Cylinder head rebuild shop

#1

Advanced

Thread Starter

I searched the forum and I canít find any recent information on who to send my 120k mile cylinder heads for inspection and refresh. Older threads all mention Steve but it doesnít look like he does that work anymore.

Any experience out there on shops doing this work. Ones to use, ones to advoid. Your experiences and recommendations would be appreciated.

thanks. Iím in the upper Midwest but can ship heads anywhere in the US.

Any experience out there on shops doing this work. Ones to use, ones to advoid. Your experiences and recommendations would be appreciated.

thanks. Iím in the upper Midwest but can ship heads anywhere in the US.

#2

Unfortunately, Steve has passed.

He used to work for Rennsport Systems in Oregon. They can be reached at porsche@rennsportsystems.com

He used to work for Rennsport Systems in Oregon. They can be reached at porsche@rennsportsystems.com

#4

Ollie's https://olliesengineering.com/services-pricing/

rothsport https://rothsport.com/

xtreme cyclinder heads

have sent stuff to ollie's and been happy with the work. but ollie's website says not doing headwork, have to call.

had one set of heads done by rothsport, no issues and happy with price and time frame.

only talked with xtreme cylinder heads on the phone, they were booked way out for my time frame.

lots of good comments on the pelican engine rebuilding forum about xtreme.

should be many more good shops. just make sure they have experience with 993 heads and not just porsche in general.

the process is all labor except valve guides and probably exhaust valves. figure around 3 grand.

for shipping you can mount the heads to cam housing to keep things secure and have the shop clean the cam housing also.

still going to cost another 250 or more round trip to ship. so maybe save some money if you can find a local shop.

rothsport https://rothsport.com/

xtreme cyclinder heads

Facebook Post

have sent stuff to ollie's and been happy with the work. but ollie's website says not doing headwork, have to call.

had one set of heads done by rothsport, no issues and happy with price and time frame.

only talked with xtreme cylinder heads on the phone, they were booked way out for my time frame.

lots of good comments on the pelican engine rebuilding forum about xtreme.

should be many more good shops. just make sure they have experience with 993 heads and not just porsche in general.

the process is all labor except valve guides and probably exhaust valves. figure around 3 grand.

for shipping you can mount the heads to cam housing to keep things secure and have the shop clean the cam housing also.

still going to cost another 250 or more round trip to ship. so maybe save some money if you can find a local shop.

#5

Rennlist Member

Unless you are building a world beater race engine, anyone can redo these heads. These are simple 2 valve heads. The world has moved on to 4 and 5 valve variable lift and timing heads which can be tricky. The only real different thing about 993 is the 8 mm valves and their ability to wear out the original guides. Many good indies just do the heads themselves. After drilling out the guides they have pilots and 3 angle cutters and a final old school lap. Any machine shop does these things everyday. Check the rocker bushings and the rocker face. It is all simple stuff as compared to the modern tricky stuff.

I was at Ollie's last month. Tim said they are not doing head work anymore as they are way short of help. They are very busy doing case machining. Contrary to popular opinion these are garden variety head work for the machine shop.

I was at Ollie's last month. Tim said they are not doing head work anymore as they are way short of help. They are very busy doing case machining. Contrary to popular opinion these are garden variety head work for the machine shop.

#6

RL Community Team

Rennlist Member

Rennlist Member

Hi Gjbacci,

May I ask what made you have concerns about the heads and draw the conclusion that they need servicing?

Andy

May I ask what made you have concerns about the heads and draw the conclusion that they need servicing?

Andy

Last edited by pp000830; 05-23-2024 at 10:42 PM.

#7

Advanced

Thread Starter

Nothing in particular. For a 28 year old car with 120k miles it ran well. typical oil leaks around chain case and clogged SAI system. Oil consumption was not bad at less than a quart per thousand. I realize all could have been done with the engine in.

I work on my cars as a hobby. This is one of three sports cars I maintain and the one I have owned the longest since 1999. My home shop is pretty well equipped with a lift and multiple other fun stuff so dropping the engine was enjoyable to me and not particularly difficult. I spent the most time inspecting and cataloging all parts and connections.

