My front roll center/bump steer solution

#61

Burning Brakes

It isn't 100% clear to me from these pictures, but could someone confirm if the rear inner trailing arm attachment points are raised on this car? It looks like there's some sort of spacer added at the attachment points, but I can't quite tell. If so, does anybody know how far the attachment points are raised? Just trying to understand if the factory took measures to level out the roll axis by raising the rear roll center after they raised the front roll center by relocating the control arm attachment points. Makes sense that they would have, just want to confirm. Thanks.

Edit: Hmmm... For some reason, this post didn't capture the pictures I was referring to. See Post 41 from Michael Mount to view the pictures of the rear suspension that I'm referring to.

Edit: Hmmm... For some reason, this post didn't capture the pictures I was referring to. See Post 41 from Michael Mount to view the pictures of the rear suspension that I'm referring to.

#62

Race Car

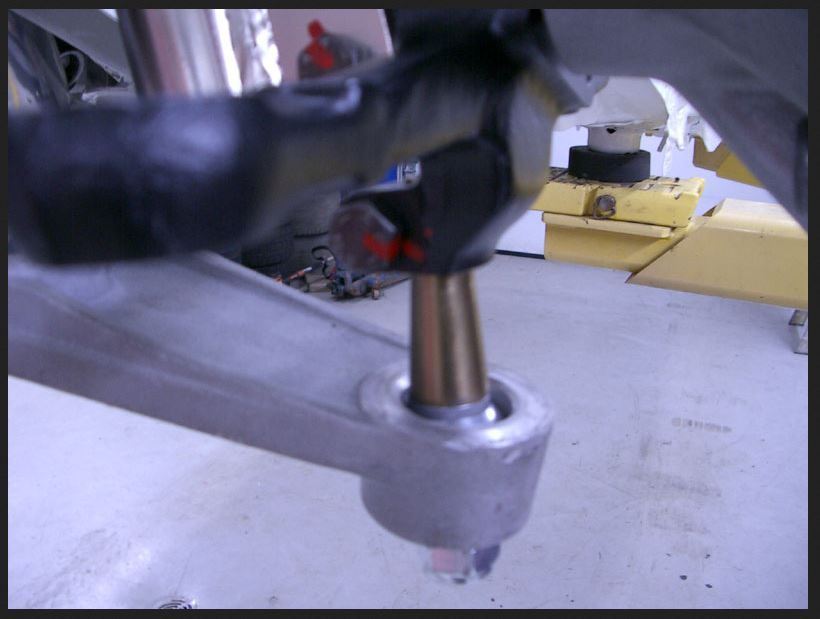

Ok, bumping this because we are packing up for Barber this coming weekend so I decided to replace both ball joint pins as a precaution and found one side that was fairly new (1-2 track weekends) that had a hairline crack and was ready to snap at any time.

Does anybody here have the capacity/access to CNC mill if I supply the CAD file of factory dimension a-arm with cylindrical pocket for a spherical bearing that will lock in place with internal snap rings/grooves for a serviceable/replaceable pin.

If we DNF from the lead this weekend, I am strapping a bundle of stock a-arms to the top of Elon Musk's next launch to Mars.

T

Does anybody here have the capacity/access to CNC mill if I supply the CAD file of factory dimension a-arm with cylindrical pocket for a spherical bearing that will lock in place with internal snap rings/grooves for a serviceable/replaceable pin.

If we DNF from the lead this weekend, I am strapping a bundle of stock a-arms to the top of Elon Musk's next launch to Mars.

T

#63

Three Wheelin'

Thread Starter

Ok, bumping this because we are packing up for Barber this coming weekend so I decided to replace both ball joint pins as a precaution and found one side that was fairly new (1-2 track weekends) that had a hairline crack and was ready to snap at any time.

Does anybody here have the capacity/access to CNC mill if I supply the CAD file of factory dimension a-arm with cylindrical pocket for a spherical bearing that will lock in place with internal snap rings/grooves for a serviceable/replaceable pin.

If we DNF from the lead this weekend, I am strapping a bundle of stock a-arms to the top of Elon Musk's next launch to Mars.

T

Does anybody here have the capacity/access to CNC mill if I supply the CAD file of factory dimension a-arm with cylindrical pocket for a spherical bearing that will lock in place with internal snap rings/grooves for a serviceable/replaceable pin.

If we DNF from the lead this weekend, I am strapping a bundle of stock a-arms to the top of Elon Musk's next launch to Mars.

T

#64

Race Car

17mm, 1 inch extended length.

Ran the 19s before though, but the slotted pinch bolt area on spindle is weakened and you are just moving failure point somewhere else.

I would go the route you did but we travel pretty far distances to race and it's always a best served intention to keep parts/spares as non-specialty as possible.

Potentially, in stable, we'll have 4 cars.

Can't justify paying $6500 for 4 sets, $1600 each of aftermarket a-arms.

I had this ball rolling and my friend has stalled out on it.

Meeting up with a RL/racer Kovakis at Barber to see if we can collaborate on this.

