16V adjustable cam timer *installed*

#46

Inventor

Rennlist Member

Rennlist Member

Thread Starter

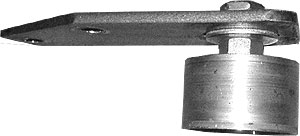

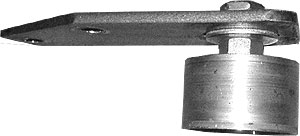

Weissach1982 - 3/16"x2"x6" flat steel. This roller is an 85-86 idler roller (928 105 571 02), but I'm going to move to a 78-84 idler roller (928 105 571 00).

I tried fitting the large tensioner pulley. It fits, barely. It would be tough to get the cover over it. It puts a different angle on the belt, and more torque would be applied to the bearing.

What's worse, higher torque, or higher speed?

I tried fitting the large tensioner pulley. It fits, barely. It would be tough to get the cover over it. It puts a different angle on the belt, and more torque would be applied to the bearing.

What's worse, higher torque, or higher speed?

#47

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

I would have some question about using an idler pulley or "tensioner pulley" on the tight high load portion of the timing belt . The normal position of those rollers is on the no load loose portion of the belt . The part which is unloaded just passing through . All the work is being done by the belt being pulled down the front of the engine by the crank gear (one reason the drivers side camshafts break most often ) The timing belt as it goes from the crank gear up to the passenger side cam DOES NO WORK so loads are light . The tensioner cup shaped washers can be damaged by turning the engine backwards with a wrench on the crank ...why ? they re not designed to handle all the load of turning the camshafts compressing valve springs . My point is those rollers may or may not be adequate for the higher loads ....I do not know . The tension tools measure the loose portion of the belt it can be much higher in other parts of the belt .

#48

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Jim bailey - thanks for the info.

I did not know that the tensioner's bi-metal washers were the reason for the warnings not to turn the crank CCW. Fortunately, I released all the tension (to create slack) before moving the crank.

The bearing in the idler pulley is of good size, however, I will be checking it's condition frequently.

The outside diameter of the idler pulley is 45mm, the belt is 1" wide. I would like to find a slightly larger pulley/bearing, 50-55mm from another application.

I did not know that the tensioner's bi-metal washers were the reason for the warnings not to turn the crank CCW. Fortunately, I released all the tension (to create slack) before moving the crank.

The bearing in the idler pulley is of good size, however, I will be checking it's condition frequently.

The outside diameter of the idler pulley is 45mm, the belt is 1" wide. I would like to find a slightly larger pulley/bearing, 50-55mm from another application.

#49

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Join Date: May 2001

Location: Hotlanta - NE of the Perimeter

Posts: 12,269

Received 266 Likes

on

153 Posts

Not to dampen the spirits of advance thinking, but I too, have reservations about adding an additional roller in the TB circuit. As mentioned, if the bracket were to fail, it may be possible that the TB may slacken enough to jump a tooth!!!

Another thought too - a recent post regarding the TB failure listed the root cause as a frozen tensioner just like this one. IF that were to occur, I'm certain that the same results will manifest themself upon the motor - ouch!

Now, back to your regularily scheduled programing.

Another thought too - a recent post regarding the TB failure listed the root cause as a frozen tensioner just like this one. IF that were to occur, I'm certain that the same results will manifest themself upon the motor - ouch!

Now, back to your regularily scheduled programing.

#50

Drifting

Join Date: Jul 2002

Location: Los Angeles, CA

Posts: 3,348

Likes: 0

Received 0 Likes

on

0 Posts

The title of this post is *16 valve* adjustable cam timer...

Not 32 valve.

Not all, but *most* 16v engines are non-interference, so there

is no issue with playing around with something like this...

It seems like a pretty simple way to make some gains...

I'd really like to see a before/after dyno, to show torque curves, etc...

Not 32 valve.

Not all, but *most* 16v engines are non-interference, so there

is no issue with playing around with something like this...

It seems like a pretty simple way to make some gains...

I'd really like to see a before/after dyno, to show torque curves, etc...

#51

Inventor

Rennlist Member

Rennlist Member

Thread Starter

bcdavis - You tell 'em!

We don't need those 32V 'fraidy cats telling us what's what.

I've decided to use one large wide bearing for the roller to handle the torque and be less of a worry.

~52mm outside diameter by ~24mm wide high speed sealed bearing on a steel plate bracket replacing the rear power steering bracket.

...

I went on a drive in the country a few days ago. Besides being sweeter in the twisties, I noticed that it ran hotter. Which (unlike in Ernest's car) is a good thing. Before the installation of the PorKen Widget, it ran too cool while cruising, barely getting out of the white zone, this I now apply to my cams being slightly retarded from ideal.

So, adding just a degree or two, to syncronize the cams/compensate for tolerances, can restore that new car perk!

We don't need those 32V 'fraidy cats telling us what's what.

I've decided to use one large wide bearing for the roller to handle the torque and be less of a worry.

~52mm outside diameter by ~24mm wide high speed sealed bearing on a steel plate bracket replacing the rear power steering bracket.

...

I went on a drive in the country a few days ago. Besides being sweeter in the twisties, I noticed that it ran hotter. Which (unlike in Ernest's car) is a good thing. Before the installation of the PorKen Widget, it ran too cool while cruising, barely getting out of the white zone, this I now apply to my cams being slightly retarded from ideal.

So, adding just a degree or two, to syncronize the cams/compensate for tolerances, can restore that new car perk!

Last edited by PorKen; 10-30-2003 at 01:40 PM.

