DIY: Coolant Pipes and Various Other Fun Stuff

#16

UPDATE:

So the re-installation went well! I will complete the write-up as soon as I can. Car is driving great! I will be putting a kit together for this job through my work in case anyone else wants to undertake this task and replace all the coolant hoses and vac lines in the engine bay. I cleaned everything up as it was going back together and I love how clean the engine bay looks now!

So the re-installation went well! I will complete the write-up as soon as I can. Car is driving great! I will be putting a kit together for this job through my work in case anyone else wants to undertake this task and replace all the coolant hoses and vac lines in the engine bay. I cleaned everything up as it was going back together and I love how clean the engine bay looks now!

#17

Rennlist Member

Hey man I just saw this post. Lots of great information.

I've got some coolant leaking from the front of my car which I hope is just a radiator. But it's coming from the belly pan near the front of the passenger door. Figure it's coolant leaking from the front only slightly and then overflowing from the pan halfway back.

I'm actually moving to the Daytona area in a month. So maybe I'll just pay you guys a visit if a rear coolant line blows.

I've got some coolant leaking from the front of my car which I hope is just a radiator. But it's coming from the belly pan near the front of the passenger door. Figure it's coolant leaking from the front only slightly and then overflowing from the pan halfway back.

I'm actually moving to the Daytona area in a month. So maybe I'll just pay you guys a visit if a rear coolant line blows.

#18

Hey man I just saw this post. Lots of great information.

I've got some coolant leaking from the front of my car which I hope is just a radiator. But it's coming from the belly pan near the front of the passenger door. Figure it's coolant leaking from the front only slightly and then overflowing from the pan halfway back.

I'm actually moving to the Daytona area in a month. So maybe I'll just pay you guys a visit if a rear coolant line blows.

I've got some coolant leaking from the front of my car which I hope is just a radiator. But it's coming from the belly pan near the front of the passenger door. Figure it's coolant leaking from the front only slightly and then overflowing from the pan halfway back.

I'm actually moving to the Daytona area in a month. So maybe I'll just pay you guys a visit if a rear coolant line blows.

#19

Rennlist Member

Been following this thread for awhile now. Great work. I wish there were more details on the actual removal of the engine, as this is the only part I am worried about, so hopefully you can provide us with something decent to go off of.

Regarding pinning vs. welding, in your opinion (anyone can chime in) what is the probability of having issues again in the future with pinning? I've read the pros and cons of each, and I understand that welding can have pinhole leaks, and is more invasive (i.e. more needs to be removed), takes more skill/tools, etc. but with pinning, you are relying on the JB Weld to hold the pipes in place without causing leaks over time. I know that with the pinning (screws) the pipes won't eventually back out causing a catastrophic failure, but the issue from the Porsche factory in Stuttgart was that they used glue to hold the pipes in place which eventually breaks down and leaks. Isn't JB Weld essentially the same thing? Over time (even if it's another 50k miles and 10 years) wouldn't the constant hot-cold-hot cycle of running the car cause the JB Weld to break down and eventually leak, putting you right back where you are now?

I wanted to weld because it seems more permanent assuming it's done right (never have to worry about it again), but the pinning seems much easier in comparison.

Regarding pinning vs. welding, in your opinion (anyone can chime in) what is the probability of having issues again in the future with pinning? I've read the pros and cons of each, and I understand that welding can have pinhole leaks, and is more invasive (i.e. more needs to be removed), takes more skill/tools, etc. but with pinning, you are relying on the JB Weld to hold the pipes in place without causing leaks over time. I know that with the pinning (screws) the pipes won't eventually back out causing a catastrophic failure, but the issue from the Porsche factory in Stuttgart was that they used glue to hold the pipes in place which eventually breaks down and leaks. Isn't JB Weld essentially the same thing? Over time (even if it's another 50k miles and 10 years) wouldn't the constant hot-cold-hot cycle of running the car cause the JB Weld to break down and eventually leak, putting you right back where you are now?

I wanted to weld because it seems more permanent assuming it's done right (never have to worry about it again), but the pinning seems much easier in comparison.

#20

Burning Brakes

Been following this thread for awhile now. Great work. I wish there were more details on the actual removal of the engine, as this is the only part I am worried about, so hopefully you can provide us with something decent to go off of.