Still welcoming any people who want in,

T

Ran the 19s before though, but the slotted pinch bolt area on spindle is weakened and you are just moving failure point somewhere else.

I would go the route you did but we travel pretty far distances to race and it's always a best served intention to keep parts/spares as non-specialty as possible.

Potentially, in stable, we'll have 4 cars.

Can't justify paying $6500 for 4 sets, $1600 each of aftermarket a-arms.

I had this ball rolling and my friend has stalled out on it.

Meeting up with a RL/racer Kovakis at Barber to see if we can collaborate on this.

Still welcoming any people who want in,

T

#65

Rennlist Member

#66

Three Wheelin'

Thread Starter

17mm, 1 inch extended length.

Ran the 19s before though, but the slotted pinch bolt area on spindle is weakened and you are just moving failure point somewhere else.

I would go the route you did but we travel pretty far distances to race and it's always a best served intention to keep parts/spares as non-specialty as possible.

Potentially, in stable, we'll have 4 cars.

Can't justify paying $6500 for 4 sets, $1600 each of aftermarket a-arms.

I had this ball rolling and my friend has stalled out on it.

Meeting up with a RL/racer Kovakis at Barber to see if we can collaborate on this.

Still welcoming any people who want in,

T

Ran the 19s before though, but the slotted pinch bolt area on spindle is weakened and you are just moving failure point somewhere else.

I would go the route you did but we travel pretty far distances to race and it's always a best served intention to keep parts/spares as non-specialty as possible.

Potentially, in stable, we'll have 4 cars.

Can't justify paying $6500 for 4 sets, $1600 each of aftermarket a-arms.

I had this ball rolling and my friend has stalled out on it.

Meeting up with a RL/racer Kovakis at Barber to see if we can collaborate on this.

Still welcoming any people who want in,

T

I think that my setup is doable for a small fleet like yours. With the exception of M030 versions, '87+ 944/951 spindles can be had for cheap, and the SCCH pins are not expensive. Make sure any extra spindles are magnafluxed before doing any work to them, and then you can have an extra pair of modified spindles on hand in case any of your cars has an incident on track.

#67

Race Car

Sorry I never came back to this but when you bumped the thread I must have been away.

So....., over the long weekend, I made time to make some accurate measurements of a stripped a-arm ball joint pocket.

Here's a quick drawing I made this morning in the free software eMachineShop.

* The PTFE lined spherical at Pegasus Racing (referenced in this thread) measures at 1.4375" OD, which means that the stock ball joint bore just needs to be bored cylindrical + ..0125 in size leaving virtually the same material strength as the factory arm.

* The race width of the spherical is .593", more than enough room in the factory arm to machine an upper and lower snap ring groove to place the spherical.

* The smaller top cross section depicted by a smaller rectangle that is the land for the grease/dust boot could be totally eliminated during machining since the spherical is self lubricating.

* The spherical has a pin ID of .750", or 19.050mm, only .001" difference in metric conversion for those that already have 19mm bored spindles.

* For those that race, use the longer ping, or just have a street car that have seen worn ball joints, this upper, now unnecessary portion is usually a point of interference.

Now, I'm ready to go with this if I can find somebody to make pins.

T

Last edited by 951and944S; 05-29-2018 at 10:10 AM. Reason: Format

#68

Nordschleife Master

#69

Race Car

A street car will never reach the force levels on even the stock joints (or extended pins like we use) compared to a track car running a Hoosier R7 (insert favorite race tire) setting fast laps, track record and running at the front of competitive road racing, over curbs, high levels of suspension articulation, more massive braking forces, very high spring rates, so a modification like this would not make much sense to those owners anyway.

I guess though, you could leave the boot land if you wanted to, and also resolve the open bottom by leaving a +xx" measurement (the thickness of a cover) difference between the two snap ring groove to allow for a shield for the bottom. These are a "pass through" pin that would have threads on the bottom with a nut.

99% of "street car" owners couldn't get more than 80% capability out of one of these cars, even with their new 996TT brakes, Momo steering wheel and the latest GT turbocharger...

It's on the track where these problems arise....., there's a reason for that.

T

#70

Burning Brakes

Lol....., correct.....!

A street car will never reach the force levels on even the stock joints (or extended pins like we use) compared to a track car running a Hoosier R7 (insert favorite race tire) setting fast laps, track record and running at the front of competitive road racing, over curbs, high levels of suspension articulation, more massive braking forces, very high spring rates, so a modification like this would not make much sense to those owners anyway.

I guess though, you could leave the boot land if you wanted to, and also resolve the open bottom by leaving a +xx" measurement (the thickness of a cover) difference between the two snap ring groove to allow for a shield for the bottom. These are a "pass through" pin that would have threads on the bottom with a nut.

99% of "street car" owners couldn't get more than 80% capability out of one of these cars, even with their new 996TT brakes, Momo steering wheel and the latest GT turbocharger...

It's on the track where these problems arise....., there's a reason for that.

