Can this GTS Crank be saved?

#16

Rennlist Member

Thread Starter

Interesting fact - State of Georgia doesn't permit Nitriding . Crank needs to go to NC for that.

#17

Rennlist Member

Thread Starter

Spoke with my machinist about cross drilling. Found this here on RL.

Also asked about going to Honda sized journals and moving them off center. Probably too late to move them off center, Journals are at about 2.027(I think)

Still can have them reduced to Honda sizes 1.88 according to him.

I am in new territory. Can I get custom rods made for the Honda sized journals?

Thoughts?

We having fun yet?

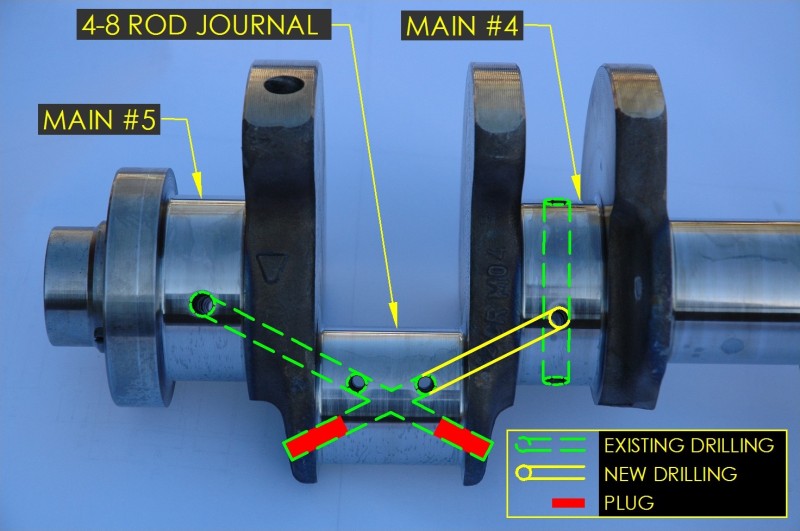

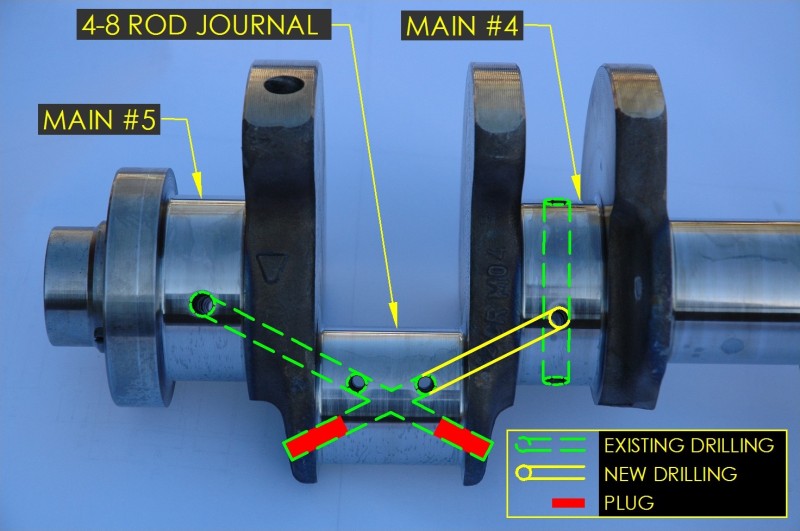

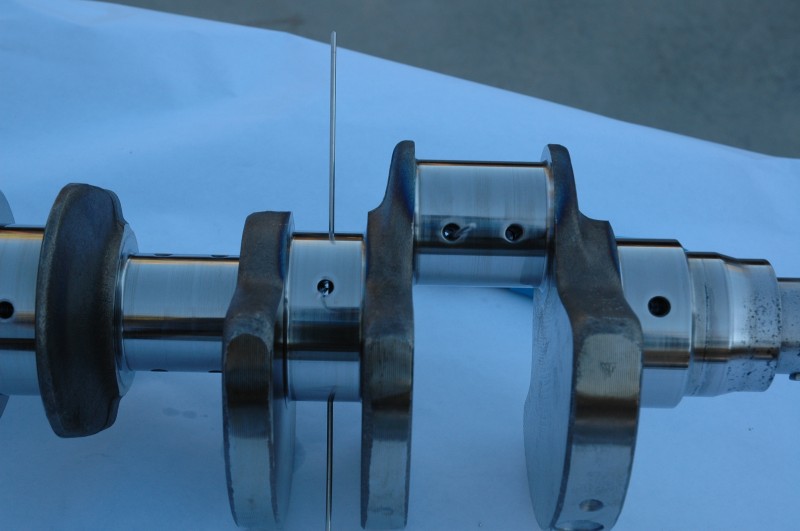

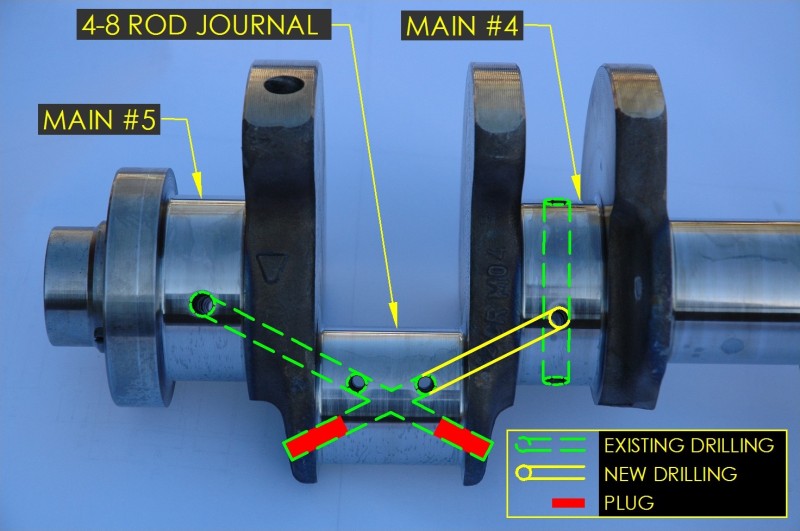

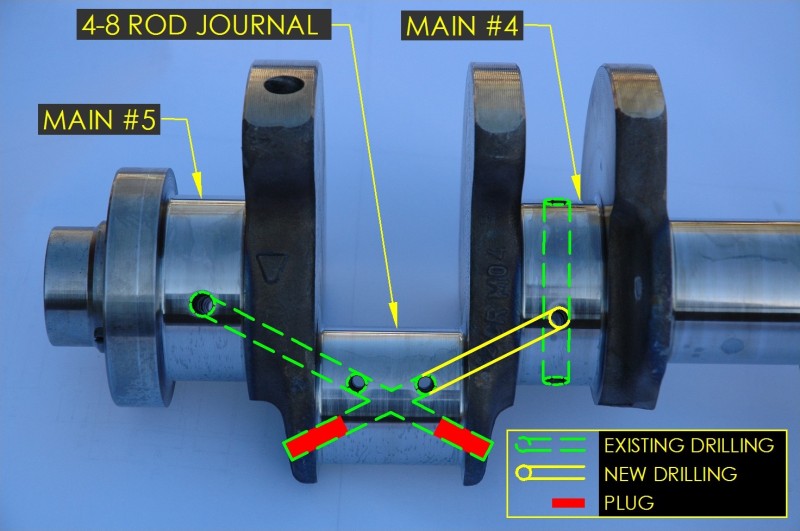

4-8 rod journal w/ new cross-drill @ #4 main:

