Any Rebuilt Tensioners NOT leaking? How?

#61

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

H'man, right, you can't add oil before installing the 83+, unlike the earlier tensioner.

You appear to have the fill technique down better than I do. I'm lucky if I get 1/2 to 1 ounce in before it come gushing out the overflow bleeder. Then if I try to pump the tensioner, it comes out the end boot. That would seem to indicate it is full, but it is likely I have trapped air that I wasn't able to expell, based on the fill volume.

You appear to have the fill technique down better than I do. I'm lucky if I get 1/2 to 1 ounce in before it come gushing out the overflow bleeder. Then if I try to pump the tensioner, it comes out the end boot. That would seem to indicate it is full, but it is likely I have trapped air that I wasn't able to expell, based on the fill volume.

#62

Inventor

Rennlist Member

Rennlist Member

#65

Inventor

Rennlist Member

Rennlist Member

Dave,

It would take away all the moving parts!

I suppose it's a failsafe version of most old tensioners out there, which have no harmonic dampening, and little or no compensation for engine expansion, anyway.

...

Heinrich,

It would be interesting to try using that old-school setup (on a 16V of course), and see how the belt wears.

Someday I plan to work on an Audi or other sprung/dampened adaptation as part of my fantasy of making a variable valve timing system.

It would take away all the moving parts!

I suppose it's a failsafe version of most old tensioners out there, which have no harmonic dampening, and little or no compensation for engine expansion, anyway.

...

Heinrich,

It would be interesting to try using that old-school setup (on a 16V of course), and see how the belt wears.

Someday I plan to work on an Audi or other sprung/dampened adaptation as part of my fantasy of making a variable valve timing system.

#66

Inventor

Rennlist Member

Rennlist Member

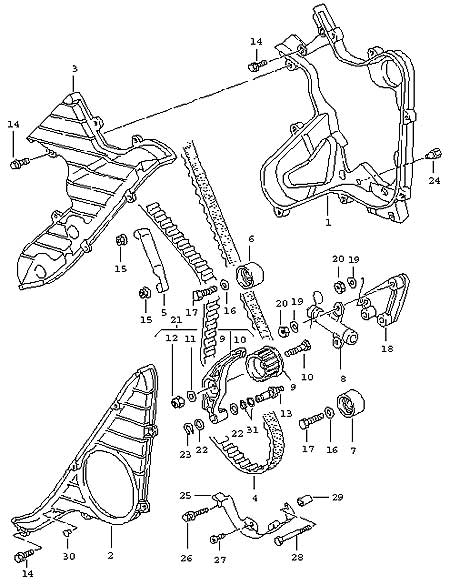

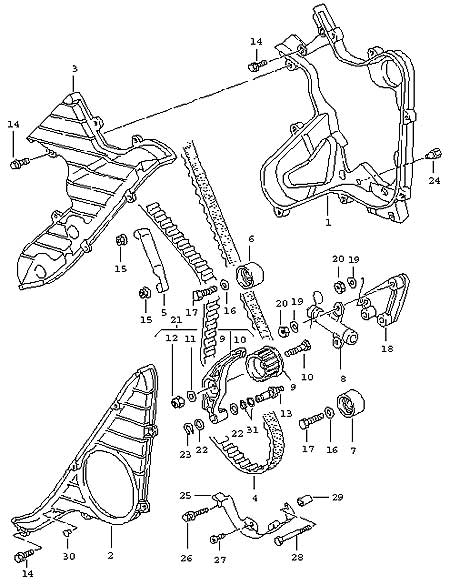

Sorry to keep tangenting this thread, but I just noticed that 968's (92-95) have an Audi style one piece sprung hydraulic dampener. I wonder why Porsche didn't equip GTS's with a similar system?

The 968's and 944's have a cogged tensioner pulley too. I've been looking for a pulley like that everywhere, funny that it would be on a Porsche!

The 968's and 944's have a cogged tensioner pulley too. I've been looking for a pulley like that everywhere, funny that it would be on a Porsche!

#68

Inventor

Rennlist Member

Rennlist Member

Notice that the drawing shows the pin which you remove when the belt is on (looks like a hand grenade pin).

(8) 944 105 172 03 tensioner for toothed belt

(9) 944 105 631 10 tensioning roller

968 Belt Tensioner

(8) 944 105 172 03 tensioner for toothed belt

(9) 944 105 631 10 tensioning roller

968 Belt Tensioner

#69

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Ken: That looks totally simple. It's locked down and rigid, right? I'd like some give for block expansion. Even the early 928 tensioners do that. But then we'd end up roughly back where we are. If there was some way to include a spring that could keep the tension more even under differing conditions.

