Porsche 928: How to Replace Timing Belt and Water Pump

It might be a little extra labor, but changing the water pump when you go to replace the timing belt in your Porsche 928 will save you a ton of time and money later on down the road. Consider it good insurance against future repairs you'll have to do with a car that's 30 years removed from the manufacturing line.

This article applies to the Porsche 928 (1979-1995).

Replacing the timing belt and water pump in your 928 is not an easy task. If you are at all hesitant about performing any of these steps, it's recommended to take your vehicle to your local auto body shop to have the job performed by a professional. Read on to learn what's involved in this repair.

Materials Needed

- Timing belt #928-105-157-00

- Water pump #928-106-015-22

- Tensioner spring

- Tensioner pulley

- Idler pulley

- VC gasket

- Gasket scraper

- Torque wrench

- Wrench set

- Needle nose pliers

- Hex key set

- Jack and jack stands

- Feeler gauge set

- Bowl/basket

Step 1 – Remove front of engine

- Start with a cold engine. Disconnect the battery ground strap behind the tool tray.

- Raise front of car. Put the jack under the lower control arm rear support to raise the jack stand higher at the front point.

(Related Article: Porsche 928: How to Jack Up Your Porsche - Rennlist.com)

- Open hood and set out service covers/blankets. Remove engine belly pans (9mm and 10mm sockets).

- Loosen coolant reservoir cap. Loosen the radiator drain cock with a flat head screwdriver and drain radiator. Should be 2.5 gallons of liquid.

- Remove left and right side engine block drain plugs and drain block. Should be about 1.5 gallons of liquid.

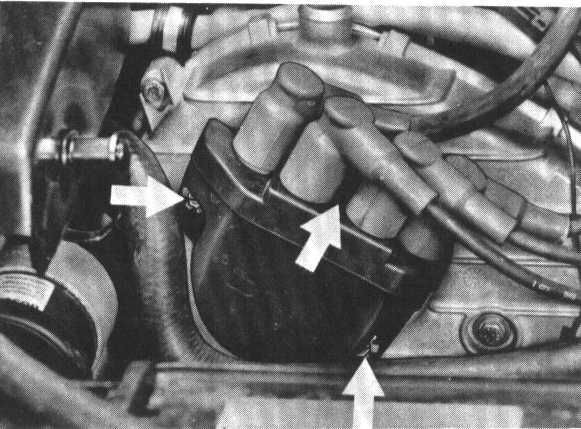

Figure 3. Block coolant drain plug.

Figure 4. Coolant drain cock access hole.

- Remove the air cleaner intake hoses.

- Remove the upper and lower radiator hoses.

- Replace and snug radiator drain cock.

- Replace two engine block drain plugs.

- Unplug electrical connectors on each fan, and remove wiring from the clips on fan shroud.

- Remove the jumper post cover.

- Loosen or remove clamp on power steering reservoir to allow clearance.

- Loosen air pump hose to filter. Tie back so it stays out of your way.

- Remove screwbolts on top of fan shroud.

- Remove fan shroud. You may need to loosen oil cooler line — a little oil may drip. If you do this, snug it back together because later on, when you hand-crank the engine, you could pump enough oil up to spill.

- Loosen alternator lockdown bolt with an open-end wrench. Use a hex key on the adjuster. Loosen pivot bolt if you feel it’s necessary. Remove belt.

- Loosen bolts for power steering pump, and use a socket on the adjuster. Remove belt and mark it.

- Loosen air pump lockdown bolt, and loosen adjuster nut. Remove the belt and mark it.

- Loosen bolts for A/C compressor belt. Remove belt and mark it.

- Remove oil dipstick.

- Mark spark plug wires (you can do this by putting tape across the distributor beneath the wires and writing the plug cylinder numbers there).

- Unplug all wires (and coil wire on the bottom) and lay back on the engine. Use a hex key on the plug wire loom at front/center of engine. Lay this section across the front of the intake manifold.

- Loosen screws from each distributor and lay aside. Note which is left vs. right.

Step 2 – Remove timing belt

- Disconnect the belt tension sensor from the front of the right timing belt cover.

- Detach the oil dipstick guide from the timing belt cover.

- Remove both timing belt covers with a socket. The left side should have three bolts. There are two bolts on the right cover — disconnect the tensioner sensor. Lay covers aside with bolts in proper holes.

- NOTE: For five-speed cars – remove clutch slave cylinder. Take off clamp on clutch hose holder and remove push rod. Let cylinder with connected line hang down.