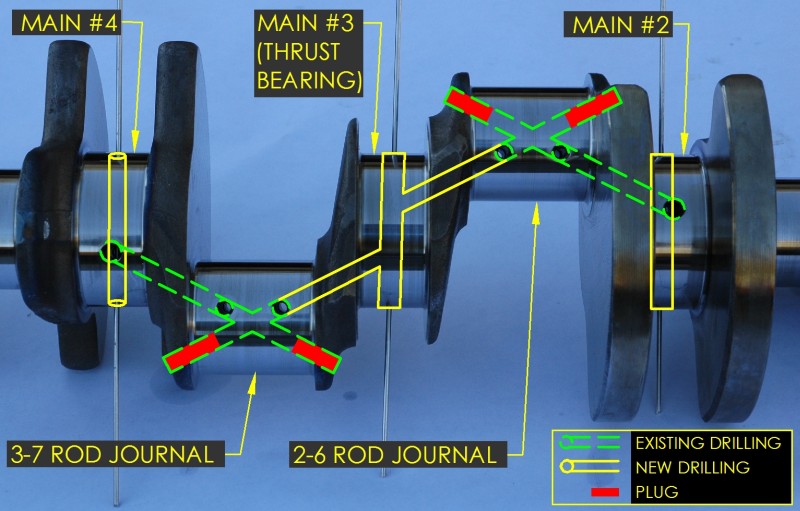

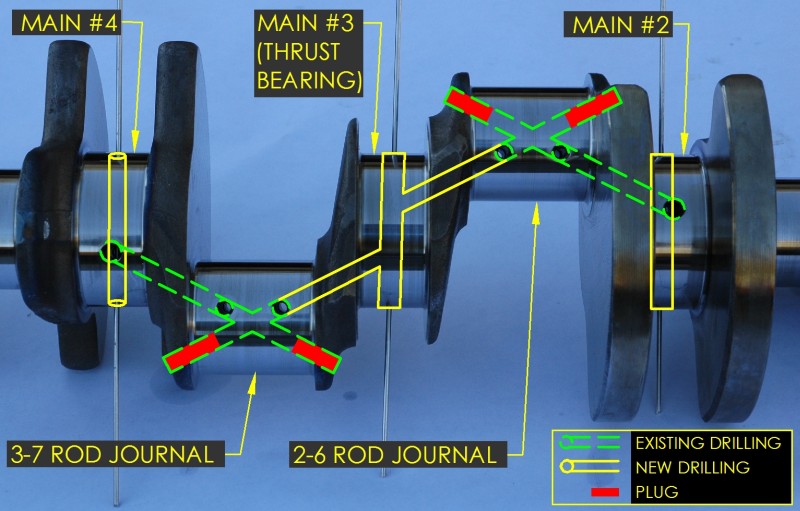

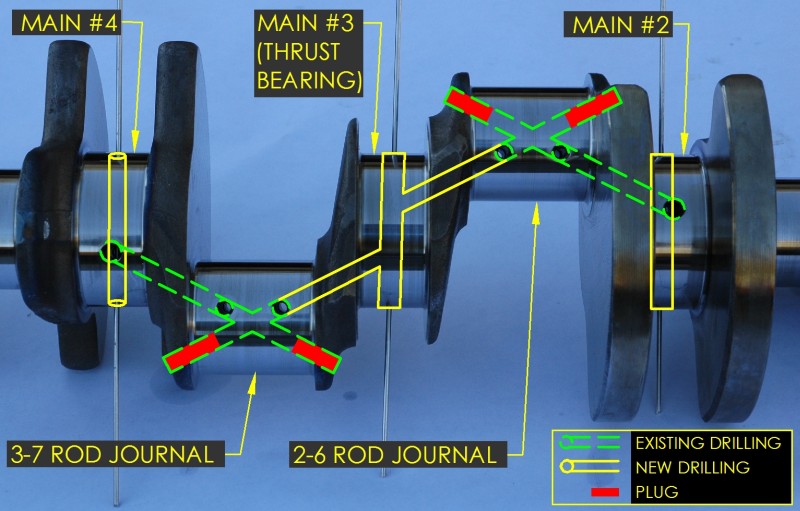

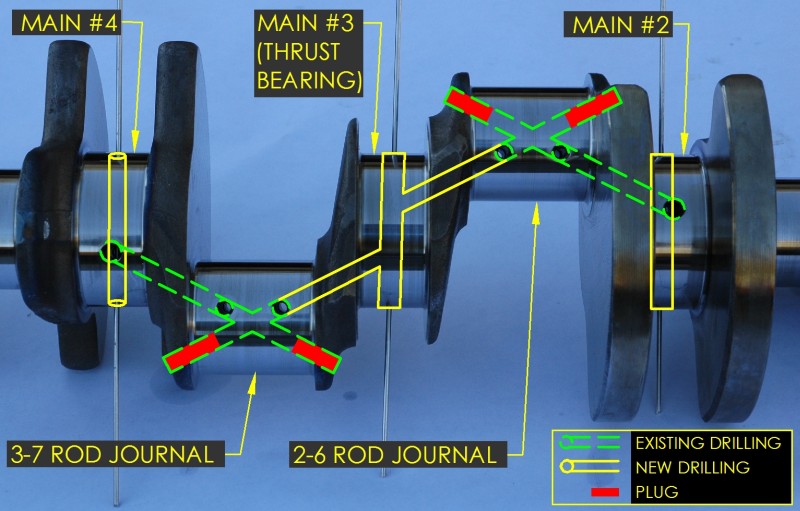

2-6 & 3-7 rod journals w/ new cross-drill @ #3 main (thrust bearing journal):

