Randy Probst Drives APR's 997 Turbo

#31

Addict

Rennlist Member

Rennlist Member

Todd, thanks for your explanation.....

I always thought tuning was "done" at full load 6th gear (simulated) conditions so that the car would perform on the road how it does on the dyno and all the paramters fuelling/timing/boost etc were correct for this maximum load situation. By virtue of this the engine will be fine in any of the other less loaded gears ie get it right at full load and it will work fine in lesser loads (although I realise there are also many "part load" maps which I know they work on using engine dyno (not quite sure how you manage to tune for part loads on a chassis dyno ?)

So reading the above how does your low loaded run (low loaded because you aren't allowing the boost to build where it actually does in 6th gear - ie ~3000rpm) represent what the engine is actually producing to a DIN standard - it doesn't make sense to me - you are basically saying your dyno charts should NOT be compared to a DIN Porsche power/torque diagram ? My point is that the Maha and engine dynos DO follow the DIN procedure just like Porsche do it, with the Maha having that "setting" you can see on the sheet above..... So are we saying the Mustang,Dyno-Dynamics, or Dynapak are basically not able to do what the Maha does so you are using your own methods ?

Your comments on slippage also puzzle me - you may have read, my clutch also slips on the road when its cold - I reckon they slip at about the 760NM level - this is not an unrealistic level in fact your package claims quite a lot more than this....

I always thought tuning was "done" at full load 6th gear (simulated) conditions so that the car would perform on the road how it does on the dyno and all the paramters fuelling/timing/boost etc were correct for this maximum load situation. By virtue of this the engine will be fine in any of the other less loaded gears ie get it right at full load and it will work fine in lesser loads (although I realise there are also many "part load" maps which I know they work on using engine dyno (not quite sure how you manage to tune for part loads on a chassis dyno ?)

So reading the above how does your low loaded run (low loaded because you aren't allowing the boost to build where it actually does in 6th gear - ie ~3000rpm) represent what the engine is actually producing to a DIN standard - it doesn't make sense to me - you are basically saying your dyno charts should NOT be compared to a DIN Porsche power/torque diagram ? My point is that the Maha and engine dynos DO follow the DIN procedure just like Porsche do it, with the Maha having that "setting" you can see on the sheet above..... So are we saying the Mustang,Dyno-Dynamics, or Dynapak are basically not able to do what the Maha does so you are using your own methods ?

Your comments on slippage also puzzle me - you may have read, my clutch also slips on the road when its cold - I reckon they slip at about the 760NM level - this is not an unrealistic level in fact your package claims quite a lot more than this....

#32

Instructor

Todd, thanks for your explanation.....

I always thought tuning was "done" at full load 6th gear (simulated) conditions so that the car would perform on the road how it does on the dyno and all the paramters fuelling/timing/boost etc were correct for this maximum load situation. By virtue of this the engine will be fine in any of the other less loaded gears ie get it right at full load and it will work fine in lesser loads (although I realise there are also many "part load" maps which I know they work on using engine dyno (not quite sure how you manage to tune for part loads on a chassis dyno ?)

I always thought tuning was "done" at full load 6th gear (simulated) conditions so that the car would perform on the road how it does on the dyno and all the paramters fuelling/timing/boost etc were correct for this maximum load situation. By virtue of this the engine will be fine in any of the other less loaded gears ie get it right at full load and it will work fine in lesser loads (although I realise there are also many "part load" maps which I know they work on using engine dyno (not quite sure how you manage to tune for part loads on a chassis dyno ?)

Top rpms in 6th gear equates to well north of 190mph.

Even the best dyno fans can't provide cooling support anywhere near those speeds.

Maha's fan system claims a maximum output of 62mph (100km/h) and that is only up to about 10ft from the fan outlet. At the rear of the car, where a Porsche engine resides, velocity drops to 25mph (40 km/h). See this diagram from their marketing literature:

With roll balancing option chosen during the dyno order, I think all the dynos I mentioned can go to 200mph top speed.

But that does not mean testing should be done to that speed!

The length of time it takes for a high hp Porsche to do a full pull through 6th gear is well over 15 seconds! Such over-stressing of the car proves what? That is not tuning for realistic street conditions.

