HIGHWAYMAN: Bringing the Devore 928 back from the dead

#646

Developer

Here is how we finished up at the dyno: 503 HP at 6000 rpm and 504 lb ft of torque at 4500 rpm.

We got as high as 513 HP at one point, but the fueling and timing was edgy... so we took one degree of ignition timing out and put a little fuel back so Adam can pound on it all day and never worry.

Note we only had two valve cover breathers providing crankcase ventilation for these pulls. I put hoses on them and ran them to the front of the motor so you could watch. No puking, very few fumes, and what their was, was water. Good piston rings, fitment, and oil scraper/windage tray doing its job.

For longer pulls, the rest of the oil control system must be installed, i.e: oil separator with return pump and a crankcase vacuum system. I use two pan-o-vacs, one it each side of a dual exhaust system.

This is now our GOOD BASE TUNE. Now we are going to use this platform to develop an after-market intake manifold solution for the 928. Thanks to Adam, he's funding our R&D on this project.

We got as high as 513 HP at one point, but the fueling and timing was edgy... so we took one degree of ignition timing out and put a little fuel back so Adam can pound on it all day and never worry.

Note we only had two valve cover breathers providing crankcase ventilation for these pulls. I put hoses on them and ran them to the front of the motor so you could watch. No puking, very few fumes, and what their was, was water. Good piston rings, fitment, and oil scraper/windage tray doing its job.

For longer pulls, the rest of the oil control system must be installed, i.e: oil separator with return pump and a crankcase vacuum system. I use two pan-o-vacs, one it each side of a dual exhaust system.

This is now our GOOD BASE TUNE. Now we are going to use this platform to develop an after-market intake manifold solution for the 928. Thanks to Adam, he's funding our R&D on this project.

#647

Race Car

Nicely done Carl.

#648

Developer

After we got the tune in for the extrude-honed intake manifold with the big intake shoe and 90mm throttle body, we removed the intake and installed a dead-stock intake manifold, shoe, and OEM equipment throttle body and did another pull.

No other changes were made.

Here are the charts of the two pulls so you can compare, and picture of the computer screen showing HP and Torque on each of the two pulls compared. The net drop was about 60 HP! Sorry the graph is blurry - I took about a dozen pics of the computer screen but my phone just wouldn't focus.

Anyway, as some of you already knew and as we suspected, the stock intake manifold is limiting the output of our engine. This is why Adam wants us to develop a new intake solution for him.

I'm swamped at work here today and tomorrow (been in the dyno cell for a few days! , so if I do not answer your questions right away please know that I will.

, so if I do not answer your questions right away please know that I will.

No other changes were made.

Here are the charts of the two pulls so you can compare, and picture of the computer screen showing HP and Torque on each of the two pulls compared. The net drop was about 60 HP! Sorry the graph is blurry - I took about a dozen pics of the computer screen but my phone just wouldn't focus.

Anyway, as some of you already knew and as we suspected, the stock intake manifold is limiting the output of our engine. This is why Adam wants us to develop a new intake solution for him.

I'm swamped at work here today and tomorrow (been in the dyno cell for a few days!

, so if I do not answer your questions right away please know that I will.

, so if I do not answer your questions right away please know that I will.

#649

Race Car

It has been stated in the past extrude hone does not work, but this clearly shows that it does.

How much does it cost to have done??

How much does it cost to have done??

#650

Developer

I really like that picture of the computer screen showing the overlay of the two intake manifolds. It really shows how the stock intake manifold falls on its face at the higher rpm's; and the extrude-honed manifold + throttle body made a big difference.

We are discussing ITB's over here as a possibility for our final solution, they are very sexy to look at (no doubt) but can be a bear to air filter. We are looking at several designs for a saleable after-market intake solution for the 928, using a single common throttle body and a good air filter setup. I will likely start a new thread just on this topic, so Adam can have his thread back.

