991.2 - Water Cooled Intercoolers

#1

I know there are several bits and pieces out there on intercooler sprayers but I am hoping to come up with more difinitive information.

Based on what I could find it appears that the sprayers are most commonly applied using a lower pressure high volume sprayer, washer pump. Using a larger 3-5 Gallon tank in the frunk the Distilled/DI water is pumped and injection on the outside just before the intercoolers in the direction to the air stream.

So the questions are as follows?

1.) When on track do you run the sprayers 100% of the time or boost actuate with a time delay?

2.) Any clues on what nozzles provide the best atomization, flow...?

Any other tips or suggestions?

Based on what I could find it appears that the sprayers are most commonly applied using a lower pressure high volume sprayer, washer pump. Using a larger 3-5 Gallon tank in the frunk the Distilled/DI water is pumped and injection on the outside just before the intercoolers in the direction to the air stream.

So the questions are as follows?

1.) When on track do you run the sprayers 100% of the time or boost actuate with a time delay?

2.) Any clues on what nozzles provide the best atomization, flow...?

Any other tips or suggestions?

Last edited by dsddcd; 05-03-2020 at 01:43 PM.

#2

In the past using methanol/water injection I have had success using a kit designed specifically for it such as the Sno performance kits as they come with the correct pump and nozzles. I had mine activated at a certain boost pressure on my old setup. I would not want it on 100% of the time as it could lead to serious issues at low/part throttle (over fueling and/or hydrolocking).

#3

I know there are several bits and pieces out there on intercooler sprayers but I am hoping to come up with more difinitive information.

Based on what I could find it appears that the sprayers are most commonly applied using a lower pressure high volume sprayer, washer pump. Using a larger 3-5 Gallon tank in the frunk the Distilled/DI water is pumped and injection just before the intercoolers in the direction to the air stream.

So the questions are as follows?

1.) When on track do you run the sprayers 100% of the time or boost actuate with a time delay?

2.) Any clues on what nozzles provide the best atomization, flow...?

Any other tips or suggestions?

Based on what I could find it appears that the sprayers are most commonly applied using a lower pressure high volume sprayer, washer pump. Using a larger 3-5 Gallon tank in the frunk the Distilled/DI water is pumped and injection just before the intercoolers in the direction to the air stream.

So the questions are as follows?

1.) When on track do you run the sprayers 100% of the time or boost actuate with a time delay?

2.) Any clues on what nozzles provide the best atomization, flow...?

Any other tips or suggestions?

There are various ways of controlling when you want to spray the intercooler.

1. Temperature delta between IC outlet temps and ambient.

2. Boost pressure.

3. Injector DC

4. Throttle position

5. Absolute IC outlet temp

6. Combinations of the above.

Some version of 1, 5 and 3 would be ideal.

Depending on how you set up your IC sprayer you will have it more useful/functional and save water.

Lots of DIY options available with IC sprayer controllers available. Some are just based on absolute temps, some factor in delta between ambient and IC outlet temps, some look at injector DC etc. How fancy do you want to get, and do you want to start cutting into the engine harness?

I used to have an IC sprayer on my RX-7, until I just went to a much larger air-air intercooler (not front mount). I didn't drag race, so never had to worry about heat soak and even in rarely had issues. They do the job very well, but I think should have some sort of controller

#4

In the past using methanol/water injection I have had success using a kit designed specifically for it such as the Sno performance kits as they come with the correct pump and nozzles. I had mine activated at a certain boost pressure on my old setup. I would not want it on 100% of the time as it could lead to serious issues at low/part throttle (over fueling and/or hydrolocking).

#5

Agriculture nozzles (for spraying weeds etc) for commercial use are excellent options. Durable, readily available, and capable of creating a VERY fine mist.

There are various ways of controlling when you want to spray the intercooler.

1. Temperature delta between IC outlet temps and ambient.

2. Boost pressure.

3. Injector DC

4. Throttle position

5. Absolute IC outlet temp

6. Combinations of the above.

Some version of 1, 5 and 3 would be ideal.

Depending on how you set up your IC sprayer you will have it more useful/functional and save water.

Lots of DIY options available with IC sprayer controllers available. Some are just based on absolute temps, some factor in delta between ambient and IC outlet temps, some look at injector DC etc. How fancy do you want to get, and do you want to start cutting into the engine harness?

I used to have an IC sprayer on my RX-7, until I just went to a much larger air-air intercooler (not front mount). I didn't drag race, so never had to worry about heat soak and even in rarely had issues. They do the job very well, but I think should have some sort of controller

There are various ways of controlling when you want to spray the intercooler.

