What material to use for center console side panels?

#16

Rennlist Member

@hans14914 : This sounds like a great SendCutSend type of job, if you get a nice CAD file.

For other folks on this thread, having just worked on my passenger side panel, there is some contouring of the piece that looks intentional. How important is it?

Cheers

For other folks on this thread, having just worked on my passenger side panel, there is some contouring of the piece that looks intentional. How important is it?

Cheers

#17

Rennlist Member

@hans14914 : This sounds like a great SendCutSend type of job, if you get a nice CAD file.

For other folks on this thread, having just worked on my passenger side panel, there is some contouring of the piece that looks intentional. How important is it?

Cheers

For other folks on this thread, having just worked on my passenger side panel, there is some contouring of the piece that looks intentional. How important is it?

Cheers

I am honestly not sure if those pieces had a shape when they were made, or if its just from resting in situation for an extended period of time and getting memory. I recall several of the ones in storage kind of returning to a flat state over the years. Will have to go and check that out.

With something as thin as .060, it should take the shape its supposed to with the fasteners and the groove in the console.

To answer the question above, left and right would be the same, but if using ABS you would want to mirror the part so the textured part of the panel faced in.

The following 2 users liked this post by hans14914:

depami (05-14-2024),

Zirconocene (05-14-2024)

#18

Team Owner

Great idea for the usb port Hans,

NOTE left and right console panels are different,

this can be confirmed by looking at the pictures in post 8

NOTE left and right console panels are different,

this can be confirmed by looking at the pictures in post 8

Last edited by Mrmerlin; 05-14-2024 at 06:17 PM.

The following users liked this post:

davek9 (05-15-2024)

#19

Rennlist Member

Between the acrylic (plexi-glass) and the ABS I would lean towards the ABS. The acrylic has a much higher tendency to suddenly and massively crack. ABS is harder to find at the local hardware store, though.

#20

Rennlist Member

Interesting not sure if it matters but my original drivers panel has a slot that allows the panel to slide over the bracket that holds the shelf. PITA too!

#21

Rennlist Member

It looks like there is a difference between the years too. All of my cars are 86 or newer.

I will need to track down some examples of the various earlier years.

I can get the "new" style ones done fairly quickly.

Making a wild guess there was a change for the 85 model year and probably one somewhere around 80 and possibly 82?

I will need to track down some examples of the various earlier years.

I can get the "new" style ones done fairly quickly.

Making a wild guess there was a change for the 85 model year and probably one somewhere around 80 and possibly 82?

#22

Team Owner

IIRC the later style covers are easier to RnR since the hole for the bracket has been omitted,

this means you dont have to remove the parcel tray to remove the side cover.

this means you dont have to remove the parcel tray to remove the side cover.

The following users liked this post:

Babado (05-15-2024)

#23

Rennlist Member

That is correct. All the covers I have removed have always had a full slot versus a captive one.

I am not sure if there if later can be retrofit to earlier. I have no early cars here for testing.

I am not sure if there if later can be retrofit to earlier. I have no early cars here for testing.

#24

Team Owner

I will bet the later covers will retrofit with little to no modding,

and you would never know the difference.

and you would never know the difference.

#25

Rennlist Member

Last edited by Jerry Feather; 05-19-2024 at 06:48 PM.