I am refreshing and inspecting multiple systems and pulling the engine made everything easier. So on my list is

steering rack rebuild

rear suspension busing re-build (already did the front and have PSS10’s all around

rebuild starter and alternator

address clutch wear

replace engine sound pad

ceracoat blower fan

rewire SAI pump and replace check valve

install new shift linkage and a Short shift kit

have Speedline wheels refurbished

reprogram immobilizer thru ECU doctors

inspect pistons and assuming they are good which I inspect re-ring

inspect cams, chains, etc. replace chain followers

have a shop clean, inspect and repair as necessary cylinder heads

Probably some other things I forgot to mention. Just a fun project to refresh an awesome car.

I work on my cars as a hobby. This is one of three sports cars I maintain and the one I have owned the longest since 1999. My home shop is pretty well equipped with a lift and multiple other fun stuff so dropping the engine was enjoyable to me and not particularly difficult. I spent the most time inspecting and cataloging all parts and connections.

I am refreshing and inspecting multiple systems and pulling the engine made everything easier. So on my list is

steering rack rebuild

rear suspension busing re-build (already did the front and have PSS10’s all around

rebuild starter and alternator

address clutch wear

replace engine sound pad

ceracoat blower fan

rewire SAI pump and replace check valve

install new shift linkage and a Short shift kit

have Speedline wheels refurbished

reprogram immobilizer thru ECU doctors

inspect pistons and assuming they are good which I inspect re-ring

inspect cams, chains, etc. replace chain followers

have a shop clean, inspect and repair as necessary cylinder heads

Probably some other things I forgot to mention. Just a fun project to refresh an awesome car.

Trending Topics

#8

Rennlist Member

You are fully competent to all the work that you mentioned except for machine shop work. That is one of the great things about these cars, you can easily work on them as a hobby and have fun. The work itself can be hard at times but the expertise required is general in nature. The cars are simple and being German they come apart and go back together without drama. A little sweat and blood mixed in with the beer makes a good day out in the garage.

** for the heads , pull the springs and do the wiggle test. The valve guides will be shot. Then off to a good local machine shop.

* Also while you have it apart, send the injectors out for cleaning and measuring. They will all be a combination of leaking and/or poor spray pattern and will vary by at least 40% on fuel delivery. Low cost and they will be like new.

* The alternator will be trickier than what you are used to on other cars as the bearing setup is way different and the bearings are not common. Check for part availability before tearing into it.

* Measure the cylinders and they will be good at only 120,000 miles. A bottle brush hone will break up the glaze but a quick run through with a real Sunnan stone hone at the machine shop is always best. Then new rings

* for the rear suspension the bushings are not just a rebushing like the front control arms. The rear control arm comprise of a non replaceable ball joint which will be OK but not great The trailing leg bushing is a rubber unit that can be sourced from Elephant Racing. However the hooker is the forward leg is a monoball like bushing that is not replaceable and you will find that is shot. At 120+ K miles it is gone and will show movement besides being loose. New control arms are the only remedy. Dansk makes an excellent aftermarket one for a lot less money than the Porsche one. On the lower rear link aka"toe link" which goes through the carrier and picks up the lower mount of the shock will have the ball joint worn out and it is not replaceable. The other links, KT and camber may be OK for the ball joint but the 30 year old inboard bushings need to be replaced with quality ones from Elephant.

Have fun I am in the same process with my 1995 993.

** for the heads , pull the springs and do the wiggle test. The valve guides will be shot. Then off to a good local machine shop.

* Also while you have it apart, send the injectors out for cleaning and measuring. They will all be a combination of leaking and/or poor spray pattern and will vary by at least 40% on fuel delivery. Low cost and they will be like new.

* The alternator will be trickier than what you are used to on other cars as the bearing setup is way different and the bearings are not common. Check for part availability before tearing into it.

* Measure the cylinders and they will be good at only 120,000 miles. A bottle brush hone will break up the glaze but a quick run through with a real Sunnan stone hone at the machine shop is always best. Then new rings

* for the rear suspension the bushings are not just a rebushing like the front control arms. The rear control arm comprise of a non replaceable ball joint which will be OK but not great The trailing leg bushing is a rubber unit that can be sourced from Elephant Racing. However the hooker is the forward leg is a monoball like bushing that is not replaceable and you will find that is shot. At 120+ K miles it is gone and will show movement besides being loose. New control arms are the only remedy. Dansk makes an excellent aftermarket one for a lot less money than the Porsche one. On the lower rear link aka"toe link" which goes through the carrier and picks up the lower mount of the shock will have the ball joint worn out and it is not replaceable. The other links, KT and camber may be OK for the ball joint but the 30 year old inboard bushings need to be replaced with quality ones from Elephant.

