27/8 or 54 trim hybrid 8?

#16

Professional Hoon

Rennlist Member

Rennlist Member

Join Date: Jan 2010

Location: Melbourne, Australia

Posts: 7,090

Likes: 0

Received 4 Likes

on

4 Posts

- Modified the turbo mount (new bolts, t3/t4 to gt adapter & another adapter/shim for the t3/g4 to gt adapter to turbo mount)

- custom water lines and tree for temp sensor

- custom oil lines with inline oil filter

- modified compressor housing to fit under throttle body

- custom exhaust down pipe (i made my whole exhaust when i changed turbos)

- modified exhaust x-over (up section to turbo)

My build thread covers everything i'v done, and if you continue along to the rebuild i'm pretty sure i covered that i took to much away from the turbo mount exposing the o-ring from the side not getting a proper seal (fixed that) and the issue with the adapter that the o-rings where in to deep that i had to mill 2mm off each side.

- custom water lines and tree for temp sensor

- custom oil lines with inline oil filter

- modified compressor housing to fit under throttle body

- custom exhaust down pipe (i made my whole exhaust when i changed turbos)

- modified exhaust x-over (up section to turbo)

My build thread covers everything i'v done, and if you continue along to the rebuild i'm pretty sure i covered that i took to much away from the turbo mount exposing the o-ring from the side not getting a proper seal (fixed that) and the issue with the adapter that the o-rings where in to deep that i had to mill 2mm off each side.

#17

Thanks for the explanation Paulyy.

That sounds like a lot of effort!

That sounds like a lot of effort!

#18

Rennlist Member

Thread Starter

Yeah I took care of any leaks a little while back (new crush rings throughout, water-checked the headers, etc.), and I've driven enough 951's in various trim to know I want to boot this thing forward into this century a bit ;-)

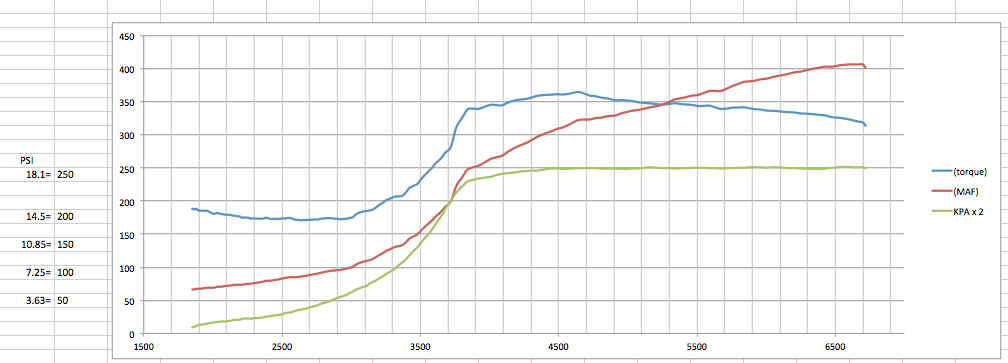

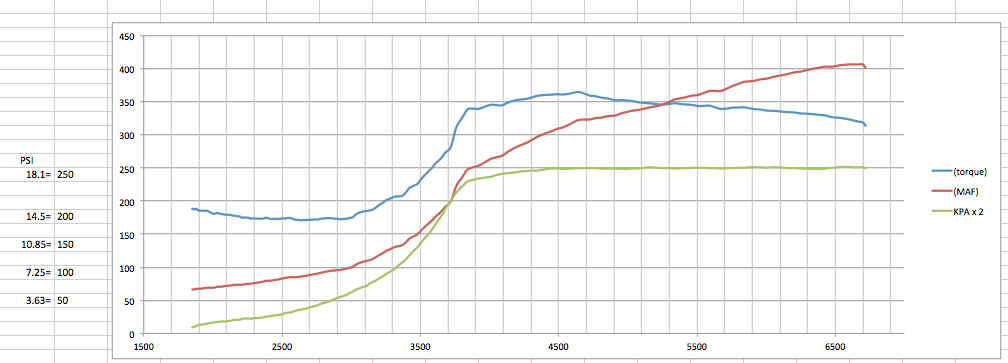

Looking through my friend's stuff a bit more I found a better dyno of his final tune. This was more than a decade ago. He's digging for the exact build (we went through various setups back then). But the rate of climb of the turbo is impressive. I figured I'd look into seeing how things have progressed since this build, otherwise I was basically going to duplicate it.

Looking through my friend's stuff a bit more I found a better dyno of his final tune. This was more than a decade ago. He's digging for the exact build (we went through various setups back then). But the rate of climb of the turbo is impressive. I figured I'd look into seeing how things have progressed since this build, otherwise I was basically going to duplicate it.

#19

Professional Hoon

Rennlist Member

Rennlist Member

Join Date: Jan 2010

Location: Melbourne, Australia

Posts: 7,090

Likes: 0

Received 4 Likes

on

4 Posts

i realised you are running webcams (didn't see it until now on the dyno chart) They will be hurting your bottom end. I suggest you remove them and run stock cams.

The biggest issue is the actual rear housing. It creates to much back pressure. What your friend did could help

Here's Shawns turbo upgrade to a to4e 50 trim. might shed some info for you

https://rennlist.com/forums/944-turb...edictions.html

K26 in blue

to4e 50 trim in red.

The biggest issue is the actual rear housing. It creates to much back pressure. What your friend did could help

Here's Shawns turbo upgrade to a to4e 50 trim. might shed some info for you

https://rennlist.com/forums/944-turb...edictions.html

K26 in blue

to4e 50 trim in red.

#21

Rennlist Member

I think some of you guys might be missing the point.

Have a look at the new cars. They have almost no lag. New technology... New turbos.

the k26 is about 30 years old in technology of turbos.

My turbo (gtx3076 / .83) which is rated at 700 hp has 2psi of boost in 3rd gear at 2000 rpm.

5psi @ 3000

10psi @ 3500

18psi @ 3700

.

Have a look at the new cars. They have almost no lag. New technology... New turbos.

the k26 is about 30 years old in technology of turbos.

My turbo (gtx3076 / .83) which is rated at 700 hp has 2psi of boost in 3rd gear at 2000 rpm.

5psi @ 3000

10psi @ 3500

18psi @ 3700

.

Then, "2 psi at 2,000 RPM"

Well if it's making positive pressure at 2,000 RPM, it shouldn't take another 1,000 RPM to go from 2psi to 5 psi.

Normally, once positive pressure gets achieved things shoulld happen really quick.

I't's more about engineering the entire system properly as opposed to choosing "old technology" vs " new technology " turbos.

#22

Professional Hoon

Rennlist Member

Rennlist Member

Join Date: Jan 2010

Location: Melbourne, Australia

Posts: 7,090

Likes: 0

Received 4 Likes

on

4 Posts

It feels as the positive pressure is the struggle of the spool but enough energy to spin the turbo enough to make some positive pressure.

I really should be dropping turbine housing size though.

Here's the log

I really should be dropping turbine housing size though.

Here's the log