Fuel system upgrade for higher output motors

#1

Rennlist Member

Thread Starter

Hey gents. Figured I'd post this here for anyone looking to upgrade their fuel system which is necessary when increasing power past the 600ish threshold. This pictures here are representative of a GT2 fuel system but a majority will apply to the 996TT fuel system with the difference being the routing of the fuel hoses in the front of the car.

Basically all we did here is to use a -6AN fuel line from the fuel tank all the way to the fuel rail. I am running a Walbro 450 fuel pump which is fitted into the OEM fuel basket. I had a billet pump bracket on hand so I used that in my applications but Radium now makes an adapter sleeve that will allow you to clip the Walbro 450 directly into the OEM plastic fuel basket cover. The adapter is about $100 available directly from Radium. Fuel is then fed through the factory tank lid. You will have to drill out the OEM fuel supply fitting so that you can install a -6AN 90║ fitting. I used a Stat-O-Seal crush washer between the underside of the fuel tank lid and the -6AN fitting to provide a positive seal. A -6AN fuel line is then routed from the top of the tank lid to a Bosch Motorsport fuel filter. This fuel filter provides minimal back pressure and includes a viewable window which displays the amount of back pressure the filter provides as it becomes clogged over time. This will give you an idea of when it is time to replace the internal filter cartridge. The Bosch filter also has an integrated fuel temperature and fuel pressure sensor which will provide data in case your car is set up with Motec, Aim, or other data logging systems. A simplified cheaper version of the Bosch Motorsport fuel filter is available without the fuel temp/pressure sensor.

After passing through the fuel filter, fuel is routed to the rear of the car again via a -6AN line. We split the line directly under the center of the car with a -6AN male to male connector but you could run the line in one piece all the way to the fuel rail. By having a connection directly under the car will allow one to add a check valve if necessary. You could use an aeromotive -6AN male to male check valve for a plug and play set up if necessary. We chose to skip the check valve but can easily add one later. The rest of the -6AN line is routed to the fuel rail and connected via a Krontec Motorport connector. I am using a fire sleeve over the fuel line in the engine compartment to provide thermal insulation and also installed it in a couple of areas where the -6AN line comes in proximity with the coolant pipes.

I removed the OEM fuel supply line altogether but that can only be done with the engine and fuel tank removed from the car. I will add that we are only using a single -6AN fuel supply line and the stock OEM fuel return line. I would only recommend running the stock OEM return line if you have the ability to scale down fuel pump output during time of low fuel demand (low throttle, idle, etc.). Our testing showed that the output of the Walbro 450 simply is too great for the restrictive OEM fuel return line thus raining base idle fuel pressure. In my case we are using a Motec DHB to vary the amount of fuel pump output depending of fuel demand and as such were have greatly reduced the return fuel volume which allows us to use the OEM return line. This was done to keep fuel recirculation to a minimum, reduce stress on the pump, and reduce fuel temperatures in the process as my car does not have a fuel cooler). Long story short, in cases where the Walbro pump is operating at 100% output at all times, I would also recommend installing a -6AN fuel return line.

As far as wiring goes, we are powering the fuel pump directly from the battery through the Motec DHB instead of through the OEM relay. Wiring directly off the battery will minimize voltage losses.

Hope someone finds this useful...

