Tensioner pivot bolt supercede/upgrade?

#1

Racer

Thread Starter

Join Date: Mar 2006

Location: Chattanooga, TN

Posts: 331

Likes: 0

Received 0 Likes

on

0 Posts

In the midst of a timing belt/water pump job. When I pulled the covers, I found about 1/3 of the belt had been shredded into the covers. My investigation soon found a broken tensioner pivot bolt. Hard to believe it didn't break or shred... it had to have been that way even on the way to SITM!

So, I tear everything off the front of the block, replace water pump, front seal, etc... putting together now and I wanted to replace the tensioner pivot bolt. ('80 US 5speed, by the way) Well, I've been trying to get it from 928 Specialists, and it's no longer in thier catalogue. Apparently, prior to '83 is no longer available. After getting Jeannie and Dave involved, they fix me up with the '83 bolt and bushings, which she said the bolt was bigger, and the bushings would make it work. Well, this morning I find that the bolt is bigger, much bigger, and the bushings will work with the new bolt, but won't work in my tensioner arm.

Right now, I'm planning to figure out what hole size will work with the new bolt and bushings and have my tensioner arm bored by a machine shop to that size (to get the hole direction exactly right). Does anyone have any other suggestions (besides trying to get a later arm). Has anyone done this before? How critical is the inside finish on the bore? There seems to be plenty of material there to take the overbore? I'm thinking I should go a couple thousands larger and paint with rustoleum, as the previous bushings appeared seized in bore due to rust...

Been down for two weeks again... would sure love to have this thing going this weekend....

Oh, one other note, does everyone normally put the timing light on and check/adjust timing after a timing belt job? I'm going to plan on it this time because of the lack of tension the last time I checked it... but hadn't heard of anyone doing this previously.

Michael

So, I tear everything off the front of the block, replace water pump, front seal, etc... putting together now and I wanted to replace the tensioner pivot bolt. ('80 US 5speed, by the way) Well, I've been trying to get it from 928 Specialists, and it's no longer in thier catalogue. Apparently, prior to '83 is no longer available. After getting Jeannie and Dave involved, they fix me up with the '83 bolt and bushings, which she said the bolt was bigger, and the bushings would make it work. Well, this morning I find that the bolt is bigger, much bigger, and the bushings will work with the new bolt, but won't work in my tensioner arm.

Right now, I'm planning to figure out what hole size will work with the new bolt and bushings and have my tensioner arm bored by a machine shop to that size (to get the hole direction exactly right). Does anyone have any other suggestions (besides trying to get a later arm). Has anyone done this before? How critical is the inside finish on the bore? There seems to be plenty of material there to take the overbore? I'm thinking I should go a couple thousands larger and paint with rustoleum, as the previous bushings appeared seized in bore due to rust...

Been down for two weeks again... would sure love to have this thing going this weekend....

Oh, one other note, does everyone normally put the timing light on and check/adjust timing after a timing belt job? I'm going to plan on it this time because of the lack of tension the last time I checked it... but hadn't heard of anyone doing this previously.

Michael

#2

Rennlist Member

The pivot bolt has a 12mm body with M8 threads .... and the corresponding carrier arm bore is 15mm to accept the latest bushings: are these the bushings you received? ( there were two vesrions of the split white ones, neither of which you want).

I upgraded my '80 to HTD gears and TB and installed the '84/85 tensioner with oil reservoir, bleed screws and matching arm with low tension alarm ... I've got an extra '85 tensioner assembly, but couldn't find the earlier arm for yours .... otherwise, it would be a freebie .

I upgraded my '80 to HTD gears and TB and installed the '84/85 tensioner with oil reservoir, bleed screws and matching arm with low tension alarm ... I've got an extra '85 tensioner assembly, but couldn't find the earlier arm for yours .... otherwise, it would be a freebie .

#3

Racer

Thread Starter

Join Date: Mar 2006

Location: Chattanooga, TN

Posts: 331

Likes: 0

Received 0 Likes

on

0 Posts

Garth,

So the hole is supposed to be 15mm then. I'm guessing the original bolt (for the '80) had about a 10mm shaft and thus the hole was around 13mm diameter? Almost wonder if I couldn't cut the hole out even larger and install a self lubricated or teflon coated bushing with a 12mm id in that bore. That would take care of the corrosion with the plastic liners also.