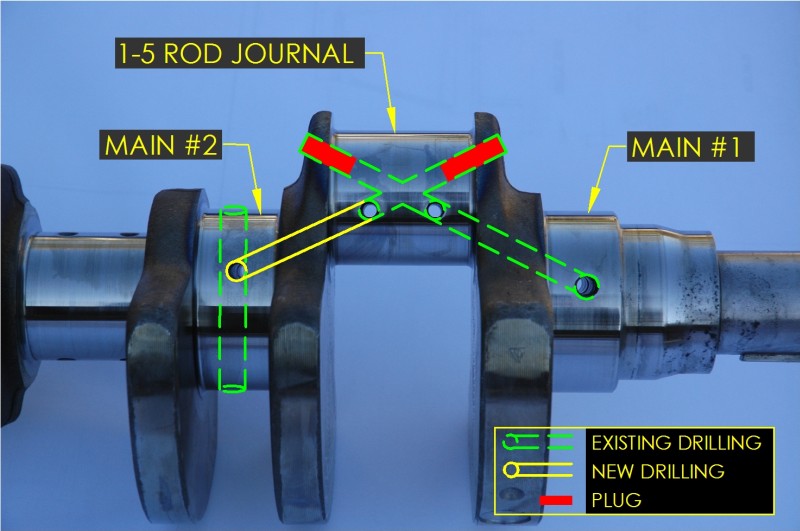

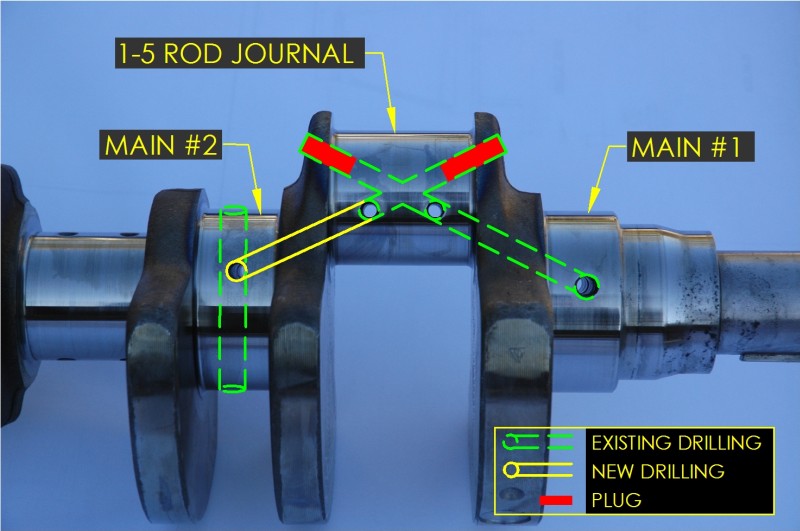

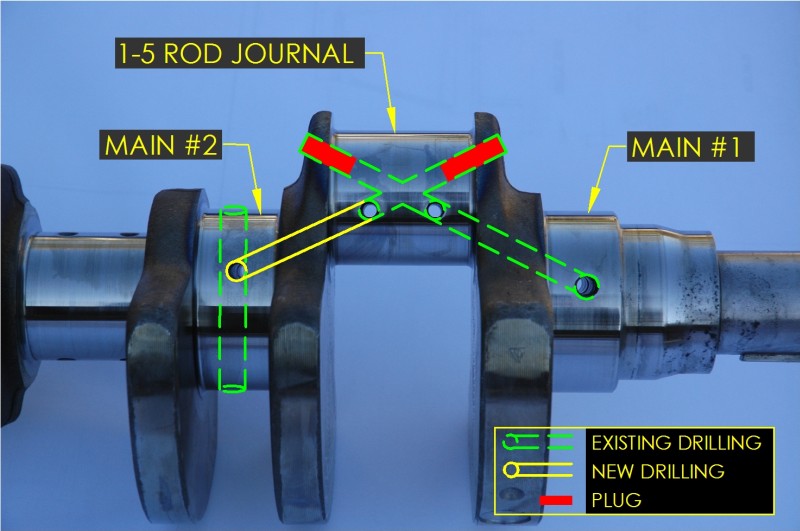

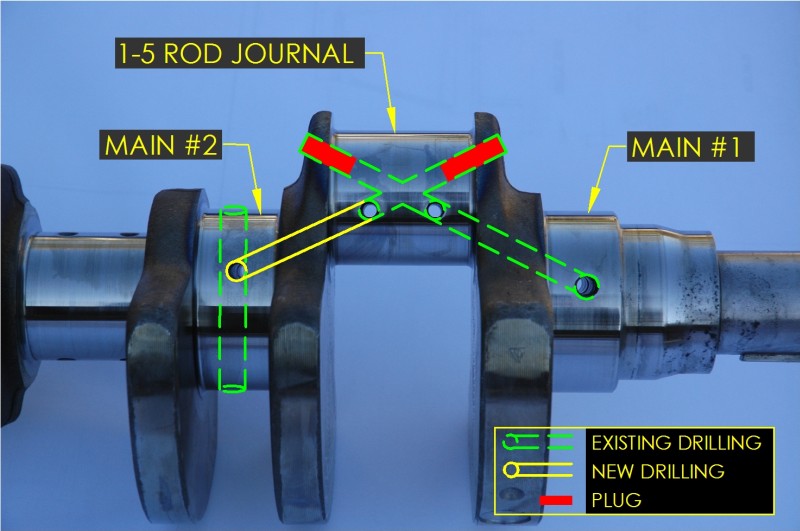

1-5 rod journal w/ new cross-drill @ #2 main:

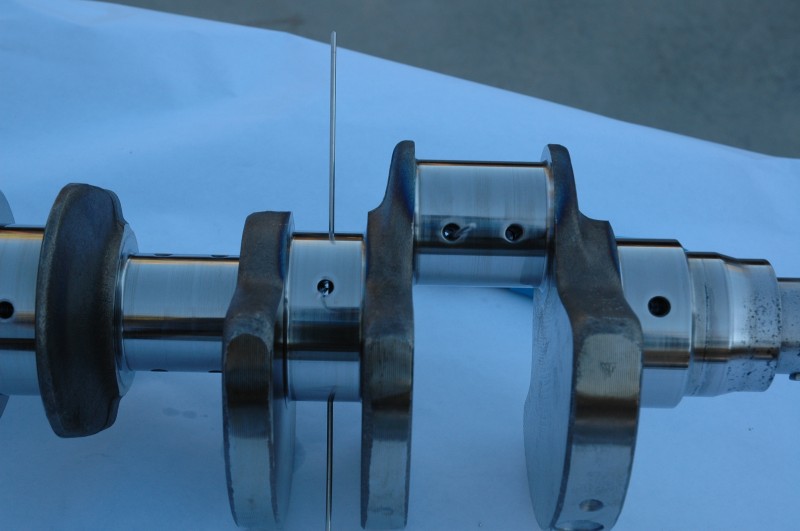

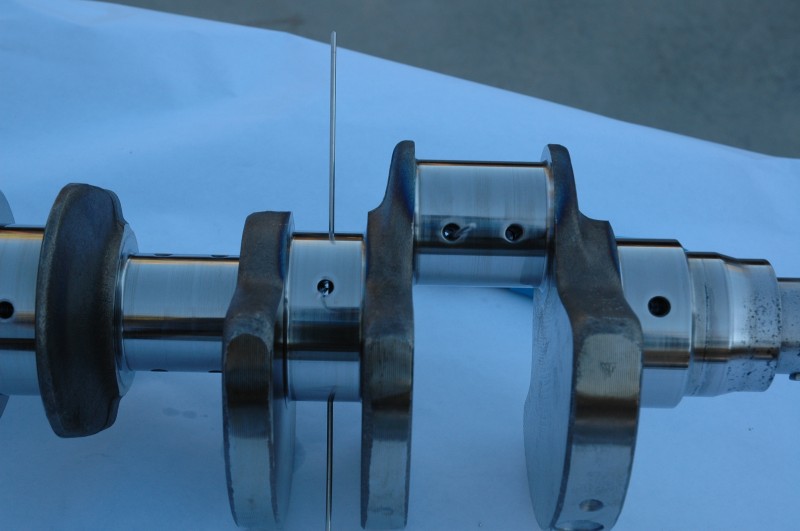

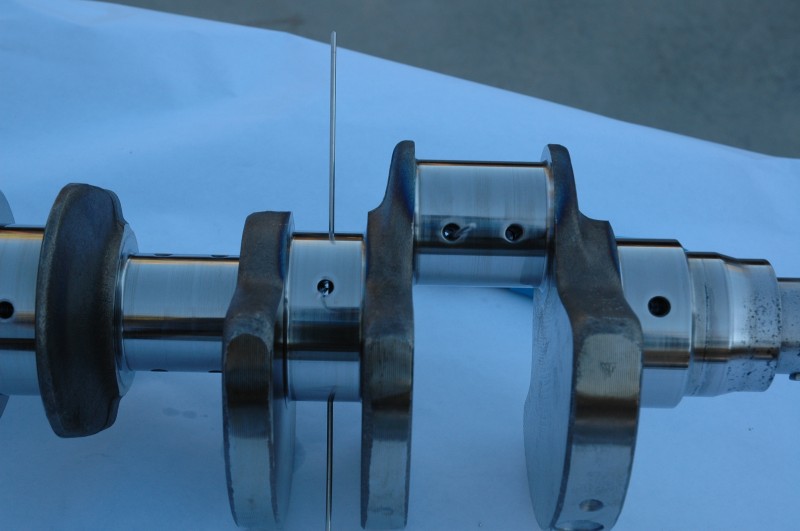

Another pic of drilling at #2 main. The existing cross-drill and the new cross-drill are perpendicular and intersect each other:

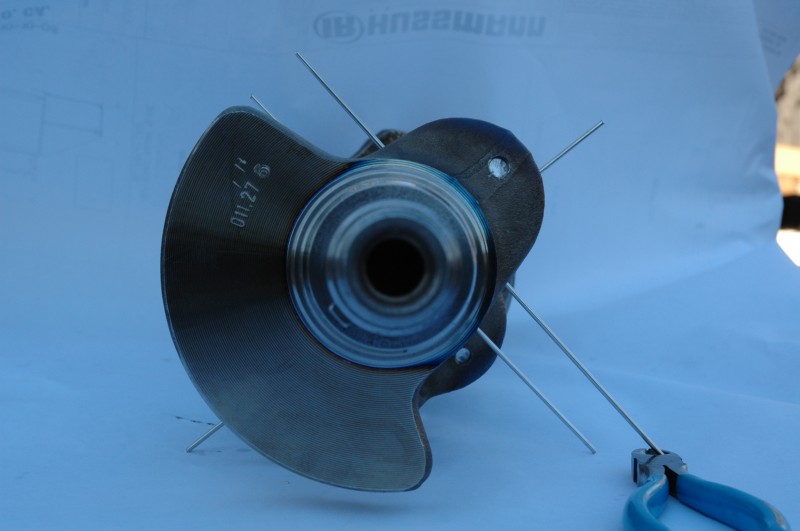

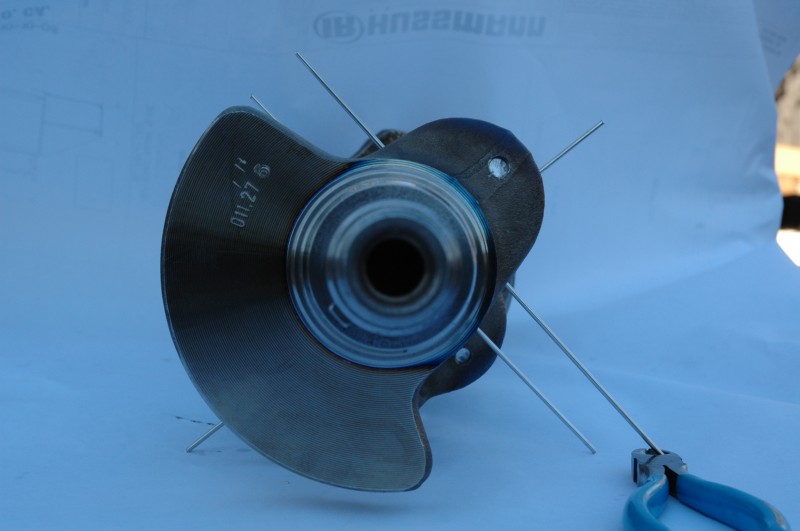

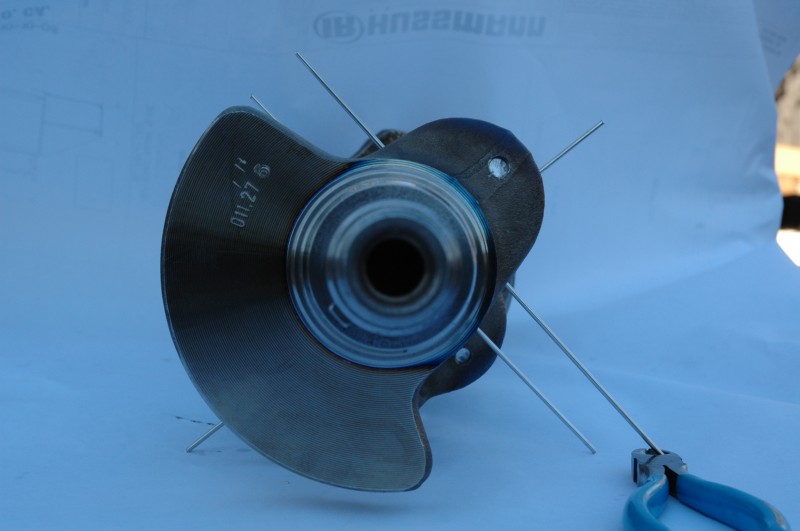

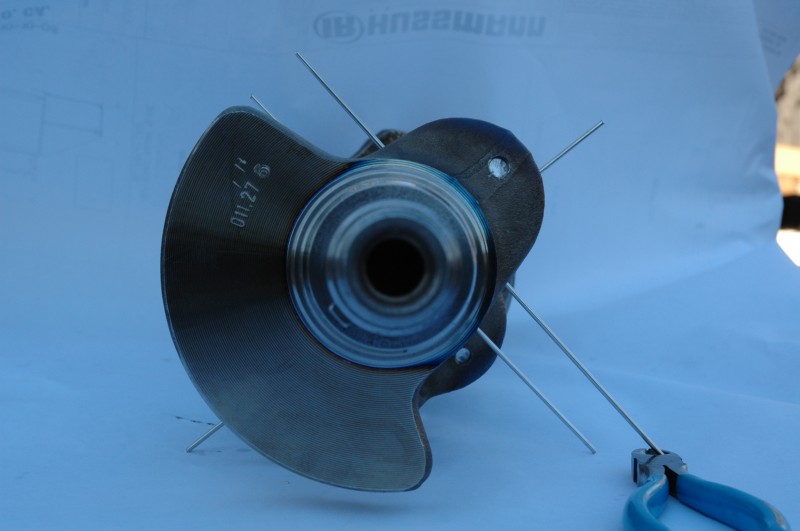

End-on pic from crank nose:

Also asked about going to Honda sized journals and moving them off center. Probably too late to move them off center, Journals are at about 2.027(I think)

Still can have them reduced to Honda sizes 1.88 according to him.

I am in new territory. Can I get custom rods made for the Honda sized journals?

Thoughts?

We having fun yet?

4-8 rod journal w/ new cross-drill @ #4 main:

2-6 & 3-7 rod journals w/ new cross-drill @ #3 main (thrust bearing journal):

1-5 rod journal w/ new cross-drill @ #2 main:

Another pic of drilling at #2 main. The existing cross-drill and the new cross-drill are perpendicular and intersect each other:

End-on pic from crank nose:

#18

Former Sponsor

#19

Former Sponsor

Spoke with my machinist about cross drilling. Found this here on RL.

Also asked about going to Honda sized journals and moving them off center. Probably too late to move them off center, Journals are at about 2.027(I think)

Still can have them reduced to Honda sizes 1.88 according to him.

I am in new territory. Can I get custom rods made for the Honda sized journals?

Thoughts?

We having fun yet?

4-8 rod journal w/ new cross-drill @ #4 main:

2-6 & 3-7 rod journals w/ new cross-drill @ #3 main (thrust bearing journal):

1-5 rod journal w/ new cross-drill @ #2 main:

Another pic of drilling at #2 main. The existing cross-drill and the new cross-drill are perpendicular and intersect each other:

End-on pic from crank nose:

Also asked about going to Honda sized journals and moving them off center. Probably too late to move them off center, Journals are at about 2.027(I think)

Still can have them reduced to Honda sizes 1.88 according to him.

I am in new territory. Can I get custom rods made for the Honda sized journals?

Thoughts?

We having fun yet?

4-8 rod journal w/ new cross-drill @ #4 main:

2-6 & 3-7 rod journals w/ new cross-drill @ #3 main (thrust bearing journal):

1-5 rod journal w/ new cross-drill @ #2 main:

Another pic of drilling at #2 main. The existing cross-drill and the new cross-drill are perpendicular and intersect each other:

End-on pic from crank nose:

Before custom crankshafts were built, picture #2 was a common modification that we had done.

#20

Rennlist Member

Thread Starter

Your picture #1 and #3 are incorrect...unless you have a crankshaft that didn't get drilled correctly, from the factory. The yellow passages in those pictures should already exist.

Before custom crankshafts were built, picture #2 was a common modification that we had done.

Before custom crankshafts were built, picture #2 was a common modification that we had done.

#21

Former Sponsor

There's a huge "learning curve" to 928 crankshafts regarding what needs to be done/should be done/can be done.

It's important to figure out, from the very beginning, what needs to be done and what the options are.

