Ferodo DS 1.11 pad wear with Radi-Cal setup

#31

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Right up front I will state I am a big fan of Essex and Clark. I have had issues in the past with another brand of pads that have been mentioned in this thread and they took care of me without question. The manufacturer of those other pads told me literally I was using the pads incorrectly. Do a search, my issue was on a BMW but there are plenty of delaminating / crumbling pads from that other brand on 991 GT3's. The difference is that Ferodo reformulated their pads.

Ferodo has been outstanding to deal with over the years. We have a very long history with them, and they place a priority on our input. We talk with them and get shipments from them every week. There is constant communication, and they are incredibly responsive to our needs. That is not the case with many brake pad suppliers. Many (if not most) are out of touch with their customer base, isolated behind many layers of distribution. They are also committed to keeping their customers happy.

__________________

'09 Carrera 2S, '08 Boxster LE (orange), '91 Acura NSX, Tesla Model 3 Performance, Fiesta ST

Jeff Ritter

Mgr. High Performance Division, Essex Parts Services

Essex Designed AP Racing Radi-CAL Competition Brake Kits & 2-piece J Hook Discs

Ferodo Racing Brake Pads

Spiegler Stainless Steel Brake Lines

704-824-6030

jeff.ritter@essexparts.com

'09 Carrera 2S, '08 Boxster LE (orange), '91 Acura NSX, Tesla Model 3 Performance, Fiesta ST

Jeff Ritter

Mgr. High Performance Division, Essex Parts Services

Essex Designed AP Racing Radi-CAL Competition Brake Kits & 2-piece J Hook Discs

Ferodo Racing Brake Pads

Spiegler Stainless Steel Brake Lines

704-824-6030

jeff.ritter@essexparts.com

#32

Have you ever taken, and do you have the capability to take disc temperatures? Knowing the temps you're hitting could be extremely helpful in selecting components. If your disc temps are crazy high, you're going to be hell on pads no matter who made them. The solution there would be to try and get your disc temps down. If you're discs are running hot, everything downstream of them is hot. Hot discs= hot pads= hot pistons= hot calipers=hot fluid. Heat is the enemy, and you always have to try and get to the root of the problem.

Regardless, Jeff, it's nice to see a vendor and company step up. Before-sales customer service is easy, it's the after-sales customer care that distinguishes the good from the bad.

#33

Rennlist Member

Join Date: Jan 2013

Location: West Vancouver and San Francisco

Posts: 4,281

Received 1,258 Likes

on

613 Posts

Some small chunks coming off the edges is normal and not problematic. Having half the pad come off is NOT normal.

MaxLTV and Jadski,

MaxLTV and Jadski,

- When did you buy those pads that had the large chunks come off the back plate?

- Did you ask the person who sold you those pads for assistance at the time the issue occurred?

#34

Good question. I was referring to the stock iron red brakes. The stock pads take more pedal effort than some of the higher friction compounds out there, but many would consider that a good thing (harder to trigger ABS on initial pressure, more force range to modulate over).

#35

Rennlist Member

Join Date: Jan 2013

Location: West Vancouver and San Francisco

Posts: 4,281

Received 1,258 Likes

on

613 Posts

I only used the early (2014-2015) versions of stock pads and I believe the compound was changed in 2016 or 2015 after I stopped using stock pads, but the stock pads that I used were tapering and wearing much faster than Ferodo DS1.11 or even PFC11 and were wearing rotors faster as well. I know for sure that the newer compound fixed tapering to a large extent if not completely, but not sure about wear of pads and rotors.

#36

Rennlist Member

The set I posted pictures of came from Apex in July 2016 and I got another set from the same source in August 2017 (same issue) and another one that my mechanic installed in early 2017, but I don't know when or where he got them from. All 3 had some crumbling, but only two sets failed with most of the material flying off the pad. I gave these pads another try despite crumbling because I really like how they feel (less grabby, easier to modulate) and low rotor wear. Switched to RE10 for now. Clark from Apex reached out and offered a complementary set, which I definitely appreciate.

Another vote for Clark at Apex and Jeff at Essex. both have tremendous integrity and great customer service.

While i might try the new Ferodo compound again down the road, I am very happy with the RE10's from Clark so far....

#37

Race Director

I hope Essex - Ferodo get to the bottom of this and let us know what the cause of these Ferodo pads either crumbling apart or wearing out super quick was. I do appreciate Jeff from Essex being very involved on this forum for us. Also Clark at apexperformance.net is a great store to buy from. I've stopped by his store many times on business trips and also ordered from him on line. Luckly Clark sell Pagid and RE10 pads and many many other things for this hobby.