#26

Rennlist Member

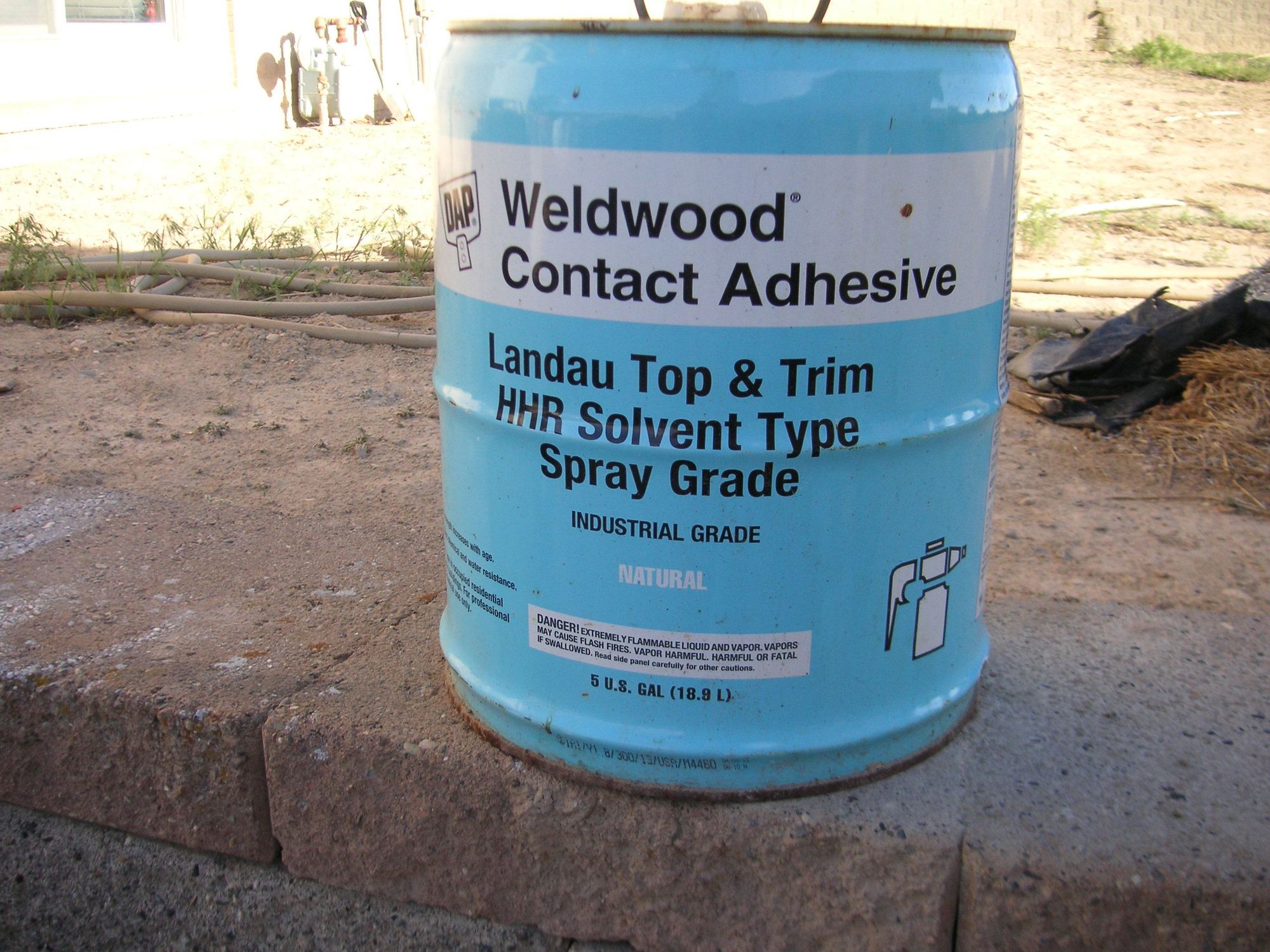

You may also notice that in my picture I have my two panels laid out on some black ABS plastic. I had mentioned above that I would think about doing these panels in aluminum, and I still think that is a good idea, but when the mention of ABS plastic was made above in this thread it struck my memory that I actually have several pieces of that stuff which are drops from sheets of the stuff that I had bought for another project. I have been wondering what I might ever make out of the drops. One nice thing about my drops is that they are 3/32 inch thick. I noticed that there was a mention of 1/16 inch ABS and that 1/8 was too thick. I think 1/16 it too thin and also that 1/8 is too much. I am left with the conclusion that 3/32 is just about perfect for these panels; and it actually is very close to the fiberboard that the originals are made out of. I have 10 pieces of the 3/32 inch ABS and can make 10 pair of these panels with it.

