Oil line question...

#1

Instructor

Thread Starter

Join Date: Feb 2005

Location: Louisville, Ohio

Posts: 172

Likes: 0

Received 0 Likes

on

0 Posts

Hey guys, I just spent the last three nights fighting with every bolt to remove the drivers side heat exchanger. Got to love 16 years of road grime !  I have a leak at the black fitting in the picture below. My question to you guys is...

I have a leak at the black fitting in the picture below. My question to you guys is...

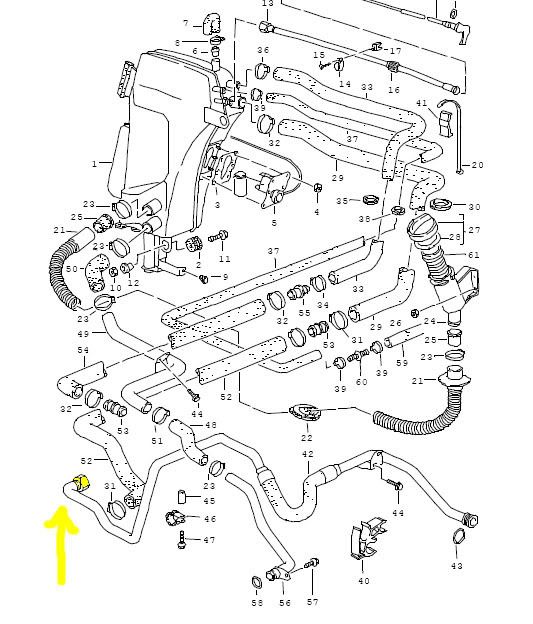

I loosened the outer black pipe fitting which is a compresion fitting on the inner threaded fitting. Should I remove the fitting from the case and clean/reinstall or can I just retighten and then reassemble the outer fitting? Should I worry about a torque setting or over tightening ? Are there any o rings/seals here? I robbed this picture from another post mine was definitely leaking.

I have a leak at the black fitting in the picture below. My question to you guys is...

I have a leak at the black fitting in the picture below. My question to you guys is...I loosened the outer black pipe fitting which is a compresion fitting on the inner threaded fitting. Should I remove the fitting from the case and clean/reinstall or can I just retighten and then reassemble the outer fitting? Should I worry about a torque setting or over tightening ? Are there any o rings/seals here? I robbed this picture from another post mine was definitely leaking.

#2

Seared

Rennlist Member

Rennlist Member

Brian,

I think it's just a compression fitting and I'm sure the shop manual calls for a specific torque value. I would keep the case-mounted fitting intact while removing the compression nut.

Although this PET image is for the 993, I have the feeling that this line is very similar. It does not show an o-ring:

Andreas

I think it's just a compression fitting and I'm sure the shop manual calls for a specific torque value. I would keep the case-mounted fitting intact while removing the compression nut.

Although this PET image is for the 993, I have the feeling that this line is very similar. It does not show an o-ring:

Andreas

#5

Instructor

Thread Starter

Join Date: Feb 2005

Location: Louisville, Ohio

Posts: 172

Likes: 0

Received 0 Likes

on

0 Posts

I may have a problem

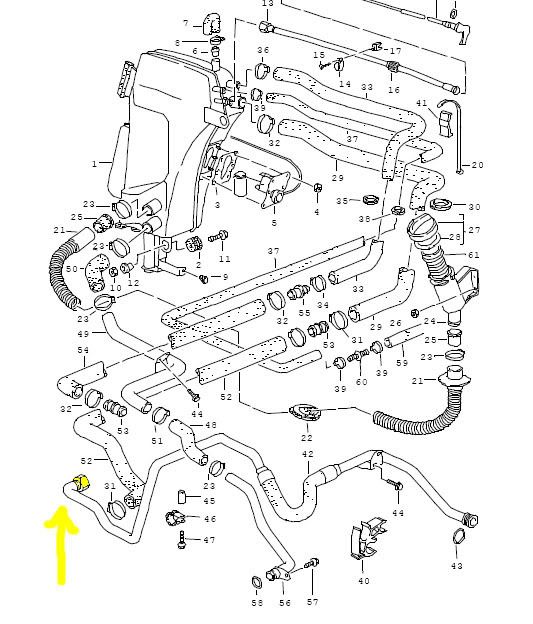

after removing the fitting/cleaning and reinstalling, running engine and hoping for no leaks I discovered what appears to be a crack in the case -look in picture right below black fitting.