My personal thanks to Adam for his willingness to press on, he's been a super client to work with.

He has offered to buy the parts for this project if I provide the labor, so be sure to thank him.

We are discussing ITB's over here as a possibility for our final solution, they are very sexy to look at (no doubt) but can be a bear to air filter. We are looking at several designs for a saleable after-market intake solution for the 928, using a single common throttle body and a good air filter setup. I will likely start a new thread just on this topic, so Adam can have his thread back.

My personal thanks to Adam for his willingness to press on, he's been a super client to work with.

He has offered to buy the parts for this project if I provide the labor, so be sure to thank him.

#651

Developer

It has been stated in the past extrude hone does not work, but this clearly shows that it does.

How much does it cost to have done??

How much does it cost to have done??

Pictures and discussion on those items are within this thread.

I think that the fellas that tried extrude-honing and reported no benefit were still using the stock intake shoe and throttle body. If I'm right, then they just moved the restriction, they did not remove it like we did.

Last edited by Carl Fausett; 04-13-2017 at 02:21 PM.

#652

Banned

Thread Starter

Been on the phone with Carl regarding the above results; to be sure, I am very pleased with these numbers but my gut tells me we are leaving HP on the table.

I couldn't believe the difference between the stock manifold and the extrude honed manifold, but that tells me that there is still room in the manifold department to find more power.

If someone wants the extrude honed manifold after we are done, it will be for sale. What I've asked Carl to do is to get with his people and come up with a REAL manifold solution that can benefit us all. This can be a whole new manifold or even ITBs, but either way I'm sick of this restriction.

Some notes regarding the dyno pull:

Good job Carl, let's see where we go with this thing.

I couldn't believe the difference between the stock manifold and the extrude honed manifold, but that tells me that there is still room in the manifold department to find more power.

If someone wants the extrude honed manifold after we are done, it will be for sale. What I've asked Carl to do is to get with his people and come up with a REAL manifold solution that can benefit us all. This can be a whole new manifold or even ITBs, but either way I'm sick of this restriction.

Some notes regarding the dyno pull:

- keep in mind that these numbers are with dyno quality headers. These are not the merged collector headers we will use on the car, which will make more power.

- The whole windage / oil thing was pretty much hype. The motor, under these conditions, does not produce any measurable blow by; Carl's windage system works.

- Currently, we are 76.56hp per liter with the extrude honed manifold. Tons of room to grow here.

Good job Carl, let's see where we go with this thing.

#654

Developer

From a reader: "396 cubes. 500 torque and ponies. Nice square engine with some big block numbers."

Its a good start. I have Oliver rods in there and a forged crank. This platform will support more if I can just get the air to it. Using the Electromotive TecGT all-in-one EMS, I can fuel and tune any intake I dream up. No limits!

Its a good start. I have Oliver rods in there and a forged crank. This platform will support more if I can just get the air to it. Using the Electromotive TecGT all-in-one EMS, I can fuel and tune any intake I dream up. No limits!

#655

Race Car

A relatively simple intake solution like this is all I need for my stock-block 5.0L, GT cams, and headers racecar - Ronn's GT. For that combination, I think this intake should be good for an additional 30-ish hp with a tune.

Therefore, 350 rwhp is perfect for my needs for running at Road America, and it won't destroy gearboxes like a stroker inevitably does.

Therefore, 350 rwhp is perfect for my needs for running at Road America, and it won't destroy gearboxes like a stroker inevitably does.

#657

Nordschleife Master

It would be interesting to see a test of the two remaining combinations:

(1) Stock throttle body element + modified main casting

(2) Modified throttle body element + stock main casting

It's possible (although I wouldn't go far as saying probable) that all the gains are coming from modifying the throttle body element.

Some other thoughts:

- I recall Jim Morton predicting that the stock throttle body element would hit the wall at 450hp, which is pretty close to where the two power curves really diverge.

