08 CTT PDCC Failure, Lessons learned, and a bleeding question

#16

RL Community Team

Rennlist Member

Rennlist Member

The new parts should arrive on Friday and I'll update what material they are made of.

My HHR secondary cat bypasses arrive on Friday as well, so I guess all is not lost! With my Softronic tune, I should be at 636hp/ 637TQ at the flywheel.

Cheers,

TomF

#17

I looked at mine and indeed the rubbers had moved, and the hoses already showed sign of wear on the metal weave. I pushed the rubbers back in place and tightened them with ziplocks.

#18

RL Community Team

Rennlist Member

Rennlist Member

It failed in exactly the same place as the OP above and on the same type of stainless braided line. No need to post a pic as it looks literally exactly the same. The metal bracked rubbed against the stainless weave and it gave way. The hole is actually really small. I may cut lengths of hose and sleeve the length of both new lines in it as a preventative measure. The real solution is fabbing up a proper bracket for the PDCC loop that has to be lowered to change the oil. I have yet to see a car that the original rubber mounts have not failed.

Cheers,

TomF

Cheers,

TomF

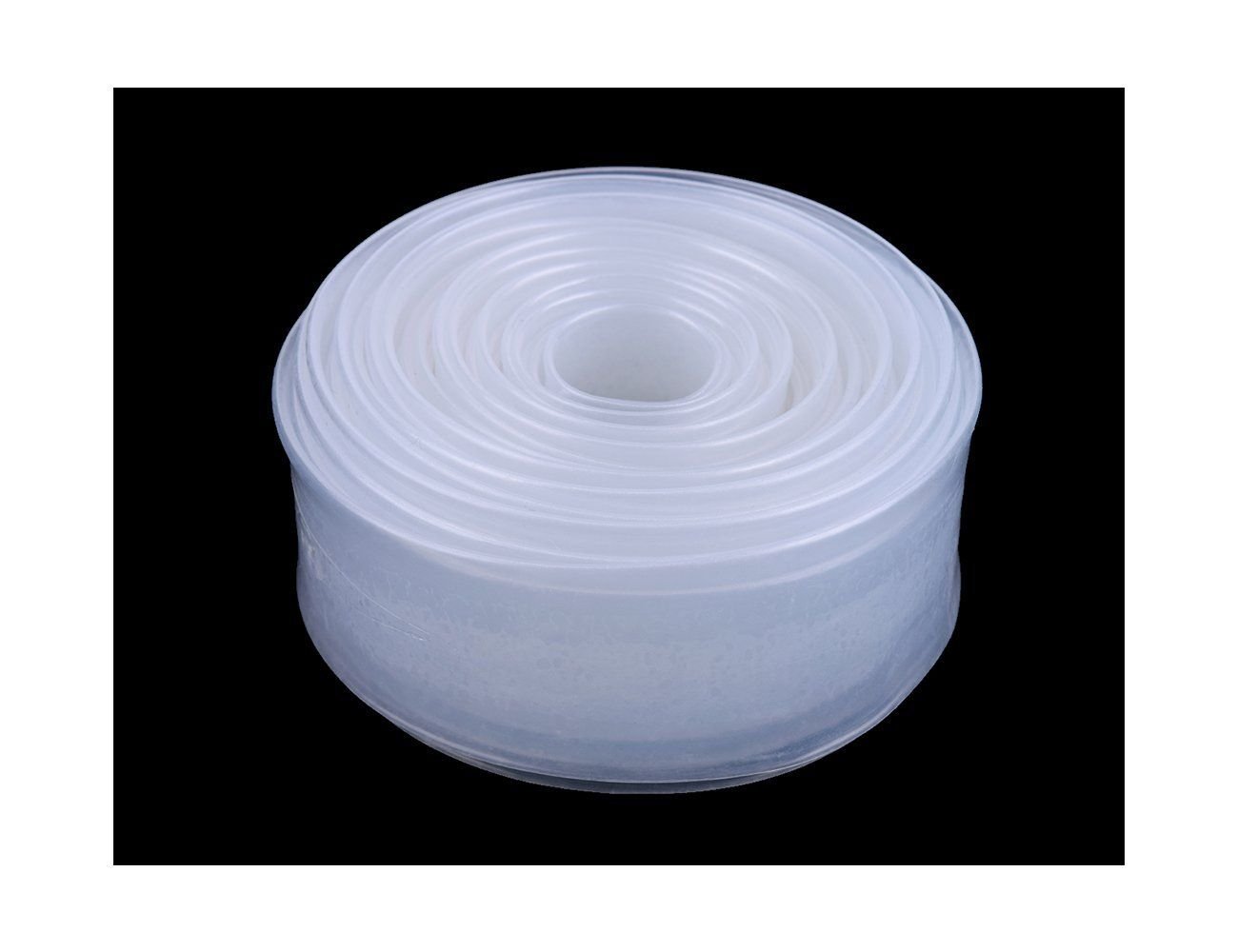

The product I used was this from Amazon:

Once the line fitting has been taken loose, it's the right size to easily slip over the connection hardware at the end of each line segment, and once heated, shrinks down to be a nice and tight fit over the line. I'm hoping this smoother coating will provide a less abrasive surface to prevent the line failure.