I appreciate the offer of the later tensioner. I went through the tensioner I had (no boot, rusted and nasty), then I rebuilt the tensioner that was on my spare engine (also an '80 model). That one had a split boot, and all the oil inside was dried up and nasty. I cleaned all my washers, the inside of the bore, the piston and then reinstalled with fresh oil. Burped the oil through the system and then installed a new boot, clamp and boot spacer with a little bubble of air in the top. I think that the tensioner will work well now, if I give it a good arm to work with...

Next time... I may have to follow in PorKen's footsteps and adapt the tensioner and pulley system from a subaru flat four... it's simple (spring loaded, self contained), works and uber-reliable (180,000 miles and counting on my '94 wagon/pet carrier!). Although, there's twice as many valves relying on the '928 one... tension seems to be very close to the same though.

So the hole is supposed to be 15mm then. I'm guessing the original bolt (for the '80) had about a 10mm shaft and thus the hole was around 13mm diameter? Almost wonder if I couldn't cut the hole out even larger and install a self lubricated or teflon coated bushing with a 12mm id in that bore. That would take care of the corrosion with the plastic liners also.

I appreciate the offer of the later tensioner. I went through the tensioner I had (no boot, rusted and nasty), then I rebuilt the tensioner that was on my spare engine (also an '80 model). That one had a split boot, and all the oil inside was dried up and nasty. I cleaned all my washers, the inside of the bore, the piston and then reinstalled with fresh oil. Burped the oil through the system and then installed a new boot, clamp and boot spacer with a little bubble of air in the top. I think that the tensioner will work well now, if I give it a good arm to work with...

Next time... I may have to follow in PorKen's footsteps and adapt the tensioner and pulley system from a subaru flat four... it's simple (spring loaded, self contained), works and uber-reliable (180,000 miles and counting on my '94 wagon/pet carrier!). Although, there's twice as many valves relying on the '928 one... tension seems to be very close to the same though.

#4

Addict

Rennlist Member

Rennlist Member

You can get a used bolt and new bushings (still vailable because they are the same as the 5 speed shifter bushings) from 928international. I know because I ordered the 10mm bolt for a 79 only to find someone had upgraded to a 12mm bolt and new tensioner pivot assembly.

Just another option.

Chris

Just another option.

Chris

#7

Racer

Thread Starter

Join Date: Mar 2006

Location: Chattanooga, TN

Posts: 331

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Chris

You can get a used bolt and new bushings (still vailable because they are the same as the 5 speed shifter bushings) from 928international. I know because I ordered the 10mm bolt for a 79 only to find someone had upgraded to a 12mm bolt and new tensioner pivot assembly.

Just another option.

Chris

Just another option.

Chris

Which is when I found that the 10mm shoulder bolt is not available from Porsche (I think it is available from McMaster-Carr though).

I think the bigger shoulder is a good idea, should keep it from bending and causing belt tracking issues. So I think I'm gonna go with this new bolt... as long as I can get the tension arm bored correctly.

Trending Topics

#8

Inventor

Rennlist Member

Rennlist Member

#9

Racer

Thread Starter

Join Date: Mar 2006

Location: Chattanooga, TN

Posts: 331

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by PorKen

Remind me again what a 'shoulder bolt' was for?

Did you originally try to use a spring loaded tensioner acting on the factory pivoting tensioner arm? Seems like a simpler, yet still troubled solution? (troubled in that there was the weak link of the bolt)...

I haven't seen the latest version of the plate. Looks great!

#10

Nordschleife Master

This is why the later engines have a brace from the water pump to the top of the bolt. Simple, cheap and your water pump may already be drilled for it.

#11

Burning Brakes

Sorry if I missed this in previous threads, but I'd recommend updating to the later bolt, bushings, and pivot arm. I did this a few years ago on my '83 after its original flimsy white nylong bushings shredded (in fact totally disappeared without a trace) and allowed the tensioner arm to wiggle around at random. Pretty scary. There are multiple versions of the arm out there; I believe they are something along the lines of

a) early (pre-'87?) version with the flimsy bushings;

b) middle ('87?) version that needs a new bolt but uses nice sturdy bushings (this is what I upgraded to with no other changes for my '83); and

c) later version where the offset between the center of the load bearing surface of the bolt and the center of the tensioner bearing (that contacts the belt) was eliminated. I believe this change can also be done but requires the later water pump.

This information is all in the archives and has been discussed more than once.

I really don't know if your '80 is compatible with option (b) but I would HIGHLY recommend going this route if you can.