I tried Ferodo and they didn't work well for me. PFC doesn't make a pad for my car. I am back to Pagid and having the usual consistent good results I've had over the years with them. However its sort of fun to try different things and I want to see how RE10 pads compare for me.

I tried Ferodo and they didn't work well for me. PFC doesn't make a pad for my car. I am back to Pagid and having the usual consistent good results I've had over the years with them. However its sort of fun to try different things and I want to see how RE10 pads compare for me.

#38

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

[

I tried Ferodo and they didn't work well for me. PFC doesn't make a pad for my car. I am back to Pagid and having the usual consistent good results I've had over the years with them. However its sort of fun to try different things and I want to see how RE10 pads compare for me.[/QUOTE]

MIke RE-10s are not available for the rear of your car.

I tried Ferodo and they didn't work well for me. PFC doesn't make a pad for my car. I am back to Pagid and having the usual consistent good results I've had over the years with them. However its sort of fun to try different things and I want to see how RE10 pads compare for me.[/QUOTE]

MIke RE-10s are not available for the rear of your car.

__________________

Clark

ApexPerformance.net

Premier Racing Outfitters

Toll free: 866-505-2739

Direct: 843-299-0997

EM: chamerly@apexperformance.net

www.apexperformance.net

Save 10% on your next order over $75 on most items- enter Promocode Rennlist-10 on your next order or mention Rennlist during your phone order.

PCA Club Racing - National Sponsor

Clark

ApexPerformance.net

Premier Racing Outfitters

Toll free: 866-505-2739

Direct: 843-299-0997

EM: chamerly@apexperformance.net

www.apexperformance.net

Save 10% on your next order over $75 on most items- enter Promocode Rennlist-10 on your next order or mention Rennlist during your phone order.

PCA Club Racing - National Sponsor

#39

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

I hope Essex - Ferodo get to the bottom of this and let us know what the cause of these Ferodo pads either crumbling apart or wearing out super quick was. I do appreciate Jeff from Essex being very involved on this forum for us. Also Clark at apexperformance.net is a great store to buy from. I've stopped by his store many times on business trips and also ordered from him on line. Luckly Clark sell Pagid and RE10 pads and many many other things for this hobby.

I tried Ferodo and they didn't work well for me. PFC doesn't make a pad for my car. I am back to Pagid and having the usual consistent good results I've had over the years with them. However its sort of fun to try different things and I want to see how RE10 pads compare for me.

I tried Ferodo and they didn't work well for me. PFC doesn't make a pad for my car. I am back to Pagid and having the usual consistent good results I've had over the years with them. However its sort of fun to try different things and I want to see how RE10 pads compare for me.

In terms of wear rate, there are two sides to that coin. As I noted above, both the disc wear rates and the pad wear rates need to be considered. There are no freebies involved unfortunately. If you run extremely abrasive pads, they'll devour your discs. That is even more true if you run the car cold at all (to and from the track, around town, canyon carving). The DS1.11 is a softer compound than some of the others on the market, which makes them incredibly kind to discs. We've had customers get incredible durability out of our AP Racing discs (and other brand discs) when running the DS1.11. The composition of the DS1.11 also makes them far easier to bed-in vs. some of the competing pad brands, and they don't have as many problems with judder and vibration. All of these factors need to be considered, and the DS1.11 typically hits the sweet spot when all facets of the user experience is considered.

For people running other types of discs, a potential long-term cost savings strategy would be to switch to AP Racing discs which tend to flow more air, run cooler, and last longer than anything else on the market. As I described in detail above, starting with a cool disc increases the longevity of the disc itself, pads, fluid, ball joints near the discs, etc. There are far-reaching benefits of keeping overall brake temps down.

#40

Race Director

^^^ thanks Jeff...makes sense to me...

#41

Pro

Just removed my second set of ferrodo s no issues what so ever, even wear and no flaking

Clark from apex is fantastic to work with

Last edited by Ddesimone17; 02-06-2019 at 10:29 PM.

#42

I had Pagid RS29 which I was very happy with and also tried the Ferodo DS1.11. Hard to describe but it just doesn’t have the same ‘feel’. Probably will go back to Pagid. Has anyone tried Endless CCRG?