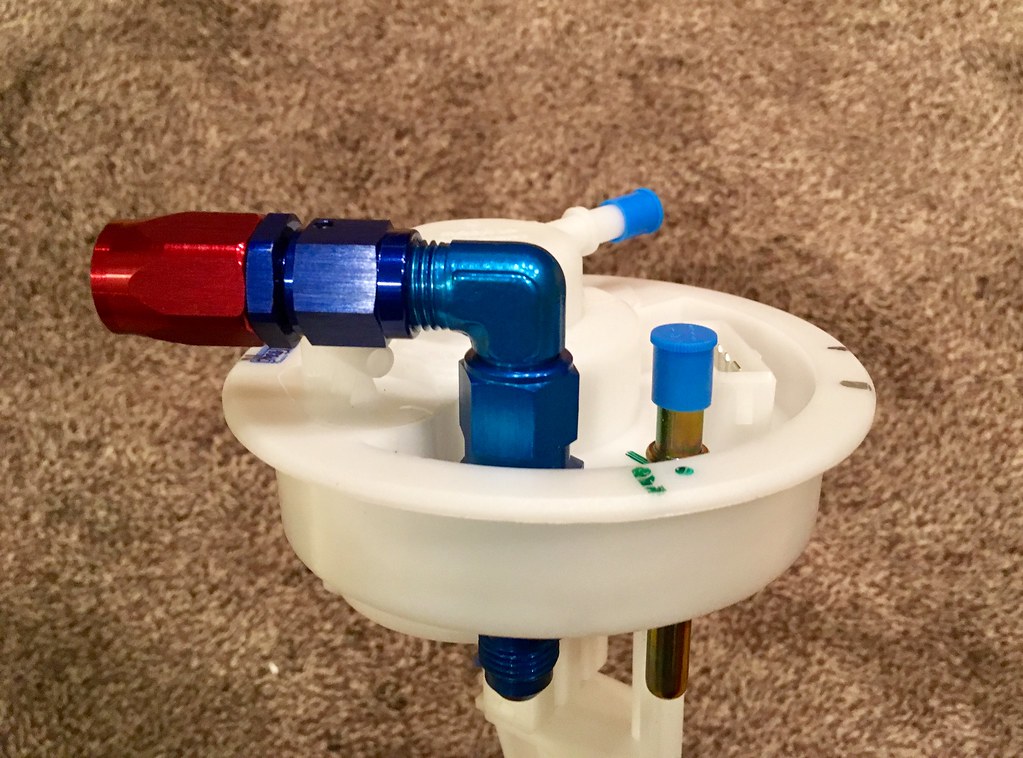

OEM fuel tank lid with installed -6AN fuel supply fitting. A Stat-O-Seal is visible under the fitting.

Top of OEM fuel tank lid with a 90║ -6AN fuel supply fitting

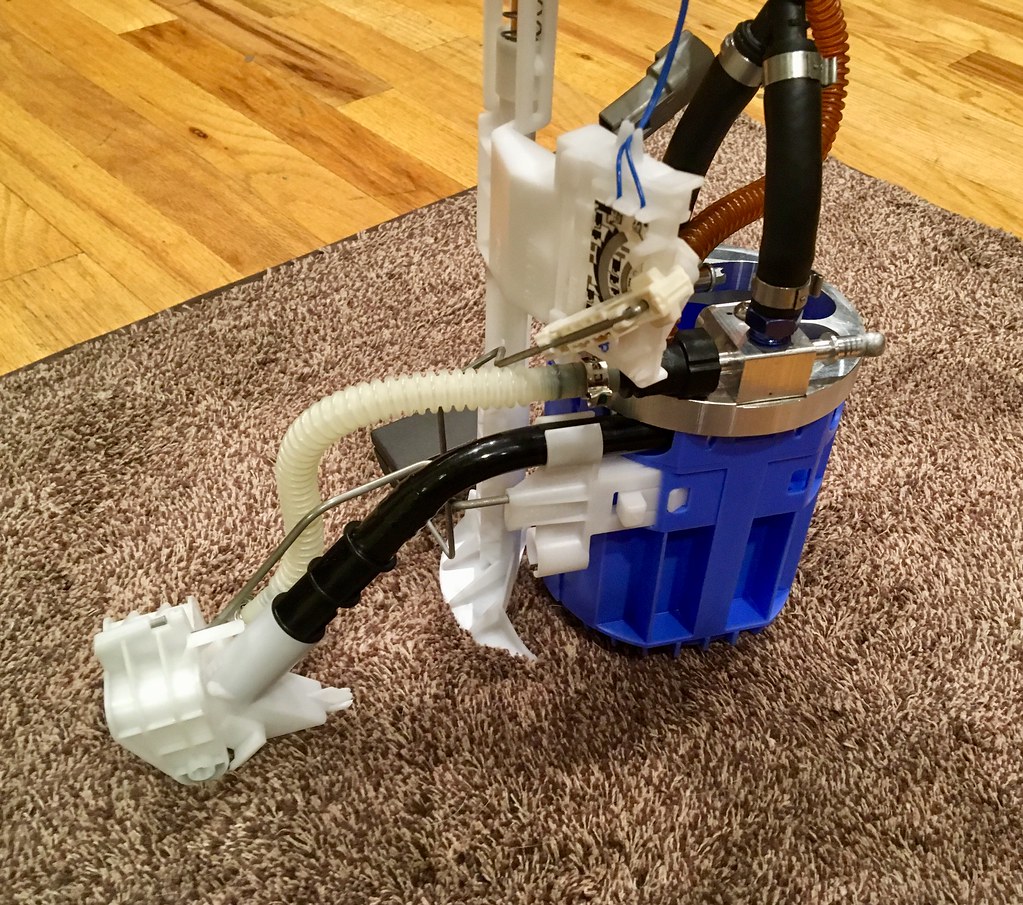

Fuel system inside the tank with a Walbro 450 pump

OEM jet pump provided filing of the fuel basket under low fuel level conditions and accelaration. The 996TT has dual jet pumps due to the nature of the AWD hump in the fuel tank where the fuel pump basket is installed higher up in the tank as opposed to the bottom as on the RWD cars. The jet pump plugs into the back of the fuel basket and is powered by a portion of the fuel pump output pressure.