#19

RL Community Team

Rennlist Member

Rennlist Member

Thanks for the tip, Pete. I will certainly consider the heat shrink tubing option. I just got my tracking number from Sunset, so my parts are on the way!

Cheers,

TomF

Cheers,

TomF

#20

Addict

Rennlist Member

Rennlist Member

Thread Starter

...now I just need to get the engine back together

#21

RL Community Team

Rennlist Member

Rennlist Member

I just got an update on the parts- they will be here tomorrow. I will take a photo of the failed line and let you all know what protective measures I use to keep the same problem from reoccurring. I will have to wait to get it up on a lift to design a proper bracket to hold the PDCC loop.

Cheers,

TomF

Cheers,

TomF

#22

RL Community Team

Rennlist Member

Rennlist Member

Okay, here are the pics of the lines. The first picture are the new lines, which are a very different design from the old. The yellow line has more rubber guarding vulnerable sections and the green line is rubber-coated with additional rubber rub guards. I added several of the rubber guards from the old lines at the place where the line failed.

The second pic is of the failure point. Note the fraying to the left of the upper line- this is where the bracked rubbed on the line, despite being secured with zip ties.

The replacement was very straight forward and I replaced the reservoir at the same time as I had a new spare from my last CTT. As it turns out, my entire PDCC stystem was replaced in March of 2013, including the sway bar and pump. Clearly they used the old design lines however at the time of the work.

I filled up the reservoir before starting and the level dropped immediately and I topped it up until it stabilized. There was a lot if foaming as well. I let it idle for ten minutes, made sure it was topped up and then shut the engine down. I bled the system on the swaybar for a second or so until the fluid ran consistently out.

I took it for a ten minute drive and then stopped and checked the level and for any foaming and bubbles. It was fine, so I then headed out for a bit of a longer drive and everything appears to be good.

While I had an appointment scheduled with the local dealer to have the bleeding done with the PIWIS, I have since cancelled. I suspect that the PIWIS bleeding is necessary so that the dealer can get the project done more quickly. It is my suspicion that any small bubbles will work their way out of the system through the reservoir and as long as the fluid level is kept up, everything should be fine.

BTW, I did not run the pump completely dry when the line blew. There was still some fluid in the system when I swapped out the parts. The key is shutting the engine down quickly so that the pump doesn't fail. The PDCC system has a tandem pump next to the power steering (with two seperate circuits). If the PDCC fails, the steering will remain intact.

I hope this helps someone in the future. I am still planning on fabbing a proper mount for the pressure loop, as the bracket rubbing on the PDCC line was the cause of the rupture. Even with several zip ties to secure the loop, it is still very imperfect solution and needs proper engineering.

Cheers,

TomF

The second pic is of the failure point. Note the fraying to the left of the upper line- this is where the bracked rubbed on the line, despite being secured with zip ties.

The replacement was very straight forward and I replaced the reservoir at the same time as I had a new spare from my last CTT. As it turns out, my entire PDCC stystem was replaced in March of 2013, including the sway bar and pump. Clearly they used the old design lines however at the time of the work.

I filled up the reservoir before starting and the level dropped immediately and I topped it up until it stabilized. There was a lot if foaming as well. I let it idle for ten minutes, made sure it was topped up and then shut the engine down. I bled the system on the swaybar for a second or so until the fluid ran consistently out.

I took it for a ten minute drive and then stopped and checked the level and for any foaming and bubbles. It was fine, so I then headed out for a bit of a longer drive and everything appears to be good.

While I had an appointment scheduled with the local dealer to have the bleeding done with the PIWIS, I have since cancelled. I suspect that the PIWIS bleeding is necessary so that the dealer can get the project done more quickly. It is my suspicion that any small bubbles will work their way out of the system through the reservoir and as long as the fluid level is kept up, everything should be fine.

BTW, I did not run the pump completely dry when the line blew. There was still some fluid in the system when I swapped out the parts. The key is shutting the engine down quickly so that the pump doesn't fail. The PDCC system has a tandem pump next to the power steering (with two seperate circuits). If the PDCC fails, the steering will remain intact.

I hope this helps someone in the future. I am still planning on fabbing a proper mount for the pressure loop, as the bracket rubbing on the PDCC line was the cause of the rupture. Even with several zip ties to secure the loop, it is still very imperfect solution and needs proper engineering.

Cheers,

TomF

Last edited by TomF; 03-18-2017 at 01:04 PM. Reason: Corrected to reflect two seperate pumps

#23

Rennlist Member

I took my 2017 C4S in to have a rear wheel re balanced and they came back and told me the PDCC unit on the driver side rear had a leak. They gave me a loaner and have the replacement on order. Hopefully this is a rare occurrence. The car has just about 1000 miles and I had no clue the unit was leaking.

