Porsche 993: Why is My Car Losing Power?

The Porsche 993 has its fair share of components that can fail and result in loss of engine power. Luckily, many of these components can easily be inspected to determine if they are the cause of this lack of performance.

This article applies to the Porsche 993 (1993-1998).

As the first 911 equipped with On Board Diagnostics 2 (OBD II), the Porsche 993 monitors many components to ensure proper operation of the vehicle. Many engine-related problems can be detected by the on-board computer and illuminate the check engine light to alert the owner of a problem. That being said, many components can age or breakdown, and, while not operating correctly, will not trigger a check engine light. With partial failure of monitored components, or failure of non-monitored components, poor engine performance and a loss of power will be evident. This article will take a look at the potential causes of a loss of power on both OBD I & OBD II 993 models.

Materials Needed

- Digital multi-meter

- Test light

- A willing helper/friend

- Scan tool (optional)

Fuel System

One of the first areas to inspect when experiencing a loss of power in your 993 is the fuel system.

DME Relay

The DME (Digital Motor Electronics) uses a relay to power the fuel pump when the car is running. This relay is a common source of problems as the solder joints in the relay can crack and make poor contact or no contact at all. The engine can intermittently cut out, stall, or fail to start if the relay has gone bad. The easiest way to ensure everything is working correctly is to swap in a new or known good relay. If poor engine power is still evident, the problem likely lies elsewhere. It is also highly recommended that a spare relay be carried in the glove box at all times as it can save you from calling a tow truck if the original relay fails.

Fuel Filter

If the car is running fine during idle or cruising speeds, but runs poorly at high RPM, then a dirty fuel filter may be the culprit. A clogged fuel filter will restrict fuel flow and the engine cannot receive enough fueling in aggressive driving situations. Porsche recommends fuel filter replacement intervals of 60,000 miles; however, owners report installing a new fuel filter as part of their annual vehicle maintenance.

Fuel Pump

The fuel pump moves fuel from the fuel tank to the fuel injection system. A dying pump may not provide sufficient fueling for the engine in higher RPM situations, and you may experience a stumbling or loss of power. Similarly, a bad electrical connection to the pump can cause the pump to become inoperable. Any abnormal noises from the pump are early signs of pump failure. Also, if the fuel filter and DME relay are good, but you are still experiencing power loss when the engine is under load, the fuel pump is likely the culprit.

Related Articles

- Porsche 993: How to Replace Fuel Filter - Rennlist.com

- Porsche 993: How to Replace Fuel Pump - Rennlist.com

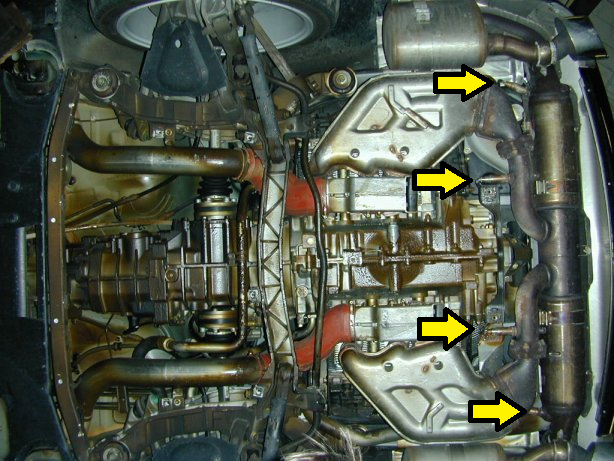

Oxygen Sensors (O2 Sensors)

With O2 sensors being such an integral part of the modern combustion engine, any fault in the sensors can lead to numerous poor running conditions. O2 sensors age the more the car is used and typically do not respond as fast as they do when new. While the sensors usually do not flat out fail, their performance will gradually degrade. Many times this degradation will not lead to a check engine light because the sensor is still operating within its parameters. However, the Porsche service manual states that a failing O2 sensor can cause erratic idling, poor fuel economy, engine hesitation, power loss, and hot starting issues. O2 sensor values on OBD II-equipped 993's can be checked with a scan tool, while voltage can be checked at the sensor on OBD I 1995 993's.

Figure 4. Single O2 sensor on 1995 993.

Figure 5. 1996-1998 O2 sensor locations.

Varioram

The varioram is a variable intake system used on 1996+ model 993s. This intake uses a three-step system that utilizes a resonance flap and six trumpet-style tubes inside of the intake manifold that vary in length depending on engine RPM. These trumpets extend and retract allowing for more bottom-end torque while also increasing high RPM horsepower. The varioram system is good for an additional 20 horsepower over non-varioram 993s; however, if this system stops functioning, significant top-end power loss will be evident.

Operation can be checked with a helper. After the engine has been running, shut the car off and open the decklid. While standing at the engine bay, have a friend turn the ignition key on and listen for the resonance flap actuation which should clearly be audible. Simultaneously, watch for movement at the actuator control arms on the left side of the intake manifold. If this cannot be observed, there is a vacuum leak rendering the varioram inoperable.

Pro Tip

While driving the car and accelerating past 5,000 RPM, there should be a noticeable change in intake noise when the varioram is properly operating.

