Synchroizer Wear Spec?

#31

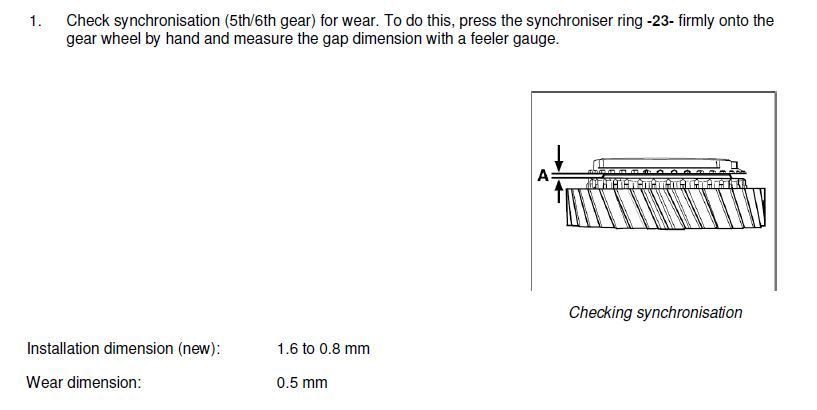

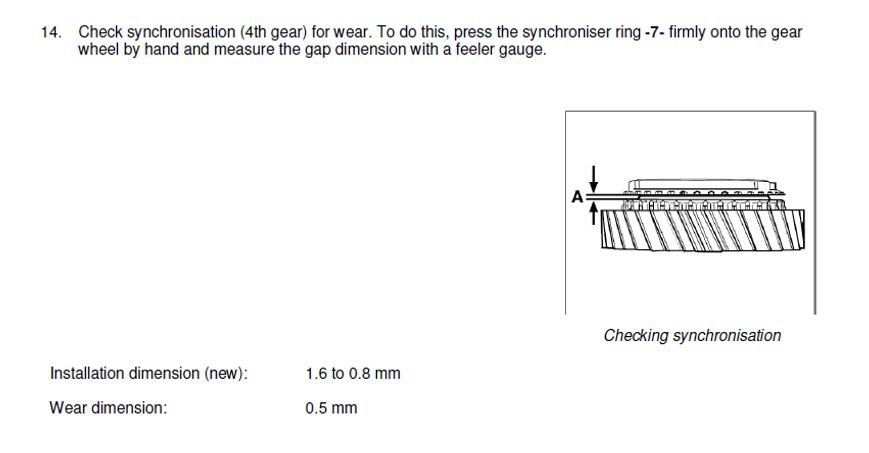

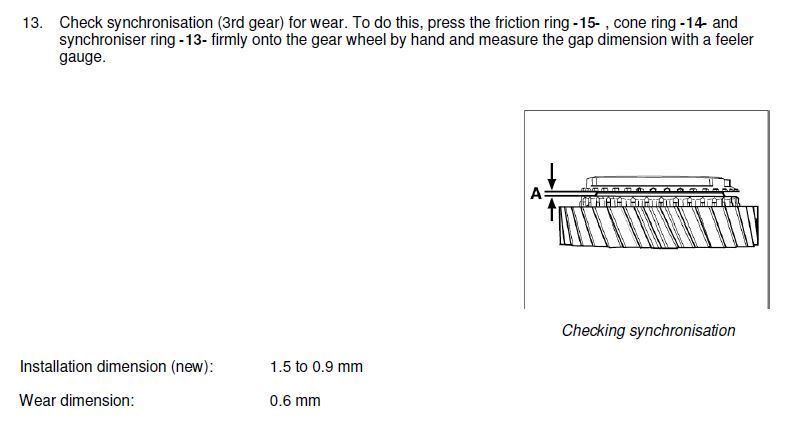

The reason I ask is because if you go back to the video I posted in #23 at time ~7:05 he is showing this exact thing we are talking about but provides a counterexample to this. Notice on the bad ring the height is still acceptable despite that he shows it is not working and clutching properly because the threads on the female cone are worn such that the clutching slips when engaged (it's not cutting through the oil film etc) with the male cone on the application of force.

Last edited by silver_tt; 01-04-2024 at 03:08 PM.

#32

Back on your issue for this post, I have been giving this more thought and understand more after reading this thread and watching those videos. My question is: Are those wear dimensions the bible? In other words maybe measurements within spec are necessary but not sufficient in checking this.

The reason I ask is because if you go back to the video I posted in #23 at time ~7:05 he is showing this exact thing we are talking about but provides a counterexample to this. Notice on the bad ring the height is still acceptable despite that he shows it is not working and clutching properly because the threads on the female cone are worn such that the clutching slips when engaged (it's not cutting through the oil film etc) with the male cone on the application of force.

The reason I ask is because if you go back to the video I posted in #23 at time ~7:05 he is showing this exact thing we are talking about but provides a counterexample to this. Notice on the bad ring the height is still acceptable despite that he shows it is not working and clutching properly because the threads on the female cone are worn such that the clutching slips when engaged (it's not cutting through the oil film etc) with the male cone on the application of force.

Good news is that these parts are relatively cheap, and are only a 3 day lead! My shift fork took nearly 2 months to arrive from Germany. Excited to dig into this. I know I can fix this myself. I'll document the entire process so others can learn.

#33

This is a good point. When I drop the transmission this weekend I'll see if I can push down on the 6th gear synchro and make it catch / press fit, or spin.

Good news is that these parts are relatively cheap, and are only a 3 day lead! My shift fork took nearly 2 months to arrive from Germany. Excited to dig into this. I know I can fix this myself. I'll document the entire process so others can learn.

Good news is that these parts are relatively cheap, and are only a 3 day lead! My shift fork took nearly 2 months to arrive from Germany. Excited to dig into this. I know I can fix this myself. I'll document the entire process so others can learn.