My point here is that meaningful chassis dyno testing is a combination of parameters in order to ensure that the tuning/testing being done is relevant to real world usage. Just because a dyno is able to measure full speed in 6th gear, and 6th gear is full load, does not mean that the results obtained are any more true than a test done in 4th gear within the cooling capabilities of the dyno cell.

#33

Addict

Rennlist Member

Rennlist Member

Todd, fully appreciate what you say - I meant to say replicating a 6th gear load not actually testing in 6th gear (since as you say this is unpractical) the Manthey run I posted was done in 5th.....

The lack of that low end loading surely gives a false boost curve and so a false IAT curve/knock curve/timing curve which must effect the power further up the rev range..... how this manifests itself I suppose is the moot point since these modern ECUs are so sophisticated that they look after themsleves "despite" what an errant tuner may do.

The lack of that low end loading surely gives a false boost curve and so a false IAT curve/knock curve/timing curve which must effect the power further up the rev range..... how this manifests itself I suppose is the moot point since these modern ECUs are so sophisticated that they look after themsleves "despite" what an errant tuner may do.

#34

Addict

Rennlist Member

Rennlist Member

Todd

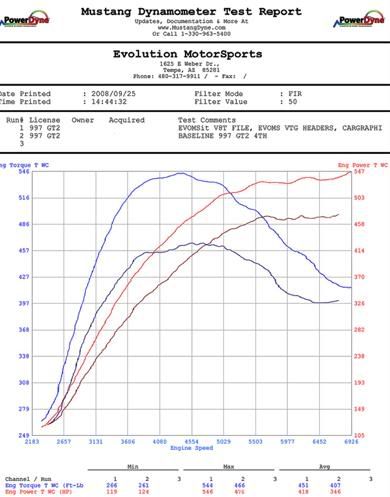

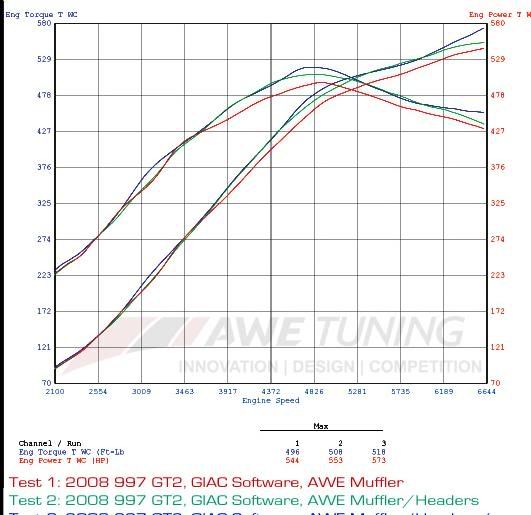

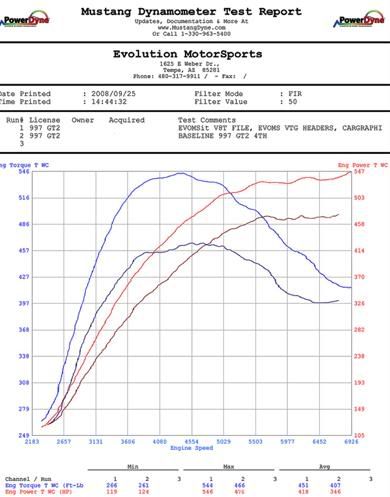

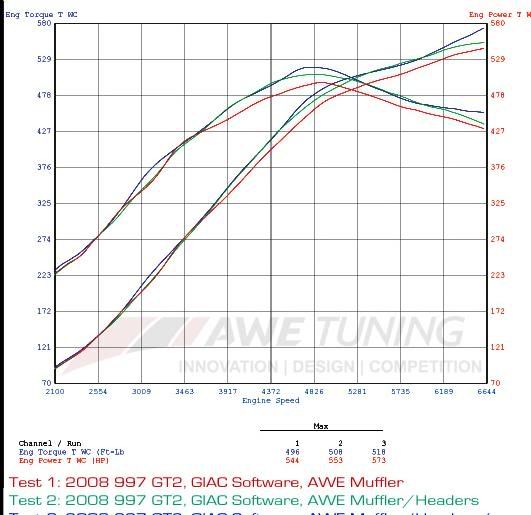

Could you comment on the graphs below, EVOMS and yours for the GT2 - how are EVO getting so much torque 546 vs yours 518ftlb - the loading looks very different, can you comment on the different way you operate your Mustang compared to EVO and how that affects the way the engine is loaded and the curves etc ?

