K16 v K24 the "lag" issue

#17

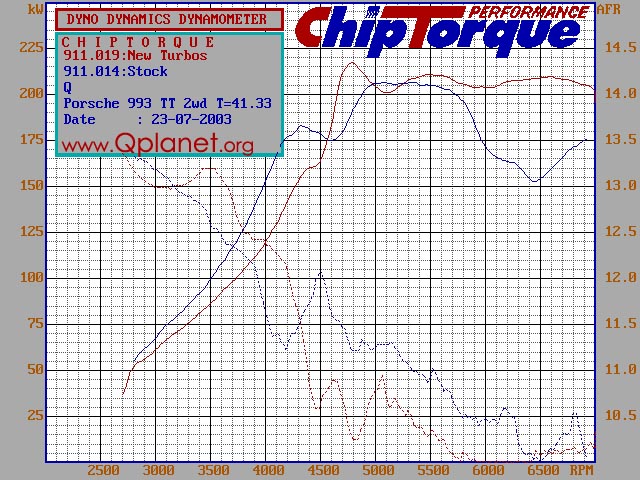

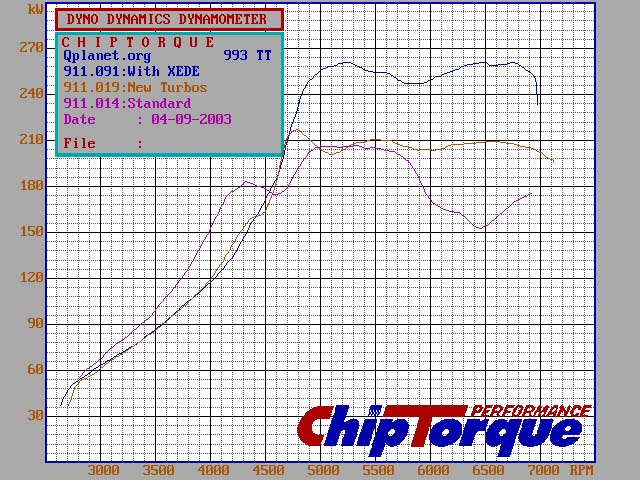

Hybrid turbos deliver in the low end but fail to deliver as good as their larger cousins in the upper end of the RPMs, as seen by TB993TTs test on a properly loaded engine dyno run, and also by real life datalogs.

Large turbos have a more pronounced "lag" which can be somewhat reduced with good mapping and tuning and the right hardware, but lag will always be there!

#18

Heat is the main issues in the smallers turbos - think of the turbo like a bicycle gear. You can get to a certain speed in 1st if you spin like a hamster, but it is much easier in 10th gear, where you can comfortably push with your legs. The cyclist stuck in 1st is going to heat up really fast and wear out. Turbos are similar. The K16 will get up to the same output as the K24 to a degree, but it is spinning so fast the air is superheated and then loses all charge density. One cheater solution used by many import tuners (and now in the 944 turbo world) is to inject water/methanol into the intake after the IC. This fogging mist greatly drops the temps of the superheated charge thru the latent heat of evaporation in the combustion chamber. The end result is also a richening of the mixture. A guy named Laust Petersen has been running mid 20's boost on a stock K26/6 on a 944 and getting more power than many using T04's. Without the injection system the K26 cannot hold more than 16# to redline

#19

I'm thinking of going to maybe K24/super 60's or something to try to move my torque curve about 1000 rpm lower. The big kick in the back happens around 4300 rpm in my car. What I'm worried about is the 'surging' some tuners have seen using too small a wheel.

