Torque tube bearings?

#31

Nordschleife Master

I'm also planning to remove the shafts from my race engine. It's just so far away from a stock engine that I'm not even sure how beneficial it is for this engine. Different stroke, lighter mass, different rpm range etc. Will be running the new, heavier, crank dampener and re-do my crank pulleys in a stronger fashion.

Fun fact is that a stock 968 piston and rod weighs 1510 gram per cylinder compared to the combination of piston and rod I run in my engine (1000 hp capable) that weighs 23% less at 1156 gram.

Fun fact is that a stock 968 piston and rod weighs 1510 gram per cylinder compared to the combination of piston and rod I run in my engine (1000 hp capable) that weighs 23% less at 1156 gram.

#32

Oh yeah. I forgot to mention. I added an S2 dampener. Thought it couldn't hurt. Definitely did not feel any difference, but as mentioned by others it's not designed to eliminate same vibrations as the balance shafts.

#33

Patrick, we both know who built the first engine. I know that the attention to details that is done in building any engine at that facility is second to none.

As for any issue of not balancing the internal components, rest assured something as basic as that would have been done.

I had along discussion about balancing with him years ago. I cannot remember much about it but ask him. If you think your confused now wait until he gets going. The theory gets real deep.

Trust your builder he knows his stuff.

As for any issue of not balancing the internal components, rest assured something as basic as that would have been done.

I had along discussion about balancing with him years ago. I cannot remember much about it but ask him. If you think your confused now wait until he gets going. The theory gets real deep.

Trust your builder he knows his stuff.

#34

Rennlist Member

Thread Starter

As we see, an interesting subject with a variety of views. In the end I will probably keep my options open on this particular motor on the basis that the parts were supplied by different vendors and manufacturers. It will also depend on the condition of this motor when we tear it down. If we don't require new pistons we might just rebuild it with a more suitable crank and dampener and use as is for now. That would give the option of trying with and without b/shafts connected. If we see that we need to bore the sleeves more than just a light honing then the option of converting to a 16v via the modified 944S head that has been offered is a possibility. New lighter pistons and pins with new crank and a different dampener than I've got here will be fitted yet we can still keep the shafts in place and try with and without. If we decide to keep it in 8v guise for now we will put the 944S budget into finishing off the other 16v project which will have all new internals and I would think run without b/shafts altogether. Options.

#35

Instructor

That info is incorrect. 100%

The vibration is the same in all inline 4 cylinder engines.

You cannot balance it out, to eliminate the inherit vibrations produced by the engine design, no matter how much counter weight you use.

The reason is simple.

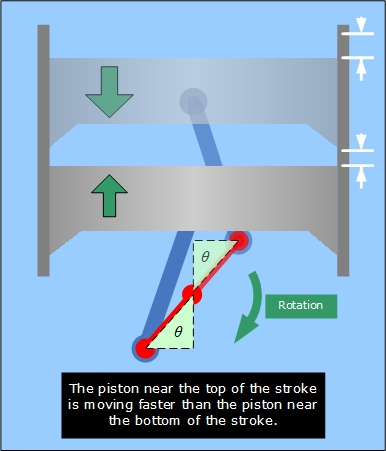

In an inline 4, the outer 2 cylinders are opposite the inner cylinders. When they are at TDC and TBC, everything is balanced perfectly (2 pistons at the top, 2 pistons at the bottom). But when the crank is turned 90 degrees from that position, the inner and outer pistons are not at the same position (not even with each other).

That's the simple version. Specifically, it's because the acceleration of the piston is greater at TDC than BDC.

F=MA (force=mass * acceleration). Therefore, the forces of the pistons at the top and bottom of the stroke (and specifically at mid stroke) do not completely cancel each other out.

This is what causes the 2nd order vibration.

This is the exact reason that the larger the inline 4 engine... the larger the vibrations (amplitude).

This cannot be balanced out no matter the size or location of the counter weights.

Anybody telling you this is either blowing smoke up your *** or just doesn't know that they are talking about.

TonyG

The vibration is the same in all inline 4 cylinder engines.

You cannot balance it out, to eliminate the inherit vibrations produced by the engine design, no matter how much counter weight you use.

The reason is simple.

In an inline 4, the outer 2 cylinders are opposite the inner cylinders. When they are at TDC and TBC, everything is balanced perfectly (2 pistons at the top, 2 pistons at the bottom). But when the crank is turned 90 degrees from that position, the inner and outer pistons are not at the same position (not even with each other).

That's the simple version. Specifically, it's because the acceleration of the piston is greater at TDC than BDC.

F=MA (force=mass * acceleration). Therefore, the forces of the pistons at the top and bottom of the stroke (and specifically at mid stroke) do not completely cancel each other out.

This is what causes the 2nd order vibration.

This is the exact reason that the larger the inline 4 engine... the larger the vibrations (amplitude).

This cannot be balanced out no matter the size or location of the counter weights.

Anybody telling you this is either blowing smoke up your *** or just doesn't know that they are talking about.

TonyG

#37

Addict

Rennlist Member

Rennlist Member

Just been reading this thread and I'm a little confused. How can four piston which are connected to a common crankshaft been in different positions to its partner and travel at different speeds. Surely if one piston accelerates at say 40 mertres per second then they all do, whether they are going up or down.

The more common inline-four configuration suffers from a secondary balance problem caused by the fact that the pistons travel faster on the top half of the crank rotation than the bottom half, which causes the engine to vibrate up and down twice per crank rotation for a total of four times per crankshaft revolution for ordinary up-down-down-up crank throws. This problem becomes worse with increased piston speed and weight, so inline-fours larger than 2.0 L usually have balance shafts and ones over 3.0 L are seldom used in passenger cars. In contrast, the flat-four has much less secondary imbalance at the expense of larger rocking vibrations, that cause it to rotate back and forth around a vertical axis. This is because the cylinders cannot be directly opposed, but must be offset so the connecting rods can be on separate crank pins, which results in the forces being slightly off-centre. The rocking vibration is usually not serious enough to require balance shafts.