TBF - Check the end float of the crank!!!!!

#1

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Thread Starter

Thrust Bearing Failure

928 Owners are always asking me about TBF on automatic 928's from 85 to 95. There are lots of theories why this happens and I do not want to go into the various reasons.

Suffice to say - ALWAYS HAVE THE END FLOAT OF THE CRANKSHAFT CHECKED BEFORE YOU BUY AN AUTO (ROGERBOX) 928.

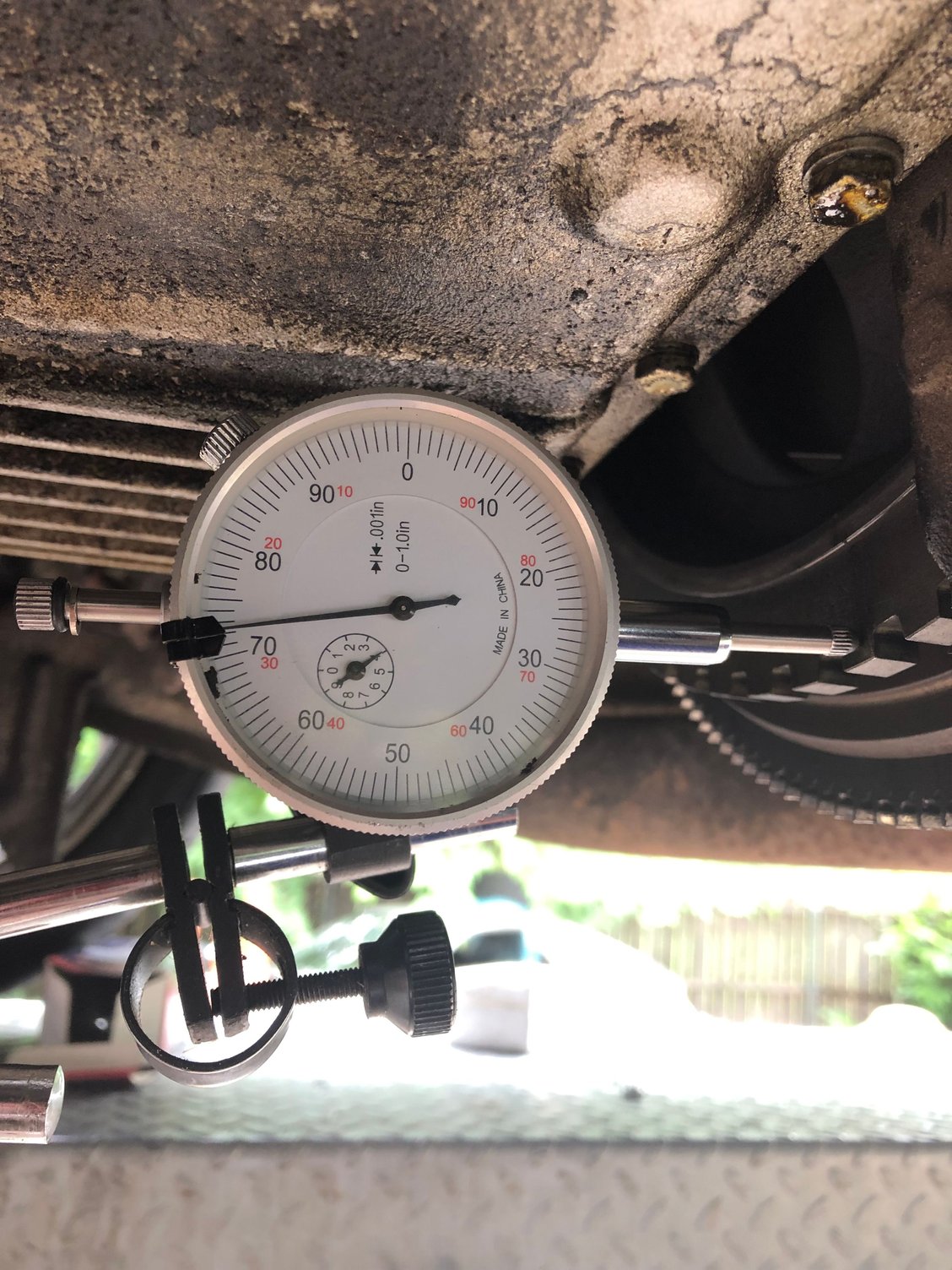

I always hear that the flex plate clamp bolt has been removed and the forward pressure on the flex plate relieved. This is only a small part of the check. It is imperative to measure the end float of the crank in the block. Basically the backward and forward movement of the crank. Obviously there needs to be some free play otherwise the crank will not turn. Factory spec is approx. 0.007" (0.18mm). Up to 0.016" (0.40mm) you are OK but anything beyond that means you are into TBF and terminal damage to the engine.

