"Neutral" torsion bar setting w/ coilovers - magic or myth?

#31

Rennlist Member

Thread Starter

Completely OT, but ENGINEERMAN, on your front rotors are the internal vanes curved and do the vanes curve in the same direction as the drilled holes? Your car looks nice and clean by the way.

Good discussion guys. Not exactly what I had intended, but good discussion none the less.

It appears as though the 'neutral torsion bar setup' only has one benefit, at least that has been posted so far...and that is to provide a force that counters rear end lift during braking. Sounds like a cure for a non-existent problem. I'm not trying to bash anyone's reasoning for doing what they're doing, and if it works for you - great! But seriously, is rear end lift during braking an inherent problem with our cars? Why "fix" something with coilovers + torsion bars (calculus) when you could solve it with shocks and springs (addition)?

Good discussion guys. Not exactly what I had intended, but good discussion none the less.

It appears as though the 'neutral torsion bar setup' only has one benefit, at least that has been posted so far...and that is to provide a force that counters rear end lift during braking. Sounds like a cure for a non-existent problem. I'm not trying to bash anyone's reasoning for doing what they're doing, and if it works for you - great! But seriously, is rear end lift during braking an inherent problem with our cars? Why "fix" something with coilovers + torsion bars (calculus) when you could solve it with shocks and springs (addition)?

#32

Rennlist Member

It will be interesting how you make out with the GC pins, E-man. I looked very closely at having a custom set machined for my Fabcar arms (by Fabcar, none the less). And they convinced me otherwise with multiple examples of failed, longer, 19mm pins.

My car is a track car, so it does get more 'abuse' than a street car.

Because you do have the geometry correcting pins, have you thought about a bumpsteer kit?

I designed one, but never followed through with getting it made (because I kept my pins the stock height.)

My car is a track car, so it does get more 'abuse' than a street car.

Because you do have the geometry correcting pins, have you thought about a bumpsteer kit?

I designed one, but never followed through with getting it made (because I kept my pins the stock height.)

#33

Rennlist Member

Thanks for the comments guys.

Shiners, yes the vanes are curved and they do curve in the same direction as the drilled holes. The previous owner had installed the Lindsey Racing Big Red kit and rotors so I do not know what brand they are.

Regarding your question re the rear lift during braking, intuitively reducing the weight of the rear tires as happens with torsion bars when braking is not a good thing I would think since it would reduce the ability of the rear wheels to slow the car. Again, intuitively I think the pure coil set up is the best way if the strength can be added in the weak points introduced when taking out the Tbars. I ultimately went with the recommendation of Bob Vaiu of Auto Edge who I trust.

Van, your comments give me some concern, I would like to talk with you some more about this. Can you send me a PM with your phone number and a contact at FABCAR with whom I could discuss. I am paranoid about things breaking at speed. I even went so far as to replace all of the suspension bolts and nuts with new grade 12.9 hardware just to be safe. If the 19mm's are a danger I will go with a what is best. If they have seen multiple examples of them breaking that worries me. Are Charlie arms really the way to go to put my mind at ease?

Thanks for the compliment on the car. I had it completely apart for 1 1/2 years and spent hundreds of hours cleaning it up as well as making improvements. I'll post a summary with lots of photos soon.

Best regards! Sorry to have hijacked your post a little Shiners!

Tom

Best

Shiners, yes the vanes are curved and they do curve in the same direction as the drilled holes. The previous owner had installed the Lindsey Racing Big Red kit and rotors so I do not know what brand they are.

Regarding your question re the rear lift during braking, intuitively reducing the weight of the rear tires as happens with torsion bars when braking is not a good thing I would think since it would reduce the ability of the rear wheels to slow the car. Again, intuitively I think the pure coil set up is the best way if the strength can be added in the weak points introduced when taking out the Tbars. I ultimately went with the recommendation of Bob Vaiu of Auto Edge who I trust.

Van, your comments give me some concern, I would like to talk with you some more about this. Can you send me a PM with your phone number and a contact at FABCAR with whom I could discuss. I am paranoid about things breaking at speed. I even went so far as to replace all of the suspension bolts and nuts with new grade 12.9 hardware just to be safe. If the 19mm's are a danger I will go with a what is best. If they have seen multiple examples of them breaking that worries me. Are Charlie arms really the way to go to put my mind at ease?

Thanks for the compliment on the car. I had it completely apart for 1 1/2 years and spent hundreds of hours cleaning it up as well as making improvements. I'll post a summary with lots of photos soon.

Best regards! Sorry to have hijacked your post a little Shiners!