#43

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

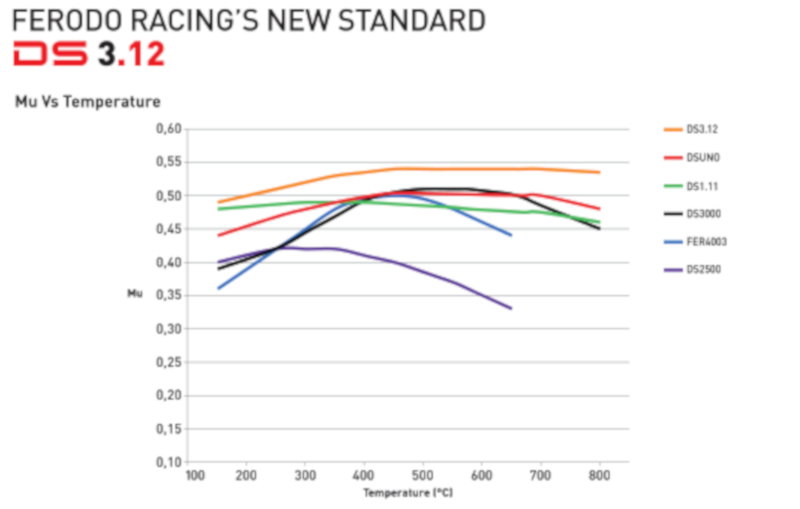

FYI...The new Ferodo DS3.12 compound is in production now. Higher mu, flatter torque curve, and longer wear than any previous Ferodo compound. We should have them in a few weeks most likely. Thanks.

#44

Thanks. I’m not very knowledgeable in this area but what does the higher mu and flatter torque curve mean on the track?

#45

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

There are physics involved, but I'll try not to get too brake nerdy and stick with the language that enthusiasts typically use to describe these forces, feelings, behaviors, etc. ��

Coefficient of Friction and Maximum Operating Temperature

Any time you rub two objects against each other friction is generated. In this case we're rubbing a semi-metallic brake pad against a spinning iron disc. Mu μ {\displaystyle \mu } refers to the coefficient of friction of the pad compound. In simple terms, that means the amount of friction that exists between the brake pads and disc. The mu value for most brake pads falls within the 0.3 to 0.6 range. The closer a pad's mu value is to zero, the less friction exists between the pad and disc. Pads with a low coefficient of friction are often described as feeling wooden, not having much bite or grab, or the driver feels like they must press the brake pedal with a lot of force to get the car to slow. Conversely, a pad with a mu value closer to one feels like it doesn’t require as much leg effort for the pad to 'bite' into the disc and slow the car. If the mu is too high however, the brakes may feel like a light switch. They’re either on or off, and difficult to control with varied pedal pressure (modulation). Breathing on them lightly or trail braking could prove difficult. The best pad compounds hit a sweet spot in terms of balancing pedal pressure and controllability.

What makes mu both interesting and complicated is that it changes constantly with temperature. The Holy Grail of brake pads would be a compound that has a perfectly flat mu curve across the entire temperature range from zero degrees to the highest temperature the pad would ever reach (for the typical HPDE driver or club racer that is approximately 1400°F). Such a pad would exhibit a linear response through the brake pedal, regardless of where and how it was being driven. From the driver’s perspective, that would mean every time they pressed the brake pedal with the same amount of force, the car would feel as if it slowed at the same rate. That consistent feedback loop would allow the driver to dial in their brain and leg to precisely control the car’s response. Each time they approached a turn, they would feel confident about how the car was going to react when they stepped on the brake pedal. When trying to shave a tenth of a second at every turn, one can imagine how valuable that would be!

Unfortunately, most pad materials have a narrow temperature window in which they generate a given amount of mu. Depending on the pad’s constituent materials, that temperature window may be what you experience when driving to the grocery store (street pads optimized for low temps), or it may be the temperatures you experience on Lap 6 at Watkins Glen (race pads optimized for high temps). To this day, no pad material exists that generates the same mu across its entire operating temperature range.

Pads also have a maximum operating temperature, which is the highest temperature at which the material can still generate friction. At some elevated temperature, any given pad is going to start burning more quickly, melting, vaporizing, etc. At that point it can no longer generate any friction on the disc face, and its mu tapers towards zero. Even though the brake pedal may still feel firm, the car doesn’t slow because very little friction is being generated between the pad and disc. That is what is referred to as pad fade. In these situations, the pad can also stick to the disc face in globs, smear, and create high spots that cause judder and vibration. We frequently see this when people drive street pads on the racetrack, because street pads have a lower maximum operating temperature than race pads and are not optimized to generate mu at track temps. What is particularly scary about some street pads, is that once they approach their maximum operating temperature their mu falls off a cliff and rapidly approaches zero. In real world terms, that means the driver doesn’t receive any warning. On one stop the car slows as expected, and on the next the pedal stays hard but the car doesn’t slow.

