LH fuel injector o-ring OD? (never mind)

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I've decided to use a fuel injector o-ring for my tensioner bracket to seal around the pesky bolt that is drilled into an oil galley. But I only have used o-rings lying around!

Anyone have an o-ring, or even better, a manifold or fuel rail, handy?

Anyone have an o-ring, or even better, a manifold or fuel rail, handy?

Last edited by PorKen; 05-07-2007 at 01:28 PM.

#2

Inventor

Rennlist Member

Rennlist Member

Thread Starter

It looks to be 14.5 - 15mm in diameter?

#3

Team Owner

what abour using a pipe sealant on the bolts or fastener? an O ring might not seal properly but then again a picture is worth a thousand words

#4

Three Wheelin'

Originally Posted by PorKen

I've decided to use a fuel injector o-ring for my tensioner bracket to seal around the pesky bolt that is drilled into an oil galley. But I only have used o-rings lying around!

Anyone have an o-ring, or even better, a manifold or fuel rail, handy?

Anyone have an o-ring, or even better, a manifold or fuel rail, handy?

Don't mess around with a 0.5A$$ seal.

Go to www.mcmaster.com

Search on part # 93786A225

It's called a pressure sealing washer.

At the top of the page is two styles shown. One has a triangular shaped inside hole and the other is round. Use the round hole style if the seal is around the shank of the bolt and the triangular type to seal around the threaded part of the bolt. The triangular hole type only comes in inch sizes, but the size is non-critical enough to fit the closest metric. I use the 3/8" size to seal the tensioner bolt on the old fashoned 928 belt tensioner. It works perfectly. I got mine from Shane Elliot. They are used on some huge Fairbanks-Morse motors he works on, but the 928 doesn't know that. I used the same thing on my airplane hydraulic system pressure relief valve and it never leaked with working pressure if ~1100 psi.

#5

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I expect people to use silicon, but this hole always has oil in it, and I've never been able to seal it properly between the plate and the engine.

That's a cool seal, Louie. This bolt hole is drilled into the front return galley from the heads, so there's little pressure.