T

A street car will never reach the force levels on even the stock joints (or extended pins like we use) compared to a track car running a Hoosier R7 (insert favorite race tire) setting fast laps, track record and running at the front of competitive road racing, over curbs, high levels of suspension articulation, more massive braking forces, very high spring rates, so a modification like this would not make much sense to those owners anyway.

I guess though, you could leave the boot land if you wanted to, and also resolve the open bottom by leaving a +xx" measurement (the thickness of a cover) difference between the two snap ring groove to allow for a shield for the bottom. These are a "pass through" pin that would have threads on the bottom with a nut.

99% of "street car" owners couldn't get more than 80% capability out of one of these cars, even with their new 996TT brakes, Momo steering wheel and the latest GT turbocharger...

It's on the track where these problems arise....., there's a reason for that.

T

https://www.speedwaymotors.com/Seals...waAkzSEALw_wcB

#71

Race Car

But a street car will be driven in the rain, with abrasive road grime splashing into the open joint. Here's a basic seal that can be added easily;

https://www.speedwaymotors.com/Seals...waAkzSEALw_wcB

https://www.speedwaymotors.com/Seals...waAkzSEALw_wcB

100% on board for people that want a more easily serviceable pin and spherical for street use.

The company I am working with will make the pins for me but with a minimum order of 50.

I am being open in the public forum on this solution because I am not looking to profit in any way.

Just burned out on repairing damage from track failures of the ball joints.

I was telling a RL'er in PM just this morning, even forgetting all the wasted money in travel and expenses if you DNF a race and/or have to pack it up and miss a last sprint, etc.

There can be catastrophic damage if a failure happens at a least friendly part of a track, so far we have been lucky.

But at a minimum, you loose a fender, fender liner, race tire (cut/flat spotted), ball joint with potential damage to the arm itself, damage to a wheel (arm is flailing around inside it).

Even with all this said, I will pack up and quit before I pay a vendor $1600 for a set of a-arms.

I still have a guy working on the billet version of the stock arms and a few RLers who are interested in helping resolve this with an economical solution that we all can share, but in the meantime, a bored out stock arm with spherical bearing and custom pin is the way I am going.

When all items are on the table, and you, MAK, or anyone else wants to configure the solution for sealed street use, I will be happy to oblige if it means modifying the pin drawing to suit everyone who has interest before I give the go-ahead for 50 pins.

More to your points (and MAK), we race in the rain as well, and I would argue, a track is at least as grit/dirt hazardous as any road.

Cars drop two wheels and drag sand/dirt onto the track at nearly every turn, not to mention that you are generally (well not us but the people behind...

) following in close proximity and have rocks/sand blown all over the front area of the car, something you wouldn't normally see on the street.

) following in close proximity and have rocks/sand blown all over the front area of the car, something you wouldn't normally see on the street.The pin will be easily removable with a nut, and I imagine reusable many times over on a street car.

It will be the spherical that would need periodic replacement if left unsealed on a street or race car but they will be easily service as well by removal of an internal snap ring at a cost of $30 ea.

Input....anyone else...?

T

#72

Nordschleife Master

...

* The PTFE lined spherical at Pegasus Racing (referenced in this thread) measures at 1.4375" OD, which means that the stock ball joint bore just needs to be bored cylindrical + ..0125 in size leaving virtually the same material strength as the factory arm.

* The race width of the spherical is .593", more than enough room in the factory arm to machine an upper and lower snap ring groove to place the spherical....

* The PTFE lined spherical at Pegasus Racing (referenced in this thread) measures at 1.4375" OD, which means that the stock ball joint bore just needs to be bored cylindrical + ..0125 in size leaving virtually the same material strength as the factory arm.

* The race width of the spherical is .593", more than enough room in the factory arm to machine an upper and lower snap ring groove to place the spherical....

#73

Burning Brakes

Another question - for people who have taken steps to level out the control arms on their lowered track cars, what length ball joint pins (or other technique to level your control arms) have you guys used? I'm seeing several indications of 1" longer than stock. Anybody use a different length? Thanks.

#74

Rennlist Member

A 17mm pin at X" length and a spherical bearing that drops into the existing control arm socket and gets captured with the existing snap ring grove.

It's possible this bearing size does not exist and i'm not sure what kind of tolerances would be allowed for this joint.

I've always understood that most failures in these arms occur from binding between the ball joint socket and pin.

The spherical bearing addresses this issue so if it's possible to leave the rest of the joint alone that would offer the simplest solution. May not increase it's overall strength but hopefully reduces the potential for failure.

Would a 1.375" OD bearing work to eliminate the need to bore out the arms or does .06" undersized become to sloppy for this application?

#75

Drifting

I used 7.15 degree reamer for the steering knuckle and free hand drilled them (steering knuckle on the spindles) out very carefully and a BBK bumpsteer kit for a 94-98 mustang (it uses the 14x1.5 thread pitch to mate up to the 944 inner tie rods) and used 944 manual steering inner tie rods(because they are shorter) I had to grind a little off the outer tie rod to get it to align but it works well with a thin jam nut. My setup is in my posted photo album.