Throttle Cable/Switch Question

#1

I took off my intake to clean it after 175k worth of dirt and air. As I'm putting it back together I can't remember if the throttle cable should be slightly open or be resting on the contact on the intake. Can someone provide guidance? I'd hate to rev to 6k after putting this thing back together. I couldn't find anymore slack in the cable am I missing something?

#2

if i understand your question correctly--- the answer is this: when the throttle is closed, there should be contact with the idle control valve microswitch. if there is not, the car will not idle properly, as this switch sends a signal to the dme to control the idle. i had this problem after putting in new rubber intake tubes---the allignment was not the same, and i had to adjust the throttle cable in order to reestablish proper contact with the idle control microswitch. hope this helps---tomj

#4

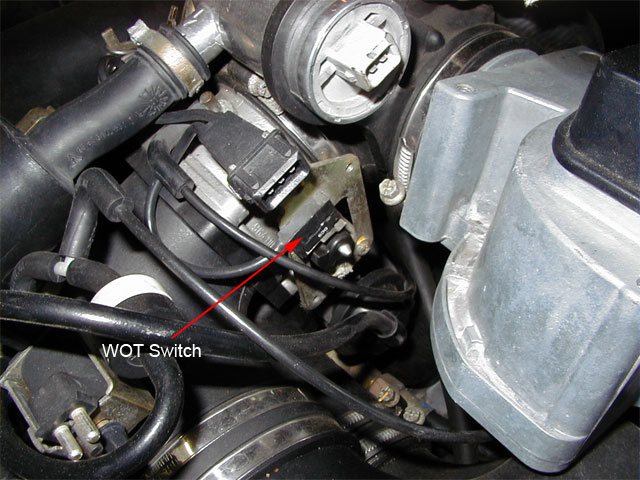

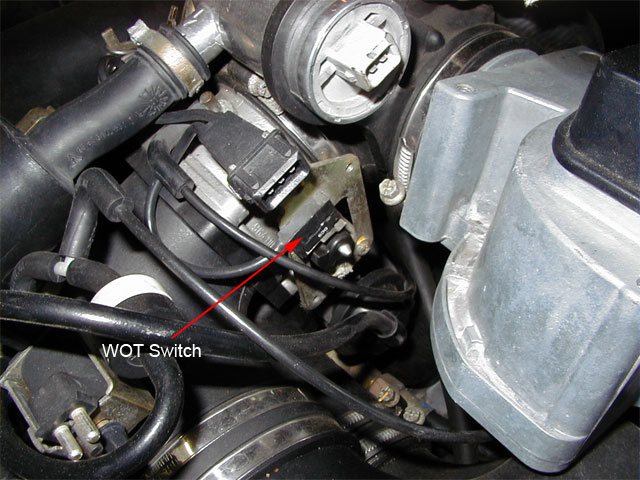

You can tighten or loosen the throttle cable with the adjusting nut located behind the accelerator pedal. You want the idle switch to activate and the throttle plate to close completely at off-throttle and you want the WOT switch to activate at 78% or greater throttle opening.

Last edited by JasonAndreas; 09-25-2007 at 12:48 AM.

#5

Jason,

I always thought of the nut behind the pedal as the final adjustment !!

The cable adjust is under the gearbox ,plastic nut and thread . typical PIA !!

Geoff

----------------------------------------------------------------

KS400200,the oldest 964 on Rennlist,unless you know differently !

I always thought of the nut behind the pedal as the final adjustment !!

The cable adjust is under the gearbox ,plastic nut and thread . typical PIA !!

Geoff

----------------------------------------------------------------

KS400200,the oldest 964 on Rennlist,unless you know differently !

#6

elliottc,

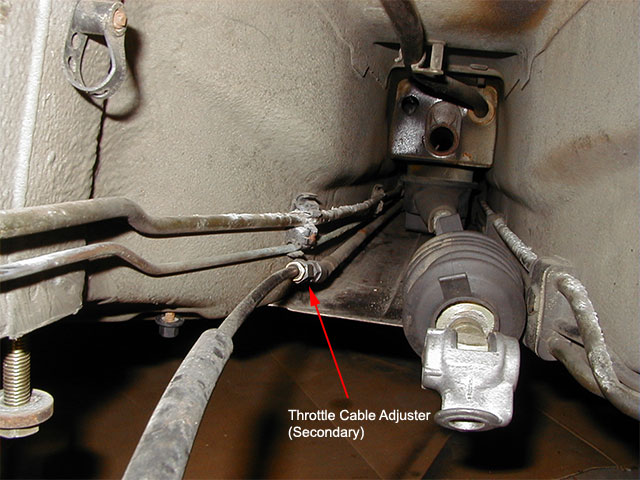

Here is the other adjustment location, you will have to remove the transmission undertray to get at it.