Cylinder Head Temperature Sensor

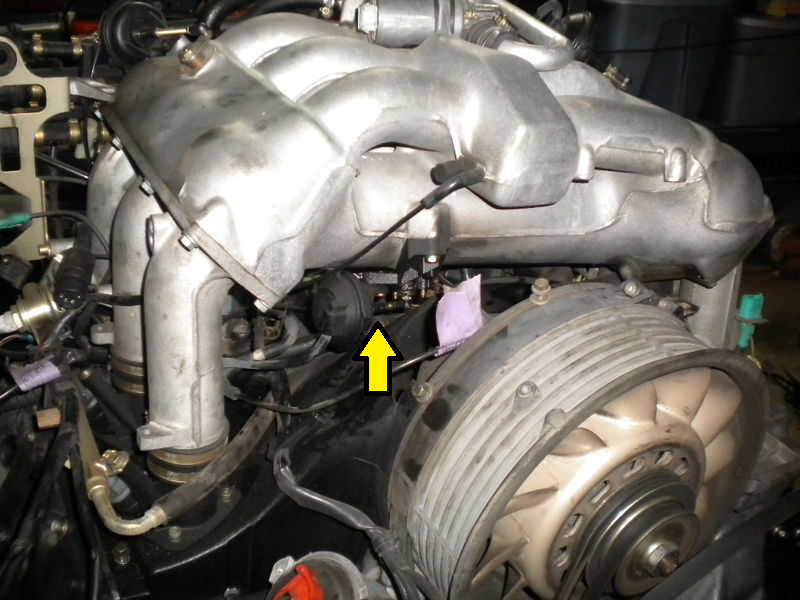

Along with the intake air temperatures provided by the mass airflow sensor, the cylinder head temperature sensor (aka CHT) is used to monitor the engine and calculate proper fuel mixture. If the sensor fails or the ECU calculates an implausible reading, the car will revert to a preset map that assumes the engine is at a fully-warm operating temperature. Owners have reported that replacing the CHT sensor will yield positive results with regards to engine performance. The CHT sensor is located on cylinder number 3. Resistance can be checked at the sensor plug with a digital multi-meter and should vary depending on engine temperature. Measurements should read: 32 degrees Fahrenheit 4.4k-6.8k ohms, 60-85 degrees 1.4k-3.6k ohms, 105 degrees 1.0k-1.3k ohms, 175 degrees 0.250k-0.390k ohms, and 265 degrees 0.090k ohms.

Figure 8. White wire running to CHT.

Figure 9. Check resistance at CHT plug.

Distributor

Distributor Drive Belt

The 3.6 liter engine in the 993 came equipped with dual spark plugs per cylinder. In order to operate both sets of spark plugs, Porsche utilized a belt drive system inside of its twin distributor setup to keep both distributors operating in unison. Unfortunately, this drive belt is known to fail prematurely because of ozone gas buildup in the distributor. Failure of the drive belt renders the second distributor useless and can cause a wide array of problems ranging from minor performance issues to severe engine damage depending on where the second distributor rotor stopped spinning. Most owners report a loss of power in the upper RPM range usually accompanied by pinging or engine knock. The simplest way to test for a distributor drive belt failure is to remove the secondary distributor cap and attempt to turn the rotor. If it spins freely, the belt has failed. Similarly, you can test the drive belt by removing the coil wire from the top of the primary distributor and attempt to start the engine. This forces the engine to run on only the secondary distributor. If the engine fails to run, the drive belt is bad.

Distributor Caps and Rotors

The distributor caps and rotors are wear items and should be replaced at regular intervals. Many owners tend to replace them every 30,000 miles. Individuals who experience poor performance at mid-to-high RPM have reported major improvements in driveability and power after installing new caps and rotors.

Figure 10. Dual distributor.

Figure 11. Distributor drive belt replacement.

Pro Tip

At this point in the 993's life, all cars should already have a distributor vent kit installed to reduce the likelihood of a belt failure. If your car does not have a vent kit installed, they are still available from Porsche (part # 000-043-202-52).

Ignition Coils

Similar to the twin distributor, the 993 also uses two ignition coils. If one ignition coil fails, the timing can become retarded, and loss of engine power will become evident. The primary and secondary resistance in each coil can be checked with a digital multi-meter. The primary resistance should measure approximately 0.6 ohms and the secondary, 7.0k ohms. Any significant deviation from these measurements is typical of a bad coil. Testing for current across each coil can also help determine if the problem is in the coil itself, or if there is a short to ground elsewhere.

Pro Tip

If both ignition coils check out okay, it is worth inspecting the wiring running from the coils to the ignition module located under the driver's seat to ensure there is no short to ground.

Mass Airflow Sensor

While the mass airflow sensor (aka MAF) is pretty trouble-free on 993 models, it can become contaminated with oil if running an aftermarket air filter. The hot-wire MAF measures the amount of air entering the engine and relays this information back to the ECU for proper fueling adjustments to be made. Most aftermarket air filters, if overly oiled, can contaminate the hot-wire thus causing a deviation in the measurement of the air entering the engine versus the actual amount. In turn, owners experience poor engine performance. The MAF should be cleaned with a product specifically developed for MAF sensors. It is not a bad idea to occasionally clean the MAF to maintain proper operation regardless of whether or not you are having any problems.

Boost Leaks (Turbo Models Only)

The 993 turbo models use several boost hoses and couplers to route air from the turbochargers into the intercooler and finally the engine. The factory hoses have been known to pop off or tear. The result is that boost pressure made by the turbochargers exits out of the leaking hoses, and the full charge of air does not make its way into the engine. Owners experience additional turbo lag and a general loss of power from boost hose leaks. When a hose is leaking, it is often accompanied by a whistling noise when the turbocharges are producing boost under load. The hoses can be easily inspected and often times fixed rather easily. Upgraded hoses and hose clamps are available from both Porsche and aftermarket suppliers.

Related Discussions

- Varioram Testing? - Rennlist.com

- Distributor Drive Belt Replacement Thread Collection - Rennlist.com

- MAF Sensor a Maintenance Item - Rennlist.com

- How to Replace Cylinder Head Temperature Sensor - Rennlist.com