Cross drilled crank question

#1

Pro

Thread Starter

Hi guys,

The engine's coming apart nicely and it'll be off to the machine shop shortly. Going on the belief that the only dumb question is the unasked one, I have a question about what cross-drilling the crankshaft really means. Here's a pic of my crank, we're looking at cylinder #1. I see a single hole drilled in the crank area that gets covered by the rod bearings. This is what every cylinder looks like, one single hole.

So when folks say I "need to cross-drill the #2 and #3", does that mean for the two middle sections, have the machine shop drill a similar hole 180 degrees from the single hole? That's my guess, but I'd like to have confirmation.

The engine's coming apart nicely and it'll be off to the machine shop shortly. Going on the belief that the only dumb question is the unasked one, I have a question about what cross-drilling the crankshaft really means. Here's a pic of my crank, we're looking at cylinder #1. I see a single hole drilled in the crank area that gets covered by the rod bearings. This is what every cylinder looks like, one single hole.

So when folks say I "need to cross-drill the #2 and #3", does that mean for the two middle sections, have the machine shop drill a similar hole 180 degrees from the single hole? That's my guess, but I'd like to have confirmation.

#2

Rennlist Member

i had my old crank crossdrilled on my n/a- yes that would mean drilling through the exhisting hole and out the other side- make sure they chamfer the other side like the OE side is- you can also have them do a perpendicular drill if they know how- where the oil holes are only 90degrees apart- there by keeping the oil from being drawn to one side - ive heard of that but never had problems w/ my crossdrill either. I would do all four if you do them. MAKE SURE they flush the hell out of the holes before they reassemble as you dont want a bunch of debris getting into your oiling system.

#4

Race Director

The recommendation for only doing #2 and #3 is not for cost savings, but to balance the flow among all 4 rod journals. Greg Fordhal ran a flow test on cranks and found that doing #2 and #3 ONLY balance the flow for all 4 journals. I trust Greg knowledge on this. My current race motor has all 4 drilled, but my spare more I had then drill just #2 & #3 180 away from the existing holes.

#5

Pro

Thread Starter

Excellent, thanks Joe. I knew the point of just doing the middle ones was to balance out the flow among all of them. I just didn't know "where" the holes went. Oh, and is that just the #2 and #3 on the rod bearing area, or also include the mains?

So since you've had several motors apart, and this is my first, some more questions. I gotten the crank bolt off, the water pump and all various sprockets on the front. To get the crank out I need to remove the girdle, and the oil pump right? Flywheel? Anything else?

I've got the factory manuals and I'm reading other engine threads, but sometimes its not until you do it, do you realize "oh, that's what they meant". So any other tips?

So since you've had several motors apart, and this is my first, some more questions. I gotten the crank bolt off, the water pump and all various sprockets on the front. To get the crank out I need to remove the girdle, and the oil pump right? Flywheel? Anything else?

I've got the factory manuals and I'm reading other engine threads, but sometimes its not until you do it, do you realize "oh, that's what they meant". So any other tips?

#6

Hey Man

Rennlist Member

Rennlist Member

I have a question relating to your photo. Was that lateral depression cut into your main bearing hole for a reason? I've never seen that before and wonder if it's to provide more oil to the slot in the bearing shell. Since main bearings never seem to fail I was just wondering.

#7

Race Director

Excellent, thanks Joe. I knew the point of just doing the middle ones was to balance out the flow among all of them. I just didn't know "where" the holes went. Oh, and is that just the #2 and #3 on the rod bearing area, or also include the mains?

So since you've had several motors apart, and this is my first, some more questions. I gotten the crank bolt off, the water pump and all various sprockets on the front. To get the crank out I need to remove the girdle, and the oil pump right? Flywheel? Anything else?

I've got the factory manuals and I'm reading other engine threads, but sometimes its not until you do it, do you realize "oh, that's what they meant". So any other tips?

So since you've had several motors apart, and this is my first, some more questions. I gotten the crank bolt off, the water pump and all various sprockets on the front. To get the crank out I need to remove the girdle, and the oil pump right? Flywheel? Anything else?