Good luck,

Rick

a) early (pre-'87?) version with the flimsy bushings;

b) middle ('87?) version that needs a new bolt but uses nice sturdy bushings (this is what I upgraded to with no other changes for my '83); and

c) later version where the offset between the center of the load bearing surface of the bolt and the center of the tensioner bearing (that contacts the belt) was eliminated. I believe this change can also be done but requires the later water pump.

This information is all in the archives and has been discussed more than once.

I really don't know if your '80 is compatible with option (b) but I would HIGHLY recommend going this route if you can.

Good luck,

Rick

#13

Rennlist Member

Bus,

The dimensions I quoted are correct AFAIK for all tensioner assemblies through GTS models - many of the parts and designs change slightly, so not all are compatible.

Your '80 tensioner is OK - it will work with the '83 or '84 arm that is the first to be bored 15mm. Using that with the 12mm shoulder bolt will permit using the current OEM bushings. Personally, I venture that it is a waste of time to modify to anything smaller.

For my '80, I turned a set of 15mm od bushings from nylatron ( stay away from teflon) - and packed the intermediate space with a swipe of synthetic grease. There will be no premature wear or corrosion here ...

If my water pump ever dies ( it's only 26, so still young ...), I have the full S4 tensioner with pivot stud (M10 threads, cross brace, center cover, and S4 pump core to complete the upgrades to S4/GT era .... the point being is that all this stuff is bolt-on , and fits.

The dimensions I quoted are correct AFAIK for all tensioner assemblies through GTS models - many of the parts and designs change slightly, so not all are compatible.

Your '80 tensioner is OK - it will work with the '83 or '84 arm that is the first to be bored 15mm. Using that with the 12mm shoulder bolt will permit using the current OEM bushings. Personally, I venture that it is a waste of time to modify to anything smaller.

For my '80, I turned a set of 15mm od bushings from nylatron ( stay away from teflon) - and packed the intermediate space with a swipe of synthetic grease. There will be no premature wear or corrosion here ...

If my water pump ever dies ( it's only 26, so still young ...), I have the full S4 tensioner with pivot stud (M10 threads, cross brace, center cover, and S4 pump core to complete the upgrades to S4/GT era .... the point being is that all this stuff is bolt-on , and fits.

#14

Racer

Thread Starter

Join Date: Mar 2006

Location: Chattanooga, TN

Posts: 331

Likes: 0

Received 0 Likes

on

0 Posts

I bored the hole to .532" and inserted the '83-84 bolt and bushings. reassembled with some high quality grease and it worked great.

I think, if I had more time to plan, I would have found a teflon coated bushing with a 12mm ID (many bushings at the tops of shock absorbers are this size, so a discarded shock with a 12mm rod might be a good free donor). I'd have the arm bored to the od of the bushing and press it in place. The bushing should offer a tighter fit and smoother movement. I'm just not crazy about how the plastic bushings feel... just about anywhere they're located!

I think, if I had more time to plan, I would have found a teflon coated bushing with a 12mm ID (many bushings at the tops of shock absorbers are this size, so a discarded shock with a 12mm rod might be a good free donor). I'd have the arm bored to the od of the bushing and press it in place. The bushing should offer a tighter fit and smoother movement. I'm just not crazy about how the plastic bushings feel... just about anywhere they're located!

#15

Racer

Thread Starter

Join Date: Mar 2006

Location: Chattanooga, TN

Posts: 331

Likes: 0

Received 0 Likes

on

0 Posts

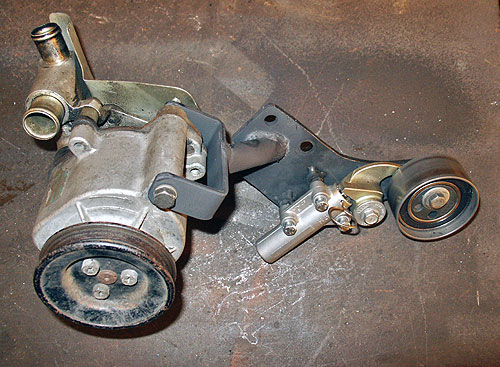

Nothing exists without pics...

the problem:

the debris:

http://i46.photobucket.com/albums/f1...8/IMG_0315.jpg

Seems to run a little quieter now!

the problem:

the debris:

http://i46.photobucket.com/albums/f1...8/IMG_0315.jpg

Seems to run a little quieter now!