Regarding pinning vs. welding, in your opinion (anyone can chime in) what is the probability of having issues again in the future with pinning? I've read the pros and cons of each, and I understand that welding can have pinhole leaks, and is more invasive (i.e. more needs to be removed), takes more skill/tools, etc. but with pinning, you are relying on the JB Weld to hold the pipes in place without causing leaks over time. I know that with the pinning (screws) the pipes won't eventually back out causing a catastrophic failure, but the issue from the Porsche factory in Stuttgart was that they used glue to hold the pipes in place which eventually breaks down and leaks. Isn't JB Weld essentially the same thing? Over time (even if it's another 50k miles and 10 years) wouldn't the constant hot-cold-hot cycle of running the car cause the JB Weld to break down and eventually leak, putting you right back where you are now?

I wanted to weld because it seems more permanent assuming it's done right (never have to worry about it again), but the pinning seems much easier in comparison.

Regarding pinning vs. welding, in your opinion (anyone can chime in) what is the probability of having issues again in the future with pinning? I've read the pros and cons of each, and I understand that welding can have pinhole leaks, and is more invasive (i.e. more needs to be removed), takes more skill/tools, etc. but with pinning, you are relying on the JB Weld to hold the pipes in place without causing leaks over time. I know that with the pinning (screws) the pipes won't eventually back out causing a catastrophic failure, but the issue from the Porsche factory in Stuttgart was that they used glue to hold the pipes in place which eventually breaks down and leaks. Isn't JB Weld essentially the same thing? Over time (even if it's another 50k miles and 10 years) wouldn't the constant hot-cold-hot cycle of running the car cause the JB Weld to break down and eventually leak, putting you right back where you are now?

I wanted to weld because it seems more permanent assuming it's done right (never have to worry about it again), but the pinning seems much easier in comparison.

When you pin the coolant pipes all it does is keep them from blowing out they can still leak over time.

Also im not sure if I missed it or not but did you just re glue the ones that failed and didnt touch the remaining ones? If so that a whole lot of work to not re glue the non failed coolant pipes.

#21

Drifting

Join Date: Jul 2013

Location: Fishtown - Philadelphia

Posts: 2,202

Likes: 0

Received 4 Likes

on

3 Posts

That's amazing, great job! I need friends like you! I can just only hope my pipes never need to be replaced. Petrified of the repair costs as this DIY is likely beyond my capability and you need plenty of space and tools to do this work.

#22

Drifting

Join Date: Jul 2013

Location: Fishtown - Philadelphia

Posts: 2,202

Likes: 0

Received 4 Likes

on

3 Posts

Hey man I just saw this post. Lots of great information.

I've got some coolant leaking from the front of my car which I hope is just a radiator. But it's coming from the belly pan near the front of the passenger door. Figure it's coolant leaking from the front only slightly and then overflowing from the pan halfway back.

I'm actually moving to the Daytona area in a month. So maybe I'll just pay you guys a visit if a rear coolant line blows.

I've got some coolant leaking from the front of my car which I hope is just a radiator. But it's coming from the belly pan near the front of the passenger door. Figure it's coolant leaking from the front only slightly and then overflowing from the pan halfway back.

I'm actually moving to the Daytona area in a month. So maybe I'll just pay you guys a visit if a rear coolant line blows.

#23

Been following this thread for awhile now. Great work. I wish there were more details on the actual removal of the engine, as this is the only part I am worried about, so hopefully you can provide us with something decent to go off of.

Regarding pinning vs. welding, in your opinion (anyone can chime in) what is the probability of having issues again in the future with pinning? I've read the pros and cons of each, and I understand that welding can have pinhole leaks, and is more invasive (i.e. more needs to be removed), takes more skill/tools, etc. but with pinning, you are relying on the JB Weld to hold the pipes in place without causing leaks over time. I know that with the pinning (screws) the pipes won't eventually back out causing a catastrophic failure, but the issue from the Porsche factory in Stuttgart was that they used glue to hold the pipes in place which eventually breaks down and leaks. Isn't JB Weld essentially the same thing? Over time (even if it's another 50k miles and 10 years) wouldn't the constant hot-cold-hot cycle of running the car cause the JB Weld to break down and eventually leak, putting you right back where you are now?

I wanted to weld because it seems more permanent assuming it's done right (never have to worry about it again), but the pinning seems much easier in comparison.