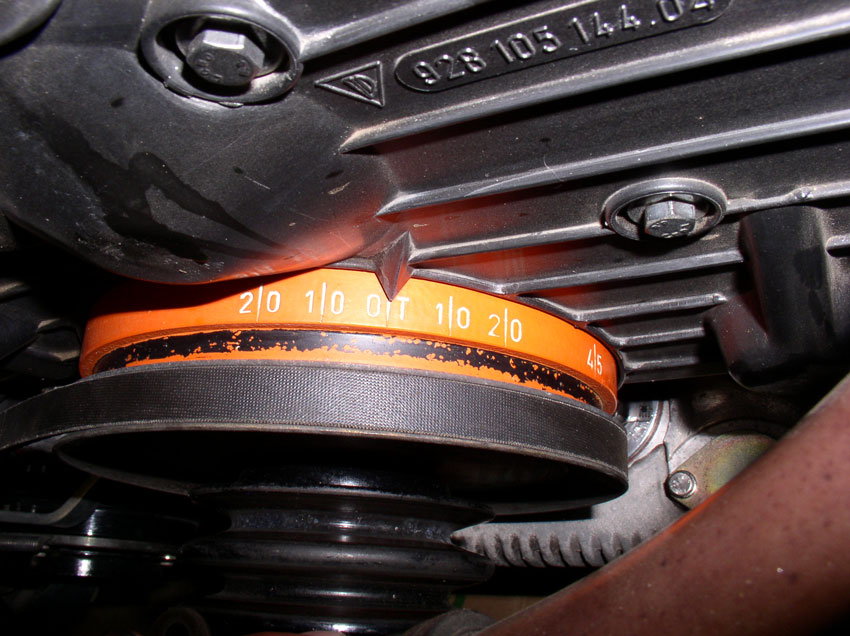

- To remove the timing belt, use a socket on the crank bolt. Turn crank clockwise to the top dead center 0º mark on the crank pulley.

- With crank at 0º check that the notches on the back of the camshaft sprockets are aligned with the notches in the backing plates.

- Turn crank (clockwise) to 45º mark.

- Add marks to each camshaft pulley for the 45º alignment.

- Pull engine two additional turns to ensure that the added 45º marks continue to align.

- Mount the Flywheel Lock with original 13mm bolts to hold crankshaft. The tool mounts where the clutch slave cylinder was installed. On the automatic cars there is simply a cover plate. The two bolts are short so leave washers off to snug up the flywheel lock.

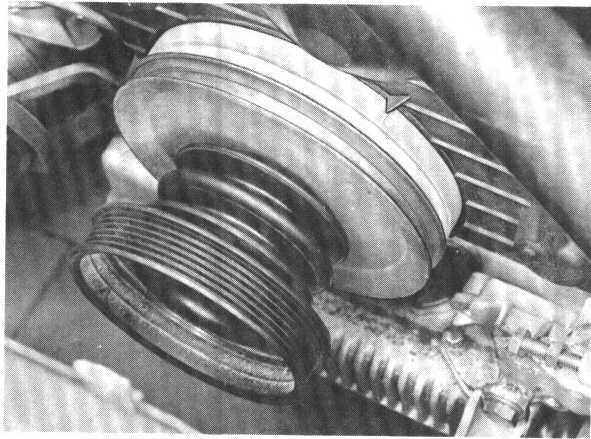

- Remove crankshaft bolt. It should be torqued to 218 ft/lbs.

- Remove pulleys, and wiggle vibration damper (this may take some time). Also remove the collar.

- Loosen console with alternator from engine – use sockets on bolts. This is to provide room to remove the center timing belt cover.

- Observe wiring harness that runs across the front of the engine. This harness comes from the alternator and starter between the left timing belt cover and the center timing belt cover, has a smaller split to the connector by the left headlight, and runs back under the right timing belt cover and up and forward to the jump point. Follow this harness and note the bracket behind the right timing belt cover.

- NOTE: There is also a wire running from the harness under the right fuel rail and connecting under the right timing belt cover. Disconnect this.

- Disconnect signal wire running to the A/C compressor.

- Disconnect harness wire that splits to left headlight connector. Replace screw so it’s not lost.

- Disconnect the end of harness wire at jump point. Replace screw/jump contact so it’s not lost.

- End of the harness also feeds into a small rectangle connector. Use a screwdriver to pry it in half.

- Remove screwbolt that holds the harness bracket to the right-side engine lift point. Careful — there are a lot of lines and hoses in the way. Put this screwbolt in a safe place.

- With harness free, carefully thread it out to the front of the block.