Have fun I am in the same process with my 1995 993.

#9

Advanced

Thread Starter

Great stuff Floyd

Thank you much.

You didn’t mention anything about the rear subframe bushings, or did I not understand the descriptions.

With the engine out I’m just getting into the rear end inspection.

thanks again. This forum and contributors like you also make these cars great.

Thank you much.

You didn’t mention anything about the rear subframe bushings, or did I not understand the descriptions.

With the engine out I’m just getting into the rear end inspection.

thanks again. This forum and contributors like you also make these cars great.

#10

Race Car

Not sure where you're at, but in the Northeast, you may want to reach out to Mark at Exotech.

I had Mark machine my heads, new valve guides (valve guides were TOAST at 68k mi), exhaust valves, etc a few years ago when I did a top end rebuild myself. Old school shop, nothing fancy about it. Did a great job.

He's a local PCA club member and racer.

http://exotechpower.com

If you end up replacing your cams (check for pitting), plan to have your rocker arms reground. Steve Weiner did mine when he was still around.

I had Mark machine my heads, new valve guides (valve guides were TOAST at 68k mi), exhaust valves, etc a few years ago when I did a top end rebuild myself. Old school shop, nothing fancy about it. Did a great job.

He's a local PCA club member and racer.

http://exotechpower.com

If you end up replacing your cams (check for pitting), plan to have your rocker arms reground. Steve Weiner did mine when he was still around.

Last edited by 95_993; 05-23-2024 at 08:29 AM.

The following users liked this post:

dalves11 (05-23-2024)

#11

RL Community Team

Rennlist Member

Rennlist Member

The reason why I asked is we now have examples of these cars with over a quarter million miles on the odometer that run just fine and do not have internal engine issues.

Even though, if it gives you satisfaction and it is not too expensive to break down the engine and do a top-end rebuild go for it!

Andy

Last edited by pp000830; 05-23-2024 at 10:42 PM.

#12

Rennlist Member

To your post #9 above about rear subframe bushing. The rear subframe bushings are very large and are not really involved in constant motion of the rear suspension like all the suspension parts are. They purely serve as isolators and although 30 years old they have no visable cracks or checking and still have good resiliency when poked. Therefore I did not change them. To that point, the 993 is the first 911 to ever have rear suspension system isolation.

When you take the rear suspension elements apart you will have the "V" shaped control arm, and 3 dog bone shaped links. The links are : 1) upper rear most is the "KT" (kinematic toe link; 2) the rear lower link is the "toe " control link and the forward upper link is the camber adjust link.

don't forget to refresh (new ) the sway bar bushings, drop links and rear strut top hats as they take a real beating due to dealing with the weight of the engine/trans. If it is rubber then it worn and definitely aged out. Also check your ride height before you take it apart. My car with pure stock ,original USA ride height suspension was actually within one mm of the ROW ride height. the springs had sagged that much. I replaced the springs with the OEM ROW ones (not the 030 or 033 ones) and when all done the suspension now sits at the same height but correct for the ROW setup. I went with the new Bilstein Porsche Classic struts and the car drives just like a brand new car as it should.

When you take the rear suspension elements apart you will have the "V" shaped control arm, and 3 dog bone shaped links. The links are : 1) upper rear most is the "KT" (kinematic toe link; 2) the rear lower link is the "toe " control link and the forward upper link is the camber adjust link.

don't forget to refresh (new ) the sway bar bushings, drop links and rear strut top hats as they take a real beating due to dealing with the weight of the engine/trans. If it is rubber then it worn and definitely aged out. Also check your ride height before you take it apart. My car with pure stock ,original USA ride height suspension was actually within one mm of the ROW ride height. the springs had sagged that much. I replaced the springs with the OEM ROW ones (not the 030 or 033 ones) and when all done the suspension now sits at the same height but correct for the ROW setup. I went with the new Bilstein Porsche Classic struts and the car drives just like a brand new car as it should.