- Was the stock manifold test run without flappy, flappy open, or flappy closed?

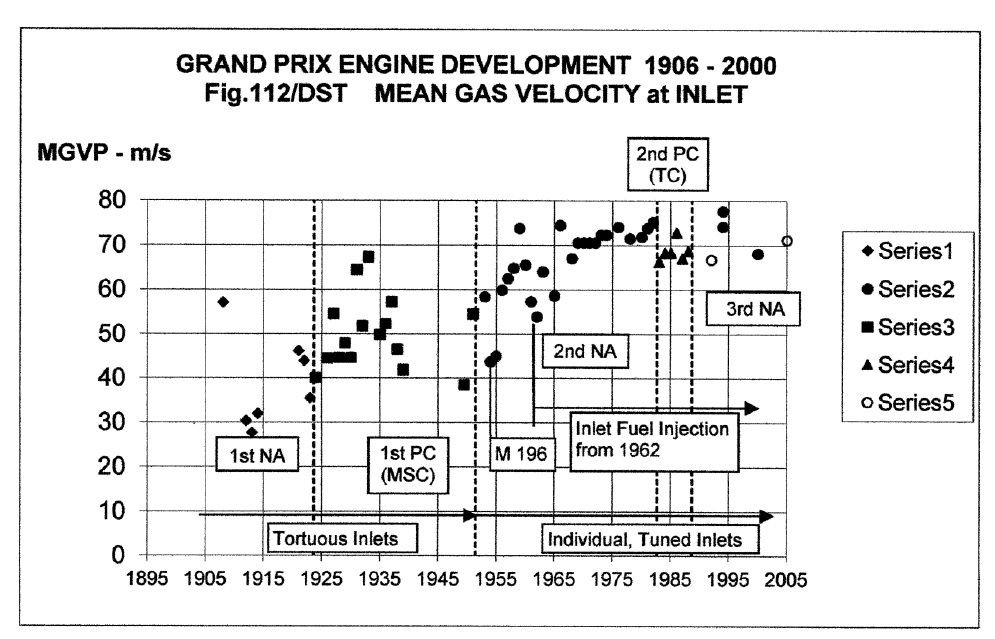

- Did the dyno estimate volumetric efficiency over the rpm range? I'd be interested in that, because it would allow me to compute the mean gas velocity in the intake runners. MAF or dyno inlet turbine data would do as well. As background, the history of Grand Prix engines over the last hundred years has been that straight runner intakes have averaged about 70 m/s and curvy (or "torturous") runner intakes have averaged about 55 m/s mean gas velocity:

More about this here: http://www.grandprixengines.co.uk/Note_34.pdf

Last edited by ptuomov; 04-13-2017 at 05:19 PM.

#660

Developer

We are proceeding on the intake manifold for Adam's car, and I have partnered with an excellent fab shop and welder in an effort to speed the development along rather than doing all the work ourselves in house. They are working with my specifications but have also been given some freedom to provide their input where they see it. These are likely to be not only on the performance/tuning side but also ease of manufacturing.

I am working to come up with an after-market design for these 6.5L motors I am making that is reproducible, so we can make them as I need them.

I think I will see some prototype drawings soon and will share. The design has a rear-facing TB, as the 928 intake does now.

The finished manifold will go on Adam's motor and we will go back to the same engine dyno and test it. We already have numbers for Adam's engine with the dead-stock intake and TB , and the extrude-honed intake with larger TB (see post 636 above), so comparison should be very straight-forward.

I am working to come up with an after-market design for these 6.5L motors I am making that is reproducible, so we can make them as I need them.

I think I will see some prototype drawings soon and will share. The design has a rear-facing TB, as the 928 intake does now.

The finished manifold will go on Adam's motor and we will go back to the same engine dyno and test it. We already have numbers for Adam's engine with the dead-stock intake and TB , and the extrude-honed intake with larger TB (see post 636 above), so comparison should be very straight-forward.