Could you comment on the graphs below, EVOMS and yours for the GT2 - how are EVO getting so much torque 546 vs yours 518ftlb - the loading looks very different, can you comment on the different way you operate your Mustang compared to EVO and how that affects the way the engine is loaded and the curves etc ?

#35

Instructor

Join Date: Feb 2005

Location: Sunny Southern California

Posts: 161

Likes: 0

Received 0 Likes

on

0 Posts

Very interesting and educational comment. And somewhat disturbing. Now I understand the significance of Vbox. I wonder if an engine dyno is subjected to the same degree of variation caused by manipulation of software settings.

Also from Todd's comment it would appear any single dyno doesn't have much meaning as far as absolute value is concerned? It is only the *change* that is reliable. For example, the change from pre and post installation of a component.

Also from Todd's comment it would appear any single dyno doesn't have much meaning as far as absolute value is concerned? It is only the *change* that is reliable. For example, the change from pre and post installation of a component.

Any load type dyno, whether Mustang, Maha, Dyno-Dynamics, or Dynapak, can be calibrated to show whatever you want them to show....

HOWEVER, as long as the software parameters that are used for the baseline are ALSO used for the modification test, the results are valid, REGARDLESS OF SHAPE OR SCALE. ...

HOWEVER, as long as the software parameters that are used for the baseline are ALSO used for the modification test, the results are valid, REGARDLESS OF SHAPE OR SCALE. ...

#36

Instructor

Yes, an engine dyno is just as susceptible. Engine dynos rely on software to convert raw sensor signals into mapped curves, and settings in that software can be changed just like with the software used on a chassis dyno.

So, unless all these settings are somehow used universally by all dyno operators, or if tuner dynos were subject to governing body regulation, not even the results from an engine dyno can be taken absolutely.

I am glad to see that this information is slowly seeping into the forum readers. We've been preaching this for years.

Bear in mind that there are a lot of variables that need to be controlled for Vbox runs, too, in order to make them universally comparable, like ambient temp, road surface/grade, headwind/tailwind, etc., but at least the TOOL being used for data capture is a "sealed box" for all intents and purposes.

So, unless all these settings are somehow used universally by all dyno operators, or if tuner dynos were subject to governing body regulation, not even the results from an engine dyno can be taken absolutely.

I am glad to see that this information is slowly seeping into the forum readers. We've been preaching this for years.

Bear in mind that there are a lot of variables that need to be controlled for Vbox runs, too, in order to make them universally comparable, like ambient temp, road surface/grade, headwind/tailwind, etc., but at least the TOOL being used for data capture is a "sealed box" for all intents and purposes.

#37

Addict

Rennlist Member

Rennlist Member

Yes, an engine dyno is just as susceptible. Engine dynos rely on software to convert raw sensor signals into mapped curves, and settings in that software can be changed just like with the software used on a chassis dyno.

So, unless all these settings are somehow used universally by all dyno operators, or if tuner dynos were subject to governing body regulation, not even the results from an engine dyno can be taken absolutely.

I am glad to see that this information is slowly seeping into the forum readers. We've been preaching this for years.

Bear in mind that there are a lot of variables that need to be controlled for Vbox runs, too, in order to make them universally comparable, like ambient temp, road surface/grade, headwind/tailwind, etc., but at least the TOOL being used for data capture is a "sealed box" for all intents and purposes.

So, unless all these settings are somehow used universally by all dyno operators, or if tuner dynos were subject to governing body regulation, not even the results from an engine dyno can be taken absolutely.

I am glad to see that this information is slowly seeping into the forum readers. We've been preaching this for years.

Bear in mind that there are a lot of variables that need to be controlled for Vbox runs, too, in order to make them universally comparable, like ambient temp, road surface/grade, headwind/tailwind, etc., but at least the TOOL being used for data capture is a "sealed box" for all intents and purposes.

Ruf always quotes what he considers accurate numbers which are not always what his engine dyno says but he knows from experience what is what, also Manthey seem to quote good numbers - these guys do not really compete in the numbers wars as their products have to stand the rigours of teh Autobahn (and track in RS case)

Pbox data as you say can also vary quite wildly with surface and atmo conditions but I agree it is more telling for the customer if he takes these elements into account....