Tom

Best

#34

Drifting

Originally Posted by ENGINEERMAN

If you convert to coil overs alone the shock bolts carry 100% of the weight of the car PLUS the shock loads, correct?

As far as the control arm issue - the control arms have 3 modes of failure. 1.) Breaking of the cast arm itself, 2.) Breaking of the ball joint pin, 3.) Ball joint pin pulling out of the socket in the control arm. The longer pin will help with the binding although I would be curious to see how much articulation you lost due to the larger diameter pin and if that offsets the gain of the correcting the geometry of the arm. One of the keys of the Charlie and RE arms is that they use spherical bearings with a wider range of articulation. Also, and this is speculative, I would be nervous that the longer pins would increase the moment arm of the pin and increase the risk of pulling the pin out. While the longer pin will keep the pin/arm relationship closer to the desired perpendicular relationship there still is articulation. So when the pin is subject to the high loadings of breaking and hitting track curbing, street potholes, etc., you essentially have a single sheer rod with an increase moment arm that will increase the stress on the ball/socket joint. Is it enough to cause it to fail? Not sure. Finally, there is the case of using a 20 year old cast aluminum arm that will see increased bending forces due to stiffer struts, springs, and sway bars.

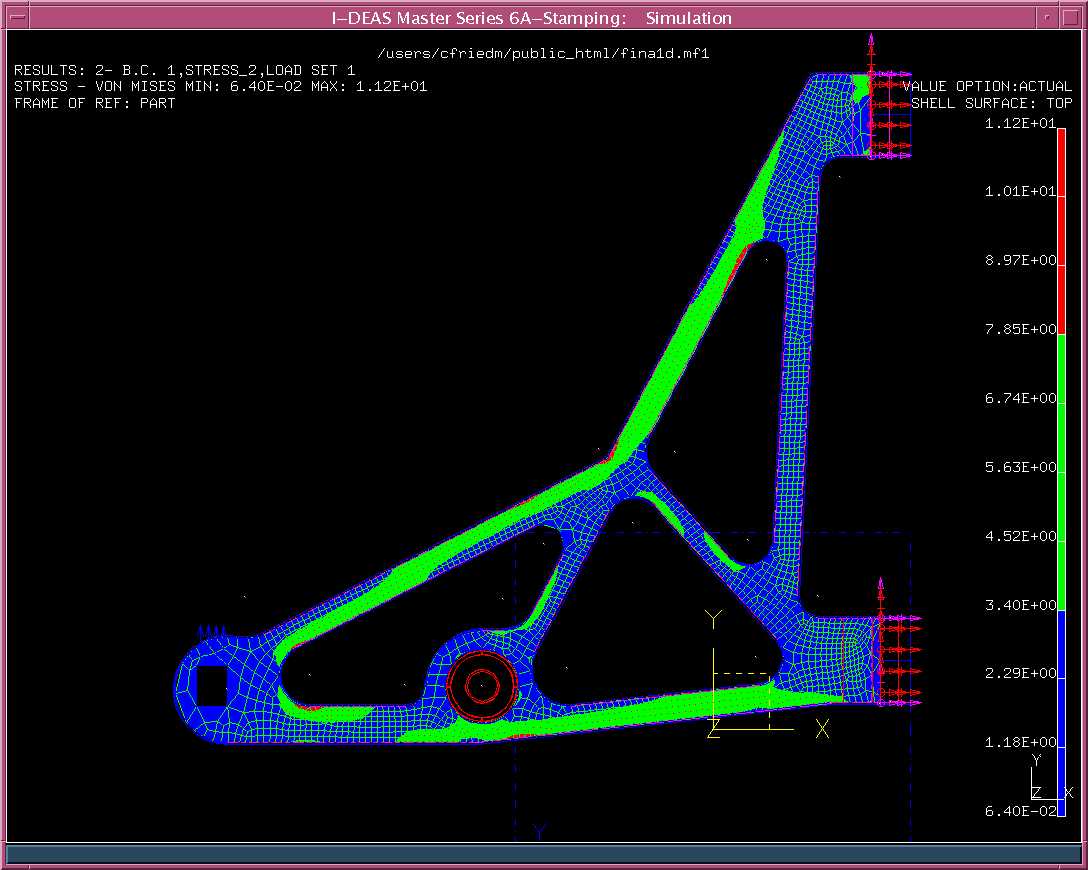

BTW, the Charlie Arms are machined from billet aluminum and use a 19 mm pin as well. I talked to Charlie himself regarding the 19 mm pin vs. a stock diameter 17 mm pin and he felt that this was a crucial design element and that the thinner steering knuckle was negligible in terms of reduced strength. Also, both the Charlie Arms and the RE arms were designed using modern solid modeling and subject to FEA analysis. I personally like the Charlie Arms better as the welds RE arms provide a potential failure point, but they are both well designed pieces.