#7

Jason,

Understood .Sorry if my nut response sounded flippant but I have come across 964s where the nut behind the pedal has been adjusted to the maximum ,

the pedal still cannot acheive full throttle etc .

The in-line adjustment needs to be about right before moving to the pedal.

I know the adjust under the gearbox is a tricky one but this is a 964 !!

At 17F I would not even start on throttle adjust !!

Geoff

----------------------------------------------------------------

KS400200,the oldest 964 on Rennlist,unless you know differently !

Understood .Sorry if my nut response sounded flippant but I have come across 964s where the nut behind the pedal has been adjusted to the maximum ,

the pedal still cannot acheive full throttle etc .

The in-line adjustment needs to be about right before moving to the pedal.

I know the adjust under the gearbox is a tricky one but this is a 964 !!

At 17F I would not even start on throttle adjust !!

Geoff

----------------------------------------------------------------

KS400200,the oldest 964 on Rennlist,unless you know differently !

Trending Topics

#9

The diagnostic interface tool and software will also indicate whether you are getting Full and closed throttle switches. The interface indicates it, and you can make adjustments with the car off.

The pedal adjustment can make a difference. I have adjusted mine as it was way off.. I haven't messed with the one in the tunnel as the software was indicating that it is getting the correct signals.

The pedal adjustment can make a difference. I have adjusted mine as it was way off.. I haven't messed with the one in the tunnel as the software was indicating that it is getting the correct signals.

#10

I know this is resurrecting a zombie, however I had the same issue and found this thread pretty useful in troubleshooting. However I can correct a few things form above to make it easier for the next person:

1) There are two adjustments for the accelerator pedal in the footwell:

a) one rod connects to the pedal itself. This can be adjusted in or out to change the height of the pedal.

b) a second rod is on the end of the accelerator cable, where it comes out of the tunnel right near the floor. Adjusting this one directly changes the length of the accelerator cable but there is not a lot to play with (at least on mine), maybe 1/2"

To adjust either of these just pop off the ball end, hold that with pliers, and loosen the 8mm jam nut. Once loose, spin the ball end in or out as needed and then re-tighten the jam nut.

2) There is one adjustment in the tunnel (picture in post 6 above). This takes a 10mm open end wrench (if I remember right). Closing the gap (screwing the pieces together) effectively lengthens the accelerator cable, and opening the gap (screwing the pieces apart) shortens the cable. This is very non-intuitive (at least it was for me) however it worked. I.e.: my 1990 C2 throttle mechanism was resting almost 3/8" above the idle microswitch...screwing the tunnel connector together closed the gap leaving the throttle resting on the microswitch. This is a really easy adjustment, only the transmission cover needs to come off, not the tunnel cover; only takes 5 min.

No more check engine light on startup and a more stable idle to boot.

1) There are two adjustments for the accelerator pedal in the footwell:

a) one rod connects to the pedal itself. This can be adjusted in or out to change the height of the pedal.

b) a second rod is on the end of the accelerator cable, where it comes out of the tunnel right near the floor. Adjusting this one directly changes the length of the accelerator cable but there is not a lot to play with (at least on mine), maybe 1/2"

To adjust either of these just pop off the ball end, hold that with pliers, and loosen the 8mm jam nut. Once loose, spin the ball end in or out as needed and then re-tighten the jam nut.

2) There is one adjustment in the tunnel (picture in post 6 above). This takes a 10mm open end wrench (if I remember right). Closing the gap (screwing the pieces together) effectively lengthens the accelerator cable, and opening the gap (screwing the pieces apart) shortens the cable. This is very non-intuitive (at least it was for me) however it worked. I.e.: my 1990 C2 throttle mechanism was resting almost 3/8" above the idle microswitch...screwing the tunnel connector together closed the gap leaving the throttle resting on the microswitch. This is a really easy adjustment, only the transmission cover needs to come off, not the tunnel cover; only takes 5 min.

No more check engine light on startup and a more stable idle to boot.