- Clean around the guide tube for the oil dipstick, and then remove it.

- Remove center timing belt cover — one bolt goes into the belt tensioner, and three bolts (one is long). Be careful to disconnect the timing belt tension sensor on the inside. Set the cover aside with the bolts in their proper holes.

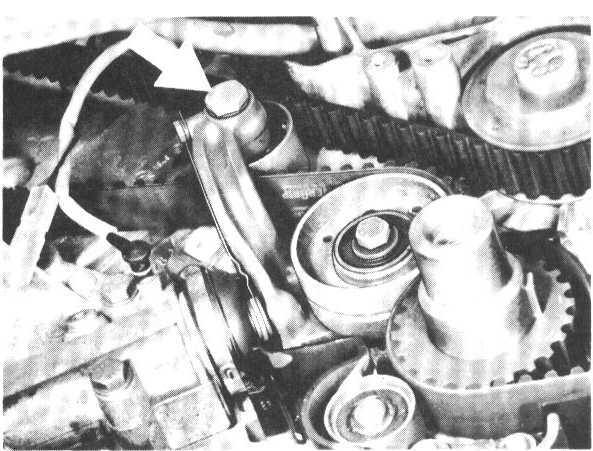

- Slacken the timing-belt by loosening the tensioner lock nut, and turning the adjusting screw counter-clockwise.

- Unscrew metal tensioner sensor strip that runs up roller bracket. Snug screw back into place.

- Unbolt (and remove the tensioning roller bracket. Careful not to lose or mangle the sensor strip or spring, etc.

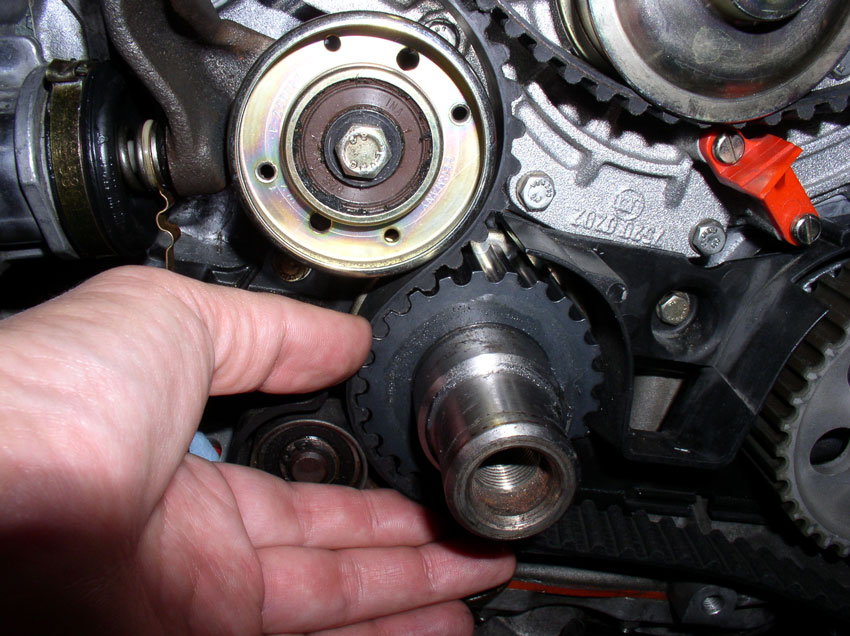

- Remove toothed-belt from right-hand side over cylinder 1-4 camshaft sprocket, water-pump sprocket, cylinder 5-8 camshaft sprocket, oil-pump sprocket and crankshaft sprocket.

- Remove timing belt.

Step 3 – Remove water pump

- Temporarily replace oil dipstick guide tube, but turn it so that it swings away from the water pump.

- Remove tensioner idler spindle from water pump (nut that threads into the pump — it does not hold the pump onto the block but it does open into the water-jacket, so some coolant may drip).

- Place new water pump next to you.

- Remove timing pointer from old pump and transfer to new pump.

- Remove the fourteen water pump bolts. First loosen each one — then go back and remove them. As you remove each bolt place it into the corresponding hole of the new pump.

- NOTE: old pump may be held to the block by the gasket. Do NOT try to pry it loose. An easy tap with the wood-handle end of a hammer should do the job.

- Clean off any remaining gasket material from block.

- Remove the oil dipstick tube for room to work.

Step 4 – Remove, rebuild, and install tensioner

- Tensioner is held to block by three bolts. One bolt has already been removed as part of the upper timing belt cover. First, remove the bolt that is the pivot for the air pump. Next, remove remaining three bolts (two above and one below) that attach tensioner cylinder to engine block.

