997.2 GT3RS 3.8 4.0 Center Plenum/Distributor Tube Thread

#31

Rennlist Member

We'll find out. I'll double check my cam adjuster bolts again, if we need to drop the motor a few inches for added clearance. We checked them for proper torque during the coolant pipe fix, but this time I might add a tack weld to each one for further peace of mind.

#32

I would speculate that the lower the mileage on your 3.8RS or 4.0 the Porsche gods shall punish you for committing the unholiest of sins.

When you drive the car regularly the natural resonance frequency of the engine actually tightens the screws and strengthens the material of the shaft, like work hardening the metal. Prolonged usage of the motor in the 4-8K rpm ranges is known to really help too, it is basic science and metallurgy, makes perfect sense.

When you drive the car regularly the natural resonance frequency of the engine actually tightens the screws and strengthens the material of the shaft, like work hardening the metal. Prolonged usage of the motor in the 4-8K rpm ranges is known to really help too, it is basic science and metallurgy, makes perfect sense.

The following 3 users liked this post by Belinko:

#33

Rennlist Member

When you drive the car regularly the natural resonance frequency of the engine actually tightens the screws and strengthens the material of the shaft, like work hardening the metal. Prolonged usage of the motor in the 4-8K rpm ranges is known to really help too, it is basic science and metallurgy, makes perfect sense.

I read your post while imagining Bill Murray speaking what you wrote out loud. Makes absolutely 1000% perfect sense.

#34

#35

This thread is frankly terrifying haha.

I recently completed a full engine rebuild of my 997 RS due to a failed oil pump.

It took nearly two years thanks to parts holdups, and cost a fortune, even with myself doing everything short of assembling the long block.

My understanding previously had been the intake plenum failures of the 4.0 and 3.8 RS were due to the bolts on the resonance flaps coming loose, perhaps due to the same harmonics that killed my oil pump.

I had sourced a full 4.0 intake (previous 4.0 build still had the factory 3.6 intake) and very carefully cleaned and loctited the flap bolts one by one.

Now I learn it's the shafts that break and I have a new fear on top of harmonics destroying oil pumps and backing out cam adjuster bolts, or vacuum pumps falling off and spraying your exhaust in oil, or any of the other failures of these so called bulletproof motors.

Would there be interest having an engineer design and build upgraded shafts, perhaps out of the fatigue proof steel posted earlier?

I just want to drive my car the way it was supposedly designed without having to worry about another potential catastrophic failure.

I recently completed a full engine rebuild of my 997 RS due to a failed oil pump.

It took nearly two years thanks to parts holdups, and cost a fortune, even with myself doing everything short of assembling the long block.

My understanding previously had been the intake plenum failures of the 4.0 and 3.8 RS were due to the bolts on the resonance flaps coming loose, perhaps due to the same harmonics that killed my oil pump.

I had sourced a full 4.0 intake (previous 4.0 build still had the factory 3.6 intake) and very carefully cleaned and loctited the flap bolts one by one.

Now I learn it's the shafts that break and I have a new fear on top of harmonics destroying oil pumps and backing out cam adjuster bolts, or vacuum pumps falling off and spraying your exhaust in oil, or any of the other failures of these so called bulletproof motors.

Would there be interest having an engineer design and build upgraded shafts, perhaps out of the fatigue proof steel posted earlier?

I just want to drive my car the way it was supposedly designed without having to worry about another potential catastrophic failure.

The following 2 users liked this post by baronmech:

Elliotw44 (05-29-2024),

point2point (05-29-2024)

#37

Rennlist Member

Dundon's flap-less manifold is the only long-term solution currently on the market that I know of.

Last edited by Mvez; 05-29-2024 at 04:38 PM.

#38

This thread is frankly terrifying haha.

I recently completed a full engine rebuild of my 997 RS due to a failed oil pump.

It took nearly two years thanks to parts holdups, and cost a fortune, even with myself doing everything short of assembling the long block.

My understanding previously had been the intake plenum failures of the 4.0 and 3.8 RS were due to the bolts on the resonance flaps coming loose, perhaps due to the same harmonics that killed my oil pump.

I had sourced a full 4.0 intake (previous 4.0 build still had the factory 3.6 intake) and very carefully cleaned and loctited the flap bolts one by one.

Now I learn it's the shafts that break and I have a new fear on top of harmonics destroying oil pumps and backing out cam adjuster bolts, or vacuum pumps falling off and spraying your exhaust in oil, or any of the other failures of these so called bulletproof motors.