1. Temperature delta between IC outlet temps and ambient.

2. Boost pressure.

3. Injector DC

4. Throttle position

5. Absolute IC outlet temp

6. Combinations of the above.

Some version of 1, 5 and 3 would be ideal.

Depending on how you set up your IC sprayer you will have it more useful/functional and save water.

Lots of DIY options available with IC sprayer controllers available. Some are just based on absolute temps, some factor in delta between ambient and IC outlet temps, some look at injector DC etc. How fancy do you want to get, and do you want to start cutting into the engine harness?

I used to have an IC sprayer on my RX-7, until I just went to a much larger air-air intercooler (not front mount). I didn't drag race, so never had to worry about heat soak and even in rarely had issues. They do the job very well, but I think should have some sort of controller

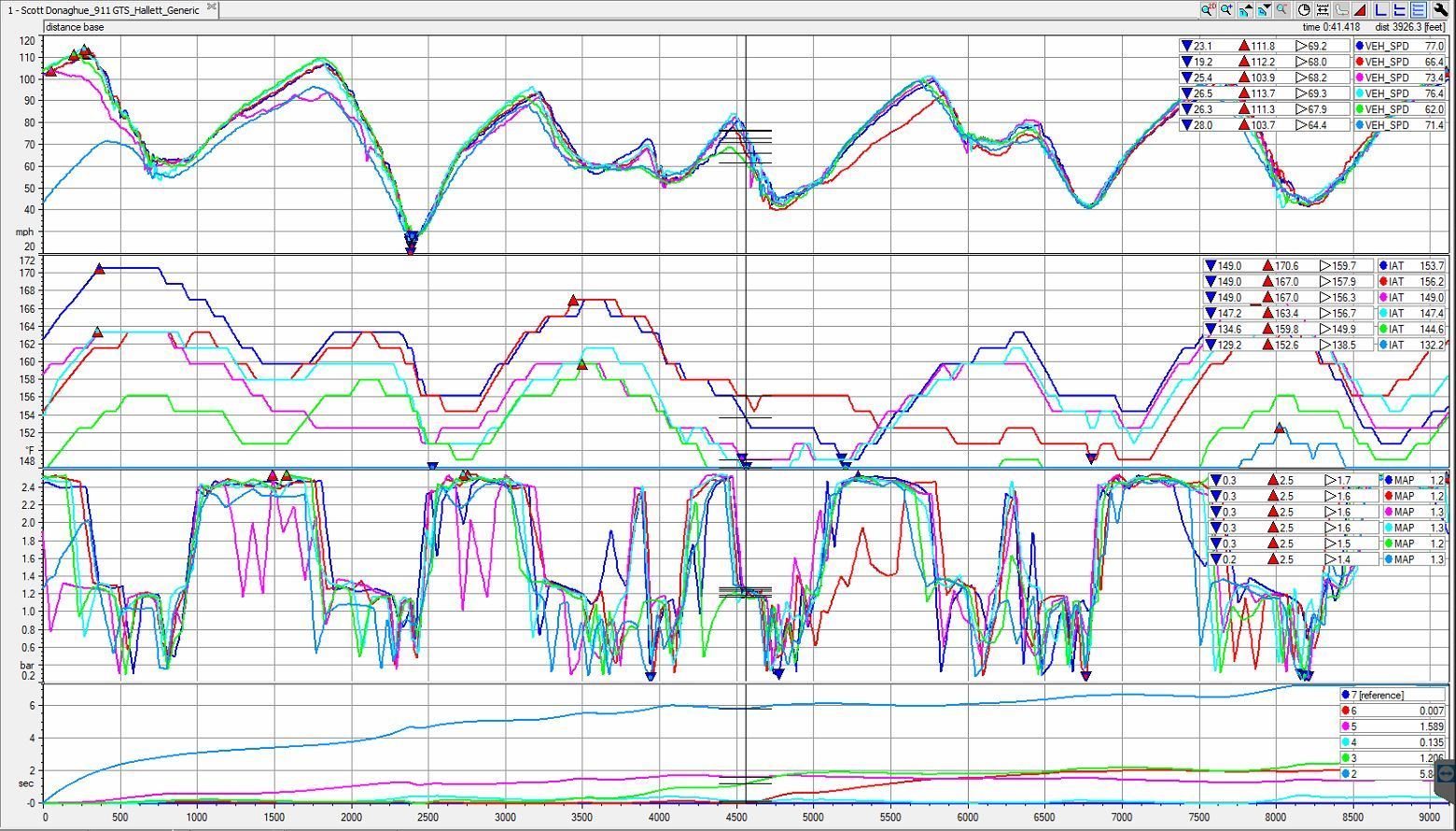

100% agree with a controller, controlling on discharge/IAT temperatures would be the most logical as this is a direct measurement but wonder if you could set up the PID well enough to get good results. To prevent cycling of the system you would want a deadband but would also need to control off of the rate of heating so it did not start spraying until after you come off the throttle. Watching my IAT logs I have noticed that there is quite a bit of heat soak in the system. In theory you could quell that by monitoring the IAT's and once they reached say 140░F the system would turn on and run for 1 min unless the temperatures stayed above the threshold then it would continue until the value was satisfied for 1min. The graph below illustrates the rise from 130░F to 170░F over a 20min time frame, the high IAT's were pulling boost and I was losing power on a 75░F day. I have seen IAT's as high as 190░ on an 80░F day and know that when the real heat comes in that the car will likely go into limp mode on me again.

#6

Here's a little video of the stock intercooler sprayer system on the 2019 Subaru STI S209. It seems it can reduce IAT by about 10C.

https://www.autoblog.com/2020/04/24/...sprayer-video/

If doing a custom controller, I would make it relatively simple. The sprayer would activate only when WOT and the IAT is above a specific temperature. If it's cool enough, the sprayer will not activate even if you're WOT in order to avoid wasting water. If the IATs are above the target temperature, but you're not WOT, then the sprayer will not activate because you're not demanding full power. You can also do a manual control like on the Subaru so that if it's cool but you still want some more cooling, you can activate the water sprayer.

https://www.autoblog.com/2020/04/24/...sprayer-video/

If doing a custom controller, I would make it relatively simple. The sprayer would activate only when WOT and the IAT is above a specific temperature. If it's cool enough, the sprayer will not activate even if you're WOT in order to avoid wasting water. If the IATs are above the target temperature, but you're not WOT, then the sprayer will not activate because you're not demanding full power. You can also do a manual control like on the Subaru so that if it's cool but you still want some more cooling, you can activate the water sprayer.

