A pictorial essay on a long term suspension and drive train conversion

#1

Rennlist Member

Thread Starter

I thought I'd begin to document the results of the suspension and drive train mods I've completed on my 1989 944 S2 over the past couple of years. The goal of the project has been to refresh all the 30 year old components that needed attention and upgrade the car to something approaching a "Firehawk" specification.

On top of the suspension and drive train mods I also did a little work on the brakes, upgrading the stock rubber lines to braided stainless, but I didn't put in larger calipers, something I may do after I've had a chance to run the car on a track and see how it does.

I elected to not put coil over shocks in the rear, mostly because I wasn't sure the original Super Seven cars used them. Since then I've come to believe they probably did so, again, after some track time I may decide to replace the Koni Sport shocks with coil overs and remove the rear torsion bars.

Anyway, I can't figure out how to add comments to each photo, so I'll describe them here and attach the pictures for your enjoyment. In general, what I've done is:

- Add a rebuilt stock ZF Limited Slip Differential to the stock transmission.

- Added stock transmission cooler.

- Install a "short" 5th gear in the box.

- Only944 Short Shift kit.

- SuperMount solid transmission mount.

- New CV joints and boots.

- Rebuilt Torque Tube with the "non-split" version and Black Sea "Super Bearings".

- New SPEC Stage 3+ clutch, rear main seal, pilot bearing.

- PowerFlex front control arm bushings.

- Rennbay ball joint kit.

- New tie rod ends.

- De-powered steering rack and poly bushings.

- Lindsey Racing 30mm front sway bar with Delrin bushings and Tarret stiffeners (Viagra?).

- LR 22mm rear sway bar with Racers Edge spherical drop links.

- LR three piece front cross member/engine support.

- Koni Sport struts and dampers front and rear.

- Goodridge SS brake lines.

- Hawk HP pads.

- SuperMount engine mounts.

- All new nuts and bolts as needed.

I'm also fixing the driver's side door handle so I can open it from outside the car, which is turning in to a true pain in the butt.

On top of the suspension and drive train mods I also did a little work on the brakes, upgrading the stock rubber lines to braided stainless, but I didn't put in larger calipers, something I may do after I've had a chance to run the car on a track and see how it does.

I elected to not put coil over shocks in the rear, mostly because I wasn't sure the original Super Seven cars used them. Since then I've come to believe they probably did so, again, after some track time I may decide to replace the Koni Sport shocks with coil overs and remove the rear torsion bars.

Anyway, I can't figure out how to add comments to each photo, so I'll describe them here and attach the pictures for your enjoyment. In general, what I've done is:

- Add a rebuilt stock ZF Limited Slip Differential to the stock transmission.

- Added stock transmission cooler.

- Install a "short" 5th gear in the box.

- Only944 Short Shift kit.

- SuperMount solid transmission mount.

- New CV joints and boots.

- Rebuilt Torque Tube with the "non-split" version and Black Sea "Super Bearings".

- New SPEC Stage 3+ clutch, rear main seal, pilot bearing.

- PowerFlex front control arm bushings.

- Rennbay ball joint kit.

- New tie rod ends.

- De-powered steering rack and poly bushings.

- Lindsey Racing 30mm front sway bar with Delrin bushings and Tarret stiffeners (Viagra?).

- LR 22mm rear sway bar with Racers Edge spherical drop links.

- LR three piece front cross member/engine support.

- Koni Sport struts and dampers front and rear.

- Goodridge SS brake lines.

- Hawk HP pads.

- SuperMount engine mounts.

- All new nuts and bolts as needed.

I'm also fixing the driver's side door handle so I can open it from outside the car, which is turning in to a true pain in the butt.

Last edited by Otto Mechanic; 06-19-2017 at 11:25 PM.