#13

Rennlist Member

I searched the forum and I canít find any recent information on who to send my 120k mile cylinder heads for inspection and refresh. Older threads all mention Steve but it doesnít look like he does that work anymore.

Any experience out there on shops doing this work. Ones to use, ones to advoid. Your experiences and recommendations would be appreciated.

thanks. Iím in the upper Midwest but can ship heads anywhere in the US.

Any experience out there on shops doing this work. Ones to use, ones to advoid. Your experiences and recommendations would be appreciated.

thanks. Iím in the upper Midwest but can ship heads anywhere in the US.

So in short, I would DEFINITELY recommend Walt! (more RL advice!

)

)Maybe Steve had an "off" day and this isn't a post to disparage him, but just a reminder to proceed with caution despite anyone's online reputation. I can't tell you NOT to use him obviously because he's not around anymore, the only advice I can give you is to do your own research outside of the forums. Ask for references, ask WHO will be doing the actual work, how it will be done (hopefully not with a black and decker beltsander like it looks in my case) and what their ultimate gameplan is. Hopefully that will give you the information and confidence to move forward with someone you can trust so you don't have to do it twice like I did.

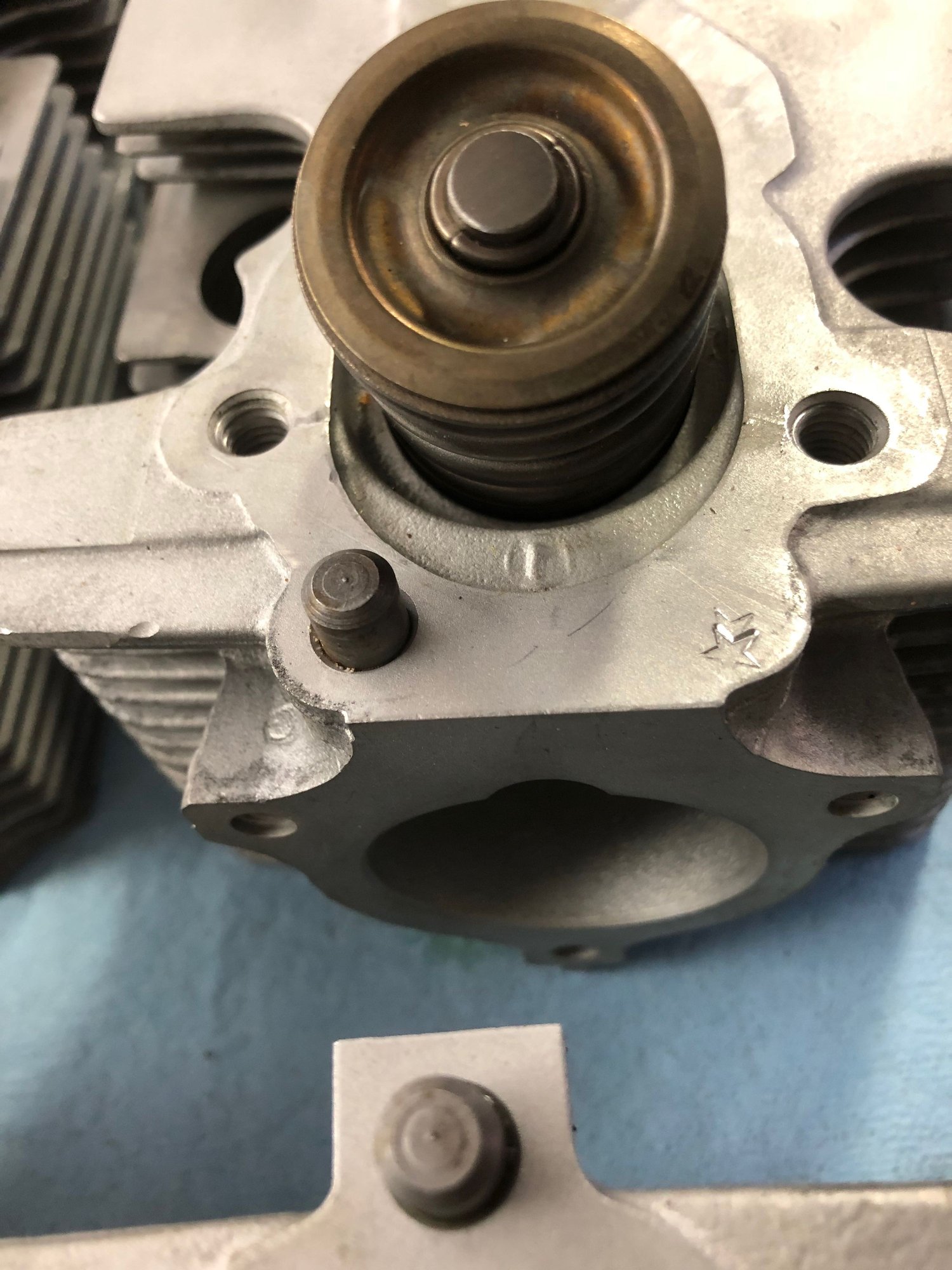

Just a couple pics of what I got back from Rennsport systems:

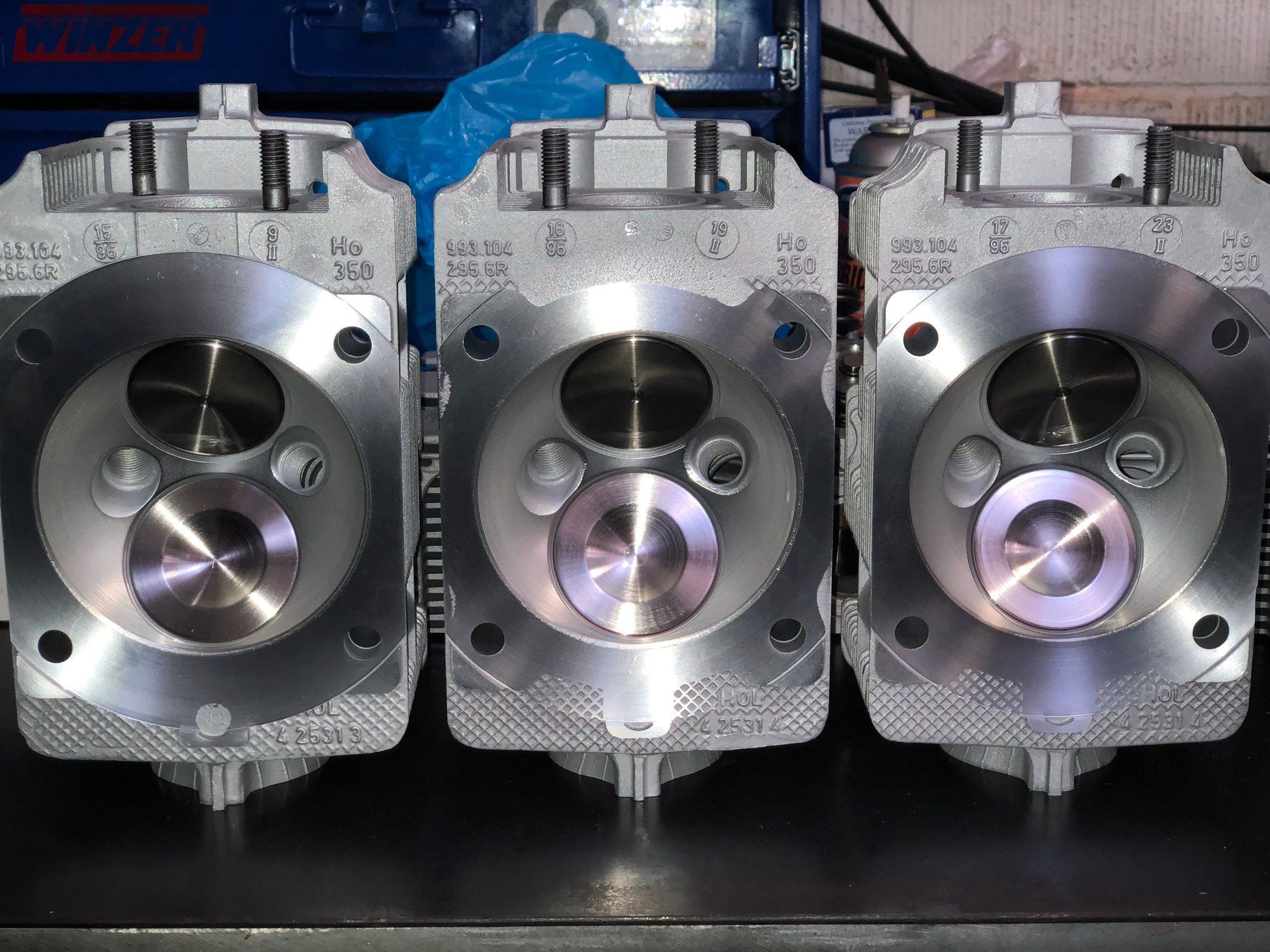

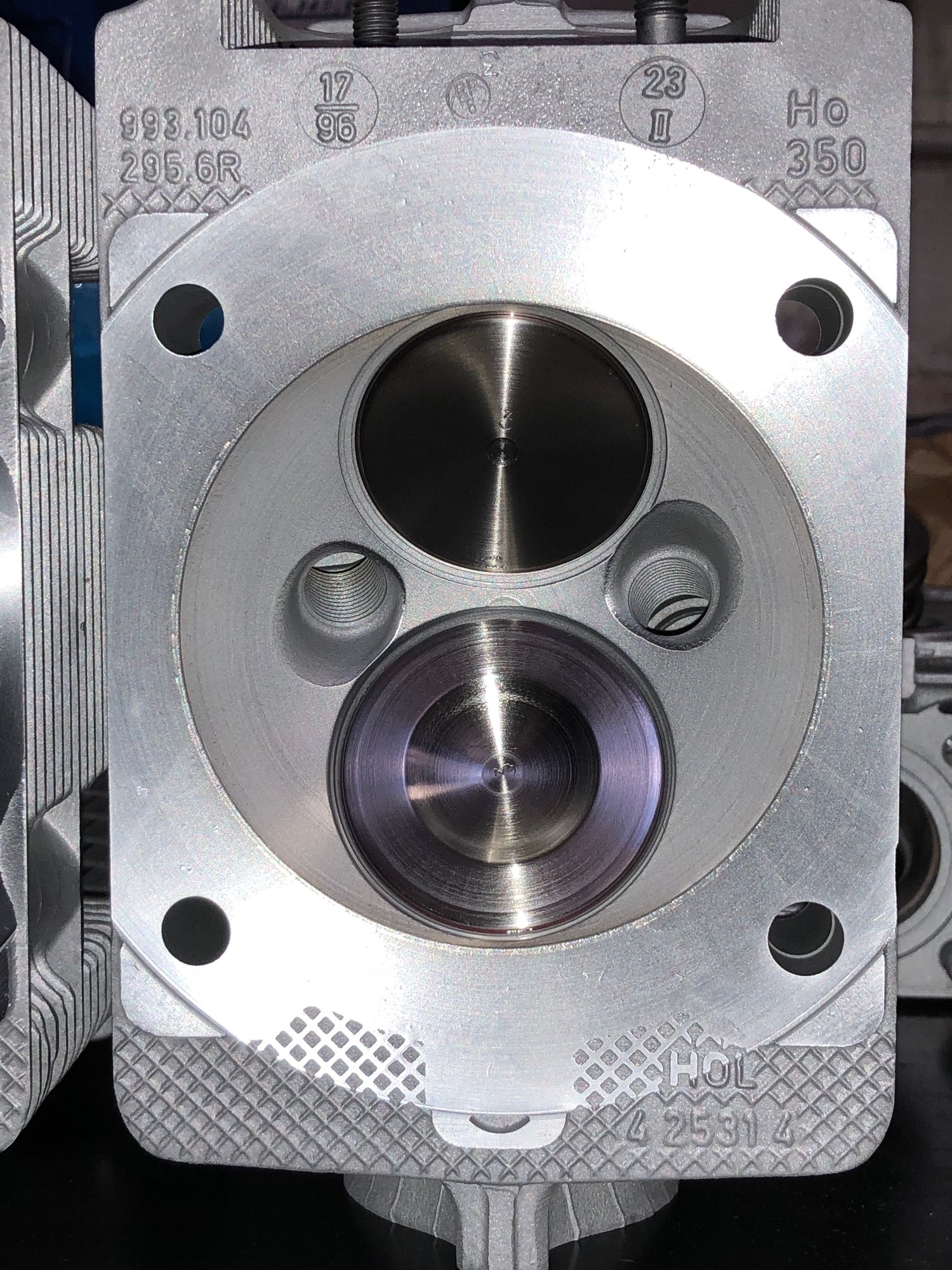

And after getting them back from Competition Engineering:

#14

Rennlist Member

It would be interesting to know what did not work when you got the heads back from Rennsport. What work were they supposed tp do other than valves and guides?

