Roof Rack Mount Track Tire Transport

#1

OK, I got my tequipment roof rack. It sure looks to me like the mounting hardware is way strong. Here is a picture of the mounting clamp that attaches to the car roof rack (welded in).

And here is where it connects into the roof. These look really solid!

Now, on the black risers that attach to the bracket (metal and very strong), I think we’re still cool.

The weakness appears to be the aluminum extrusion cross bar. I can create a pretty big deflection just by pressing on it. Now, with how I intend to distribute the load broadly across the bars, I think carrying 3 tires up there will be very safe. I plan to lay them down in a triangle form facing forward inside of a wire basket.

.O.

OO

Any thoughts, suggestions or additional observations?

And here is where it connects into the roof. These look really solid!

Now, on the black risers that attach to the bracket (metal and very strong), I think we’re still cool.

The weakness appears to be the aluminum extrusion cross bar. I can create a pretty big deflection just by pressing on it. Now, with how I intend to distribute the load broadly across the bars, I think carrying 3 tires up there will be very safe. I plan to lay them down in a triangle form facing forward inside of a wire basket.

.O.

OO

Any thoughts, suggestions or additional observations?

#2

I have used roof mounted tires for years with very few problems and no "incidents" . Some thoughts.

First, check the load rating of the bars. Tires and wheels weigh 30-50 lbs... you may want to weight yours to be sure. Also consider air resistance.... 70MPH creates alot of drag.

Secondly, use ratchet straps. Use enought so that the tires will not move in any direction. To be safe, make sure the tires are still secure if any one of them comes loose.

I used Yakama cross bars and set 4 wheel between standing upright like life savers in a pack. I had one strap over each bar and one holding the top of the tires together. The only problem I had was the bars sliding back on the drip rails, but yours should not do that as they are in cleats on the roof.

First, check the load rating of the bars. Tires and wheels weigh 30-50 lbs... you may want to weight yours to be sure. Also consider air resistance.... 70MPH creates alot of drag.

Secondly, use ratchet straps. Use enought so that the tires will not move in any direction. To be safe, make sure the tires are still secure if any one of them comes loose.

I used Yakama cross bars and set 4 wheel between standing upright like life savers in a pack. I had one strap over each bar and one holding the top of the tires together. The only problem I had was the bars sliding back on the drip rails, but yours should not do that as they are in cleats on the roof.

#3

Thanks JCP. If you were to do it again would you lay them down or leave them upright? How much do you think I'll gain by my traingular arrangement versus putting all 4 up there? The rating is 75 kg (165 lbs)

#4

Race Car

I put together a new framework for my rack today which will allow me to lay all four wheels flat. I'll be over the rated capacity, slightly, but I've always been over it without having any problems, and this will improve the aero of the four wheels and tires, and lower my center of gravity.

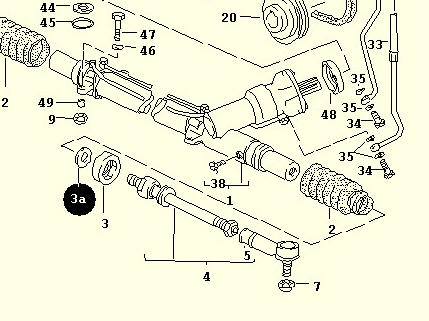

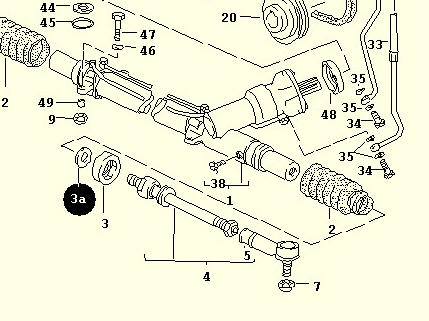

My design is pretty simple. I need to support the center and the edges of each wheel, and I need to minimize weight. The two crossmembers of the rack are very strong. The middle two wheels will merely bridge them, so I used a pair of 1-inch square pieces of aluminum to bridge the gap between the rack's crossmembers, and also hold the centers of those wheels. In this picture the rack's crossmembers are indicated by the two pieces of aluminum running perpendicular to the frame.

But the front and rear wheels (although they're the lighter pair from the front of the car) will be hanging off the front and rear of the rack. I used a 1-inch steel piece to support them. It's significantly stronger than the aluminum.

The diagonal pieces and the pieces connecting the shorter longitudinals are thin aluminum. They're only there to keep the frame from distorting.

Here are two tires I used to test the proportions.

Here is a lousy picture of the tires sitting on the rack. I hadn't tightened everything down, yet, or added the padding that the tires will actually sit on, but you get the idea.

Don't anyone tell my wife I built this in my office.

My design is pretty simple. I need to support the center and the edges of each wheel, and I need to minimize weight. The two crossmembers of the rack are very strong. The middle two wheels will merely bridge them, so I used a pair of 1-inch square pieces of aluminum to bridge the gap between the rack's crossmembers, and also hold the centers of those wheels. In this picture the rack's crossmembers are indicated by the two pieces of aluminum running perpendicular to the frame.

But the front and rear wheels (although they're the lighter pair from the front of the car) will be hanging off the front and rear of the rack. I used a 1-inch steel piece to support them. It's significantly stronger than the aluminum.

The diagonal pieces and the pieces connecting the shorter longitudinals are thin aluminum. They're only there to keep the frame from distorting.

Here are two tires I used to test the proportions.

Here is a lousy picture of the tires sitting on the rack. I hadn't tightened everything down, yet, or added the padding that the tires will actually sit on, but you get the idea.

Don't anyone tell my wife I built this in my office.