Would there be interest having an engineer design and build upgraded shafts, perhaps out of the fatigue proof steel posted earlier?

I just want to drive my car the way it was supposedly designed without having to worry about another potential catastrophic failure.

I recently completed a full engine rebuild of my 997 RS due to a failed oil pump.

It took nearly two years thanks to parts holdups, and cost a fortune, even with myself doing everything short of assembling the long block.

My understanding previously had been the intake plenum failures of the 4.0 and 3.8 RS were due to the bolts on the resonance flaps coming loose, perhaps due to the same harmonics that killed my oil pump.

I had sourced a full 4.0 intake (previous 4.0 build still had the factory 3.6 intake) and very carefully cleaned and loctited the flap bolts one by one.

Now I learn it's the shafts that break and I have a new fear on top of harmonics destroying oil pumps and backing out cam adjuster bolts, or vacuum pumps falling off and spraying your exhaust in oil, or any of the other failures of these so called bulletproof motors.

Would there be interest having an engineer design and build upgraded shafts, perhaps out of the fatigue proof steel posted earlier?

I just want to drive my car the way it was supposedly designed without having to worry about another potential catastrophic failure.

With that said, it is clear that Porsche has known about the issue and also seems to explain why Porsche Motorsport has chosen to use the smaller manifold on the latest generation of the 2015/16 Mezger Cup 3.8 engine. I suspect they knew that using the larger manifold would not prudent from a reliability standpoint long term. In light of the AP admission in print that there is a problem with the manifolds, I'm really surprised some attorney has not sued Porsche to force a redesign / remedy. I can imagine a car at 180mph on the Autobahn swallowing up parts of the flapper rod at 8K rpm would likely not end well for both the car and also the occupant.