#3

Rennlist Member

Thread Starter

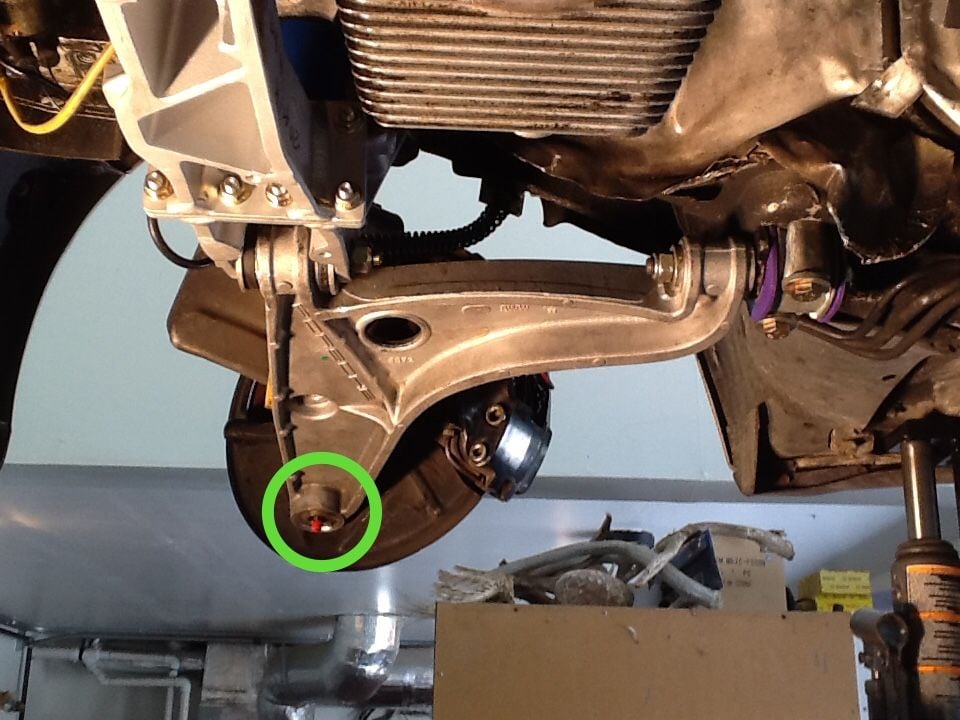

It's not clear from the picture, but yes I did. I ended up using a different epoxy though since the type that came with the ball joints never set up. The kit shipped with a "Super Glue" product that needs pre-mixing, I thought I mixed it well but I guess I didn't. After 24 hours it still hadn't set so I tried a heat gun on it; no joy. I ended up scraping it out and using a DevCon 5 minute clear epoxy that has one of those "swirling" thingamabobs on it to mix the epoxy as you apply it; worked like a charm.

I can take close ups if you'd like to see them. You can see some grease intrusion on the passenger side ball joint, I tried to be careful with the grease pressure but a little managed to get under the epoxy "cap". I don't think it will hurt.

Regards,

#5

Rennlist Member

Thread Starter

Here's another I missed showing the new Goodridge SS brake lines. I decided to keep the original stress relief coils so you sort of have to squint to see the line itself...

It also has a little more detail on the new ball joints.

It also has a little more detail on the new ball joints.

#6

Rennlist Member

Thread Starter

I'll post pictures of the de-powered rack after I install it. Maybe I'll take a few shots of it on the bench. It's not nearly as pretty looking as XSChop's, shown here:

https://rennlist.com/forums/924-931-...l#post12234564

https://rennlist.com/forums/924-931-...l#post12234564

#7

Rennlist Member

Thread Starter

Here's a picture also posted on another thread about the best sequence to use when installing the rack. The only "gotcha" I discovered has to do with placing the upper driver's side rack bolt.

If you follow the Clark's procedure you'll:

- install the top passenger side bolt.

- couple the rack pinion gear to the intermediate steering shaft (U joint).

- install the remaining 3 rack bolts and torque to spec.

The problem comes when installing the upper driver's side rack bolt; there's not enough room between the rack and the alternator to get the bolt in.

The solution is to remove the upper passenger side bolt after coupling the rack to the intermediate shaft, then rotate the rack "up" (pointing the mounting clamps towards the cockpit), insert the upper driver's side bolt, then rotate the rack back down to align it with the cross member. Insert and torque all rack bolts to manufacturer's specification.

Don't forget to install the ground wire and put new tie wraps on the equalizer tube (thanks Mike). The picture shows a "de-powered" rack based on the design used by XSChop and others, originally based on work done to de-power a Mazda Miatta steering rack. The cross member shown is a Lindsey Racing 3 piece, allowing easy access to the bottom end of the engine.

Regards,

If you follow the Clark's procedure you'll:

- install the top passenger side bolt.

- couple the rack pinion gear to the intermediate steering shaft (U joint).

- install the remaining 3 rack bolts and torque to spec.

The problem comes when installing the upper driver's side rack bolt; there's not enough room between the rack and the alternator to get the bolt in.