For instance, "oversize" rod bearings come two to a package, but the price is for each bearing. At $53 per shell (×12), this adds up in a big hurry! If you have a damaged crankshaft that can be machined to 2.000", it will be cheaper (and better) to buy a custom rod and use Chevy rod bearings (way cheaper, harder, with a huge selection) especially if one is building a custom engine, than welding and machining a crank back to standard. Honda journals at 1.8880" are probably too small for the steel that a stock crankshaft is made from (and gets worse if the crank is offset ground)....the "overlap" from the main bearing to the rod bearing gets a bit scetchy and really calls out for a completely different material to start with.

There are several more "gotchas" that Kevin is going to find, before he's done. *It's an interesting learning curve, to get involved with, bit like everything in life, knowledge requires a certain amount of learning.

It's important to figure out, from the very beginning, what needs to be done and what the options are.

For instance, "oversize" rod bearings come two to a package, but the price is for each bearing. At $53 per shell (×12), this adds up in a big hurry! If you have a damaged crankshaft that can be machined to 2.000", it will be cheaper (and better) to buy a custom rod and use Chevy rod bearings (way cheaper, harder, with a huge selection) especially if one is building a custom engine, than welding and machining a crank back to standard. Honda journals at 1.8880" are probably too small for the steel that a stock crankshaft is made from (and gets worse if the crank is offset ground)....the "overlap" from the main bearing to the rod bearing gets a bit scetchy and really calls out for a completely different material to start with.

There are several more "gotchas" that Kevin is going to find, before he's done. *It's an interesting learning curve, to get involved with, bit like everything in life, knowledge requires a certain amount of learning.

#22

Rennlist Member

Thread Starter

There's a huge "learning curve" to 928 crankshafts regarding what needs to be done/should be done/can be done.

It's important to figure out, from the very beginning, what needs to be done and what the options are.

For instance, "oversize" rod bearings come two to a package, but the price is for each bearing. At $53 per shell (×12), this adds up in a big hurry! If you have a damaged crankshaft that can be machined to 2.000", it will be cheaper (and better) to buy a custom rod and use Chevy rod bearings (way cheaper, harder, with a huge selection) especially if one is building a custom engine, than welding and machining a crank back to standard. Honda journals at 1.8880" are probably too small for the steel that a stock crankshaft is made from (and gets worse if the crank is offset ground)....the "overlap" from the main bearing to the rod bearing gets a bit sketchy and really calls out for a completely different material to start with.

There are several more "gotchas" that Kevin is going to find, before he's done. *It's an interesting learning curve, to get involved with, bit like everything in life, knowledge requires a certain amount of learning.

It's important to figure out, from the very beginning, what needs to be done and what the options are.

For instance, "oversize" rod bearings come two to a package, but the price is for each bearing. At $53 per shell (×12), this adds up in a big hurry! If you have a damaged crankshaft that can be machined to 2.000", it will be cheaper (and better) to buy a custom rod and use Chevy rod bearings (way cheaper, harder, with a huge selection) especially if one is building a custom engine, than welding and machining a crank back to standard. Honda journals at 1.8880" are probably too small for the steel that a stock crankshaft is made from (and gets worse if the crank is offset ground)....the "overlap" from the main bearing to the rod bearing gets a bit sketchy and really calls out for a completely different material to start with.

There are several more "gotchas" that Kevin is going to find, before he's done. *It's an interesting learning curve, to get involved with, bit like everything in life, knowledge requires a certain amount of learning.

So, to continue...

Turning the rod end journals to 2.000" is a better approach and affords me me options. I like that.

Once I have the pistons (968) and S3 block matched then I will need to find the correct custom rods.

Kevin

*

#23

Former Sponsor

However, the center two pairs of rod bearings (#2 and #6 plus #3 and #7) are fed only from #2 and #4 main bearings....which means these rod bearings only get oil from one main bearing ( which is already feeding oil to the front and rear pairs of rod bearings.) Logic tells you that drilling #3 main bearing and sending the oil to these center rod bearings should help. Also seems like a good idea, right?

The "gotcha" of this whole thing is that #2 and #6 are always the first rod bearings to fail....and #3 and #7 never are the first ones to fail....even though they get the exact same oiling!

The answer to your question is that drilling the crankshaft like your #3 picture isn't going to hurt anything, if done correctly. It's also not going to solve all the different problems with the rod bearings.

The truth is, rod bearing failure in the 928 engine comes from 6 distinctly different causes....and the "end" result always looks almost exactly the same, which is very frustrating. People "fix" one or two of the different causes and then have what looks like the same exact failure. It takes some real tenacity to figure out all the different causes...and a whole bunch of money. People usually give up and go play with something else!

#24

Rennlist Member

Thread Starter

So, if you look at how the crank is drilled, from the factory, #1 and #5 rod bearings are fed from both the front and #2 main bearings. The same is true for #4 and #8 rods, which are fed from #4 and #5 main bearings. Seems like a pretty good idea.

However, the center two pairs of rod bearings (#2 and #6 plus #3 and #7) are fed only from #2 and #4 main bearings....which means these rod bearings only get oil from one main bearing ( which is already feeding oil to the front and rear pairs of rod bearings.) Logic tells you that drilling #3 main bearing and sending the oil to these center rod bearings should help. Also seems like a good idea, right?