CE has been around forever. I knew Ray Litz and he did case machining work on my 356 stuff. He had a bunch of fixtures for doing all kinds of work for his mills. For doing "go-fast" stuff you do need to some tricky machining. It was easy for him as he did not have to go through a special set up for each operation. This made him good, fast and not expensive. It was fun to go see him at the shop when he was in Altadena. All gone now..

CE has been around forever. I knew Ray Litz and he did case machining work on my 356 stuff. He had a bunch of fixtures for doing all kinds of work for his mills. For doing "go-fast" stuff you do need to some tricky machining. It was easy for him as he did not have to go through a special set up for each operation. This made him good, fast and not expensive. It was fun to go see him at the shop when he was in Altadena. All gone now..

#15

Rennlist Member

It would be interesting to know what did not work when you got the heads back from Rennsport. What work were they supposed tp do other than valves and guides?

CE has been around forever. I knew Ray Litz and he did case machining work on my 356 stuff. He had a bunch of fixtures for doing all kinds of work for his mills. For doing "go-fast" stuff you do need to some tricky machining. It was easy for him as he did not have to go through a special set up for each operation. This made him good, fast and not expensive. It was fun to go see him at the shop when he was in Altadena. All gone now..

CE has been around forever. I knew Ray Litz and he did case machining work on my 356 stuff. He had a bunch of fixtures for doing all kinds of work for his mills. For doing "go-fast" stuff you do need to some tricky machining. It was easy for him as he did not have to go through a special set up for each operation. This made him good, fast and not expensive. It was fun to go see him at the shop when he was in Altadena. All gone now..

As far as my heads were concerned, aside from being dirty and having worn guides, these were virgin heads when I sent them out. They were as manufactured and had never seen a machinist. When they came back they were still filthy. Some literally had spiderwebs in the fins. That was the least of my issues though. Whoever machined them had also not only butchered them (look at the pics in my original post to see the gouges and very imperfect surfaces), but had also stamped a star on the mating surface (WHY???). When my mechanic got them he was flabbergasted and called me to tell me to come over and look. There was no question that they needed to at least get Walt's eyes on them. Here's what Walt had to say when he got them:

"The heads are filthy! Dirt and debris are visible on the valve stems and inside the ports/ 3 valve springs were upside down. " No biggie" 4 Springs were getting rusty! Guides were sized perfectly! Seats seem to have been machined at a different angle than the valves. This makes the valves seem to have little or no contact point on the seats. A leak down test of all valves in their installed position shows fair to poor seating. The stem heights are within spec. But vary as much as .28mm. " Not great! But not terrible." Exhaust valves have been heavily ground, yet some valves still show pitting on the 45 Surface. Porsche suggests replacing the Ex. valves and not grinding them. Cylinder surfaces have been cut and the finish is quite rough. As though a dull or improper bit was used. The cylinder surfaces are never to be cut more than .2mm. And they are supposed to have a surface finish of at least 32 micro inches, according to Porsche. These were FAR Worse than 32. And have a runout of as much as .10mm and vary head to head by over .065mm. We are not sure how the held the heads to machine them. Or how well the mating surface was prepped that contacts their fixture.They had a Star stamped into the mating surface of the cam tower area that displaced metal as high as .177 mm. Strange place to stamp a head. ) "

So I mean I guess he sized the guides perfectly, so that's a plus? But obviously we needed to redo the valve job. So in addition to the $1500 I sent Rennsport Systems to butcher my heads yet size the valve guides perfectly, I was on the hook for an additional $1500 for Walt's work to fix them. A big bummer for me and a painful lesson learned which is what I was hoping to pass along (I'm clearly still a bit raw about it).