Regarding pinning vs. welding, in your opinion (anyone can chime in) what is the probability of having issues again in the future with pinning? I've read the pros and cons of each, and I understand that welding can have pinhole leaks, and is more invasive (i.e. more needs to be removed), takes more skill/tools, etc. but with pinning, you are relying on the JB Weld to hold the pipes in place without causing leaks over time. I know that with the pinning (screws) the pipes won't eventually back out causing a catastrophic failure, but the issue from the Porsche factory in Stuttgart was that they used glue to hold the pipes in place which eventually breaks down and leaks. Isn't JB Weld essentially the same thing? Over time (even if it's another 50k miles and 10 years) wouldn't the constant hot-cold-hot cycle of running the car cause the JB Weld to break down and eventually leak, putting you right back where you are now?

I wanted to weld because it seems more permanent assuming it's done right (never have to worry about it again), but the pinning seems much easier in comparison.

Everyone has their own opinions with this stuff. This is my 2nd time doing pinning. About a year ago I did my 996TT the exact same way. Myself and the new owner drive the car VERY hard without any leaks. In my opinion there is no way for any leaks to occur from pinning (I guess time will tell on my two jobs). Each casting that the aluminum pipes go inside has a stop where the pipe bottoms out. In theory; the pin should hold it in place combined with the glue. I believe the glue breaks down because of the heating and cooling but what really speeds up the process is the fact that the pipe can actually be pushed out without a pin to hold it. I've spoken to a lot of people who say that pinning will prevent a catastrophic failure but will eventually cause a leak. I have yet to read about or hear someone say they have had coolant leak from a pinned line.

There is a decent amount of additional work involved in getting the parts off the engine to weld them. After that I would suggest swapping over to new aftermarket pipes and having someone like BBI weld them for you. This whole process just adds more time to the engine being out. EVOMs stopped welding because they said they had a few cars experience the pinhole leaks.

I'm confident enough mechanically that if I did have a leak (God forbid) I can go back in and fix it again.

Welding the coolant pipes is the permanent way of doing it.

When you pin the coolant pipes all it does is keep them from blowing out they can still leak over time.

Also im not sure if I missed it or not but did you just re glue the ones that failed and didnt touch the remaining ones? If so that a whole lot of work to not re glue the non failed coolant pipes.

When you pin the coolant pipes all it does is keep them from blowing out they can still leak over time.

Also im not sure if I missed it or not but did you just re glue the ones that failed and didnt touch the remaining ones? If so that a whole lot of work to not re glue the non failed coolant pipes.

#24

Drifting

From what I've read, welding is sort of overkill because the coolant is not flowing at very high pressure in the pipes, and basically if you just have a way of keeping the pipe in place (pins) with proper adhesives there's no reason for it to start leaking or come off, and especially so if you use new aluminum fittings instead of rubber that can rot. Another supposed complication with welding is the heat cycling on the welds making them crack if not done 100% properly.

Last edited by Skwerl; 07-27-2017 at 11:56 AM.

#25

From what I've read, welding is sort of overkill because the coolant is not flowing at very high pressure in the pipes, and basically if you just have a way of keeping the pipe in place (pins) with proper adhesives there's no reason for it to start leaking or come off, and especially so if you use new aluminum fittings instead of rubber that can rot. Another supposed complication with welding is the heat cycling on the welds making them crack if not done 100% properly.

I don't think this is mentioned enough but really you should also be replacing all the rubber hoses that these pipes attach to while you are in there. At least two of mine tore when removing them. They have a tendency to stick really hard to the surface they have been clamped to. Hopefully by tomorrow I'll have a complete kit put together consisting of all rubber hoses, sharkwerks metal coolant pipes, and complete vac system lines as well. This will be available through Motorsports by Reeves.

#26

Burning Brakes

If your coolant pipes ever decided to start leaking let me know I would give you a hand and I have a shop so we would have everything we need

#27

Drifting

Join Date: Jul 2013

Location: Fishtown - Philadelphia

Posts: 2,202

Likes: 0

Received 4 Likes

on

3 Posts

If you are going to tackle this job I am more than willing to help you with a step by step removal. Just shoot me a PM when you are getting ready to do so. I actually prefer how easy the removal is to the amount of work you have to do once the engine is out. With a lift and engine table the engine out process is actually pretty pleasant!

Everyone has their own opinions with this stuff. This is my 2nd time doing pinning. About a year ago I did my 996TT the exact same way. Myself and the new owner drive the car VERY hard without any leaks. In my opinion there is no way for any leaks to occur from pinning (I guess time will tell on my two jobs). Each casting that the aluminum pipes go inside has a stop where the pipe bottoms out. In theory; the pin should hold it in place combined with the glue. I believe the glue breaks down because of the heating and cooling but what really speeds up the process is the fact that the pipe can actually be pushed out without a pin to hold it. I've spoken to a lot of people who say that pinning will prevent a catastrophic failure but will eventually cause a leak. I have yet to read about or hear someone say they have had coolant leak from a pinned line.