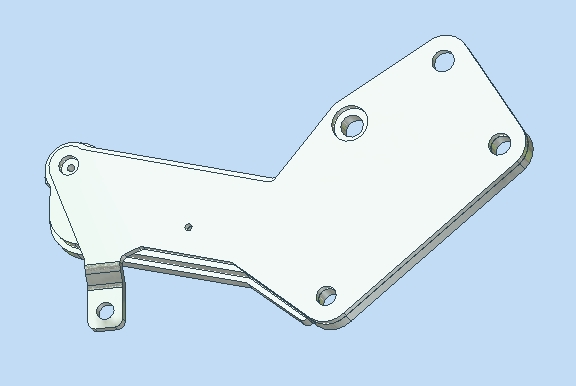

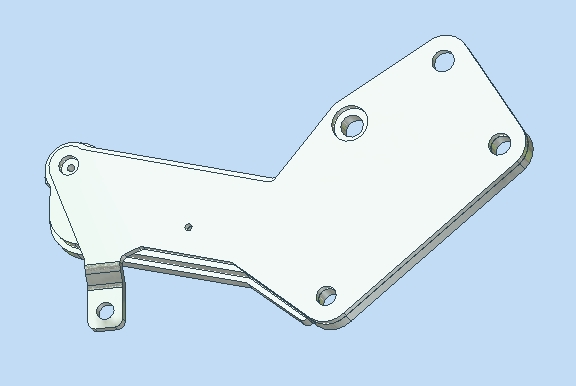

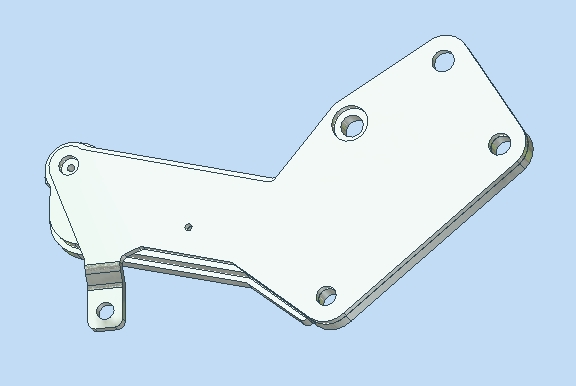

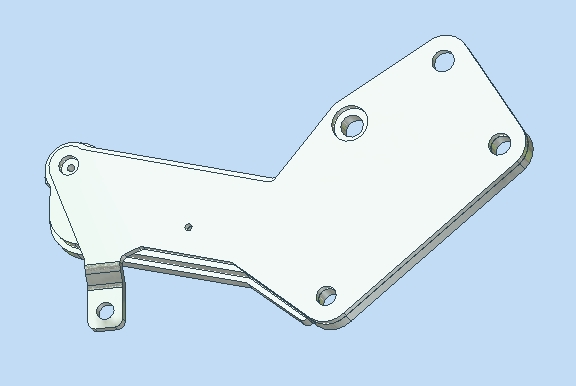

Here's where I would like to put the o-ring. It's captured by the plate, and should seal if I make the hole the correct size?

I didn't want to use a tensioner gasket. But now that I think about it, maybe that's the best method. I have a few MM's to spare between the pulley and the balancer.

That's a cool seal, Louie. This bolt hole is drilled into the front return galley from the heads, so there's little pressure.

Here's where I would like to put the o-ring. It's captured by the plate, and should seal if I make the hole the correct size?

I didn't want to use a tensioner gasket. But now that I think about it, maybe that's the best method. I have a few MM's to spare between the pulley and the balancer.

#6

Three Wheelin'

Originally Posted by PorKen

I expect people to use silicon, but this hole always has oil in it, and I've never been able to seal it properly between the plate and the engine.

That's a cool seal, Louie. This bolt hole is drilled into the front return galley from the heads, so there's little pressure.

Here's where I would like to put the o-ring. It's captured by the plate, and should seal if I make the hole the correct size?

I didn't want to use a tensioner gasket. But now that I think about it, maybe that's the best method. I have a few MM's to spare between the pulley and the balancer.

That's a cool seal, Louie. This bolt hole is drilled into the front return galley from the heads, so there's little pressure.

Here's where I would like to put the o-ring. It's captured by the plate, and should seal if I make the hole the correct size?

I didn't want to use a tensioner gasket. But now that I think about it, maybe that's the best method. I have a few MM's to spare between the pulley and the balancer.

It looks like your plate is a sandwich of two layers. What's to keep the oil from coming out between layers, or between the plate and head? Maybe use "The Right Stuff" to seal? I probably looked at it wrong. Is the counterbore the side that fits against the head? The O ring fits inside the counterbore against the head? That should work if there are no threads on the bolt at that point. Why not use a standard size easy to obtain O ring? Tying into the odd size injector O ring might make it hard for a customer down the road during maintenance.

#7

Inventor

Rennlist Member

Rennlist Member

Thread Starter

The bolt threads...hmmn, didn't think of that. (The picture is of the back side of the bracket.)

The spacer plate is 1/8" thick, and I thought the fuel injector o-ring, which has a part number, would be easier to source?

I guess I could use studs for the middle two bolt holes. That would give a threadless area for the o-ring.

The spacer plate is 1/8" thick, and I thought the fuel injector o-ring, which has a part number, would be easier to source?

I guess I could use studs for the middle two bolt holes. That would give a threadless area for the o-ring.

Trending Topics

#8

Three Wheelin'

Originally Posted by PorKen

The bolt threads...hmmn, didn't think of that. (The picture is of the back side of the bracket.)

The spacer plate is 1/8" thick, and I thought the fuel injector o-ring, which has a part number, would be easier to source?

I guess I could use studs for the middle two bolt holes. That would give a threadless area for the o-ring.

The spacer plate is 1/8" thick, and I thought the fuel injector o-ring, which has a part number, would be easier to source?

I guess I could use studs for the middle two bolt holes. That would give a threadless area for the o-ring.

#9

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Thanks for the feedback Louie. I'm going to go with the factory tensioner gasket, and instructions for sealer on the threads.

According to my stress analysis program, that bolt takes most of the torque, so I would rather have it be filled, anyway.

According to my stress analysis program, that bolt takes most of the torque, so I would rather have it be filled, anyway.

#10

Three Wheelin'

Originally Posted by PorKen

Thanks for the feedback Louie. I'm going to go with the factory tensioner gasket, and instructions for sealer on the threads.

According to my stress analysis program, that bolt takes most of the torque, so I would rather have it be filled, anyway.

According to my stress analysis program, that bolt takes most of the torque, so I would rather have it be filled, anyway.