Lower compression?

#1

Suggestions for best way to lower compression?

Beyond custom pistons, anyone know what CR would be by usage of 944 pistons or 944 turbo pistons (928 block deck is higher?)

Any thoughts on fabricating a particularly thick head gasket (maybe then to 0-ring it all) as an alternative?

10-1 is high for turbo or supercharging.

Motor is 85 32 valve.

Mark

Beyond custom pistons, anyone know what CR would be by usage of 944 pistons or 944 turbo pistons (928 block deck is higher?)

Any thoughts on fabricating a particularly thick head gasket (maybe then to 0-ring it all) as an alternative?

10-1 is high for turbo or supercharging.

Motor is 85 32 valve.

Mark

#2

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

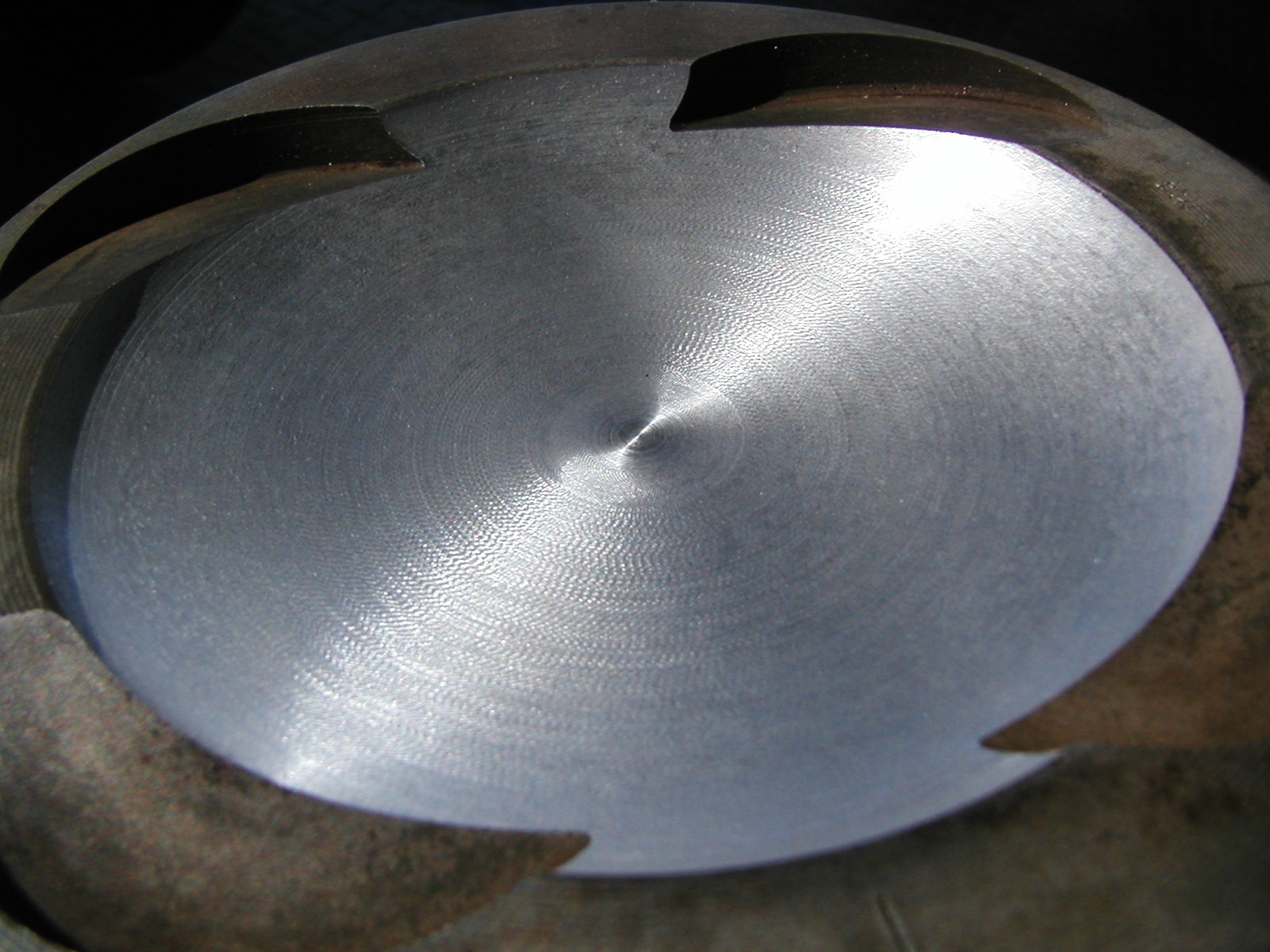

Simple process to have the pistons machined..coming up with a profile and where to remove the material and how much is the harder part