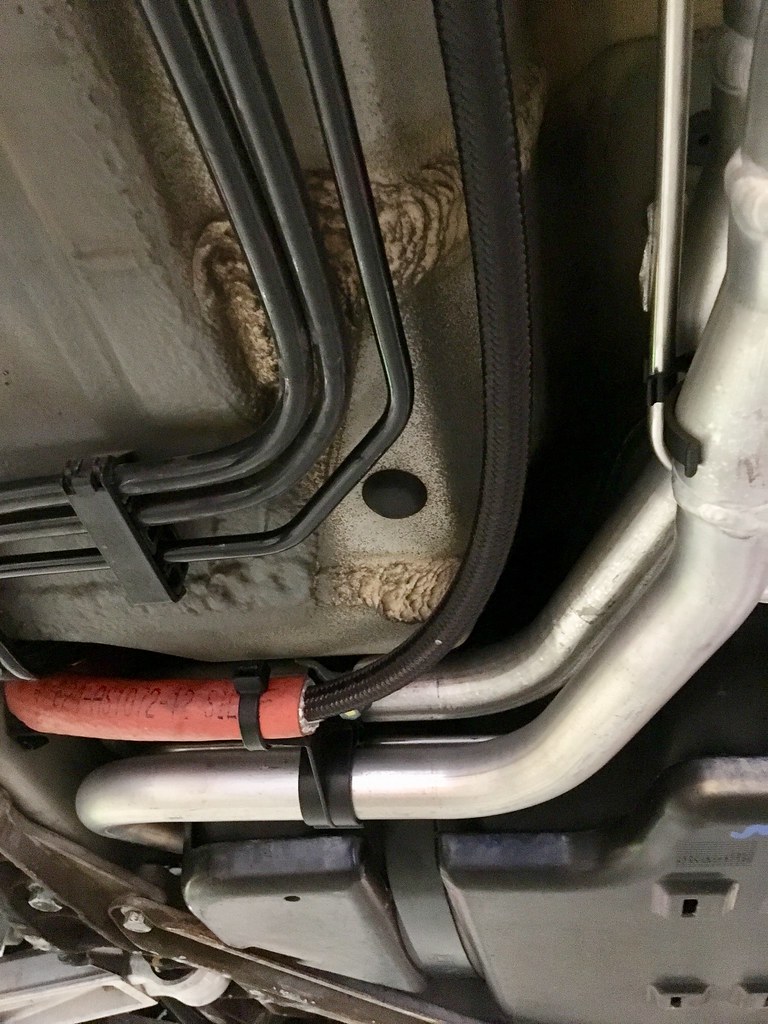

Fuel tank lid and routing of the -6AN pump. This will be slightly different on 996TT cars where this lid is not under the battery

Bosch Motorsport fuel filter and -6AN line routing. The top line is fuel flow to the filter, the bottom line is fuel out of the filter. The fuel pressure/temp sensor is visible just post filter. The connector and wire is not plugged in as pictured.