#70

Inventor

Rennlist Member

Rennlist Member

Bill,

You could have the fixed big pulley as in the picture for ballpark tensioning. Then have a smaller pulley between the cam gear and the big pulley, controlled by a tensioner/damper to handle fine tensioning.

The small pulley could be inside (cogged pulley) or outside (smooth pulley) of the belt.

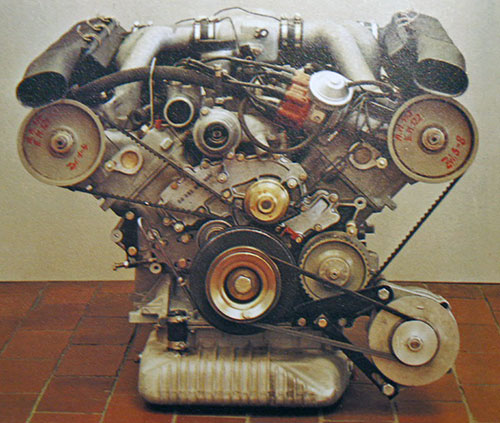

BTW: Wouldn't those airboxes be cool for a TS?

You could have the fixed big pulley as in the picture for ballpark tensioning. Then have a smaller pulley between the cam gear and the big pulley, controlled by a tensioner/damper to handle fine tensioning.

The small pulley could be inside (cogged pulley) or outside (smooth pulley) of the belt.

BTW: Wouldn't those airboxes be cool for a TS?

#71

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Originally Posted by PorKen

Bill,

You could have the fixed big pulley as in the picture for ballpark tensioning. Then have a smaller pulley between the cam gear and the big pulley, controlled by a tensioner/damper to handle fine tensioning.

The small pulley could be inside (cogged pulley) or outside (smooth pulley) of the belt.

BTW: Wouldn't those airboxes be cool for a TS?

You could have the fixed big pulley as in the picture for ballpark tensioning. Then have a smaller pulley between the cam gear and the big pulley, controlled by a tensioner/damper to handle fine tensioning.

The small pulley could be inside (cogged pulley) or outside (smooth pulley) of the belt.

BTW: Wouldn't those airboxes be cool for a TS?

#72

Inventor

Rennlist Member

Rennlist Member

It is a 928!

1974, baby!

1974, baby!

#74

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Originally Posted by Bill Ball

Ken: That looks totally simple. It's locked down and rigid, right? I'd like some give for block expansion. Even the early 928 tensioners do that. But then we'd end up roughly back where we are. If there was some way to include a spring that could keep the tension more even under differing conditions.

.... and some kind of hydraulic damper system to smooth out the vibrations in the belt just downstream of the drive cog.

So a coil spring in tension? Long spring so the tension stays somewhat consistent over a larger range of expansion. If the spring fails, no tension at all.

Perhaps a hydraulic tensioner fed by engine oil pressure, supplementing a coil spring iin compression. The spring just needs to hold the belt snug enough to get the engine started, then the oil-fed system would take over. Many moons ago, I had a system like this on my Saab Turbo, including a little ratchet arrangment that compensated for chain stretch. We don't (shouldn't...) have belt stretch issues after the initial 1k miles, so all the slack taken up as an engine cools would have to be given back as the engine warms again. A relatively large piston with a spring-regulated oil-pressure bypass regulator would keep tension on even with the engine at hot idle. That could also cut down on piston seal requirements, if you could route the bypass oil and the port above the piston directly back to the sump. We almost have that system now, by porting engine oil, through a control orifice, into the current tensioner. Route the lower port back to the sump.

#75

Inventor

Rennlist Member

Rennlist Member

Originally Posted by dr bob

.... and some kind of hydraulic damper system to smooth out the vibrations in the belt just downstream of the drive cog.

I would like to put a damper on the tight side, as there is more room, but movement on that side affects the valve timing. (Which is the basis of my variable valve timing plan.)

The more I think about it, a fixed big pulley, with an accessory sprung/damped small pulley would be quite safe*. It would also be cheap to implement, as the tensioner/damper could be from a smaller engine, since it is not supplying the bulk of the tension. The smaller pulley would only be compensating for expansion and long term belt stretch.

Then again, the Audi S4 tensioner is pretty simple:

* An unlikely failure in the tensioner would still leave the fixed tension.