#36

Rennlist Member

Thread Starter

No worries on the hijack, I find all discussion regarding suspension setups interesting.

The reason I asked about your rotors is that it is unusual to see the vanes and drilled holes running in the same direction. My understanding is that for strengthening purposes the vanes and holes typically cross eachother (see the pic below). You have them on the correct sides since the vanes are oriented correctly, so no worries there.

What caught my eye was that your inner holes hit the brake pad first, and with drilled rotors the outside holes are supposed to hit the pad first. Just like with slotted rotors, the slots aim forward at the top of the rotor. The vanes are the important part though, so it appears that it's just the way those are made.

Anyway, just an observation...

The reason I asked about your rotors is that it is unusual to see the vanes and drilled holes running in the same direction. My understanding is that for strengthening purposes the vanes and holes typically cross eachother (see the pic below). You have them on the correct sides since the vanes are oriented correctly, so no worries there.

What caught my eye was that your inner holes hit the brake pad first, and with drilled rotors the outside holes are supposed to hit the pad first. Just like with slotted rotors, the slots aim forward at the top of the rotor. The vanes are the important part though, so it appears that it's just the way those are made.

Anyway, just an observation...

#37

Rennlist Member

I'm learning a lot from you guys! Thanks a lot! I do appreciate it! This is turning out to be one of the best threads I have seen. After all my 951 makes PLENTY of power. Getting it to the ground and making it handle is what really makes the difference... of course tuning up the driver doesn't hurt either!

Shiners, now you have me wondering re the rotors. I will have to look closer to verify the way the vanes run relative to the drilled holes. Are you thinking that I have them on backwards?

Skip, yes I agree each bolt only carries the percentage of the total weight supported by that wheel. Re the Rennbay 19mm ball joints the necked portion is the same diameter as stock (with an nicely blended large radius so total articulation is the same. Also I can't imagine that they will pull out since I went with the metal cups vs plastic (I think they are probably alu-bronze or oil-lite).

Re the control arms themselves I agree that I am concerned about how much life the 20 year old aluminum arm has left (the fatigue issue with aluminum). The Charlie Arms are nice pieces and it appears that they agree with the 19mm approach (and I am comforted to hear that Charlie did not feel that boring the spindles out to 19mm was something to worry about). Have you guys seen the Lindsey Racing Chrome Moly ones? They appear to be about the same price. I would tend to lean toward the Chrome Moly because (again) the fatigue issues with aluminum although it will probably be years before that issue comes into play and I am sure that properly manufactured welds are not going to fail (hell half the world is welded together). What say you?

Thanks again... I'm gping to bed! Take care!

Shiners, now you have me wondering re the rotors. I will have to look closer to verify the way the vanes run relative to the drilled holes. Are you thinking that I have them on backwards?

Skip, yes I agree each bolt only carries the percentage of the total weight supported by that wheel. Re the Rennbay 19mm ball joints the necked portion is the same diameter as stock (with an nicely blended large radius so total articulation is the same. Also I can't imagine that they will pull out since I went with the metal cups vs plastic (I think they are probably alu-bronze or oil-lite).

Re the control arms themselves I agree that I am concerned about how much life the 20 year old aluminum arm has left (the fatigue issue with aluminum). The Charlie Arms are nice pieces and it appears that they agree with the 19mm approach (and I am comforted to hear that Charlie did not feel that boring the spindles out to 19mm was something to worry about). Have you guys seen the Lindsey Racing Chrome Moly ones? They appear to be about the same price. I would tend to lean toward the Chrome Moly because (again) the fatigue issues with aluminum although it will probably be years before that issue comes into play and I am sure that properly manufactured welds are not going to fail (hell half the world is welded together). What say you?

Thanks again... I'm gping to bed! Take care!

#39

Rennlist Member

Thread Starter

Originally Posted by ENGINEERMAN

Shiners, now you have me wondering re the rotors. I will have to look closer to verify the way the vanes run relative to the drilled holes. Are you thinking that I have them on backwards?

I've seen slotted and drilled rotors mounted in different directions when made with straight vanes, but conventional wisdom states that the outer hole (or the outer end of the slot) should hit the brake pad first. Your rotors seem to counter that theory based on the vane direction.

My understanding was that the holes/slots should run in the opposite direction of the vanes (if the vanes are directional) to help prevent cracking and warping.

Originally Posted by ENGINEERMAN

After all my 951 makes PLENTY of power. Getting it to the ground and making it handle is what really makes the difference...

