(Another) Caliper rebuild thread

#17

Race Car

I'm curious if you have any data to backup the statement quoted above. It was my understanding in the OEM setup that the ceramic pucks isolated the brake heat from transferring to the pistons. Honestly that's the one reason i rebuilt with OEM components instead of yours was fear of brake heat transfer to your pistons without the ceramic isolation.

#18

+1, agree data with RB stainless pistons vs stock w. ceramic pucks would add a vote of confidence...

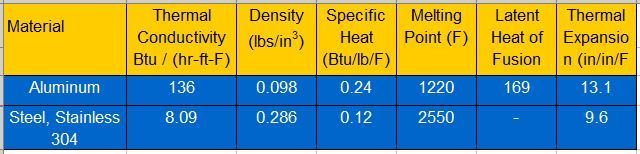

Another question, any issue/concern with heat expansion rates within the piston bore using a stainless vs aluminum piston?

If the above is good, I'd be 'in' for future rebuilds...

Cheers,

Rob

Another question, any issue/concern with heat expansion rates within the piston bore using a stainless vs aluminum piston?

If the above is good, I'd be 'in' for future rebuilds...

Cheers,

Rob

I think you make a great kit and thank you for supporting the 996 GT3 community.

I'm curious if you have any data to backup the statement quoted above. It was my understanding in the OEM setup that the ceramic pucks isolated the brake heat from transferring to the pistons. Honestly that's the one reason i rebuilt with OEM components instead of yours was fear of brake heat transfer to your pistons without the ceramic isolation.

I'm curious if you have any data to backup the statement quoted above. It was my understanding in the OEM setup that the ceramic pucks isolated the brake heat from transferring to the pistons. Honestly that's the one reason i rebuilt with OEM components instead of yours was fear of brake heat transfer to your pistons without the ceramic isolation.

#20

Former Vendor

Finished the caliper rebuild last weekend. I was actually surprised at how easy it ended up being - well, except for the very last part (see below). A few lessons learned that might be useful for others:

All of the internals were in almost perfect shape. No marring or wear on the sides of the piston holes below the seals. And, all the seals looked like they were in perfect shape still. There were a couple holes that had a little spot of wear at the external side - above the seal and below the dust boot (like something got under the dust boot briefly). They didn't impact the piston movement, but you could see a little shiny area. I used a little 2000 grit sand paper and removed any high spots.

The big uh-oh came when I was reinstalling the last caliper. One of the caliper bolts starting spinning in the wheel carrier - stripped out the aluminum. Doh! I ordered the timesert kit and a caliper studs all the way around to take care of that issue forever. Tarret has awesome stuff!

Overall, the technical skill needed was less than 5 out of 10. Just a little patience and some basic tools. Racing Brake parts fit perfectly. Happy with the product and the results!

FFaust - you need a puck? Shoot me a pm!

-td

- Getting the calipers disconnected from the car requires a flare nut wrench. It's virtually impossible without it (because you'll round off the nut)

- Getting the pistons out is fairly easy with an air compressor and a blower nozzle. When you get one out, just put it back in a little and use a speed clamp to hold it there. Pop the next one out and repeat. Don't put them in too deep or they'll be hard to ultimately remove. If you get them jammed back in a little too far - you'll have to wiggle them pretty good to get them out.

- use a couple shop towels over the top of the caliper and where you have the blower nozzle because some fluid will shoot out when each piston pops.

- be sure you have enough pressure in the tank. If you don't you'll do what I did the first time and pressurize the caliper but none of the pistons will eject. When you remove the nozzle, the caliper will back-spew brake fluid everywhere.

- the dust boots come out with a small flat head and a little leverage.

- the internal seals come out with a small hook. I had a set of spring hooks that worked great.

- getting the seals back in was also simple if you soaked them in a little brake fluid first and then pushed one side into the recess for the seal and hold it there while you push the opposite side into the caliper.

- with the RB brake kit, getting the dust boots on was as simple as stretching them onto a piston and then pulling down.