I've got the factory manuals and I'm reading other engine threads, but sometimes its not until you do it, do you realize "oh, that's what they meant". So any other tips?

Re crank... mains are already 180 deg cross drilled

Re removal. you can leave the flyhwheel on, but it bolts to the crank so you would want to take it off too. Otherwise you are spot on.

Trending Topics

#8

Race Director

I have a question relating to your photo. Was that lateral depression cut into your main bearing hole for a reason? I've never seen that before and wonder if it's to provide more oil to the slot in the bearing shell. Since main bearings never seem to fail I was just wondering.

#9

Three Wheelin'

Join Date: Jul 2002

Location: Connersville IN

Posts: 1,807

Likes: 0

Received 0 Likes

on

0 Posts

thats another style of chaphering the hole with a round file, I do mine that way after chamfering the hole with a tool. I drilled mine out the outer most point of the journal so that centrifugal forcfe pulls the oil out of the end of the crank. I don't drill them ll way through ie:crossdrilling.

#10

Three Wheelin'

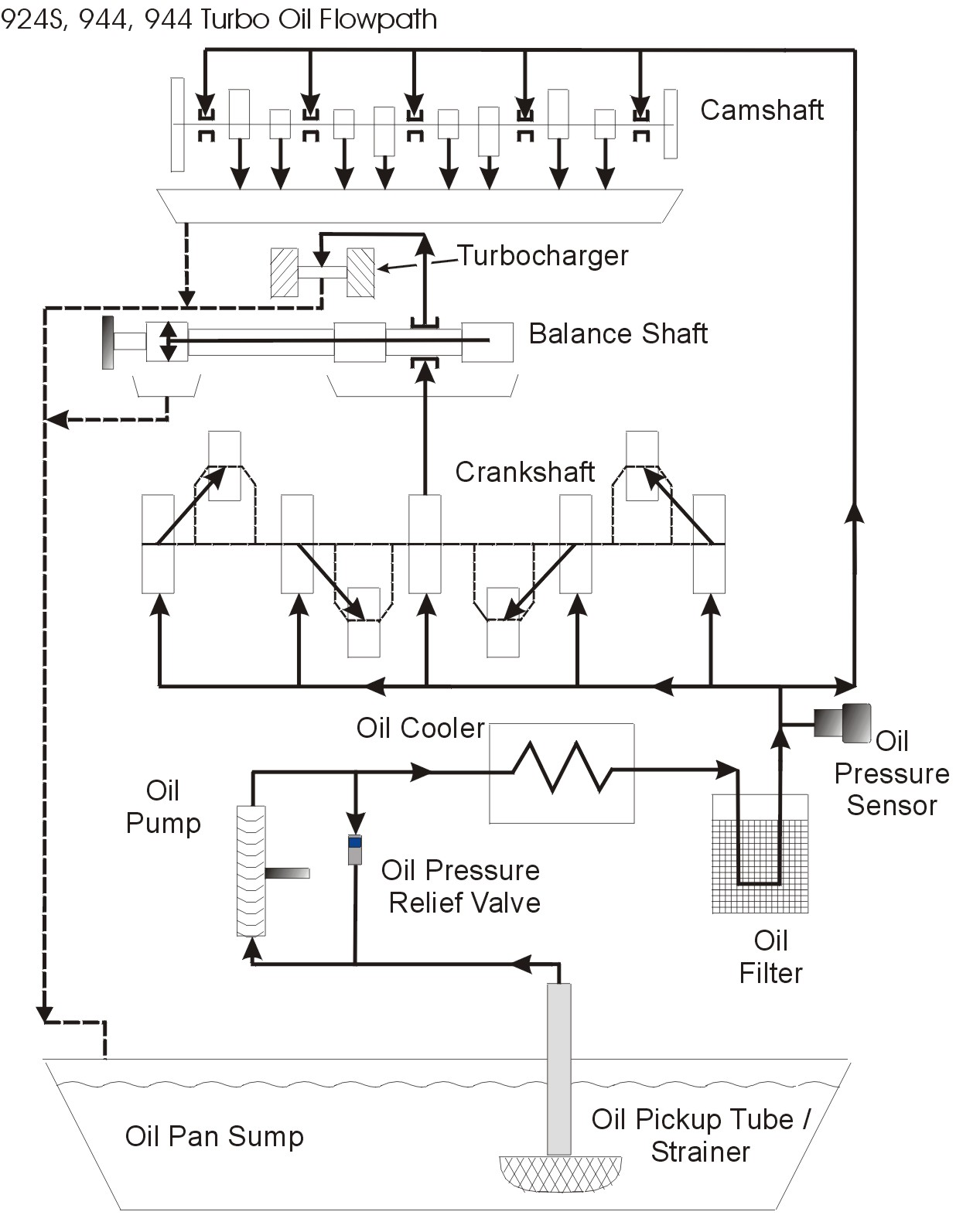

This is interesting for me, especially because I didn't even know how oil flowed through the crank until last month. Some observations/questions I have-

1) That extra cut in litespeeds main journals look to me like it would increase oil flow by making a larger path for it to enter the hole. By "round file" I assume that badcoupe means die grinder.

2) At first that extra machining looked like the hole was machined at an angle (it actually would have to be done with an end-mill, not a drill bit) to help "scoop up" the oil. With no real experience with cranks, to me that sounds like a good way to get the most flow.

3) The 90 degree hole "perp drilling" on the rod journal makes sense because centrifugal force would help the oil flow out of the hole, but it seems that doing it to the main journals wouldn't really help, other than the fact that it's another hole.

4) Cross drilling only #2 and 3 makes sense if it means that doing all four robs 2 and 3 because 1 and 4 flow too much, but you guys aren'y being specific about rod vs. crank journals

1) That extra cut in litespeeds main journals look to me like it would increase oil flow by making a larger path for it to enter the hole. By "round file" I assume that badcoupe means die grinder.