#20

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Joined: Jun 2001

Posts: 1,398

Likes: 2

From: Australia. >>> Now in Gibraltar

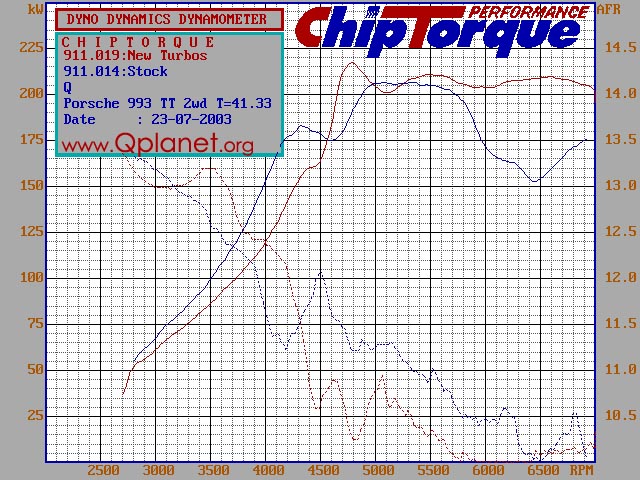

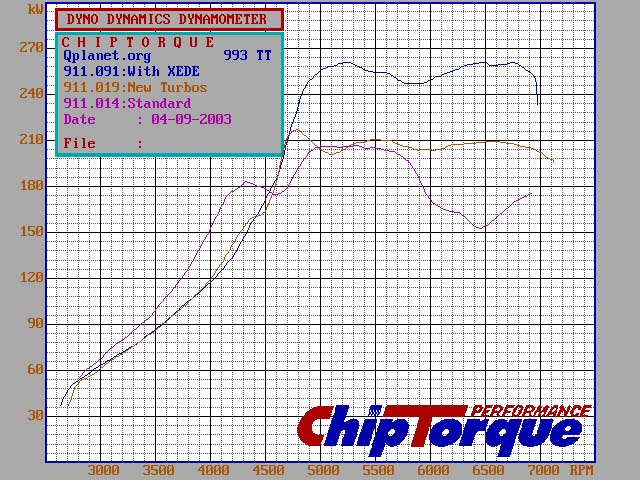

following on from Jean's dyno graph......

I have a dyno sheet of K16's and hiflowed K24's

back to back on the same car, no other modifications,

both using the standard K16 engine mapping

for those who want to know what the differences are in driving the 2 setups

the power curve really does match the way it drives.

these K24's were slow to respond, but the top end felt so smooth and effortless.

it didn't feel boosted, it just felt that is the way it was supposed to be.

adding a remap, and some more boost changed it's behaviour quite dramatically

I have a dyno sheet of K16's and hiflowed K24's

back to back on the same car, no other modifications,

both using the standard K16 engine mapping

for those who want to know what the differences are in driving the 2 setups

the power curve really does match the way it drives.

these K24's were slow to respond, but the top end felt so smooth and effortless.

it didn't feel boosted, it just felt that is the way it was supposed to be.

adding a remap, and some more boost changed it's behaviour quite dramatically

#22

IMO there is not really such thing unless you move to VTGs. You can have a decent sized compressor (K24 or K26) with a smallish K16 turbine that will boost almost as fast as a stock K16, but it will normally also run out of breath faster than a large compressor/large turbine at high revs, as it will create backpressure and heat soak resulting from the faster spinning small wheel.

Hybrid turbos deliver in the low end but fail to deliver as good as their larger cousins in the upper end of the RPMs, as seen by TB993TTs test on a properly loaded engine dyno run, and also by real life datalogs.

Large turbos have a more pronounced "lag" which can be somewhat reduced with good mapping and tuning and the right hardware, but lag will always be there!

Hybrid turbos deliver in the low end but fail to deliver as good as their larger cousins in the upper end of the RPMs, as seen by TB993TTs test on a properly loaded engine dyno run, and also by real life datalogs.

Large turbos have a more pronounced "lag" which can be somewhat reduced with good mapping and tuning and the right hardware, but lag will always be there!

#23

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Joined: Jun 2001

Posts: 1,398

Likes: 2

From: Australia. >>> Now in Gibraltar

In this instance, new compressor wheels were fitted, housings machined, turbine wheel cropped, wastegate enlarged.

My brief to the turbo guy was to hiflow a set of K16's so I would have minimal lag, and some decent top end.