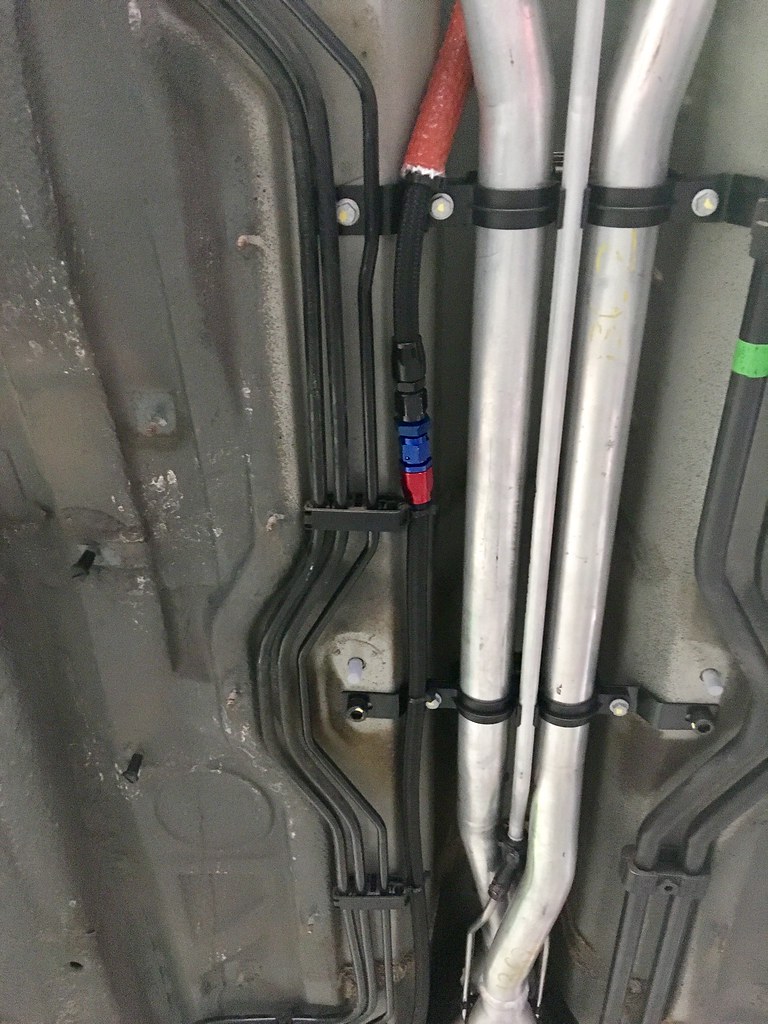

Routing of the -6AN line under the car

Close up of the Krontec Motorsport 45║ fuel rail connector

Basically all we did here is to use a -6AN fuel line from the fuel tank all the way to the fuel rail. I am running a Walbro 450 fuel pump which is fitted into the OEM fuel basket. I had a billet pump bracket on hand so I used that in my applications but Radium now makes an adapter sleeve that will allow you to clip the Walbro 450 directly into the OEM plastic fuel basket cover. The adapter is about $100 available directly from Radium. Fuel is then fed through the factory tank lid. You will have to drill out the OEM fuel supply fitting so that you can install a -6AN 90║ fitting. I used a Stat-O-Seal crush washer between the underside of the fuel tank lid and the -6AN fitting to provide a positive seal. A -6AN fuel line is then routed from the top of the tank lid to a Bosch Motorsport fuel filter. This fuel filter provides minimal back pressure and includes a viewable window which displays the amount of back pressure the filter provides as it becomes clogged over time. This will give you an idea of when it is time to replace the internal filter cartridge. The Bosch filter also has an integrated fuel temperature and fuel pressure sensor which will provide data in case your car is set up with Motec, Aim, or other data logging systems. A simplified cheaper version of the Bosch Motorsport fuel filter is available without the fuel temp/pressure sensor.

After passing through the fuel filter, fuel is routed to the rear of the car again via a -6AN line. We split the line directly under the center of the car with a -6AN male to male connector but you could run the line in one piece all the way to the fuel rail. By having a connection directly under the car will allow one to add a check valve if necessary. You could use an aeromotive -6AN male to male check valve for a plug and play set up if necessary. We chose to skip the check valve but can easily add one later. The rest of the -6AN line is routed to the fuel rail and connected via a Krontec Motorport connector. I am using a fire sleeve over the fuel line in the engine compartment to provide thermal insulation and also installed it in a couple of areas where the -6AN line comes in proximity with the coolant pipes.

I removed the OEM fuel supply line altogether but that can only be done with the engine and fuel tank removed from the car. I will add that we are only using a single -6AN fuel supply line and the stock OEM fuel return line. I would only recommend running the stock OEM return line if you have the ability to scale down fuel pump output during time of low fuel demand (low throttle, idle, etc.). Our testing showed that the output of the Walbro 450 simply is too great for the restrictive OEM fuel return line thus raining base idle fuel pressure. In my case we are using a Motec DHB to vary the amount of fuel pump output depending of fuel demand and as such were have greatly reduced the return fuel volume which allows us to use the OEM return line. This was done to keep fuel recirculation to a minimum, reduce stress on the pump, and reduce fuel temperatures in the process as my car does not have a fuel cooler). Long story short, in cases where the Walbro pump is operating at 100% output at all times, I would also recommend installing a -6AN fuel return line.