The following users liked this post:

AdamSanta85 (11-27-2023)

#7

This is a bit more invasive then an external sprayer and that is to ditch air to air cooling and go right to water jacket based cooling coupled with using the AC to chill the water. http://www.speedhunters.com/2017/08/...-boost-charge/

Trending Topics

#9

bump as this is proper spot for this discussion

I guess 122 degrees IAT and 90% TPS input would be a good place to start

https://www.motortrend.com/features/...2068%20degrees.

Heres a place that has generic kit and some spare parts, if we could just solve the clean IAT/TPS input/output I think the rest of this could be completed in a weekend.

I agree with using the factory bottle, just debating using the existing pump or adding another. I checked the 2RS diagram and it looks like it just has its own windshield pump.

https://www.coolingmist.co.uk/index....product_id=137

I guess 122 degrees IAT and 90% TPS input would be a good place to start

and a system that sprays water on the intercooler matrix when intake air temperatures exceed 122 degrees F, with 90 percent throttle openings, can reduce intake air temperature by as much as 68 degrees.

Preuninger says early in the GT2 RS' development, the powertrain engineers figured the system would be worth looking at if it showed a reduction of 40 degrees, and they were stunned when testing showed reductions of up to 60 degrees. "It's a real example of how you can't calculate everything," he says. "You have to try stuff out."

The water spray system is fed by a 1.3-gallon tank, and because of its extreme operating parameters, Preuninger says it won't often need refilling. If it does run dry, the engine management system simply dials back the available power. Refilling the tank, which is mounted in the trunk and easily accessible, is as easy as buying a bottle of distilled water.

Preuninger says early in the GT2 RS' development, the powertrain engineers figured the system would be worth looking at if it showed a reduction of 40 degrees, and they were stunned when testing showed reductions of up to 60 degrees. "It's a real example of how you can't calculate everything," he says. "You have to try stuff out."

The water spray system is fed by a 1.3-gallon tank, and because of its extreme operating parameters, Preuninger says it won't often need refilling. If it does run dry, the engine management system simply dials back the available power. Refilling the tank, which is mounted in the trunk and easily accessible, is as easy as buying a bottle of distilled water.

Heres a place that has generic kit and some spare parts, if we could just solve the clean IAT/TPS input/output I think the rest of this could be completed in a weekend.

I agree with using the factory bottle, just debating using the existing pump or adding another. I checked the 2RS diagram and it looks like it just has its own windshield pump.

https://www.coolingmist.co.uk/index....product_id=137

Last edited by AdamSanta85; 11-27-2023 at 04:06 PM.

The following users liked this post:

IRunalot (11-28-2023)