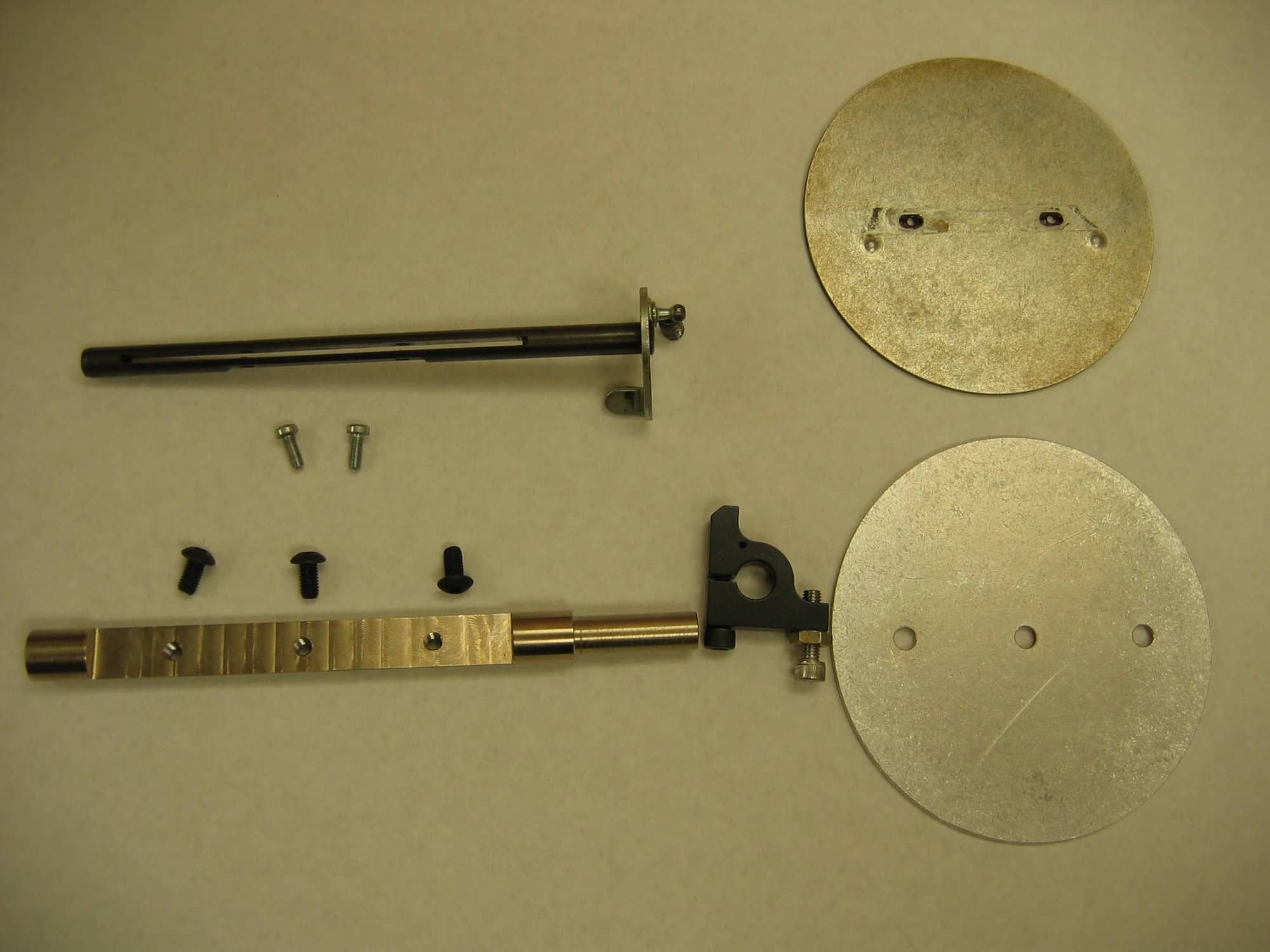

The redesign of the flap rod is a potential solution that I have discussed with my shop. While certainly possible, it is by no means a simple process even though they have full Haas machining capability. Using a rod made from a much better material, designed to eliminate potential stress risers, or possibly made with a larger diameter rod/bushing would all be a possibility. We will look at that when the time comes for my engine build later this year.

The flapless Dundon style manifold is obviously a solution but you do give up performance in the mid to low range for sure. Based on testing my shop has done on this on the dyno, it appears to be about 10% on the 996GT3 manifold which uses a single tube. The top end remains unaffected naturally. The RSR does not use flaps in the manifold but the range of operation on that application is virtually all from 7000 to 9400. As such, the flaps are not needed.

Last edited by powdrhound; 05-29-2024 at 06:57 PM.

#39

Agent Orange

Rennlist Member

Rennlist Member

I spoke with Jamie while my engine was being rebuilt, the Dundon intake unfortunately wasn't a solution due to 1) cost and 2) the necessity to use a tune that would make the car illegal for street use in California.

My engine builder created the screens on each end of the manifold to prevent a potential broken piece of the rod from falling into the combustion chamber again. I sleep well at night knowing I have this remedy. He might be willing to produce a batch of them if there is enough interest.

If there are enough of us, especially those of us who have large paid invoices thanks to Porsche's poor design, craftsmanship and quality, there may indeed be a case... Especially considering this is the "halo" car that they botched.

My engine builder created the screens on each end of the manifold to prevent a potential broken piece of the rod from falling into the combustion chamber again. I sleep well at night knowing I have this remedy. He might be willing to produce a batch of them if there is enough interest.

If there are enough of us, especially those of us who have large paid invoices thanks to Porsche's poor design, craftsmanship and quality, there may indeed be a case... Especially considering this is the "halo" car that they botched.

The following users liked this post:

point2point (05-29-2024)

#43

Rennlist Member

It's essentially a Cobb stage 1, that has been customized for the 93mm throttle body and more airflow. I thought Cobb tunes are legal in CA? I just spoke with Jamie about this. He actually recommended I use a header w/cats.

#45

Rennlist Member

The flapless Dundon style manifold is obviously a solution but you do give up performance in the mid to low range for sure. Based on testing my shop has done on this on the dyno, it appears to be about 10% on the 996GT3 manifold which uses a single tube. The top end remains unaffected naturally. The RSR does not use flaps in the manifold but the range of operation on that application is virtually all from 7000 to 9400. As such, the flaps are not needed.

. I can live with some power loss under 3500 RPM, which I never see that low on track anyway. For street driving, it makes zero difference to me if I gained or lost 10% in the low range, especially since the RS already has the 4.89 R&P.

. I can live with some power loss under 3500 RPM, which I never see that low on track anyway. For street driving, it makes zero difference to me if I gained or lost 10% in the low range, especially since the RS already has the 4.89 R&P.The cost of the Dundon system is honestly outrageous, and an upgraded flapper would probably work for alot of people, perhaps especially those who aren't concerned about track performance. The reality is if you want more track performance, the Dundon manifold is the best bang for buck to get 4.0-4.1L levels of HP, and a big increase in mid-range, which is what this car really needs.

RSR didn't need it for sure, with the cams and gearing it ran, but it was also the endurance racer that saw up to 12-24 hrs at a time. Fewer moving parts typically = more reliable.

Last edited by Mvez; 05-29-2024 at 08:10 PM.