I run the Blaszak control arms Van mentioned above. Balljoint replacement has never been easier.

#40

Drifting

Boy this is a serious hijack. I'm not a big fan of the Lindsey control arms. They are way over priced for what you get and it improperly use a rod end for the ball joint socket. Rod ends are not meant to be loaded in single shear, and the excuse of using a larger than needed thread to compensate is just poor engineering. If you want to go with steel arms, go with the Racers Edges arms. Solid modelling/FEA designed arms rather than intuitive engineering designs such as the Lindsey, Kokeln, Blaszak, etc. Blaszak is an alternative if you need to save money in that they are way overbuilt which covers any lack of stress analysis, but are as inelegant as they come. IMHO, the Charlie Arms and RE arms are the only two viable designs available on the market. They are well designed using actual modern engineering analysis, and first rate materials and fabrication. I have the Charlie arms and they are truly engineering works of art.

#41

Rennlist Member

Thread Starter

"Inelegant"? Hey, I resemble that remark! Seriously though, does something need to be pretty to be functional? First thing everyone says when they see the Charlie Arms is "wow those look great!" BFD!

IMHO, the proof is in the pudding. When there are failures, we hear about them. Failure rates among all the aftermarket arms seem to me to be fairly similar... extremely low. Do failures happen? Sure, but it is very rare, and no one aftermarket arm seems to fail more than the others. Compare the failure rates of aftermarket arms to failure rates of stock arms and I think you'll agree that ANY aftermarket arm is a viable option.

One can argue engineering and design concepts all day long, but if they aren't failing... they aren't failing. I'll take real world results over conceptual analysis any day.

IMHO, the proof is in the pudding. When there are failures, we hear about them. Failure rates among all the aftermarket arms seem to me to be fairly similar... extremely low. Do failures happen? Sure, but it is very rare, and no one aftermarket arm seems to fail more than the others. Compare the failure rates of aftermarket arms to failure rates of stock arms and I think you'll agree that ANY aftermarket arm is a viable option.

One can argue engineering and design concepts all day long, but if they aren't failing... they aren't failing. I'll take real world results over conceptual analysis any day.

#43

Rennlist Member

Hey Skip, don't forget Fabcar! Those are the control arms I use, and although they are not aluminum, they are light weight, strong as hell, and rebuildable. Perhaps even somewhat "elegant" (at least in their design)...

#45

Drifting

Originally Posted by shiners780

"Inelegant"? Hey, I resemble that remark! Seriously though, does something need to be pretty to be functional? First thing everyone says when they see the Charlie Arms is "wow those look great!" BFD!

IMHO, the proof is in the pudding. When there are failures, we hear about them. Failure rates among all the aftermarket arms seem to me to be fairly similar... extremely low. Do failures happen? Sure, but it is very rare, and no one aftermarket arm seems to fail more than the others. Compare the failure rates of aftermarket arms to failure rates of stock arms and I think you'll agree that ANY aftermarket arm is a viable option.

One can argue engineering and design concepts all day long, but if they aren't failing... they aren't failing. I'll take real world results over conceptual analysis any day.

IMHO, the proof is in the pudding. When there are failures, we hear about them. Failure rates among all the aftermarket arms seem to me to be fairly similar... extremely low. Do failures happen? Sure, but it is very rare, and no one aftermarket arm seems to fail more than the others. Compare the failure rates of aftermarket arms to failure rates of stock arms and I think you'll agree that ANY aftermarket arm is a viable option.

One can argue engineering and design concepts all day long, but if they aren't failing... they aren't failing. I'll take real world results over conceptual analysis any day.

As far as failure rate of aftermarket arms - I think you need to take into account how many are on the market. I would argue that the Fabcar has the most, followed by Charlie arms, with the Lindsey, Kokeln, and Blaszak a very distant third. If Kokeln and Lindsey combined have 20 units in the field for 12 months is that a validation of there design - not in my opinion. With that small of a subset, if two units failed next week their failure rate would jump from 0 to 10%. Also, cyclic fatigue is an issue so I think the jury is still out on the newer arms.

Also I don't necessarily agree with your statement that if there are failures we hear about them. We hear about them if they happen to an active Rennlister or in our regional track community but that’s about it. Even then, when I talk to guys like Eric Steinel who preps 944's from this half of the country I get a different perspective about what stuff is failing and what isn't. I don't feel I can totally rely on anecdotal evidence when making a decision on stuff like this, and consequently also base my decision on other factors such as sound engineering principals of design. If a project has a blatant design flaw such as the Lindsey and Kokeln units and offer little in the way of cost savings why would you use it? I have been burned too many times by going with the cheaper option especially with the Porsche.