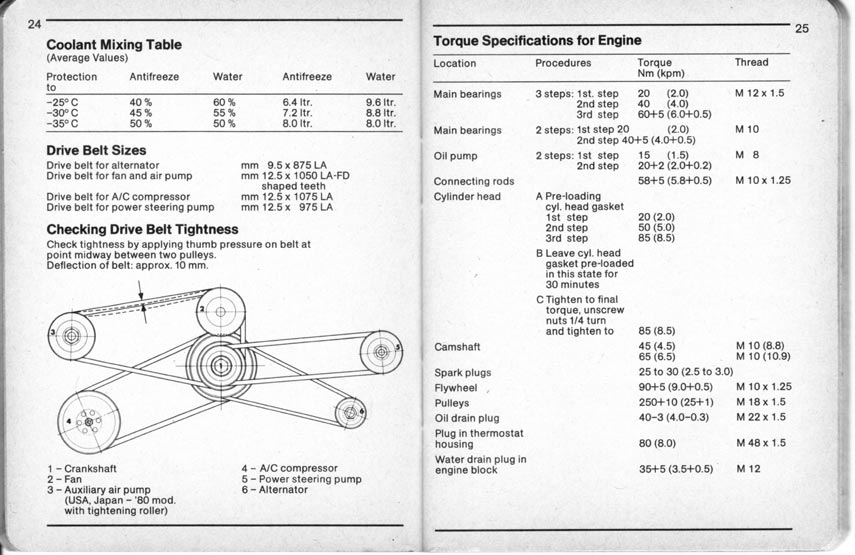

Either you didn't convert to ft/lbs or they changed the spec. The early tech spec book calls out 35+5 Nm, which converts to the 26-29 ft/lbs I stated.

And BTW Marc, the first time I removed my drain plugs I used a craftsman flare nut wrench and had no issues. The things are damn sturdy -- makes me wonder, were you using HF tools?

And BTW Marc, the first time I removed my drain plugs I used a craftsman flare nut wrench and had no issues. The things are damn sturdy -- makes me wonder, were you using HF tools?

Uhh, interesting, here's the WSM. 36 seemed awfully tight:

#23

Rennlist Member

Fabric, FWIW the lower torque is effective. I cleaned all surfaces, installed new crush washers, torqued to 29 ft/lbs -- doesn't leak a drop. Yet another of many spec inconsistencies in the various 928 literature...

#25

Three Wheelin'

Originally Posted by SharkSkin

Fabric, FWIW the lower torque is effective. I cleaned all surfaces, installed new crush washers, torqued to 29 ft/lbs -- doesn't leak a drop. Yet another of many spec inconsistencies in the various 928 literature...

#26

Drifting

Thread Starter

Originally Posted by marton

the radiator drain plug has an O ring? That is probably why mine is not water tight....

Marton

Marton

I'd bought a new plug in readiness some time back (it's black, original blue). It also comes with o-ring but the one I removed looks in perfect condition, o-ring and all. Will probably install a new plug but keep the old one as a spare - I'm sure it's fine. haven't drained block yet (weekend job) but the water from the rad was very clear with not one bit of crud in it. Was last changed 2 years ago so I was pleasantly surprised.

#27

Addict

Rennlist Member

Rennlist Member

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,466

Received 1,622 Likes

on

1,059 Posts

The radiator stop **** torque spec is in INCH POUNDS - NOT FOOT POUNDS!