These will be ceramic coated and go in the 6.0L

These will be ceramic coated and go in the 6.0L

#3

You can get the chambers enlarged too.

Frankly, i prefer that method because you're also removing potential hotspots by blending and polishing the chambers at the same time.

Also, if you ever want to go back to factory compression, well, changing heads is much easier than changing pistons...

Frankly, i prefer that method because you're also removing potential hotspots by blending and polishing the chambers at the same time.

Also, if you ever want to go back to factory compression, well, changing heads is much easier than changing pistons...

#4

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

You dont want to change to a thicker head gasket to alter CR. Thats not the best way to do it. Your messing with the squish band around the psiton perimiter. If you mess with that you are changing how the fuel air charge is "squished" to the center of the piston prior to combustion. You can actually end up with bigger problems by using a thicker head gasket....one of which detonation.

#6

Drifting

Depending on how much you want to lower compression, Cometic head gaskets work OK and are available in many different thickness's. If you reduce the squish band too much you may run into problems but I have used .074 headgaskets with no problem. (drop the compression ratio approx. 1/2 point.)

Trending Topics

#8

Who did your piston top machining? Does this weaken the piston in terms of hp ability? Change crank assembly balance? Mine is a budget job, trying to redo a 32v 5.0 10-1 CR to replace a 4.5 16V motor (8.5ish-1 CR) that is turbo charged. In 5.0 form, it will approach 450 hp (it has TEC-3 and 42# injectors). As I will be working with OEM pistons (budget reasons), the pistons are already going to be stressed. Again, any suggestions on who to do the piston top machining? Thanks...

#9

"If you go the piston machining route, you may also want them to machine valve reliefs to provide a little insurance in case the timing belt goes.

Damned good idea Dennis.

The releifs themselves would also lower the CR a bit too.

Damned good idea Dennis.

The releifs themselves would also lower the CR a bit too.

#11

Just use S4 pistons in your block iwth your 85/86 heads. That will lower the compression as your pistons are currently just about "flat tops".

How low do you want to go

Marc

How low do you want to go

Marc

#13

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Originally Posted by IcemanG17

Tony

By machining the pistons down does it take the valves out of "interference" range?

Brian

By machining the pistons down does it take the valves out of "interference" range?

Brian

The only other thing im gong to do is to cermanic coat the tops to reduce heat in the piston itself. Anytime you remove material from something your goign to weaken it, im sure of that. At 10-11psi, i will find out i guess.

Below are a couple of pics. The .3" profile was traced on the piston as a guide. Material wasnt removed below that line...the profile i plotted and used is in red. X depth from the top at y radius from center. Once i had this it was plugged into a CAD machine at a local machine shop and 16 pistons were turned. The numbers are still stored in the machine

Mount them in, zero it out and push a button.

Mount them in, zero it out and push a button.

#14

Three Wheelin'

I have a thick Cometic gasket in my S4...I think it was the 0.074 one--it was the thickest one that they would warrant could provide the same clamping force as their standard thickness one. There was one size higher. I don't know by how much it reduced the CR; however, I used to get some occasional tip-in leanness manifested by audible knocks when I'd floor it off the line. Now, I don't ever hear knocking under those conditions.

It sure would be nice to have a piston solution what would result in a non-interference engine, that's for sure.

RE: using 951 pistons--aren't those all 16 valve motors? Do you have to have reliefs machined in for the extra 2 valves? Will that even work?

It sure would be nice to have a piston solution what would result in a non-interference engine, that's for sure.

RE: using 951 pistons--aren't those all 16 valve motors? Do you have to have reliefs machined in for the extra 2 valves? Will that even work?

Last edited by bd0nalds0n; 08-26-2005 at 05:09 PM. Reason: Got my decimal place wrong