He hiflowed a set of K24's instead so I got everything i did not want....

so I got everything i did not want....

BIG pic HERE

My brief to the turbo guy was to hiflow a set of K16's so I would have minimal lag, and some decent top end.

He hiflowed a set of K24's instead

so I got everything i did not want....

so I got everything i did not want....BIG pic HERE

#24

Some things I've read that I'm not sure about: so if you have hybrids, say K16/24, the turbine and compressor wheel run at the same speed. The K16 part (turbine) spins faster/earlier, but it's directly coupled to the K24 compressor, building boost faster/earlier. ECU keeps boost say at 1.1 bar. With the hybrids, 1.1 bar reached faster (earlier in engine rpm) than say k24/24. I understand up to here okay.

So, why would the hybrid turbines run faster (and build heat "super heat"?). The turbo rpms needed to reach 1.1 bar on the compressor side - isn't it the same - if the compressor is the same - ie. K16/24 vs K24/24. Ie if the compressor side is the same, it would only need to run at a certain rpm to reach 1.1 bar? why would K16/24 run faster than K24/24? they should be runing at the same speed at 1.1 bar.

I would suspect if the turbine and compressor is not 'matched' to a certain extent, the turbine K16 side wouldn't be able to tranfer enough torque (not enough leverage) to turn the larger compressor side as the compressor side gets bigger?

Just trying to understand...

So, why would the hybrid turbines run faster (and build heat "super heat"?). The turbo rpms needed to reach 1.1 bar on the compressor side - isn't it the same - if the compressor is the same - ie. K16/24 vs K24/24. Ie if the compressor side is the same, it would only need to run at a certain rpm to reach 1.1 bar? why would K16/24 run faster than K24/24? they should be runing at the same speed at 1.1 bar.

I would suspect if the turbine and compressor is not 'matched' to a certain extent, the turbine K16 side wouldn't be able to tranfer enough torque (not enough leverage) to turn the larger compressor side as the compressor side gets bigger?

Just trying to understand...

#25

The hybrid turbos will only need to turn the compressor wheel at the same speed as the K24 to achieve the same pressures - correct, but the turbine keeps spinning with the exhaust pressure no matter what. In other words, you cannot control how fast the turbine spins or stop it from spinning past a certain speed. The wheel keeps spinning like a car stuck in a lower gear. The excess pressure is just bled off by the wastegate after 1.1 bar is achieved. This just means the hybrid will bleed off pressure quicker/at a lower engine rpm than the K24. The new VTG turbos CAN bleed off excess exhaust pressure before it overspins the turbine by allowing the vanes to open and bypass the turbine wheel. This is like a "pre-turbine" wastegate.

#26

eclou, Okay thanxs I think I understand. But the waste gates -don't they recirculate or bypass the exhaust gas (to control boost) so the turbine doen't run any faster? Wouldn't the wast gates open at say the 1.1 bar and keep the turbine from spinning faster once 1.1 bar is reached? I thought the wastgate bleeds off exhaust pressure proximal to the turbine (vs the diverters or blow off valves with bleed off the compressed air ( in which case I could see if the diverters were opening that the turbos will keep spinning)). I'm pretty sure that waste gates bleed off exhaust "pre-turbine".

#27

I am even confused by what I wrote. All wastegates bleed off pre-turbine. The pure K24 and the hybrid K24 should have the same shaft speed to produce the same intake pressure, but as the rpms increase the smaller turbine wheel of the hybrid will not be able to flow as much exhaust as the larger turbine and more exhaust pressure and heat will build up in the smaller turbine and then transfer that heat to the compressor side as well.

#28

Depending on which K24 setup one runs, the "lag" is more prominent or less prominent..

On my previous 993TT I ran FVD K24 race turbos with FVD sport cats and muffler bypasses and I was building boost at 2,500RPM or so.. By 3,500RPM I was at full boost if memory serves me correctly. I absolutely loved that setup and my car was a bullet..