#5

Jack: Thank you! I do the same thing, many "jobs" get completed at the office.

I can't tell from your photo's but you should use structural aluminum tubing like this. It is very strong, very light, and easy to attach to and assemble.

I can't tell from your photo's but you should use structural aluminum tubing like this. It is very strong, very light, and easy to attach to and assemble.

#6

I have actually put two sets of tires (8 total) on my car (one set behind the other) and driven 70-80MPH+ all the way to the track with no problem. I didn't notice any aero problems other than top gear accelleration being a bit more sluggish. I have noticed no significant instabiliy in the car even in sharp cross winds.

I have 8/9 inch wheels and had no problem getting 4 in a row upright. The benefit I see to the upright position is that the wheels and crossbars are pulled tightly together into a single assembly, and there are not extra parts, racks, etc, etc, Just 4 Tires and 2 crossbars.

But the other ways look fine as long as all the pieces are tightly attached. This is a very efficient way to get to the track for DE. It reduces the problem of finding space in the paddock and on the way home I frequently pass the tow rigs slogging along at 60MPH in the right lane.

Unfortunately, with racing I simply need too much crap to load in the car anymore, and street driving is ruining my suspension, not to mention peace of mind that you can get home no matter what, so I just bought a tow truck and trailer.... another era ended....

I have 8/9 inch wheels and had no problem getting 4 in a row upright. The benefit I see to the upright position is that the wheels and crossbars are pulled tightly together into a single assembly, and there are not extra parts, racks, etc, etc, Just 4 Tires and 2 crossbars.

But the other ways look fine as long as all the pieces are tightly attached. This is a very efficient way to get to the track for DE. It reduces the problem of finding space in the paddock and on the way home I frequently pass the tow rigs slogging along at 60MPH in the right lane.

Unfortunately, with racing I simply need too much crap to load in the car anymore, and street driving is ruining my suspension, not to mention peace of mind that you can get home no matter what, so I just bought a tow truck and trailer.... another era ended....

#7

Addict

Rennlist Member

Rennlist Member

Join Date: Nov 2001

Location: Austin, TX

Posts: 30

Likes: 0

Received 0 Likes

on

0 Posts

Here is what I have been using in the roof of my 911 down here in Texas. I bring 4 16" Fuchs with 225/245 Toyos to the track. I have been driving about 2 hours each way to the track using the rack for the last 18 months or so with no incidents.

The rack is a Thule and the u-bolts, aluminum and all thread is from Home Depot. Most of the weight rests on the rack with a little force on the all-thread and aluminum. The only test of strenght was an unplanned collision with the garage door at about 10 mph which broke one piece of all-thread out, broke the aluminum, dented the garage door and popped it from it's rails.

which broke one piece of all-thread out, broke the aluminum, dented the garage door and popped it from it's rails.

BTW thanks for taking the photos Richard Jackson

The rack is a Thule and the u-bolts, aluminum and all thread is from Home Depot. Most of the weight rests on the rack with a little force on the all-thread and aluminum. The only test of strenght was an unplanned collision with the garage door at about 10 mph

which broke one piece of all-thread out, broke the aluminum, dented the garage door and popped it from it's rails.

which broke one piece of all-thread out, broke the aluminum, dented the garage door and popped it from it's rails. BTW thanks for taking the photos Richard Jackson

Trending Topics

#8

Rennlist Member

Join Date: Apr 2002

Location: Illinois-Indiana

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Ditch the rack and pull a trailer. In the long run it's cheaper, easier on the tub, the suspension and finish. You can carry more heavy stuff in it like jacks and tools. It comes off in a jiffy. You're less likely to strain your back humping wheels and tires overhead. And when you get around to selling it, there might actually B a buyer!

#9

Race Car

In California, pulling a trailer means getting more speeding tickets (lower speed for cars with trailers and trucks), and you can't use the far left lanes (same as the trucks). To me, that's more hassle, not less.

#10

Addict

Rennlist Member

Rennlist Member

Join Date: Nov 2001

Location: Austin, TX

Posts: 30

Likes: 0

Received 0 Likes

on

0 Posts

I don't think I am stressing the tub or suspension beyond design limits by using the rack. I think it's more likely I am doing that after I get the rack off.

The tools and jack fit in the trunk or cab. I can be track ready in 45 minutes from taking off the rack, unpacking to fitting the tires. Wheels are high but easy enough to unload. The rack comes off easily.

The isses I really focus on are:

1) not scratching the paint

2) avoiding garage doors

The big advantage is the cost difference. The rack solution costs about $100 depending how much you pay for the Thule.

The tools and jack fit in the trunk or cab. I can be track ready in 45 minutes from taking off the rack, unpacking to fitting the tires. Wheels are high but easy enough to unload. The rack comes off easily.

The isses I really focus on are:

1) not scratching the paint

2) avoiding garage doors

The big advantage is the cost difference. The rack solution costs about $100 depending how much you pay for the Thule.

#11

Here are a couple of views of the rack. It really is quite nice.

As you can see, the mounts never get very close to the car’s exposed surfaces so the chance of doing any damage is really minimal.

I will start framing out the rack with structural aluminum now.

As you can see, the mounts never get very close to the car’s exposed surfaces so the chance of doing any damage is really minimal.

I will start framing out the rack with structural aluminum now.

#13

Addict

Rennlist Member

Rennlist Member

Join Date: Dec 2001

Location: MA

Posts: 1,010

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by sjanes

I'm almost afraid to ask, but what's that thing next to the steering wheel in the car?

Hmm...garage doors. Good point on that one. Come back after an 8 hour drive and forget that they are on the roof pull in the driveway and that good be quite a rude homecoming!