2) At first that extra machining looked like the hole was machined at an angle (it actually would have to be done with an end-mill, not a drill bit) to help "scoop up" the oil. With no real experience with cranks, to me that sounds like a good way to get the most flow.

3) The 90 degree hole "perp drilling" on the rod journal makes sense because centrifugal force would help the oil flow out of the hole, but it seems that doing it to the main journals wouldn't really help, other than the fact that it's another hole.

4) Cross drilling only #2 and 3 makes sense if it means that doing all four robs 2 and 3 because 1 and 4 flow too much, but you guys aren'y being specific about rod vs. crank journals

Last edited by kevincnc; 11-12-2007 at 09:19 PM.

#11

Hey Man

Rennlist Member

Rennlist Member

I agree on the CD'ed #2 and #3 rod bearing but what is the benefit of the 'round file' on the mains? On the mains it seems to me that exposing a larger journal/bearing oil discharge area would result in a slight pressure drop as oil would be scavenged easier. Again, has anyone ever experienced a main bearing failure in these cars? To me I have to question the benefit but maybe I'm missing something, it wouldn't be the first time.

#12

Race Director

I don't believe these cars will have a main bearing failure except for rare cases of bad bearing installation. The reason is any oil stavation would hit the weak link in the system which is the rod bearings. Remember the oil is feed to the main bearings from the block. The excess oil from the this get sent through the crank to the rod bearings. So the rods will suffer starvation long before the main bearings. This does not mean main bearing clearances are irrelevant as in fact they are critical. Wide open main bearings mean less excess oil get routed to the rods.

Remember the main bearings are already cross drilled. It is the rods that need the extra holes. Although it seems that some 83 or 84 cranks may have had the rod crossdrilled by the factory.

Remember the main bearings are already cross drilled. It is the rods that need the extra holes. Although it seems that some 83 or 84 cranks may have had the rod crossdrilled by the factory.

#14

Three Wheelin'

Join Date: Jul 2002

Location: Connersville IN

Posts: 1,807

Likes: 0

Received 0 Likes

on

0 Posts

I use a round file on all of the holes and file them by hand. this gives a little better area for the oil to get out onto the journal. It might not be necessary but it is something I do. Our midget motors turn 12000 rpm so I do everything I can to help out the oiling.