The solution is to remove the upper passenger side bolt after coupling the rack to the intermediate shaft, then rotate the rack "up" (pointing the mounting clamps towards the cockpit), insert the upper driver's side bolt, then rotate the rack back down to align it with the cross member. Insert and torque all rack bolts to manufacturer's specification.

Don't forget to install the ground wire and put new tie wraps on the equalizer tube (thanks Mike). The picture shows a "de-powered" rack based on the design used by XSChop and others, originally based on work done to de-power a Mazda Miatta steering rack. The cross member shown is a Lindsey Racing 3 piece, allowing easy access to the bottom end of the engine.

Regards,

Last edited by Otto Mechanic; 06-29-2017 at 09:32 PM.

Trending Topics

#8

Rennlist Member

Thread Starter

This afternoon I finished installing the new tie rod ends, pretty much completing the new de-powered rack part of this project.

The only problem I had installing the tie rod ends had to do with holding them tight enough to put the required 30 ft./lbs. of torque on the bolts. Clark's suggests using the tie rod puller with some sort of "pad" to secure the ball joints from spinning. Try as I might, I couldn't figure out how they made that work, maybe their tie rod puller is different from mine. Who really knows?

Instead I used a 4" C clamp to compress the ball joint enough to put on the requisite torque. It was definitely a "spit and chewing gum" solution, but it worked. I expect there might be a real tool out there somewhere that makes this easier, I haven't heard of it.

Anyway, here's photographic proof the tie rods are in. Next up, the new M030 30mm anti sway bar from Lindsey. Watch this space for further announcements

The only problem I had installing the tie rod ends had to do with holding them tight enough to put the required 30 ft./lbs. of torque on the bolts. Clark's suggests using the tie rod puller with some sort of "pad" to secure the ball joints from spinning. Try as I might, I couldn't figure out how they made that work, maybe their tie rod puller is different from mine. Who really knows?

Instead I used a 4" C clamp to compress the ball joint enough to put on the requisite torque. It was definitely a "spit and chewing gum" solution, but it worked. I expect there might be a real tool out there somewhere that makes this easier, I haven't heard of it.

Anyway, here's photographic proof the tie rods are in. Next up, the new M030 30mm anti sway bar from Lindsey. Watch this space for further announcements

#10

Race Car

I thought I'd begin to document the results of the suspension and drive train mods I've completed on my 1989 944 S2 over the past couple of years. The goal of the project has been to refresh all the 30 year old components that needed attention and upgrade the car to something approaching a "Firehawk" specification.

Kidding.

Great job.

Need somebody to drive it.....?

T

#11

Instructor

I just jacked up under the tie rod until it was tight enough to torque, same idea as the clamp. I think I read it might not be good for it when I was searching, but it was hard to keep it from spinning and it seemed like it worked ok.

#12

Rennlist Member

Thread Starter

I've been thinking of a dry sump, certainly improved lubrication of some sort but I haven't really committed to a path yet. Suggestions are very welcome since I'm still in the concept phase of that part.

Last edited by Otto Mechanic; 06-29-2017 at 09:27 PM.

#13

Rennlist Member

Thread Starter

#14

Rennlist Member

Thread Starter

#15

Rennlist Member

Thread Starter

Finished installing the new M030 30mm sway bar (another LR part) today.

Received parts (bump stops) from Pelican, next step is to remove the front struts and install the stops. You may wonder why this is happening; simply put, the PO must have had the struts worked on at some point and the bump stops were deleted (no idea why). The new Koni inserts didn't come with bump stops so I didn't notice the problem until after I'd finished the struts and re-installed them. While I was looking at other pictures of S2 struts I saw them, checked the PET and, sure enough, there's supposed to be stops.

So I tore the passenger side back down today and put the stop in it, tomorrow I'll do the driver's side. With any luck that will complete the suspension part of this project.

Received parts (bump stops) from Pelican, next step is to remove the front struts and install the stops. You may wonder why this is happening; simply put, the PO must have had the struts worked on at some point and the bump stops were deleted (no idea why). The new Koni inserts didn't come with bump stops so I didn't notice the problem until after I'd finished the struts and re-installed them. While I was looking at other pictures of S2 struts I saw them, checked the PET and, sure enough, there's supposed to be stops.

So I tore the passenger side back down today and put the stop in it, tomorrow I'll do the driver's side. With any luck that will complete the suspension part of this project.