The attached video shows a very bad case of TBF at 0.070" (1.8mm). Which is the death knell for this engine. Make sure everyone knows that the end float of the crank is the important criteria and not just releasing the flex plate pressure.

__________________

Does it have the "Do It Yourself" manual transmission, or the superior "Fully Equipped by Porsche" Automatic Transmission? George Layton March 2014

George Layton March 2014

928 Owners are ".....a secret sect of quietly assured Porsche pragmatists who in near anonymity appreciate the prodigious, easy going prowess of the 928."

Does it have the "Do It Yourself" manual transmission, or the superior "Fully Equipped by Porsche" Automatic Transmission?

George Layton March 2014

George Layton March 2014928 Owners are ".....a secret sect of quietly assured Porsche pragmatists who in near anonymity appreciate the prodigious, easy going prowess of the 928."

Last edited by ROG100; 06-05-2019 at 01:54 PM.

The following users liked this post:

frugal928 (06-24-2019)

#3

Rennlist Member

Great video Roger...but a misfortunate for that 928 you tested. What should the owner do? Part it out? I was at .006" well within spec. I also installed a Ritech Clamp as well.

#4

Rennlist Member

To be honest I have not checked this on my 86.5 928S for two reasons:

1) Worried that if I loosen the pinch bolt I won't tighten it properly, resulting in the same problem I'm trying to prevent

2) If the engine is doomed what's the point of checking it?

3) 86 engines had a different torque tube, are they still impacted?

Yes I know, head in sand. I'm not perfect.

1) Worried that if I loosen the pinch bolt I won't tighten it properly, resulting in the same problem I'm trying to prevent

2) If the engine is doomed what's the point of checking it?

3) 86 engines had a different torque tube, are they still impacted?

Yes I know, head in sand. I'm not perfect.

#5

Team Owner

I check every year car for properly tightened clamp bolts ,

NOTE and all cars get the flex plate check

NOTE the 5 speed cars will also wear out the thrust bearing on the forward side of the thrust bearing,

NOTE pressing the clutch in and then starting the car will force the crank into the bearing with no oil pressure till it starts , something to think about.

NOTE most rear pinch bolts are loose this will let the drive shaft migrate forward then the bearings and the rear clamp will hold it pressed forward

NOTE every 32 Valve car with auto trans should have the flex place check performed as these engines generally have more torque so the drive shaft will flex more.

NOTE inspecting the rear pinch bolt at the trans axle is part of the flex plate check, and if not performed could result in damage to the thrust bearing

NOTE setting torque is now 66 ft lbs I add a drop of blue loctite to the threads so if the bolt should get loose by stretching it wont come out of the clamp.

NOTE I had to replace a rear flex plate and clamp due to a rear bolt falling out and tearing up metal.

NOTE and all cars get the flex plate check

NOTE the 5 speed cars will also wear out the thrust bearing on the forward side of the thrust bearing,

NOTE pressing the clutch in and then starting the car will force the crank into the bearing with no oil pressure till it starts , something to think about.

NOTE most rear pinch bolts are loose this will let the drive shaft migrate forward then the bearings and the rear clamp will hold it pressed forward

NOTE every 32 Valve car with auto trans should have the flex place check performed as these engines generally have more torque so the drive shaft will flex more.

NOTE inspecting the rear pinch bolt at the trans axle is part of the flex plate check, and if not performed could result in damage to the thrust bearing

NOTE setting torque is now 66 ft lbs I add a drop of blue loctite to the threads so if the bolt should get loose by stretching it wont come out of the clamp.

NOTE I had to replace a rear flex plate and clamp due to a rear bolt falling out and tearing up metal.

#6

Rennlist Member

I've avoided thinking about this too much since I have a manual, but I would think, especially if your car is asymptomatic, that there is a point right before it becomes too late where you could install a clamp and prevent disaster. Given how common this affliction is, I would assume if you do nothing, eventually you'll have the problem and why not prevent it if possible?

Regarding the bolts, Roger can sell you new ones, and then there's a torque spec (which I think has been increased from the original factory value?).

Full disclosure I bought new bolts from Roger and I've never put them on because I have a manual, I'm a procrastinator and without a lift it looks like a pain. So definitely don't follow my example for anything...