As far as wiring goes, we are powering the fuel pump directly from the battery through the Motec DHB instead of through the OEM relay. Wiring directly off the battery will minimize voltage losses.

Hope someone finds this useful...

OEM fuel tank lid with installed -6AN fuel supply fitting. A Stat-O-Seal is visible under the fitting.

Top of OEM fuel tank lid with a 90║ -6AN fuel supply fitting

Fuel system inside the tank with a Walbro 450 pump

OEM jet pump provided filing of the fuel basket under low fuel level conditions and accelaration. The 996TT has dual jet pumps due to the nature of the AWD hump in the fuel tank where the fuel pump basket is installed higher up in the tank as opposed to the bottom as on the RWD cars. The jet pump plugs into the back of the fuel basket and is powered by a portion of the fuel pump output pressure.

Fuel tank lid and routing of the -6AN pump. This will be slightly different on 996TT cars where this lid is not under the battery

Bosch Motorsport fuel filter and -6AN line routing. The top line is fuel flow to the filter, the bottom line is fuel out of the filter. The fuel pressure/temp sensor is visible just post filter. The connector and wire is not plugged in as pictured.

Routing of the -6AN line under the car

Close up of the Krontec Motorsport 45║ fuel rail connector

#2

Looks good! I've had a brand new OE pump sitting on my shelf awaiting install and was going to do the same re: dropping a new Walboro into the stock basket. Seems like a nice, cheaper approach than buying an a/m setup. Nice that radium makes an adapter now, I will have to check it. Surprised with all that work why you wouldn't address the return line as the base pressure is just due to over running it. I was just gonna do the pump, wondering if I will still need a pump controller to scale it back.

#3

Rennlist Member

Thread Starter

If you run the pump without a regulator at 100% output all the time, you will overwhelm the 3.8 bar fuel pressure regulator thus raising base idle pressure since the fuel pressure regulator does not have the ability to bypass the significantly larger amount of fuel flow provided by the Walbro 450 at 100% output with the engine at idle. This is what our testing bore out.

If I recall, T10Chris is running an off the shelf PWM controller in conjunction with the Walbro 450. I think that may be an option for those not using a dedicated system like Motec. He may chime in with his experience.

Last edited by powdrhound; 10-31-2018 at 04:21 PM.

#4

The Walbro is a PWM (pulse width modulation) pump which allows you to control the output with an appropriate PWM fuel controller. As I explained in my original post, there is no need for us to run a larger return line as we are running the pump at greatly reduced output in low fuel demand conditions (partial throttle/boost, idle, etc.), effectively almost a return-less fuel set up. The pump output can be programmed infinitely based on RPM, boost, load, etc to suit whatever set up you have. Basically with the engine running at idle, we scaled the pump output all the way down just above the threshold where the base fuel pressure would start dropping with the fuel pressure regulator almost fully closed. If I recall, that sets the pump at about 20% output. The pump is then programmed to increase output based on RPM and boost increase in a linear fashion. Since, we are severely reducing the amount of fuel return, even far below the OEM specs, there is no need whatsoever for a larger return line.

If you run the pump without a regulator at 100% output all the time, you will overwhelm the 3.8 bar fuel pressure regulator thus raising base idle pressure since the fuel pressure regulator does not have the ability to bypass the significantly larger amount of fuel flow provided by the Walbro 450 at 100% output with the engine at idle. This is what our testing bore out.

If you run the pump without a regulator at 100% output all the time, you will overwhelm the 3.8 bar fuel pressure regulator thus raising base idle pressure since the fuel pressure regulator does not have the ability to bypass the significantly larger amount of fuel flow provided by the Walbro 450 at 100% output with the engine at idle. This is what our testing bore out.

#5

Yes, there's a few options for a fuel pump controller that would work in line with the Walboro pump.

#6

I'm moving back to the cold so my car will be in sleep mode for a while and I suspect taken apart. I may just do this over the winter with an FPR and pump w/ upgraded feed and return and see how it works out. Can always add the controller later on if needed.

#7

Rennlist Member

Thread Starter

I understand as I read the post, hence my question. I guess it's just personal preference. The fuel pump controller helps tremendously, I was just asking since it was all apart, wondering if upgrading the return alone would eliminate the need for a controller. I see now you said that it would still bump the base idle pressure. The controller is nice too I guess as it keeps the pump and therefore the fuel itself a little cooler as it's not always running 100%. In the past I never had an issue w/ over running the regulator, I guess I was just looking for an excuse for less work, but it seems using a controller with the pump is the way to go. (I see you edited the post now).