- Note where the bolts came from and lay them aside.

- Remove old rubber boot and clamp.

- Open tensioner and clean the inside where the tensioning rod and washers are located. Do this by pulling the plunger out. When reassembling, use a new rubber O-ring.

- Install new boot and clamp.

- Replace both tension roller and smaller idler. Remove roller bolt (10mm).

- Smaller idler is a press fit held on by a C-clip. Pointy needle-nosed pliers will work.

- Knock the old idler off (you can use a hammer). Replace with new one (do not hammer into place).

- With idler in place, transfer C-clip from old roller to new one, and bolt new roller on.

- Turn tensioner screwbolt counter-clockwise to full loose.

- Clean block and tensioner of any remaining gasket material from tensioner.

- Use a light coating of gasket sealant on gasket and mate to tensioner.

- Attach tensioner to block by fitting the upper arms to the pivot of the air pump. Do not tighten yet.

- Clean and mount the bolts through tensioner to block. Ensure they’re snug.

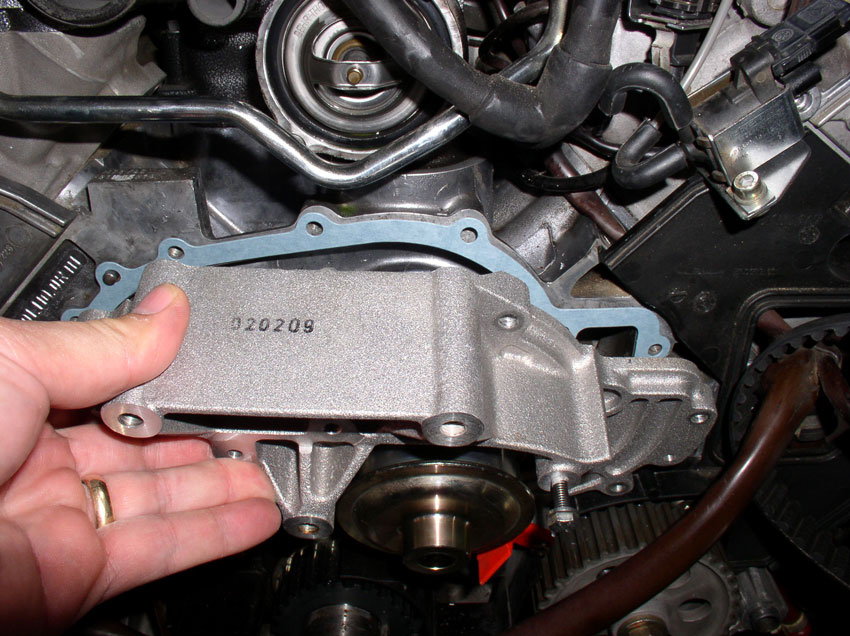

Step 5 – Install new water pump

- Hold new water pump up with screws in their holes. Inspect rear, making sure that all screws extend same distance from the pump.

- Lay old water pump next to new pump. Transfer bolts back to the old pump, cleaning each bolt and spray with WD-40 as you go.

- Use a light coating of gasket sealant on gasket and mate to pump.

- Use a light coating of gasket sealant on block side.

- Transfer bolts from far left and far right side of old pump to new water pump, and attach to block. Finger-tighten two bolts.

- Transfer other bolts to new pump and finger-tighten.

- Snug each bolt.

- Snug each bolt a little tighter and double check all are in place and tight.

Step 6 – Install and tighten new timing belt

- Pull new timing belt over oil pump, the left cam sprocket, around water pump, and over right cam sprocket. Turn/adjust camshafts counter-clockwise as necessary for the 45º marks to line up when installing the belt.

- Check all slack in belt is at tensioner.

- Install tensioner arm (with 4mm hex key).

- Screw tensioner sensor strip into tensioner arm.

- Check that all slack in belt is between right cam sprocket and tensioner.

- Use an open-end wrench and turn the tensioner clockwise to tighten the belt.

- Confirm that all belt slack is at tensioner.

- Install center timing belt cover. One bolt goes into tensioner, plus three bolts (one is long). Careful to not over-tighten bolts (cover is plastic).

- Install crank collar and damper.

- Finger-tighten the crank bolt and washer.

- Temporarily remove the flywheel lock.

- Turn the engine to TDC 0º while watching timing belt and all movements.

- Check timing marks on camshaft sprockets.

- Turn engine two turns and re-check all timing marks.