There is a decent amount of additional work involved in getting the parts off the engine to weld them. After that I would suggest swapping over to new aftermarket pipes and having someone like BBI weld them for you. This whole process just adds more time to the engine being out. EVOMs stopped welding because they said they had a few cars experience the pinhole leaks.

I'm confident enough mechanically that if I did have a leak (God forbid) I can go back in and fix it again.

You are correct. I only re-glued the two pipes that actually failed. I inspected all the other pipes and did not find them to be failing. Based off my theory above I decided against pulling them and changing the glue to JB weld.

Thanks! I have a customer with the same 997.1TT that has close to 100k miles now without a failure and he has no pinning or welding done. After what I saw though I'd suggest replacing the three plastic pipes and get the pinning done if you haven't had a failure yet.

Everyone has their own opinions with this stuff. This is my 2nd time doing pinning. About a year ago I did my 996TT the exact same way. Myself and the new owner drive the car VERY hard without any leaks. In my opinion there is no way for any leaks to occur from pinning (I guess time will tell on my two jobs). Each casting that the aluminum pipes go inside has a stop where the pipe bottoms out. In theory; the pin should hold it in place combined with the glue. I believe the glue breaks down because of the heating and cooling but what really speeds up the process is the fact that the pipe can actually be pushed out without a pin to hold it. I've spoken to a lot of people who say that pinning will prevent a catastrophic failure but will eventually cause a leak. I have yet to read about or hear someone say they have had coolant leak from a pinned line.

There is a decent amount of additional work involved in getting the parts off the engine to weld them. After that I would suggest swapping over to new aftermarket pipes and having someone like BBI weld them for you. This whole process just adds more time to the engine being out. EVOMs stopped welding because they said they had a few cars experience the pinhole leaks.

I'm confident enough mechanically that if I did have a leak (God forbid) I can go back in and fix it again.

You are correct. I only re-glued the two pipes that actually failed. I inspected all the other pipes and did not find them to be failing. Based off my theory above I decided against pulling them and changing the glue to JB weld.

Thanks! I have a customer with the same 997.1TT that has close to 100k miles now without a failure and he has no pinning or welding done. After what I saw though I'd suggest replacing the three plastic pipes and get the pinning done if you haven't had a failure yet.

Thanks, I hope i never need to call you! LOL but appreciate the offer and will take you up if I do have an issue. I'm actually moving down to Philly so no more NJ for me pretty soon.

#28

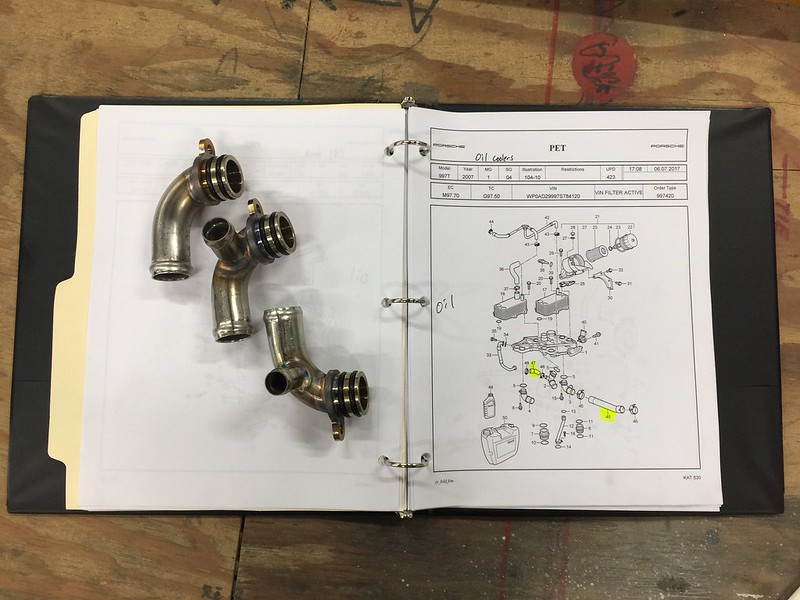

Sharkwerks Metal Coolant pipes

I want to start by talking about a few different items I had not mentioned previously. If you are removing the engine yourself and doing this whole process; itís very important that everything you disconnect gets flagged with tape, and a number, or some way of remembering which fitting goes to which. We failed to tape off everything we disconnected while removing the engine but flagged everything while working on the engine outside the car. Although I didnít end up having anything left disconnected at the end, I did manage to install the engine with the driver side ground strap routed incorrectly. This almost caused me to drop the engine back down enough to correct. In the end I only had to unbolt the turbo inlet pipe from the turbo and pull it back to get the ground strap where it needed to be. Even the technicians in our Porsche dealership flag everything on a job of this size.