Am I screwed or are there options ??

after removing the fitting/cleaning and reinstalling, running engine and hoping for no leaks I discovered what appears to be a crack in the case -look in picture right below black fitting.

Am I screwed or are there options ??

#6

RL Community Team

Rennlist Member

Rennlist Member

You will either need to band-aid it, using JB-Weld or similar agent to try to seal it temporarily, or deal with it properly: remove the engine and take the case to an aluminum welder to weld up the site, and re-tap it for the fitting. That means complete engine rebuild including bottom end...

Trending Topics

#8

Technical Guru

Rennlist Member

Rennlist Member

There is a slight chance you could TIG weld that without removing the engine and with the car on a hydraulic lift but you would definitely need to replace the oil return tube o-ring. For future reference the torque spec on the screw neck is 51.6 ft-lbs.

#9

Seared

Rennlist Member

Rennlist Member

Have you confirmed the crack by degreasing the area and allowing the engine to run for a few minutes? Did you hold the inner fitting in place with a wrench while tightening the compression fitting? If not, the tightening action may have caused the case-side fitting to thread further - possibly causing a fracture.

For your sake, I hope it's just a casting flaw.

Andreas

For your sake, I hope it's just a casting flaw.

Andreas

#10

RL Community Team

Rennlist Member

Rennlist Member

I like Jason's idea as long as the crack is only on the bottom and is accessible to the welder - I wonder if they can weld that without letting crap into the oil port - that's why I initially thought that engine disassembly was the safest bet.

Easiest thing to try is to leave it all attached, use brake cleaner to clean it all up, blow it dry, then mix up some JB-weld and wipe it around so it gets into the cracked area. If I were in your shoes, that would be my first thing to try. Give it plenty of time to cure, then see what happens. If it still leaks (which I think is unlikely) then you're off to the welder's shop!

Easiest thing to try is to leave it all attached, use brake cleaner to clean it all up, blow it dry, then mix up some JB-weld and wipe it around so it gets into the cracked area. If I were in your shoes, that would be my first thing to try. Give it plenty of time to cure, then see what happens. If it still leaks (which I think is unlikely) then you're off to the welder's shop!

#11

Instructor

Thread Starter

Join Date: Feb 2005

Location: Louisville, Ohio

Posts: 172

Likes: 0

Received 0 Likes

on

0 Posts

First of all thanks for all the advise guys.  I decided to go the cheap fix route. I took my time and cleaned around the fitting really well. I scratched the surface with sand paper and a small die grinder bit along the stress crack. I cleaned really well again and then JB Welded around the area. I let it sit overnight,

I decided to go the cheap fix route. I took my time and cleaned around the fitting really well. I scratched the surface with sand paper and a small die grinder bit along the stress crack. I cleaned really well again and then JB Welded around the area. I let it sit overnight,  said a few prayers

said a few prayers  and I feel I got lucky! No leak after running,reassembly and an hour drive.

and I feel I got lucky! No leak after running,reassembly and an hour drive.

Time will tell if the repair lasts.....

I decided to go the cheap fix route. I took my time and cleaned around the fitting really well. I scratched the surface with sand paper and a small die grinder bit along the stress crack. I cleaned really well again and then JB Welded around the area. I let it sit overnight,

I decided to go the cheap fix route. I took my time and cleaned around the fitting really well. I scratched the surface with sand paper and a small die grinder bit along the stress crack. I cleaned really well again and then JB Welded around the area. I let it sit overnight,  said a few prayers

said a few prayers

Time will tell if the repair lasts.....

-now back to my project !

-now back to my project !