Regarding the bolts, Roger can sell you new ones, and then there's a torque spec (which I think has been increased from the original factory value?).

Full disclosure I bought new bolts from Roger and I've never put them on because I have a manual, I'm a procrastinator and without a lift it looks like a pain. So definitely don't follow my example for anything...

Trending Topics

#8

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

How many 5-speed cars have been recorded as having TBF?

#10

When I built my stroker engine the measurement was .008, and after 20K hard miles it was .009

#11

Rennlist Member

To be honest I have not checked this on my 86.5 928S for two reasons:

1) Worried that if I loosen the pinch bolt I won't tighten it properly, resulting in the same problem I'm trying to prevent

2) If the engine is doomed what's the point of checking it?

3) 86 engines had a different torque tube, are they still impacted?

Yes I know, head in sand. I'm not perfect.

1) Worried that if I loosen the pinch bolt I won't tighten it properly, resulting in the same problem I'm trying to prevent

2) If the engine is doomed what's the point of checking it?

3) 86 engines had a different torque tube, are they still impacted?

Yes I know, head in sand. I'm not perfect.

The 86 engines have the same design of flex plate clamp as the later models but the difference is the drive shaft diameter is 25mm and it has three bearings. The S4 and GTS have a 28mm drive shaft with two bearings and there is a taper at each end of the shaft and the splines are the same size as the earlier models. For sure the later models exhibit TBF. During my research it was not clear if the smaller shaft let's go in the same way - I understand it can happen but cannot quote any specific examples. The original drive shaft design used up to model year 84 that uses shims to align the clamp does not exhibit TBF.

Many folks do not like the 28mm shaft because it has been known to snap as did the one on my late 90S4 just after I acquired it. My theory is that the 28mm shaft fails when the front clamp slips and the effective length of the shaft increases and thus causes a vibration leading to fatigue failure. Stop the clamp from slipping [as I did with Loctite 20 years ago] and the shaft will be fine..

Run an automatic transmission with the pinch bolt clamp and it is a crap shoot as to whether the motor will survive. There are several options that will stop this from happening- just a question of whether one pefers to play Russian roulette with the motor.

#12

Team Owner

ERIC just last week I had a 90 S4 come in that had a new used engine installed bc the original was a thrust failure engine

Anyway the engine came from a 5 speed

As Requested I did a crank endplay check

the clearance was at .012in. This is a bit higher than most autos I check

most are in the range of .008 to .010 in.

So yes you should check your 5 speed for thrust bearing wear

with the bell housing removed its pretty easy to check

Anyway the engine came from a 5 speed

As Requested I did a crank endplay check

the clearance was at .012in. This is a bit higher than most autos I check

most are in the range of .008 to .010 in.

So yes you should check your 5 speed for thrust bearing wear

with the bell housing removed its pretty easy to check

#13

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I'm talking about checking for movement as someone works the clutch. If the clutch is putting that much pressure on the crank to load up the thrust bearing, you'd be able to measure that movement on an otherwise perfectly good engine.

#14

Rennlist Member

The 86 engines have the same design of flex plate clamp as the later models but the difference is the drive shaft diameter is 25mm and it has three bearings. The S4 and GTS have a 28mm drive shaft with two bearings and there is a taper at each end of the shaft and the splines are the same size as the earlier models. For sure the later models exhibit TBF. During my research it was not clear if the smaller shaft let's go in the same way - I understand it can happen but cannot quote any specific examples. The original drive shaft design used up to model year 84 that uses shims to align the clamp does not exhibit TBF.

Could that be the problem, that all the force is concentrated right at the point it goes into the clamp which could loosen the clamp as opposed to being spread across the shaft?

Run an automatic transmission with the pinch bolt clamp and it is a crap shoot as to whether the motor will survive. There are several options that will stop this from happening- just a question of whether one pefers to play Russian roulette with the motor.

#15

A 28mm shaft is ~57% stiffer than a 25mm shaft axially and in torsion. Therefore, the 28mm shaft will have significantly less angular deflection than the 25mm, with the identical torque applied. The end fixing size reduction of the 28mm shaft is an insignificant contributor to reducing its stiffness increase and has little impact to the total angular deflection of the shaft under load..

The increased axial stiffness of the 28mm design allows for the reduction in the number of support bearings from 3 to 2.

The increased axial stiffness of the 28mm design allows for the reduction in the number of support bearings from 3 to 2.