I never had a K16 car stay with me with that setup.. In fact the only time I took a loss was against a Yamaha R1 on the highway...

What I find "laggy" is my 996 GT2 K24 setup.. That car has LAG. I dont see boost until 3,000RPM or more. Car only starts to wake up above 3,500RPM.

I think this is the main reason alot of K24 setups are given a bad rep..

On my previous 993TT I ran FVD K24 race turbos with FVD sport cats and muffler bypasses and I was building boost at 2,500RPM or so.. By 3,500RPM I was at full boost if memory serves me correctly. I absolutely loved that setup and my car was a bullet..

I never had a K16 car stay with me with that setup.. In fact the only time I took a loss was against a Yamaha R1 on the highway...

What I find "laggy" is my 996 GT2 K24 setup.. That car has LAG. I dont see boost until 3,000RPM or more. Car only starts to wake up above 3,500RPM.

I think this is the main reason alot of K24 setups are given a bad rep..

#29

I would have thought that pressure/heat/energy would be bled off with the waste gates opening and not be transmitted to the turbos (the extra exhaust gas not going through the turbos but being vented by the waste gates) in the scenario I was going through - and not exposing the smaller turbine turbo to the heat.

It must be that the volume of exhaust gas/energy required to spin/transferred to the K24 compressor (whether K16 or K24 turbine) must be similar for a given turbo RPM, and although the K16 turbine turbo starts spinning earlier/lower engine rpm, there's some 'efficiency' factor that gets maximized at higher turbo/engine rpm at which point the smaller turbos require more exhaust/pressure/engergy/heat to maintain turbo rpm... or something like that....

I'll stop thinking out loud now, I think I've strayed a little from this thread.

Ryojo

It must be that the volume of exhaust gas/energy required to spin/transferred to the K24 compressor (whether K16 or K24 turbine) must be similar for a given turbo RPM, and although the K16 turbine turbo starts spinning earlier/lower engine rpm, there's some 'efficiency' factor that gets maximized at higher turbo/engine rpm at which point the smaller turbos require more exhaust/pressure/engergy/heat to maintain turbo rpm... or something like that....

I'll stop thinking out loud now, I think I've strayed a little from this thread.

Ryojo

#30

With the 996tt forum begining to look like an offshoot of 6speed with lots of talk and little substance I thought I would treat 993tters with some data I found.

This data comes from Flat 6 magazine, the cars are 993tt stock 408PS and 993ttS Euro spec which means K24 and 450PS the gearing is the same for both cars, the temperatures were similar for all the tests

The time between when one hits the throttle pedal and when the turbos spool up and start boosting is one element of "lag" which is never tested for however the other element is using WOT from low revs and timing how long the car takes to accelerate between two times giving us a picture of the boost curve of the turbos.

I have extrapolated approximate rpm's from the before and after speeds to give the following numbers:

K16 K24

3rd gear 3650rpm - 5470rpm 2.8s 3.2s

4th gear 2820rpm-4235rpm 4.1s 4.3s

5th gear 2380rpm-3570rpm 6.2s 6.6s

6th gear 1760rpm-2640rpm 8.6s 10.4s

This data comes from Flat 6 magazine, the cars are 993tt stock 408PS and 993ttS Euro spec which means K24 and 450PS the gearing is the same for both cars, the temperatures were similar for all the tests

The time between when one hits the throttle pedal and when the turbos spool up and start boosting is one element of "lag" which is never tested for however the other element is using WOT from low revs and timing how long the car takes to accelerate between two times giving us a picture of the boost curve of the turbos.

I have extrapolated approximate rpm's from the before and after speeds to give the following numbers:

K16 K24

3rd gear 3650rpm - 5470rpm 2.8s 3.2s

4th gear 2820rpm-4235rpm 4.1s 4.3s

5th gear 2380rpm-3570rpm 6.2s 6.6s

6th gear 1760rpm-2640rpm 8.6s 10.4s

3rd 2.13

4th 3.49

5th 5.62

6th 8.51

ambient temp was 12 deg C