- getting the piston back into the caliper requires using a little force on oppsite sides of the piston and then rotating 90 degrees and pushing down on both sides again. When you get the piston started, it will go down pretty easily

- I did one caliper in about 45 minutes - trying to do it very carefully and learning the process.

- I then set up a little assembly line and did the other 3 calipers in about 45 minutes. Total rebuild time, 1.5 hours - not including a little time to simple green [soak/scrub] the calipers.

- completely flushed brakes and then bled them twice.

All of the internals were in almost perfect shape. No marring or wear on the sides of the piston holes below the seals. And, all the seals looked like they were in perfect shape still. There were a couple holes that had a little spot of wear at the external side - above the seal and below the dust boot (like something got under the dust boot briefly). They didn't impact the piston movement, but you could see a little shiny area. I used a little 2000 grit sand paper and removed any high spots.

The big uh-oh came when I was reinstalling the last caliper. One of the caliper bolts starting spinning in the wheel carrier - stripped out the aluminum. Doh! I ordered the timesert kit and a caliper studs all the way around to take care of that issue forever. Tarret has awesome stuff!

Overall, the technical skill needed was less than 5 out of 10. Just a little patience and some basic tools. Racing Brake parts fit perfectly. Happy with the product and the results!

FFaust - you need a puck? Shoot me a pm!

-td

We simplify and standardize Porsche caliper components that can make your caliper rebuilding job easier, less confusing, yet more rewarding.

Our tech assistance is only a phone call away should you need it.

Tel: 714-882-5612

http://www.racingbrake.com/category-s/7185.htm

#21

Former Vendor

Ceramic puck although can also shield the heat, but the problem is it's a different material than the pistons (aluminum), so under the heat stress it will "separate" from the piston due to different heat expansion rate, they are fragile and tend to crack or crumbled under heat and pressure load.

RB stainless steel piston is machined as one "solid" piece, and "chrome" plated for a super fine finish and hard surface that provides smooth seal movement in braking and brake release.

So RB stainless steel pistons can extend the seal life, never corrode like aluminum pistons, and be benefited from the saving of brake fluid replacement due to lower brake fluid temperature.

RB stainless steel piston is machined as one "solid" piece, and "chrome" plated for a super fine finish and hard surface that provides smooth seal movement in braking and brake release.

So RB stainless steel pistons can extend the seal life, never corrode like aluminum pistons, and be benefited from the saving of brake fluid replacement due to lower brake fluid temperature.

#23

Race Car

What I was looking for is have you measured heat transfer / temp of your pistons vs. the OEM setup...how hot does the aluminum piston get with the 1/2" ceramic barrier shielding it vs. how hot does your stainless get without that barrier.

I get that the ceramic pucks are a pain in the rear...I"m not a huge fan of bumbling around with them on pad changes but I still feel their intended purpose is well thought out in doing exactly what you're talking about which is isolating heat from the piston.

#24

RL Community Team

Rennlist Member

Rennlist Member

From what I understand, Zirconia-based ceramics are frequently used for heat rejection applications and are significantly (perhaps 1 or 2 orders of magnitude) better than SS. That said, they are tough but still crack.

Ray

Ray

#28

Rennlist Member

Thread Starter

Wow - brakes squeal sooooo bad now. It's terribly loud all the time. It probably a combo of new rotors, used (track) pads, and the new pistons and seals. It's actually as loud as my muffler bypass...

-td

-td

#30

Rennlist Member

Thread Starter

I'm going to put on some new track pads, and later this week some brand new street pads as well to see if that makes a difference. The pads on it are surely part of the issue because I can take a corner and the deflection of the rotors reduces the pad squeal. That is, it seems like the pads are dragging a little more than usual because of the new Pistons/seals, and the pads seem to "push" back from the rotors just a little under cornering (enough to reduce the squeal). And, the noise does really sound like brake pad squeal, not some other metal/metal rubbing - although I'm going to verify tonight on the lift.

-td

-td