Eric

Eric

#24

RL Community Team

Rennlist Member

Rennlist Member

I took my 2017 C4S in to have a rear wheel re balanced and they came back and told me the PDCC unit on the driver side rear had a leak. They gave me a loaner and have the replacement on order. Hopefully this is a rare occurrence. The car has just about 1000 miles and I had no clue the unit was leaking.

Eric

Eric

The newer Cayennes 2011+ have a much better and simpler layout and I suspect that there will be fewer failures reported because of errant contact between components.

As to the 911s, I really have no understanding of the layout of the system, but I suspect that many of the components are shared across many of the models.

I hope you get it all sorted out. The 2017 C4S is one of my favorites!

Cheers,

TomF

#25

Instructor

Bled the system, and it seems to be okay. At first it sucked the reservoir almost dry and foamed really badly. I filled it up again and the foam decreased after 1 or 2 minutes. I also cracked the bleeders on the sway bar, and got a good bit of air out. Let them run until good clean fluid came out.

No error codes, and the level is stable and foam free. Not too bad a job after all. Total cost under 150.00

No error codes, and the level is stable and foam free. Not too bad a job after all. Total cost under 150.00

Question??.....

So to Bleed the PDCC you let the engine idle and just open the Two bleeder valve on the rear and then the front sway bars until the fluid is clear.???

I was going to hook up a syringe and push clean 202 fluid thru .. but if it is positive pressure i rather suck it out then until clear?

I really Love my PDCC... every car will have this in the future.. Once you really use it you cant have a car without it..

I want to keep my PDCC pumps and motors clean..

#26

Addict

Rennlist Member

Rennlist Member

Thread Starter

Question??.....

So to Bleed the PDCC you let the engine idle and just open the Two bleeder valve on the rear and then the front sway bars until the fluid is clear.???

I was going to hook up a syringe and push clean 202 fluid thru .. but if it is positive pressure i rather suck it out then until clear?

I really Love my PDCC... every car will have this in the future.. Once you really use it you cant have a car without it..

I want to keep my PDCC pumps and motors clean..

So to Bleed the PDCC you let the engine idle and just open the Two bleeder valve on the rear and then the front sway bars until the fluid is clear.???

I was going to hook up a syringe and push clean 202 fluid thru .. but if it is positive pressure i rather suck it out then until clear?

I really Love my PDCC... every car will have this in the future.. Once you really use it you cant have a car without it..

I want to keep my PDCC pumps and motors clean..

But, yes, if you open them, it will pump fluid out with the engine running. Make sure you do not run it dry or you risk damaging the pump, and you will have to start all over again.

#27

another update on these line

just replaced both, couldn't tell which was leaking.

both lines are now very thick rubber, even thicker than the pic of new lines in post 22 above.

the lines are also shorter? or something, installed they are no longer close to the metal bracket(PS cooler lines?).

the rubber bumpers are still on the lines but there is a large gap to the evil metal that has been cutting the old lines.

at least someone at porsche has been paying attention to the problem.

just replaced both, couldn't tell which was leaking.

both lines are now very thick rubber, even thicker than the pic of new lines in post 22 above.

the lines are also shorter? or something, installed they are no longer close to the metal bracket(PS cooler lines?).

the rubber bumpers are still on the lines but there is a large gap to the evil metal that has been cutting the old lines.

at least someone at porsche has been paying attention to the problem.

#28

RL Community Team

Rennlist Member

Rennlist Member

another update on these line

just replaced both, couldn't tell which was leaking.

both lines are now very thick rubber, even thicker than the pic of new lines in post 22 above.

the lines are also shorter? or something, installed they are no longer close to the metal bracket(PS cooler lines?).

the rubber bumpers are still on the lines but there is a large gap to the evil metal that has been cutting the old lines.

at least someone at porsche has been paying attention to the problem.

just replaced both, couldn't tell which was leaking.

both lines are now very thick rubber, even thicker than the pic of new lines in post 22 above.

the lines are also shorter? or something, installed they are no longer close to the metal bracket(PS cooler lines?).

the rubber bumpers are still on the lines but there is a large gap to the evil metal that has been cutting the old lines.

at least someone at porsche has been paying attention to the problem.

Cheers,

Tom

#29

I had a line blow, not from rubbing, it blew in a spot where it didn't contact anything else. I drove carefully but for a long way with the red warning on the dash, it doesn't seem to have damaged the pump.

When I bled mine I didn't crack open any lines, I just filled the reservoir and started it hoping it might work, It sucked the reservoir dry quickly and I just topped it up, let it run for a while then stop for a while, top it up and drove it. It worked fine.

It might depend on which line blows ? I can't believe this post didn't come up in my searches a few months ago, it would have been very helpful.

When I bled mine I didn't crack open any lines, I just filled the reservoir and started it hoping it might work, It sucked the reservoir dry quickly and I just topped it up, let it run for a while then stop for a while, top it up and drove it. It worked fine.

It might depend on which line blows ? I can't believe this post didn't come up in my searches a few months ago, it would have been very helpful.

#30

RL Community Team

Rennlist Member

Rennlist Member