Porsche 928: Why Are My Accessory Belts Noisy?

A squealing or whining Porsche 928 can be a bit annoying to drive. Although the car may seem to be operating normally, a noisy belt can be an early warning sign of a potential failure than can leave you stranded. A quick inspection of a few components can help you easily determine the source of the noise.

This article applies to the Porsche 928 (1978-1995).

The Porsche 928 uses a unique combination of belts to drive the engine and its accessories. This makes for a fairly complicated setup compared to modern day vehicles, which simply utilize a single serpentine belt. When a belt noise arises on the Porsche 928, it can be a bit tricky to determine the source. Many times, a squeal or whine thought to be from a belt can actually be from a failing accessory instead. Even worse, the timing belt could be the source of the problem and an early sign of a potential timing belt failure. Either way, the source of the noise can usually be quickly determined by inspecting the accessory belts, accessories, and timing belt components.

Materials Needed

- Mechanics stethoscope

- Metric socket set and ratchet

- Metric combination wrench set

- Floor jack and jack stands

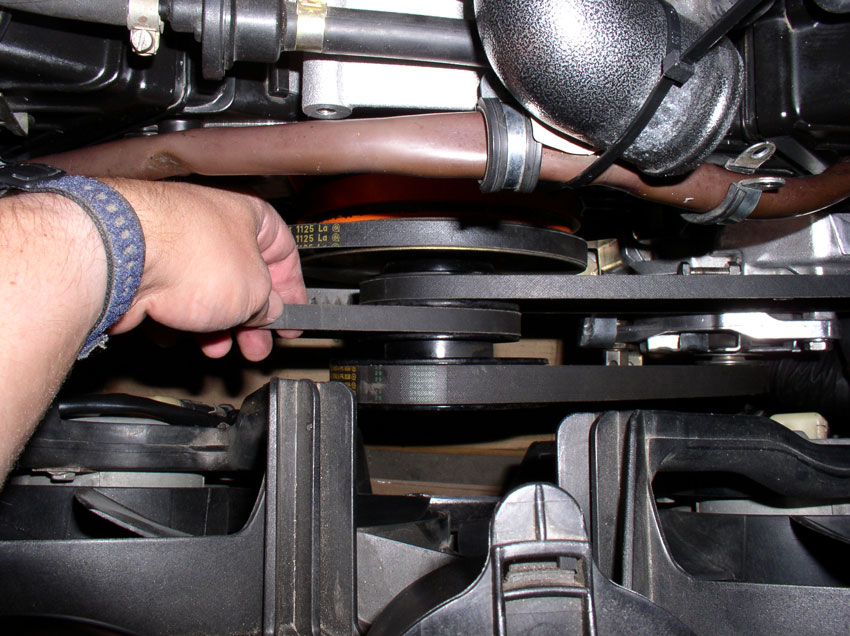

Step 1 – Inspect accessory drive belts

The first step in identifying a belt noise is to inspect the accessory drive belts. The 928 uses a variety of belts to drive the air conditioning compressor, power steering pump, alternator, as well as the the air injection pump and fan. A typical belt squeal is often due to an under-tensioned belt slipping on its pulley; however, grit, oil, grease, or a damaged belt can also cause belt slippage and noise. Inspect the condition of each belt to ensure that there are no cracks, splits, or chunks of belt missing. If the condition of any belt is the culprit, replace the worn belt. Although it is not required, many owners recommend replacing all drive belts together using belts from the same manufacturer.

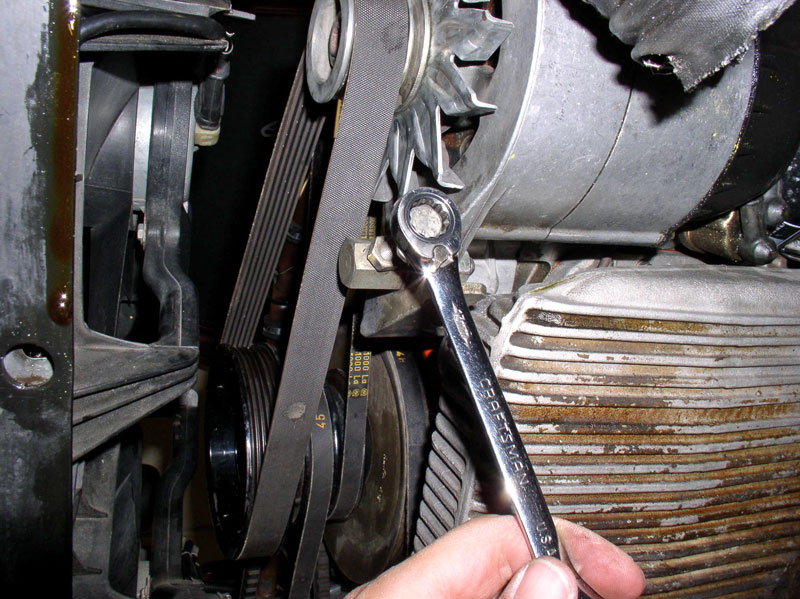

Step 2 – Set tension on accessory belts

If all belts are in good usable condition, check the tension on each belt. Correct belt tension should allow approximately 1/4" of deflection when pressing in the center point of the belt. A belt with too little tension will slip on its pulley, and not properly drive the associated accessory. As previously mentioned, this can also result in a belt squeal or whine. Also, the belt can become overheated and damaged. Similarly, a belt that is set too tight will place an excessive bearing load on the driven accessory, and can cause premature belt or accessory failure.

Figure 2. Alternator belt tension adjustment.

Figure 3. How to measure belt tension.

Pro Tip

A newly installed belt will naturally break-in and stretch. Recheck the belt tension after a day or two of driving with a new belt to ensure proper tension.

Step 3 – Inspect driven accessories

If all the accessory drive belts are in good condition and properly tensioned, one of the driven accessories could be the source of the noise. A failing bearing in any one of the accessories can often cause a growling or moaning noise similar to that of a belt noise. With a mechanics stethoscope, probe around the accessories with the engine running. Listen for any abnormal noises emanating from the accessories. The noise should be amplified through the stethoscope, and can be very apparent near any faulty accessory. An alternate method to determining accessory noise can be accomplished by removing each accessory drive belt one at a time, and listening for a change in the noise with the engine running; however, this method will require re-installation and re-tensioning of each accessory belt.

Step 4 – Inspect timing belt

If all of the belt driven accessories checks out okay but the noise persists, the problem likely lies with the timing belt or water pump. The timing belt is one of the most crucial pieces of the 928 engine as it keeps the components of the valve train in sync with the crankshaft. This often neglected belt should be replaced at least every 60,000 miles or four years. Neglected belts can lose teeth, and potentially throw off the timing. The belt tensioner pulley and idler pulley bearings can fail. It can also often make a growling or moaning noise when the engine is running. Additionally, the timing belt drives the water pump, which can begin to exhibit a noise associated with a bad bearing when failing. If you suspect the noise is coming from somewhere within the timing belt cover, do not attempt to drive the car before further investigating the problem. Although the early 16-valve 928 engines do not have an interference valve design, later 32-valve 928 models can suffer catastrophic engine damage if the timing belt breaks or jumps time.

(Related Article: How to Replace Timing Belt and Water Pump - Rennlist.com)

Related Discussions

- 928 Pulley Noise. Water Pump Noise? - Rennlist.com

- Engine Noise: Clanking, Grinding, etc. - Rennlist.com

- Rattle/Moaning Sound From Timing Belt - Rennlist.com