Differential Carrier Bearing Replacement

#1

Instructor

Thread Starter

I put the car up early this fall due to some noise/banging in the rear end during acceleration and cornering. I'm fairly certain the CV's are shot, but upon closer inspection, I noticed some excessive play in the transaxle output shafts (in and out movement). Based on what I can gather, the tapered roller bearings on the differential are starting to go. Fast forward to last week, I finally had a chance to get working on the car.

I will try to chronicle my repair on this since I haven't found much online. Note, I do have the Porsche shop manuals to help with some of the transmission tear down.

I dropped the transmission with a floor jack and a set of extra hands. Much easier than I thought. Having a buddy help steady the transaxle on the jack helped immensely. I decided to build my own transmission stand out of 2x4's for a grand total of $10. Works like a charm (see pic). To my surprise, my car does not have its original transmission. I have an '84 but the transmission bell housing code is 5S15075, indicating it was manufacturing in 1985. Additionally, it has a speedometer gear, further indicating a replacement. Another PO oversight...

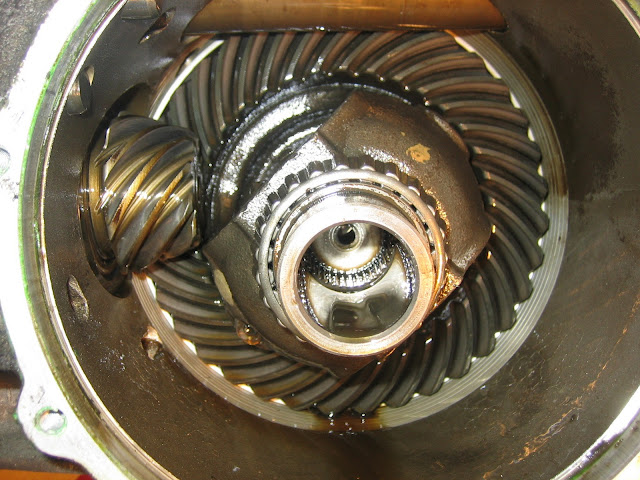

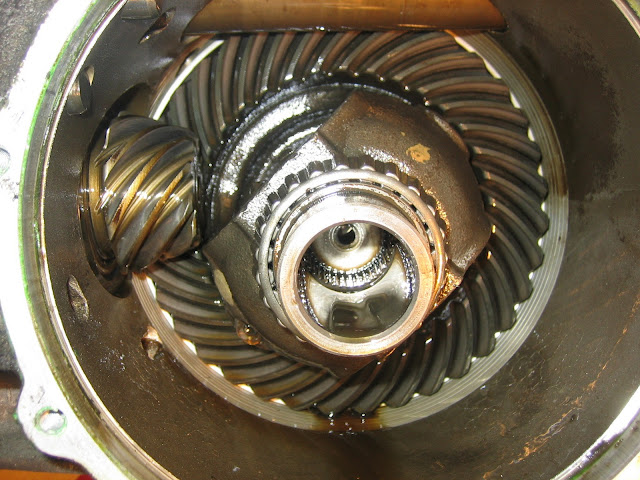

Once on the stand, I drained the gear oil and started digging in. Removed output shafts and differential cover to expose the differential. As far as I can tell, everything looks good. I don't detect any play or slop in the input shaft to the gear carrier, which is a good thing. I also did not detect any slop in the pinion bearing. Again, also a good thing.

I do have one leak on the passenger side of the transaxle from the bearing seal. This could have been replaced without dropping the transaxle by simply removing the output shaft and pulling the seal. I plan to purchase a transmission gasket set and completely reseal the entire transaxle. I've got an email into Pelican, but does anyone have an itemized list with PN's for the gasket set? I don't want to miss anything.

http://www.pelicanparts.com/cgi-bin/...9%2C%20Each%20

To remove the gear carrier, the gear selector has to be removed. Remove the gear shift linkage components first. Remove the large bolt that is on top of the gear selector shaft near the gear selector flange (not the bolt holding part of the shift linkage). This holds a spring loaded rod that I believe is the reverse lock-out. With this out, remove the three screws on the gear selector flange. Careful, this sucker is spring loaded. Don't remove the snap ring. The whole assembly should slide out.

Now the gear carrier flange bolts can be removed. The shop manual says to drive out the metal guide sleeves on the top and bottom of the flange, but I couldn't get them to budge. I was able to tap out the gear carrier while still leaving the sleeves intact on the bell housing for installation later.

My next task is to order bearings, gasket kit, drain plugs and new gear oil. I have a coworker with a hydraulic press that I plan to use to press in the outer bearing races. The manual says to heat the housing to at least 300F before pressing them in. I think the inner races should be more straight forward.

The manual also says to pay special attention to proper shim thickness for the differential. My current plan is to just use the original shims and call it good. Although the proper factory shimming might not be achieved, I figure that just having the new bearings in there will make the differential play much better than it currently is. Considering the condition and mileage of the car, I think this plan should be appropriate unless any others have some pointers.