In all honesty, I don't think that having a slightly raised base fuel pressure will effect anything as it will only marginally make the transition richer but the injectors are likely able to compensate. For me, it was mainly about lowering the fuel temperature. As with everything, there is a way to do it that gets the job done, but there is a way of doing it that gets the job done optimally.

Trending Topics

#8

Three Wheelin'

The Walbro is a PWM (pulse width modulation) pump which allows you to control the output with an appropriate PWM fuel controller. As I explained in my original post, there is no need for us to run a larger return line as we are running the pump at greatly reduced output in low fuel demand conditions (partial throttle/boost, idle, etc.), effectively almost a return-less fuel set up. The pump output can be programmed infinitely via a Motec DHB based on RPM, boost, load, etc to suit whatever set up you have. Basically with the engine running at idle, we scaled the pump output all the way down just above the threshold where the base fuel pressure would start dropping with the fuel pressure regulator almost fully closed. If I recall, that sets the pump at about 20% output. The pump is then programmed to increase output based on RPM and boost increase in a linear fashion. Since, we are severely reducing the amount of fuel return, even far below the OEM specs, there is no need whatsoever for a larger return line.

If you run the pump without a regulator at 100% output all the time, you will overwhelm the 3.8 bar fuel pressure regulator thus raising base idle pressure since the fuel pressure regulator does not have the ability to bypass the significantly larger amount of fuel flow provided by the Walbro 450 at 100% output with the engine at idle. This is what our testing bore out.

If I recall, T10Chris is running an off the shelf PWM controller in conjunction with the Walbro 450. I think that may be an option for those not using a dedicated system like Motec. He may chime in with his experience.

If you run the pump without a regulator at 100% output all the time, you will overwhelm the 3.8 bar fuel pressure regulator thus raising base idle pressure since the fuel pressure regulator does not have the ability to bypass the significantly larger amount of fuel flow provided by the Walbro 450 at 100% output with the engine at idle. This is what our testing bore out.

If I recall, T10Chris is running an off the shelf PWM controller in conjunction with the Walbro 450. I think that may be an option for those not using a dedicated system like Motec. He may chime in with his experience.

#9

One of the reasons we pursued this is due to the fact that I was running into fuel overheating issues due to all the constant and needless recirculation of the fuel when the Walbro 450 was running at 100% all the time. Not having a fuel cooler only made it worse. From a longevity standpoint, I would imagine there is also a benefit since the pump does not have to be working as hard all the time.

In all honesty, I don't think that having a slightly raised base fuel pressure will effect anything as it will only marginally make the transition richer but the injectors are likely able to compensate. For me, it was mainly about lowering the fuel temperature. As with everything, there is a way to do it that gets the job done, but there is a way of doing it that gets the job done optimally.

In all honesty, I don't think that having a slightly raised base fuel pressure will effect anything as it will only marginally make the transition richer but the injectors are likely able to compensate. For me, it was mainly about lowering the fuel temperature. As with everything, there is a way to do it that gets the job done, but there is a way of doing it that gets the job done optimally.

#10

Any pics of the front trunk setup as a whole?

#11

Rennlist Member

Thread Starter

I'd agree for pump reliability stand point that scaling the pump should add life to it, but I assume you're still using a stock FPR too? A bigger feed, return and adjustable FPR would eliminate the need for a controller; however, your setup is beyond what most here are running in street cars. I'm a big advocate of KISS and mechanical workings . Upping pressure and volume together should also keep the pump cool as the fuel is constantly circulating through the system more efficiently. Nevertheless, nice looking setup.

#13

Rennlist Member

Thread Starter

#14

What did you gain with this mod? I do use a walbro too with 980ccm bosch injectors. Does your car run more than 1.55 bar of boost? That is as far as i know the magic number.

My car runs with stock engine a time of 5,7 sec from 100-200 km/h. With stiffer rods i could raise the boost level in a lower rpm range up to 1,55 bar which would drop the time to around 5 sec time, probably under 5 seconds, depending on the weight of the car and drag.

What time your car runs from 100-200km/h?

My car runs with stock engine a time of 5,7 sec from 100-200 km/h. With stiffer rods i could raise the boost level in a lower rpm range up to 1,55 bar which would drop the time to around 5 sec time, probably under 5 seconds, depending on the weight of the car and drag.

What time your car runs from 100-200km/h?