- Using the belt tension tool of your choice, check belt tension with engine at 0º TDC. Place tool midway between the right cam sprocket and the tensioner idler. Tighten belt by turn-adjusting the tensioner screw clockwise.

- Turn the engine two more turns and re-check tension. Engine must always be at TDC 0º when checking. (NOTE: correct value for factory tool 9201 is 5.0 + 0.3).

- Turn engine and re-check belt tension a few more times.

- Refill the tensioner with 90-weight gear oil by loosening fill (left) and bleed (right) screws (this will take time). Tighten both bleed screws.

Step 7 – Install the front of the engine

- Insert the oil dipstick tube (use some gasket sealer for extra insurance).

- Plug in connecting wire for timing belt tension sensor.

- Attach upper part of dipstick tube to center timing belt cover.

- Install console mount for the alternator.

- Install the flywheel lock.

- Remove the crank bolt and washer.

- Install the pulleys with the belts in place. Back to front, the order is A/C belt (large single pulley), power steering belt, air pump belt, and alternator (thick, ribbed belt).

- Tighten crank bolt to 218 lbs. torque.

- Remove flywheel lock and replace access cover (on automatics) or clutch slave cylinder (on five-speeds). Remember washers with the two bolts.

- Replace upper timing belt covers (Right side has one short and one long 10mm bolt. The left cover has three short 10mm bolts).

- Thread wiring harness across front of engine, under right timing belt cover, and up and forward to jump point; now reconnect cable and rectangle connector (make sure to take a second and clean it first).

- Reconnect harness split to connector near left headlight.

- Reattach the harness bracket to right engine lift point.

- Reconnect wire running from right fuel rail harness to connector underneath right timing belt cover.

- Tighten A/C compressor belt and pivot bolt.

- Tighten power steering belt with the adjuster nut. Tighten two lockdown nuts and pivot bolt.

- Tighten the air pump belt with the adjuster nut, lockdown bolt, and pivot bolt.

- Tighten alternator using the hex key adjuster and lockdown bolt (tighten pivot bolt if you loosened it earlier).

- Clean the rotor and the contacts inside the distributor using sandpaper.

- Attach each distributor to timing belt cover with flat head screwdriver or socket.

- Connect spark plug and coil wires.

- Attach the front spark plug wire loom to water pump.

- Tie the wiring harness to the spark plug wire loom.

- Cylinder #1 — check its wire goes to the distributor terminal #1.

- Cylinder#2 — check its wire goes to the distributor terminal #1.

- Repeating to cylinder/terminal #8.

- Check spark plug coil wires.

- Disconnect oil cooling line and loosely replace fan shroud.

- Reconnect and tighten oil cooling lines using wrenches.

- From underneath, fit tabs at bottom of shroud into place, and connect fan wiring and clips.

- Tighten the two screwbolts on top of shroud.

- Reattach air pump filter hose.

- Tighten power steering reservoir clamp.

- Replace jump point cover.

- Replace oil dipstick.

- Reattach coolant reservoir hose.

- Attach lower radiator hose to radiator.

- Attach upper radiator hose to water manifold.

- Fill engine block with a coolant mix through the upper radiator hose and then connect the hose to the radiator. Mix should be approximately 50/50% coolant and distilled water.

- Fill radiator through lower radiator hose and connect hose to water manifold.

- Fill coolant reservoir.

- Check accessory belt tension.

- Check spark plug wire connections.

- Test upper, lower, and coolant reservoir hose clamps.

- Reconnect the battery ground strap.

- Turn car on, and set heater to full hot and fan on maximum.

- Check engine for leaks and bad noises.

- When coolant reaches operating temperature, the thermostat will open and lower radiator hose will begin to warm. At that point, periodically squeeze the lower radiator hose to help move air out of the system.

- After engine has fully warmed, shut it off (about 15 minutes).

- Check accessory belt tension.

- Check radiator hose clamps.

- Watch for leaks.

- Add coolant to the coolant reservoir and tighten the cap.

- Lower car off jack stands, etc.

- Go for a drive and listen for noises. When done, check the engine for leaks.

- Check accessory belt tension.

- After engine cools, add coolant.

- Replace engine belly pans.

Step 8 – Breaking it in

Continually check for leaks and listen for odd noises. Every now and then, check accessory belt tension and reservoir coolant level. Check and re-tension the timing belt after 1,500-2,000 miles, and then every 15,000 miles.

Related Discussions

- Timing Belt and Water Pump Procedure with Pictures - Rennlist.com

- Additional 928 Info - Rennlist.com