Stay tuned for updates.

I will try to chronicle my repair on this since I haven't found much online. Note, I do have the Porsche shop manuals to help with some of the transmission tear down.

I dropped the transmission with a floor jack and a set of extra hands. Much easier than I thought. Having a buddy help steady the transaxle on the jack helped immensely. I decided to build my own transmission stand out of 2x4's for a grand total of $10. Works like a charm (see pic). To my surprise, my car does not have its original transmission. I have an '84 but the transmission bell housing code is 5S15075, indicating it was manufacturing in 1985. Additionally, it has a speedometer gear, further indicating a replacement. Another PO oversight...

Once on the stand, I drained the gear oil and started digging in. Removed output shafts and differential cover to expose the differential. As far as I can tell, everything looks good. I don't detect any play or slop in the input shaft to the gear carrier, which is a good thing. I also did not detect any slop in the pinion bearing. Again, also a good thing.

I do have one leak on the passenger side of the transaxle from the bearing seal. This could have been replaced without dropping the transaxle by simply removing the output shaft and pulling the seal. I plan to purchase a transmission gasket set and completely reseal the entire transaxle. I've got an email into Pelican, but does anyone have an itemized list with PN's for the gasket set? I don't want to miss anything.

http://www.pelicanparts.com/cgi-bin/...9%2C%20Each%20

To remove the gear carrier, the gear selector has to be removed. Remove the gear shift linkage components first. Remove the large bolt that is on top of the gear selector shaft near the gear selector flange (not the bolt holding part of the shift linkage). This holds a spring loaded rod that I believe is the reverse lock-out. With this out, remove the three screws on the gear selector flange. Careful, this sucker is spring loaded. Don't remove the snap ring. The whole assembly should slide out.

Now the gear carrier flange bolts can be removed. The shop manual says to drive out the metal guide sleeves on the top and bottom of the flange, but I couldn't get them to budge. I was able to tap out the gear carrier while still leaving the sleeves intact on the bell housing for installation later.

My next task is to order bearings, gasket kit, drain plugs and new gear oil. I have a coworker with a hydraulic press that I plan to use to press in the outer bearing races. The manual says to heat the housing to at least 300F before pressing them in. I think the inner races should be more straight forward.

The manual also says to pay special attention to proper shim thickness for the differential. My current plan is to just use the original shims and call it good. Although the proper factory shimming might not be achieved, I figure that just having the new bearings in there will make the differential play much better than it currently is. Considering the condition and mileage of the car, I think this plan should be appropriate unless any others have some pointers.

Stay tuned for updates.

#3

Rennlist Member

Just a word of advice - the whole purpose of the those shims is to account for differences in manufacturing the bearings... Even if you get the same brand, I can promise that they weren't made by the same factory on the same day.

There are a few people that do this properly. I'm not one of them (well, I don't do it at all!) - I leave that up to Kevin Gross.

There are a few people that do this properly. I'm not one of them (well, I don't do it at all!) - I leave that up to Kevin Gross.

#4

Rennlist Member

Van is correct -- it would be a mistake to simply reuse the original shims. Whether it's bearing manufacturing tolerance, age-related wear, or other causes, the required shims always, always change. Particularly for the eight-valve, normally-aspirated cars' transmissions with their marginal pinion gear design, but true for all models, it is really important that the diff carrier bearing preload and the ring-to-pinion freeplay be restablished to spec.

You do not need to heat the housing to 300 degrees for the differential carrier bearings. This instruction is specific to the front pinion bearing. For the DCBs, yes, do heat the case locally a bit say with a plumber's torch -- it eases installation and will keep you from scrubbing down interference. I would not use a hydraulic press to install, the outer races can drop in with enough heat, or may be gently tapped in using a drift or the recommended factory press tools. A hydraulic press will be inconvenient for the left-side race and is an invitation to trouble: a lot of force where little should be necessary.

You do not need to heat the housing to 300 degrees for the differential carrier bearings. This instruction is specific to the front pinion bearing. For the DCBs, yes, do heat the case locally a bit say with a plumber's torch -- it eases installation and will keep you from scrubbing down interference. I would not use a hydraulic press to install, the outer races can drop in with enough heat, or may be gently tapped in using a drift or the recommended factory press tools. A hydraulic press will be inconvenient for the left-side race and is an invitation to trouble: a lot of force where little should be necessary.

#5

Instructor

Thanks for all the info. How critical is it to get the shimming correct - will there be catastrophic damage if I re-shimmed the diff in the same way as it came from factory?

What measurements would I need to take to determine the correct shims to fit to spec? I am doing this on a G96/30 transmission.

What measurements would I need to take to determine the correct shims to fit to spec? I am doing this on a G96/30 transmission.