Poor running after pothole encounter

#31

I checked the IMR relay and I donít see a red or green light.

im stumped.🤔☹️

#33

When I pulled the coil from each cylinder, it ran worse when the passenger side wires were pulled. Not a real discernible difference when the drivers side wires were pulled. It did not shut off at all.

#34

I would check spark to each cylinder. The easy way is to clip a timing light on each spark plug wire and see if it lights up. If they all light up you have a fuel injection problem. Then use the IR temp gauge to determine which cylinder(s) is significantly cooler. Then I would check the fuel injector connection on that cylinder(s). They can degrade over the last 40 years and become loose.

#35

to hook up an old school timing light,

remove the hot post stud cap at the 14 pin connector in the engine bay,

and connect the red wire from the timing light to it,

then connect the black wire to ground.

Pull the trigger see if you can hear a squeal from the timing light,

if so,

then you should be able to connect to a plug wire start the engine and get the light to work.

remove the hot post stud cap at the 14 pin connector in the engine bay,

and connect the red wire from the timing light to it,

then connect the black wire to ground.

Pull the trigger see if you can hear a squeal from the timing light,

if so,

then you should be able to connect to a plug wire start the engine and get the light to work.

#36

to hook up an old school timing light,

remove the hot post stud cap at the 14 pin connector in the engine bay,

and connect the red wire from the timing light to it,

then connect the black wire to ground.

Pull the trigger see if you can hear a squeal from the timing light,

if so,

then you should be able to connect to a plug wire start the engine and get the light to work.

remove the hot post stud cap at the 14 pin connector in the engine bay,

and connect the red wire from the timing light to it,

then connect the black wire to ground.

Pull the trigger see if you can hear a squeal from the timing light,

if so,

then you should be able to connect to a plug wire start the engine and get the light to work.

The following users liked this post:

Petza914 (07-05-2024)

#39

Is it possible for the knock sensor plug on the wiring harness to cause this running issue if it’s corroded? I’m going to order an end to splice into the harness but just wondering.

#40

A couple of years ago something similar happened to me in my '87 where the engine would barely run, and when it did, it was very rough.

I tried this, and I tried that, and I finally found it by buying a smoke-tester - within 5-mins of hooking it up, I found the leak.

Turns out a vacuum plug fell off a throttle-body port, below where the throttle-plate is.

I tried this, and I tried that, and I finally found it by buying a smoke-tester - within 5-mins of hooking it up, I found the leak.

Turns out a vacuum plug fell off a throttle-body port, below where the throttle-plate is.

The following users liked this post:

steveymars (07-05-2024)