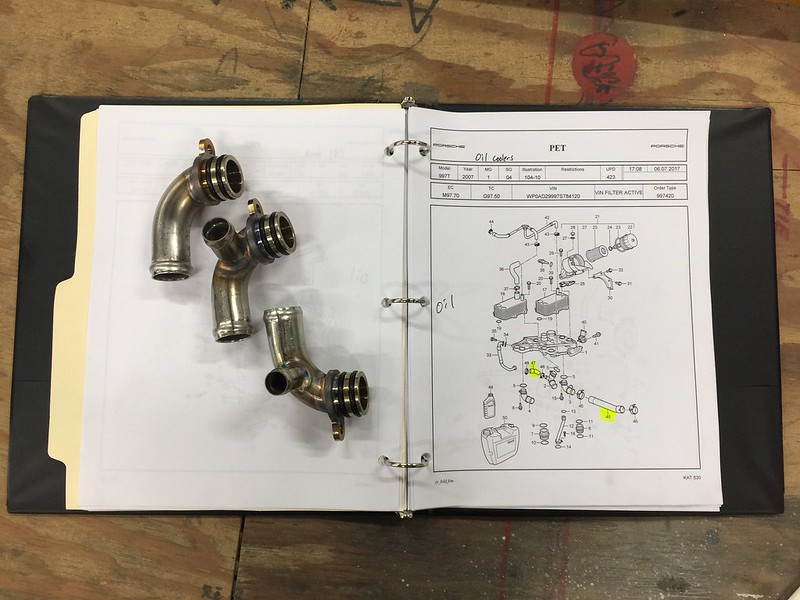

I also want to talk about the Sharkwerks metal pipes. If you have the engine out for anything I would advise that you replace these pipes! Although the 996TT and various GT3 cars can have coolant pipe issuesÖthe 997 Turbo/GT2/GT2RS all can have these three plastic pipes fail in addition to the 7 coolant lines. Iíve attached an image below of the pipes with a parts diagram. The three parts are labeled 2, 3 and 4 in the diagram. The second image shows the stock parts removed and laying next to their replacement metal pipes. Depending on mileage, use, etc these pipes can either come out as a whole or crumble upon removal. I was fortunate enough to be able to remove them without breaking. If they crumble upon removal you will have to have to take a few additional steps that I did not have to take. All three of these pipes are located underneath the two heat exchangers on top of the engine. They are bolted to the bracket labeled 1 in the diagram. Sharkwerks gives you everything you need to install with the kit including extra O-rings! They do suggest you lubricate the O-rings prior to installation using ďbrake assembly lubeĒ but I just applied some motor oil to them and that worked just fine. You could even use unmixed coolant if thatís all you have available.

So now that you have seen the Sharkwerks coolant pipes outside the car and labeled on a diagram, I have some photos to share of them installed! Below on page number 1 I have shined a flashlight on the location where we did one of the pinnings. This hose thatís clamped on to it leads to one of the pipes. Image number two shows that pipe illuminated by the flashlight. Itís hard to see in this second picture but the pipe is clamped to a long hose that heads to the left which connects to that pinned line I referenced in the first image. To get to this pipe you need to remove several items from the engine: Power steering pump/reservoir/pulley, passenger side turbo inlet pipe, passenger side fuel rail and intake manifold. I would be lying to you if I didnít say that this job takes a great deal of patience. Porsche does not give you a lot of room to unbolt the intake manifold as well as the coolant pipe itself. Its best to unclamp the hose from the pinned line and unbolt the coolant pipe and remove the pipe with the hose attached. If you scroll back up to the image of the old and new pipes together the pipe pictured to the far left is this one. You can see that the long rubber hose is still attached to the factory plastic pipe. The other smaller rubber hose attached to this pipe becomes a hard line and runs down to the passenger side turbocharger (image 3).