#52

Three Wheelin'

PorKen, I was wondering about the same thing Jim said. And then he said it. I too would just advise that on that side of the cam sprocket, the belt is seeing valve spring forces. And not only that, but they are intermittent loading. That is, there's a frequency of loading. I think it's cool that it's working, but the question is how long before it has problems. The bellview washers in the tensioner are altogether another isssue. If I were doing this, I'd use bolts with safety wire, and some kind of locking for the idler nut also. It might be smart to turn the engine thru it's cycles with a dial indicator on the idler, to see if and how much it flexes. Other than that, have fun. I still think it's totally cool that it makes this much of a difference. Yeehaw.

#53

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Gregg K,

I'm reaching my limit on 'real' engineering. (I'm a software guy.) Shopping for bearings for example has made my head hurt.

I (think I) need a sealed both sides, maximum 55mm OD, mininum 21mm wide bearing, that can handle the stresses you describe and a 10000RPM* minimum rating. And calculating the load requirement? Fuhgehdahbaodit.

*The cam gear diameter is 70mm. So a 50mm roller has a factor of 1.4 x 6200 max rpm = 8680?

I'm reaching my limit on 'real' engineering. (I'm a software guy.) Shopping for bearings for example has made my head hurt.

I (think I) need a sealed both sides, maximum 55mm OD, mininum 21mm wide bearing, that can handle the stresses you describe and a 10000RPM* minimum rating. And calculating the load requirement? Fuhgehdahbaodit.

*The cam gear diameter is 70mm. So a 50mm roller has a factor of 1.4 x 6200 max rpm = 8680?

#54

Three Wheelin'

The idler is only making a small deflection in the belt. It should be ok, that way. The idler may need a bracket on each side of the bearing. Maybe a billet part. Yep, the only thing to be aware of is the bearing needing support on both sides. And vibration loosening things.

#55

Drifting

way to go! good point about the non interference engine being safer to modify with respect to the timing belt. only way to know about durability is to put the modified design into service.

#56

Inventor

Rennlist Member

Rennlist Member

Thread Starter

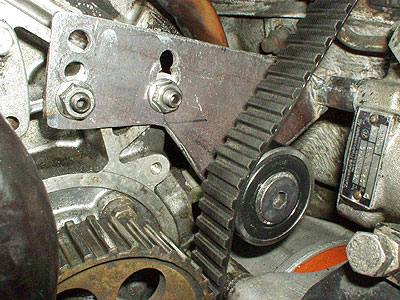

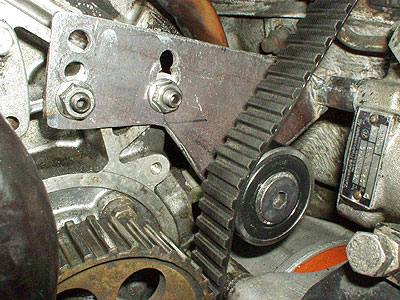

Heavy duty, 7/8" wide, double row, sealed both sides, 52mm bearing.

Gives approximately 1-5 degrees cam advance. I'm trying out 4-4.5 degrees presently.

Rear power steering bracket:

Replaced by:

Another side benefit I noticed: more teeth of the belt over the oil pump gear, which ought to reduce the per tooth stress of driving the pump.

Gives approximately 1-5 degrees cam advance. I'm trying out 4-4.5 degrees presently.

Rear power steering bracket:

Replaced by:

Another side benefit I noticed: more teeth of the belt over the oil pump gear, which ought to reduce the per tooth stress of driving the pump.

Last edited by PorKen; 10-29-2003 at 01:50 PM.

#57

Three Wheelin'

Nice. It's part of the ps bracket. You know that's not going to be going anywhere. Forgive me, I'm not normally a nosey individual. But I find this whole thing really interesting. I suppose I've come off as a pita, but I'm just good at picking on problems. One thing I see (here I go again) is that this bearing appears to not be at least as wide as the belt. The stock roller is wider than the belt. I don't know that it's a problem, but it would be more confidence inspiring to see the roller supporting the entire width. Of course, that means a more expensive bearing. But then, double row might be overkill. Are you still happy with the performance? If so, it's a great mod.

#58

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Gregg K - yer chappin' my hide!

I haven't been able to find a 1" or wider bearing less than 62mm in diameter.

62mm would fit, but to change the PS belt, you might have to remove the advance pulley. It would require a larger hole cut in the covers too.

I could press a sleeve over the bearing, in fact, I could go with a smaller bearing with a sleave. But then what if the sleave migrates?

The stock idler pulley is looking again to be all I need.

...

At 4-4.5 degrees, it was running hotter, but I could bark the tires at every stoplight with just a medium push on the go plank! I've set it back down to 2-2.5 cam degrees. There's plenty enough there.

I haven't been able to find a 1" or wider bearing less than 62mm in diameter.

62mm would fit, but to change the PS belt, you might have to remove the advance pulley. It would require a larger hole cut in the covers too.

I could press a sleeve over the bearing, in fact, I could go with a smaller bearing with a sleave. But then what if the sleave migrates?

The stock idler pulley is looking again to be all I need.

...

At 4-4.5 degrees, it was running hotter, but I could bark the tires at every stoplight with just a medium push on the go plank! I've set it back down to 2-2.5 cam degrees. There's plenty enough there.

Last edited by PorKen; 10-28-2003 at 11:02 PM.

#59

Three Wheelin'

Hey, here's an idea. Use a Loctite locking compound on a sleeve. Call their tech line and see which one is intended for the purpose. Then you're safe, and don't need such a wide bearing. Plus the bearing can be smaller in diameter. Cheaper still.