With a typical race pad, mu is low when the pad material is cold. If you push hard on the brake pedal, it doesn't feel as if the pads are gripping the brake disc very hard. Many people refer to this pad attribute as its 'cold bite'. As the disc and pad temperatures rise however, mu increases, and the driver doesn’t have to press very hard for them to grab the brake disc. Track pads also have more gradually tapering mu when temperatures get extremely high, which means they give more warning as they approach their max operating temperature.

Looking at a Brake Dyno Plot

The first thing to consider when looking at a brake dyno graph is that all brake dynamometers are different. One can view this situation exactly like engine dynos. The mu numbers one manufacturer claims or generates on their dyno aren’t comparable to the numbers generated by another manufacturer. The machines are different and the test parameters are different: number of brake events, different stop durations, different amount of time between stops, different caliper pressures, etc. We constantly see people on the forums comparing mu values across pad manufacturers but doing so is futile. A Pagid pad that Pagid claims has a mu of 0.5 at 1000°F is not the same as a Ferodo pad that Ferodo claims has a mu of 0.5 at 1000°F. No comparative conclusions can be drawn from looking at mu graphs from different manufacturers. The only value of a manufacturer’s brake dyno graph is to compare within that manufacturer’s line of brake pads (assuming the same procedures and machine were used to produce the results for all data on that graph). For example, comparing the Ferodo DS2500 to the DS3.12 on a Ferodo dyno plot is a valid comparison. The specific numbers are essentially irrelevant since you can’t compare them to other brands (unless you have your own brake dyno), but the shape of the curve and relative differences between the Ferodo pad compounds does provide valuable information. Again, ignore the actual numbers and focus on the relative differences and the shape of the curves.

The above is one of the reasons why Essex built our own brake dyno, so we can do comparative testing both for ourselves and for our race team customers. We can conduct apples-to-apples pad tests, and we know what we have before its ever run on a car. We also don’t have to blindly accept a manufacturer’s data. We find out on our own what we have, and how it compares to other available products that we’ve tested on our dyno via our own procedures.

On to the dyno graph! The dyno below was provided by Ferodo, but we’ve seen similar relative results on our own Essex brake dyno. The value in this graph is the relative differences across the Ferodo compounds. If we look at the new DS3.12 plot (orange line), we see that it has higher mu across the board from stone cold to searing hot vs. any prior Ferodo compound. That means the DS3.12 is always going to feel as if it requires less pedal effort vs. the DS1.11, regardless of whether you’re on your morning commute or driving a session at Road America. With the DS3.12 you won’t have to press the pedal as hard to slow the car.

What’s shocking about the DS3.12 is that it exhibits almost no variation in mu across an amazingly wide temperature range. Out of all the pad compounds we’ve ever tested, from all manufacturers, the DS3.12 shows the flattest torque curve across the broadest temperature range. On track, most of our customers will be running their pads in the 700-1400°F range (400-750°C). Across that range, the mu curve for DS3.12 is table-top flat. That means that on every turn, on every track you drive, on every lap, your brake pedal is going to feel almost exactly the same, providing tremendous consistency and repeatability.

What we also noted on our dyno about the DS3.12 that cannot be seen on the dyno graph, is the compound’s response to varying pressures. When we test a pad we vary the clamp load on the pad and disc. The DS3.12 shows an amazingly linear response to varying pressures, which is not the case for many other pad compounds we’ve tested over the years. Again, that is going to lead to incredible consistency and repeatability.

If you look at the DS1.11 plot (green line), you can see that it responds a bit differently vs. the DS3.12. As temperature rises, mu tapers off gradually. What that feels like as you go deeper into a brake event, is that you must press a little harder on the pedal to get the desired response from the pad. Some people like having to press harder, because it feels natural to them. Others don’t and prefer a more linear pressure throughout the entire stop, which is what the DS3.12 offers. There is no good or bad in this case, and the feel you prefer is completely a matter of personal preference.

In summary, the DS3.12’s incredibly flat torque curve and linear response to varying pressures both contribute to a tremendous amount of control. Once you calibrate your brain and leg to the DS3.12’s higher mu level, which requires less leg pressure, it should be the ultimate pad for threshold braking while controlling ABS intervention. Given our aggregate dyno data, the data Ferodo has collected from racecars in Europe, and our own field testing here in the USA, we believe the DS3.12 may be a homerun for many of our customers. As a bonus, we also have evidence from some tests that indicates the DS3.12 could last up to 20% longer than the DS1.11 under certain conditions, further enhancing its desirability. We’ll see how that plays out in the field, but we are extremely excited about this pad. It is a truly world-class compound that achieves some things we have never seen before.