The other two are accessible from the driver side of the engine. You remove the same items as the passenger side but you also need to remove the smog pump from off the driver side intake manifold. We also removed the oil filter housing and support bracket as well as the starter. The first two images show the two pipes individually highlighted by the flashlight. This is to give you a general location of each pipe. As you can see they are practically right next to each other. Image 3 is an up-close of the pipe highlighted in image 1. Image 4 shows the pipe highlighted in Image 2. The two pipes are a little trickier to remove and re-install than the first one. Itís just an awkward angle.

That pretty much concludes all I have for the Sharkwerks coolant pipe portion of the job. Hopefully this was helpful. Up next I will work on getting the GT2 clutch and slave cylinder conversion kit posted as well as the vacuum system replacement.

I want to start by talking about a few different items I had not mentioned previously. If you are removing the engine yourself and doing this whole process; itís very important that everything you disconnect gets flagged with tape, and a number, or some way of remembering which fitting goes to which. We failed to tape off everything we disconnected while removing the engine but flagged everything while working on the engine outside the car. Although I didnít end up having anything left disconnected at the end, I did manage to install the engine with the driver side ground strap routed incorrectly. This almost caused me to drop the engine back down enough to correct. In the end I only had to unbolt the turbo inlet pipe from the turbo and pull it back to get the ground strap where it needed to be. Even the technicians in our Porsche dealership flag everything on a job of this size.

I also want to talk about the Sharkwerks metal pipes. If you have the engine out for anything I would advise that you replace these pipes! Although the 996TT and various GT3 cars can have coolant pipe issuesÖthe 997 Turbo/GT2/GT2RS all can have these three plastic pipes fail in addition to the 7 coolant lines. Iíve attached an image below of the pipes with a parts diagram. The three parts are labeled 2, 3 and 4 in the diagram. The second image shows the stock parts removed and laying next to their replacement metal pipes. Depending on mileage, use, etc these pipes can either come out as a whole or crumble upon removal. I was fortunate enough to be able to remove them without breaking. If they crumble upon removal you will have to have to take a few additional steps that I did not have to take. All three of these pipes are located underneath the two heat exchangers on top of the engine. They are bolted to the bracket labeled 1 in the diagram. Sharkwerks gives you everything you need to install with the kit including extra O-rings! They do suggest you lubricate the O-rings prior to installation using ďbrake assembly lubeĒ but I just applied some motor oil to them and that worked just fine. You could even use unmixed coolant if thatís all you have available.

So now that you have seen the Sharkwerks coolant pipes outside the car and labeled on a diagram, I have some photos to share of them installed! Below on page number 1 I have shined a flashlight on the location where we did one of the pinnings. This hose thatís clamped on to it leads to one of the pipes. Image number two shows that pipe illuminated by the flashlight. Itís hard to see in this second picture but the pipe is clamped to a long hose that heads to the left which connects to that pinned line I referenced in the first image. To get to this pipe you need to remove several items from the engine: Power steering pump/reservoir/pulley, passenger side turbo inlet pipe, passenger side fuel rail and intake manifold. I would be lying to you if I didnít say that this job takes a great deal of patience. Porsche does not give you a lot of room to unbolt the intake manifold as well as the coolant pipe itself. Its best to unclamp the hose from the pinned line and unbolt the coolant pipe and remove the pipe with the hose attached. If you scroll back up to the image of the old and new pipes together the pipe pictured to the far left is this one. You can see that the long rubber hose is still attached to the factory plastic pipe. The other smaller rubber hose attached to this pipe becomes a hard line and runs down to the passenger side turbocharger (image 3).

The other two are accessible from the driver side of the engine. You remove the same items as the passenger side but you also need to remove the smog pump from off the driver side intake manifold. We also removed the oil filter housing and support bracket as well as the starter. The first two images show the two pipes individually highlighted by the flashlight. This is to give you a general location of each pipe. As you can see they are practically right next to each other. Image 3 is an up-close of the pipe highlighted in image 1. Image 4 shows the pipe highlighted in Image 2. The two pipes are a little trickier to remove and re-install than the first one. Itís just an awkward angle.

That pretty much concludes all I have for the Sharkwerks coolant pipe portion of the job. Hopefully this was helpful. Up next I will work on getting the GT2 clutch and slave cylinder conversion kit posted as well as the vacuum system replacement.

#30

This topic, steps and pics are great. I wish there was someone in SoCal that did this that I could work with. What other maintenance or mods would be timely to do while the engine is out? Water pump, GT3 engine oil dipstick mod, coil packs, etc?