#41

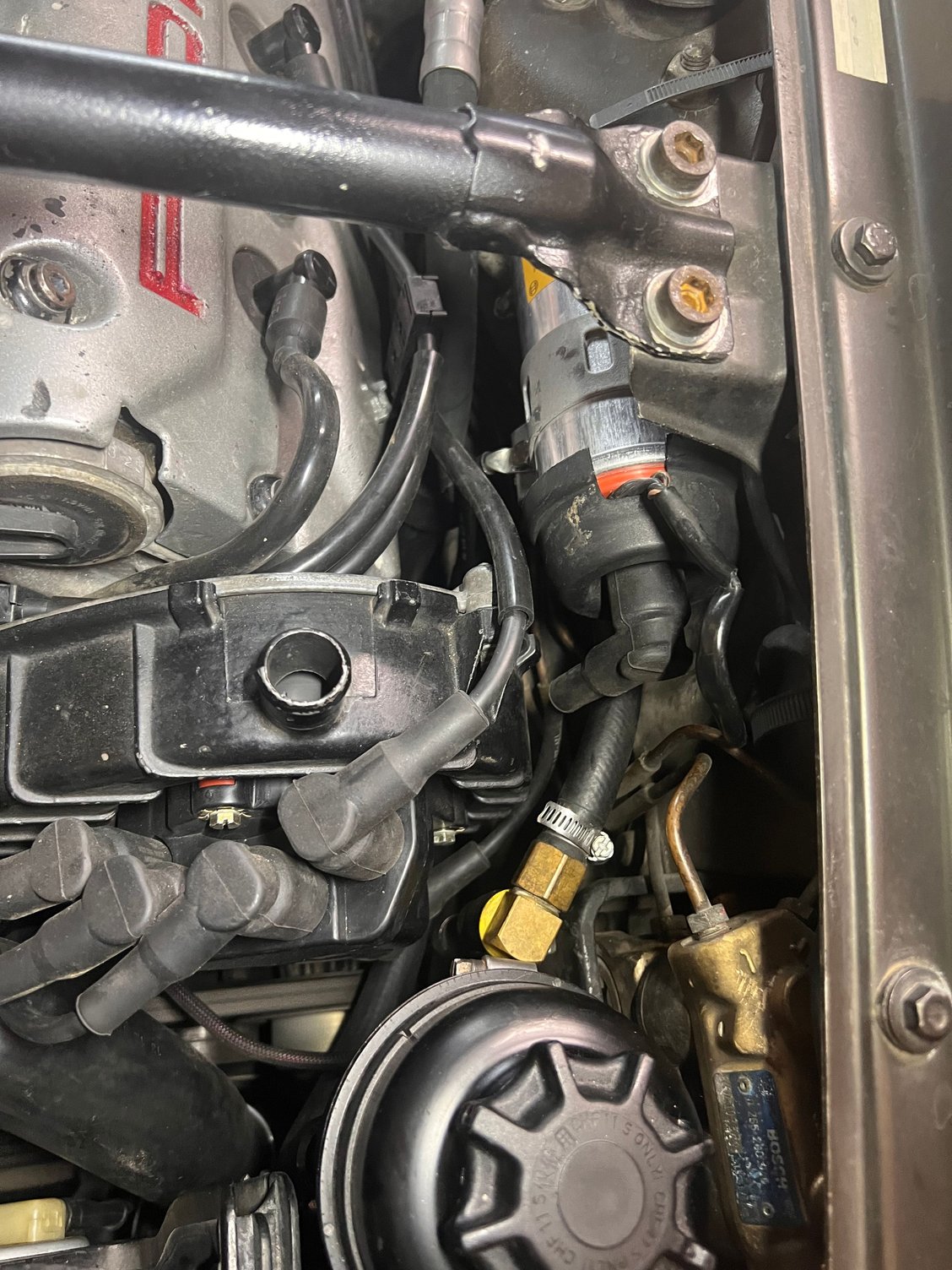

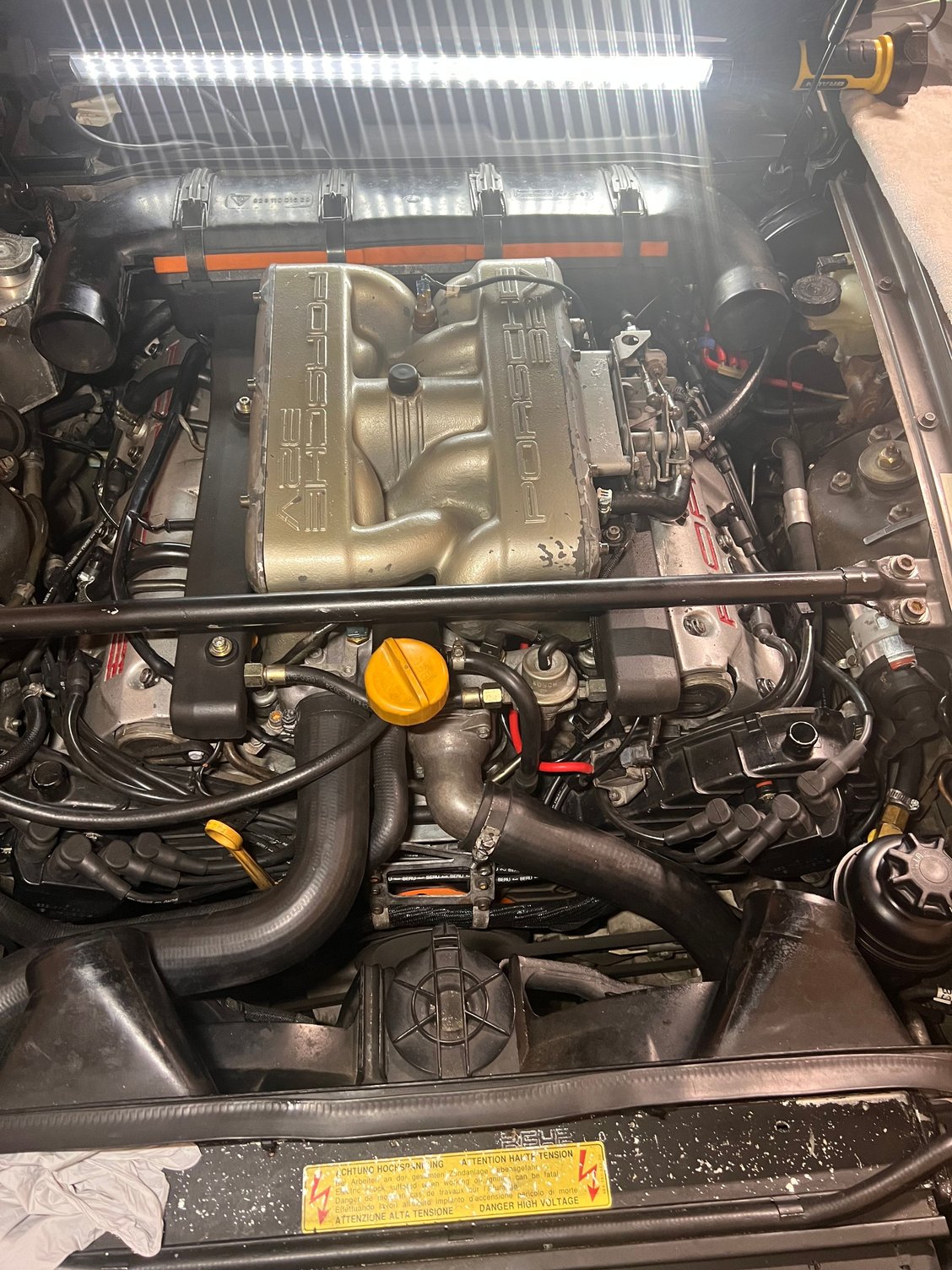

from your pictures I would get two new coil wires and swap them in,

what you dont want is the coil wires touching anything along their run,

based on the pictures , the left coil wire is touching the cam housing this can short it out.

NOTE on the coil cap it should have the wire outlet opening facing down,

as the cap can fill with water. this will ruin a good coil.

NOTE dont try to rehab old sensors with new connectors .

The EOL on the sensors can be gsauged by the connector condition,

if the connector is crumbling or the insulation is shedding then all of these sensors should be replaced .

2 knock sensors,

1 hall sensor ,

1 CPS

what you dont want is the coil wires touching anything along their run,

based on the pictures , the left coil wire is touching the cam housing this can short it out.

NOTE on the coil cap it should have the wire outlet opening facing down,

as the cap can fill with water. this will ruin a good coil.

NOTE dont try to rehab old sensors with new connectors .

The EOL on the sensors can be gsauged by the connector condition,

if the connector is crumbling or the insulation is shedding then all of these sensors should be replaced .

2 knock sensors,

1 hall sensor ,

1 CPS

#42

from your pictures I would get two new coil wires and swap them in,

what you dont want is the coil wires touching anything along their run,

based on the pictures , the left coil wire is touching the cam housing this can short it out.

NOTE on the coil cap it should have the wire outlet opening facing down,

as the cap can fill with water. this will ruin a good coil.

NOTE dont try to rehab old sensors with new connectors .

The EOL on the sensors can be gsauged by the connector condition,

if the connector is crumbling or the insulation is shedding then all of these sensors should be replaced .

2 knock sensors,

1 hall sensor ,

1 CPS

what you dont want is the coil wires touching anything along their run,

based on the pictures , the left coil wire is touching the cam housing this can short it out.

NOTE on the coil cap it should have the wire outlet opening facing down,

as the cap can fill with water. this will ruin a good coil.

NOTE dont try to rehab old sensors with new connectors .

The EOL on the sensors can be gsauged by the connector condition,

if the connector is crumbling or the insulation is shedding then all of these sensors should be replaced .

2 knock sensors,

1 hall sensor ,

1 CPS

Last edited by awilli6; 07-05-2024 at 04:12 PM.

#43