Last edited by Jerry Feather; 05-15-2024 at 11:47 PM.

The following users liked this post:

Snowglobe (06-03-2024)

#27

Rennlist Member

The next step will be to first strip the carpet off of my two panels then trace them on some paper for a pattern to cut some out from the plastic. I'll then cut each of the 10 drops into pieces shaped very roughly more than each of the panels and then glue that pattern to a piece of probably Masonite then stack the pieces up into a stack of 10 and make them into a sandwich with another piece of Masonite, or such, on the bottom, and the pattern one on the top, then drill some of the actual holes enough for screws or small bolts to keep the sandwich tight, and then cut to the outline of all 10 of them in my bandsaw. I wont need any computer program or any laser cutter or the like; and I actually have about 10 bandsaws in various configurations, so cutting them out will go very quickly and it will be for 10 pieces at a time.

When the sandwiches are cut out then I can finish the edges to the exact pattern in the belt sander, then use my milling machine to finish out the fine details of the panels like holes and slots. Then take the sandwich apart and have 10 pieces of one side from each sandwich.

One thought I have is just which side to put the texture of the plastic - - inside or outside where the carpet or other material will be glued on. My inclination is to put the pattern on the outside since that is where it usually goes. In this case the pattern or texture is a very fine tiny pebble-like texture called "Hair cell." I'm not sure what that means or what that might refer to in real life. What are the reasons for the idea to put the texture on the inside.?

When the sandwiches are cut out then I can finish the edges to the exact pattern in the belt sander, then use my milling machine to finish out the fine details of the panels like holes and slots. Then take the sandwich apart and have 10 pieces of one side from each sandwich.

One thought I have is just which side to put the texture of the plastic - - inside or outside where the carpet or other material will be glued on. My inclination is to put the pattern on the outside since that is where it usually goes. In this case the pattern or texture is a very fine tiny pebble-like texture called "Hair cell." I'm not sure what that means or what that might refer to in real life. What are the reasons for the idea to put the texture on the inside.?

Last edited by Jerry Feather; 05-15-2024 at 11:59 PM.

#28

Rennlist Member

Would there be a difference in adhesion of the carpet to the texture side vs the smooth side? I know that one sometimes wants to scuff a surface to provide some "bite" on a surface, which would make me think you'd want the smooth side away from the carpet. Not exactly what you're asking, I know, but I like thinking about these things.

Cheers

Cheers

#29

Rennlist Member

Would there be a difference in adhesion of the carpet to the texture side vs the smooth side? I know that one sometimes wants to scuff a surface to provide some "bite" on a surface, which would make me think you'd want the smooth side away from the carpet. Not exactly what you're asking, I know, but I like thinking about these things.

s

s

Last edited by Jerry Feather; 05-16-2024 at 11:00 AM.

The following users liked this post:

monkez (06-04-2024)

#30

Rennlist Member

The final phase of these panels will be to finish them in the shape made by or intended by the Factory, or some reasonable replication of that. I have studied the shape of my two panels and can not really tell too much about what they were intended to be shaped like. I have also however studied the two surfaces where they live and from that study I think I have figured out what was originally intended. There are basically two different edges that these panels are intended to relate to. The bottom edge is intended to follow the side of the tunnel and the top edge fits in the groove along the bottom edge of the center console. Those edges are not parallel to each other, or on the same plane. When you put a flat panel in, it can be bent or kind of twisted to follow both edges, and what you end up with is pretty much a flat wrap curvature. What I think the factory tried to do and probably did for the original panels, was to put some kind of soft hump in the curvature to make it much more compound that just flat. That gives the panel a much nicer, softer and more appealing look.

I'm going to work up a fairly simple set of wooden forms to be able to put that kind of shape into these new panels. We'll see how that goes.

I'm going to work up a fairly simple set of wooden forms to be able to put that kind of shape into these new panels. We'll see how that goes.

Last edited by Jerry Feather; 06-03-2024 at 11:33 AM.