Stripped camshaft sprocket retaining screw - Alternatives?

#1

Instructor

Thread Starter

Join Date: Feb 2011

Location: Raleigh, NC

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

So, as many others have apparently experienced, I managed to strip out the triple-square bolt that retains the pulley on the camshaft of my 951. I'll be drilling it out later today, but I was curious if anyone has found any alternative hardware for this location? I believe it's a M10x1.5x65 screw. I was hoping I would be able to find a torx bolt that would work instead and likely be able to take a higher torque before camming out, but I haven't seen anything yet. I know plenty of newer german cars use external torx bolts, but it's pretty much impossible to search for those 'special' fasteners. It'd be nice if we could come up with an MB or BMW equivalent that would work.

#2

you could try one of those claw/paw whatever bolt removers that you can buy at sears. But from ym experience those things are always in there extremely tight. Not sure if the factory used loctite or something similar but they seldom want to come out easily. I have drilled out a few before.

here are the remover things I'm talking about. The head of the bolt is deep in the collar though so it may not fit at all.

http://www.sears.com/shc/s/p_10153_1...=31-36396114-2

Good luck

here are the remover things I'm talking about. The head of the bolt is deep in the collar though so it may not fit at all.

http://www.sears.com/shc/s/p_10153_1...=31-36396114-2

Good luck

#3

Instructor

Thread Starter

Join Date: Feb 2011

Location: Raleigh, NC

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, there's pretty much zero clearance for anything to fit around the head. Drill and a screw extractor are probably the only options. Once the screw head is off and the pulley removed, I might try to TIG a bolt on to the remainder and turn it out if it's still stubborn.

When I was taking this thing off I wish I'd know that the entire assembly could be removed with pulley in place. The awkward placement in the engine bay probably contributed to less than perfectly straight angle on the tools. If I were to do it again (hope I won't have to in a long, long time) I wouldn't even attempt to do it on the car. Probably would hit it with an impact wrench from the bench.

I'm getting ready to paint the cam tower and intake etc. Mind if I ask what you used and how it turned out?

When I was taking this thing off I wish I'd know that the entire assembly could be removed with pulley in place. The awkward placement in the engine bay probably contributed to less than perfectly straight angle on the tools. If I were to do it again (hope I won't have to in a long, long time) I wouldn't even attempt to do it on the car. Probably would hit it with an impact wrench from the bench.

I'm getting ready to paint the cam tower and intake etc. Mind if I ask what you used and how it turned out?

#4

Rennlist Member

Use a pair of vice grips, tightened as hard as you can, around the head and turn with them. Works every time, to my experience. This works on CV bolts as well. Drilling lets you insert an "easy out" that will break, leaving you with something that cannot be drilled.

#5

Instructor

Thread Starter

Join Date: Feb 2011

Location: Raleigh, NC

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

I'm guessing you're not too familiar with this particular bolt. It's recessed about an inch into the cam pulley, in a hole that leaves essentially zero clearance at on the sides. Vice-grips or other methods are possible only once the bolt is drilled to remove the screw head and the pulley. It might come out with vice-grips after the tension is relieved, but it remains to be seen just how strong the loctite is.

#6

Three Wheelin'

It might be too late now...but did you "wake" the bolt with a hammer before you tried to remove it? It might still help in getting it out after you drill the head off...

Trending Topics

#8

Yeah, there's pretty much zero clearance for anything to fit around the head. Drill and a screw extractor are probably the only options. Once the screw head is off and the pulley removed, I might try to TIG a bolt on to the remainder and turn it out if it's still stubborn.

When I was taking this thing off I wish I'd know that the entire assembly could be removed with pulley in place. The awkward placement in the engine bay probably contributed to less than perfectly straight angle on the tools. If I were to do it again (hope I won't have to in a long, long time) I wouldn't even attempt to do it on the car. Probably would hit it with an impact wrench from the bench.

I'm getting ready to paint the cam tower and intake etc. Mind if I ask what you used and how it turned out?

When I was taking this thing off I wish I'd know that the entire assembly could be removed with pulley in place. The awkward placement in the engine bay probably contributed to less than perfectly straight angle on the tools. If I were to do it again (hope I won't have to in a long, long time) I wouldn't even attempt to do it on the car. Probably would hit it with an impact wrench from the bench.

I'm getting ready to paint the cam tower and intake etc. Mind if I ask what you used and how it turned out?

#9

Rennlist Member

I'm guessing you're not too familiar with this particular bolt. It's recessed about an inch into the cam pulley, in a hole that leaves essentially zero clearance at on the sides. Vice-grips or other methods are possible only once the bolt is drilled to remove the screw head and the pulley. It might come out with vice-grips after the tension is relieved, but it remains to be seen just how strong the loctite is.

#10

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Once you drill the head off, the bolt will almost always just turn out with your fingers. It isn't the threads that seize that particular bolt, it is something about the head surface contact.

#11

Instructor

Thread Starter

Join Date: Feb 2011

Location: Raleigh, NC

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

Alright guys, thanks for the advice. I drilled the bolt with a bit slightly smaller than the shoulder diameter of the bolt. Once I figured I was well past the head, I tried a screw extractor with a stubby wrench and it came right out with almost no torque. Removing 90% of the material for a section underneath the head just relieved the tension on it, and I didn't have to worry about damaging the collar or anything if I got too far. Now back to what I was doing in the first place. It was some slow going in that hard steel.

#12

RL Community Team

Rennlist Member

Rennlist Member

When you put in the new bolt, put a little bit of copper antiseize on the bolt head mating surface, and the threads too. It's worked great for me over the years.

#13

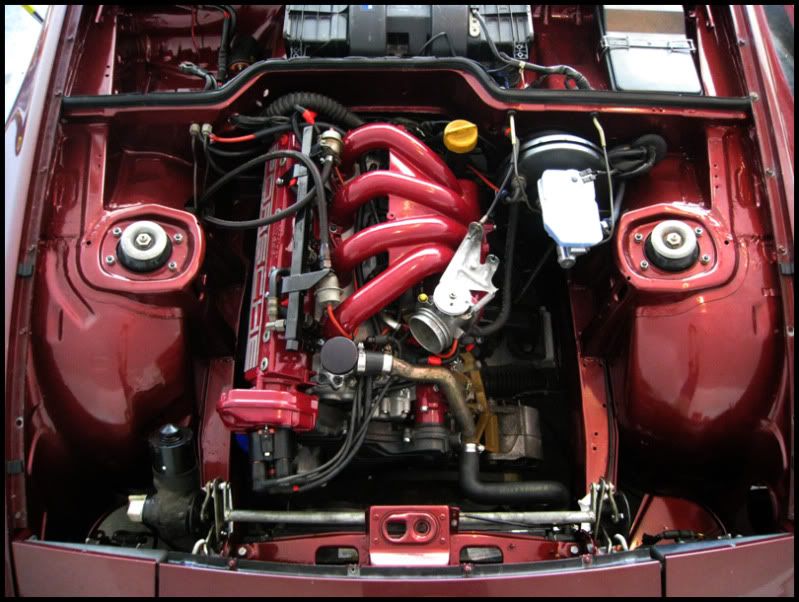

Cass, holy crap.

That is SO pretty.

I'm currently taking my engine apart and dreaming of what and how to paint as I put it back together. Thanks for the inspiration and wonderful work!