A cooler cylinder just means the spark, fuel/air & compression system is not working as it should. It could be cooler due to no spark or no fuel. Or improper air & fuel mix or a lack of compression. These engines need 4 things to happen perfectly. The basic order of diagnosing a poor running ICE is to isolate the failure and start with the simple stuff first. With the timing light you can test to see if current is flowing to each spark plug. If one or multiple cylinders are not getting current, trace your system from the spark plug to the power source. Spark plugs can fail or cause poor performance but generally they just work. If you have current running to all plugs, the next consideration is fuel into the cylinders. The easiest way to test for this with an IR temperature gauge. If a cylinder is getting spark but not fuel, the heat generating explosion when the two combine under pressure will not be occurring. By knowing which cylinder is running appreciably cooler than the others you can start investigating that particular cylinder. I.E. fuel injection connection or power to the injector. You can go multiple levels deeper but these are the basics and should point you in a direction.

#44

a knock sensor failure will not cause the engine to run rough,

it will retard the timing so less power will be generated

However if the wires get crossed / shorted at a broken connector IDK what could happen

it will retard the timing so less power will be generated

However if the wires get crossed / shorted at a broken connector IDK what could happen

#45

A cooler cylinder just means the spark, fuel/air & compression system is not working as it should. It could be cooler due to no spark or no fuel. Or improper air & fuel mix or a lack of compression. These engines need 4 things to happen perfectly. The basic order of diagnosing a poor running ICE is to isolate the failure and start with the simple stuff first. With the timing light you can test to see if current is flowing to each spark plug. If one or multiple cylinders are not getting current, trace your system from the spark plug to the power source. Spark plugs can fail or cause poor performance but generally they just work. If you have current running to all plugs, the next consideration is fuel into the cylinders. The easiest way to test for this with an IR temperature gauge. If a cylinder is getting spark but not fuel, the heat generating explosion when the two combine under pressure will not be occurring. By knowing which cylinder is running appreciably cooler than the others you can start investigating that particular cylinder. I.E. fuel injection connection or power to the injector. You can go multiple levels deeper but these are the basics and should point you in a direction.

Thank you for the explanation.