The "gotcha" of this whole thing is that #2 and #6 are always the first rod bearings to fail....and #3 and #7 never are the first ones to fail....even though they get the exact same oiling!

The answer to your question is that drilling the crankshaft like your #3 picture isn't going to hurt anything, if done correctly. It's also not going to solve all the different problems with the rod bearings.

The truth is, rod bearing failure in the 928 engine comes from 6 distinctly different causes....and the "end" result always looks almost exactly the same, which is very frustrating. People "fix" one or two of the different causes and then have what looks like the same exact failure. It takes some real tenacity to figure out all the different causes...and a whole bunch of money. People usually give up and go play with something else!

However, the center two pairs of rod bearings (#2 and #6 plus #3 and #7) are fed only from #2 and #4 main bearings....which means these rod bearings only get oil from one main bearing ( which is already feeding oil to the front and rear pairs of rod bearings.) Logic tells you that drilling #3 main bearing and sending the oil to these center rod bearings should help. Also seems like a good idea, right?

The "gotcha" of this whole thing is that #2 and #6 are always the first rod bearings to fail....and #3 and #7 never are the first ones to fail....even though they get the exact same oiling!

The answer to your question is that drilling the crankshaft like your #3 picture isn't going to hurt anything, if done correctly. It's also not going to solve all the different problems with the rod bearings.

The truth is, rod bearing failure in the 928 engine comes from 6 distinctly different causes....and the "end" result always looks almost exactly the same, which is very frustrating. People "fix" one or two of the different causes and then have what looks like the same exact failure. It takes some real tenacity to figure out all the different causes...and a whole bunch of money. People usually give up and go play with something else!

#25

Former Sponsor

First of thanks for your input. Really appreciated. This is quite the learning experience. I'm starting from zero.

So, to continue...

Turning the rod end journals to 2.000" is a better approach and affords me me options. I like that.

Once I have the pistons (968) and S3 block matched then I will need to find the correct custom rods.

Kevin

So, to continue...

Turning the rod end journals to 2.000" is a better approach and affords me me options. I like that.

Once I have the pistons (968) and S3 block matched then I will need to find the correct custom rods.

Kevin

Hopefully the crankshaft will "clean up" at 2.000" and you won't need to weld it.

This engine combination is really wonderful. The longer rod changes the entire power curve of these engines, making the small change in displacement (from a 5.4) seem more significant than it actually is. I've got five of these engines currently under construction, one of which is currently installed, broken in, and in the final tuning phase. One is past the testing phase and ready to come off my test stand. One has the machine work done and is ready to clean and assemble. Two others are in the "waiting for parts" phase of the process.

#26

Rennlist Member

Thread Starter

Now you're thinking!

Hopefully the crankshaft will "clean up" at 2.000" and you won't need to weld it.

This engine combination is really wonderful. The longer rod changes the entire power curve of these engines, making the small change in displacement (from a 5.4) seem more significant than it actually is. I've got five of these engines currently under construction, one of which is currently installed, broken in, and in the final tuning phase. One is past the testing phase and ready to come off my test stand. One has the machine work done and is ready to clean and assemble. Two others are in the "waiting for parts" phase of the process.

Hopefully the crankshaft will "clean up" at 2.000" and you won't need to weld it.

This engine combination is really wonderful. The longer rod changes the entire power curve of these engines, making the small change in displacement (from a 5.4) seem more significant than it actually is. I've got five of these engines currently under construction, one of which is currently installed, broken in, and in the final tuning phase. One is past the testing phase and ready to come off my test stand. One has the machine work done and is ready to clean and assemble. Two others are in the "waiting for parts" phase of the process.

I hope you won't mind if I reach out to you when it's time to buy custom piston rods.

Kevin

Last edited by Kevin in Atlanta; 12-06-2018 at 09:28 AM. Reason: Not B2, B1

#27

Rennlist Member

Thread Starter

Now you're thinking!

Hopefully the crankshaft will "clean up" at 2.000" and you won't need to weld it.

This engine combination is really wonderful. The longer rod changes the entire power curve of these engines, making the small change in displacement (from a 5.4) seem more significant than it actually is. I've got five of these engines currently under construction, one of which is currently installed, broken in, and in the final tuning phase. One is past the testing phase and ready to come off my test stand. One has the machine work done and is ready to clean and assemble. Two others are in the "waiting for parts" phase of the process.

Hopefully the crankshaft will "clean up" at 2.000" and you won't need to weld it.

This engine combination is really wonderful. The longer rod changes the entire power curve of these engines, making the small change in displacement (from a 5.4) seem more significant than it actually is. I've got five of these engines currently under construction, one of which is currently installed, broken in, and in the final tuning phase. One is past the testing phase and ready to come off my test stand. One has the machine work done and is ready to clean and assemble. Two others are in the "waiting for parts" phase of the process.

Kevin

#28

Former Sponsor

Just tell him to make the rod journals early (pre-1969) small block Chevy size. He can look thst number up, very easily.

#29

My guys wanted the rods first and the bearings, also the required clearance. However 2" is a common size and they should have some experience here. With regards to wanting the rods, the secondary reason was to check them for size and defects. In one job they did they found out of spec bearings and rejected them.

#30

Rennlist Member

Thread Starter

Thanks for the clarification. Will do.