Got Clutch out, Now what????

#47

Drifting

Originally Posted by Jim M.

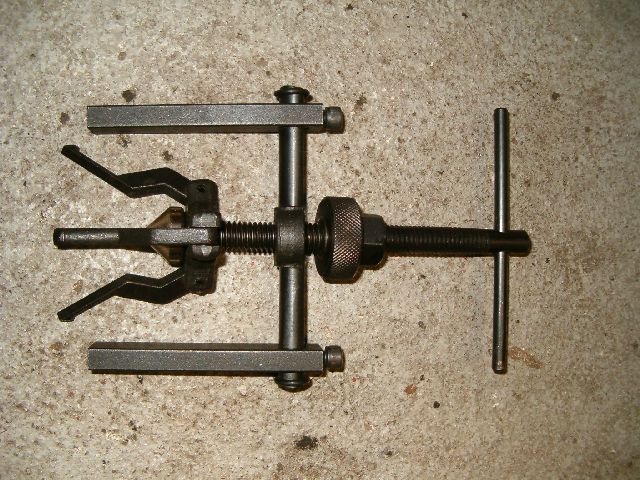

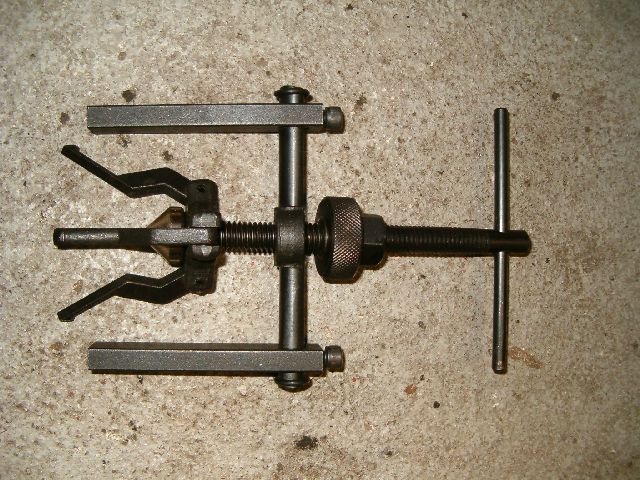

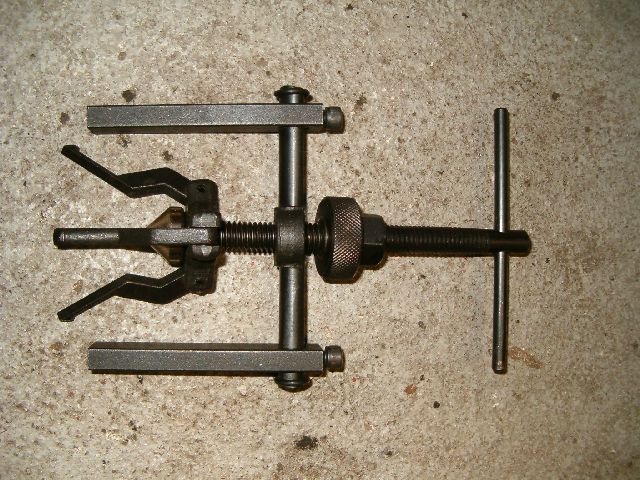

Andrew, you need a puller for the Clutch Pilot bearing: www.harborfreight.com/cpi/ctaf/Displayitem.taf?itemnumber=4876 It will turn it into a 3-minute job.

Jim Mayzurk

93 GTS 5-spd

Jim Mayzurk

93 GTS 5-spd

http://www.harborfreight.com/cpi/cta...temnumber=4876

#48

Addict

Rennlist Member

Rennlist Member

Originally Posted by UKKid35

The Harbor Freight puller doesn't actually fit properly, but you can still use it if you use two rather than three prongs.

#49

Drifting

Join Date: Nov 2001

Location: zürich, switzerland

Posts: 2,233

Likes: 0

Received 0 Likes

on

0 Posts

HTML Code:

Brendan, for the dual disk you use the dual disk pressure plate, arm, and throwout bearing both of which are not superceded with GTS parts. Buy Andrew's arm so he can get one that is correct for his single disk.

Been installed for about 1 year without problems.

Sometimes I wonder how the old arm got bent....

Marton

#50

Supercharged

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 60 Likes

on

34 Posts

Originally Posted by Vilhuer

I have what looks to be exact same puller and it did work fine with all three. Have used it twice, once to pull out outer race only as it was all that was left and once on entire bearing. Maybe mine is somewhat smaller.

#51

Supercharged

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 60 Likes

on

34 Posts

Quick update and question:

I got the pilot bearing out with the aid of Dennis' puller. MF was pretty tough to get out. Got the new one in.

I also, got the updated release arm and have fitted the new TO bearing. Question 1. I could not get the "pivot points" on the new TO bearing to align on the release arm (arm wants to spin). I thought once it's in, I can get the arm hooked onto the ball stud and then rotate the bearing to the correct orientation. Is this possible? Me thinks no. If not, what's the best way to do this?

Right now the clutch is in position with one bolt holding it in place. Question 2. Before I put the rest in and snug everything up, I was wondering if I should scuff up the flywheel or not? Would I just use a sanding block and say, 120 grit paper?

I thought I would have completed it by now, but the wife and kids have had me jumping. Thanks for the advice.

I got the pilot bearing out with the aid of Dennis' puller. MF was pretty tough to get out. Got the new one in.

I also, got the updated release arm and have fitted the new TO bearing. Question 1. I could not get the "pivot points" on the new TO bearing to align on the release arm (arm wants to spin). I thought once it's in, I can get the arm hooked onto the ball stud and then rotate the bearing to the correct orientation. Is this possible? Me thinks no. If not, what's the best way to do this?

Right now the clutch is in position with one bolt holding it in place. Question 2. Before I put the rest in and snug everything up, I was wondering if I should scuff up the flywheel or not? Would I just use a sanding block and say, 120 grit paper?

I thought I would have completed it by now, but the wife and kids have had me jumping. Thanks for the advice.

#52

Nordschleife Master

Join Date: Sep 2004

Location: Not close enough to VIR.

Posts: 9,429

Likes: 0

Received 2 Likes

on

2 Posts

Q1: huh? I don't understand what you mean by pivot points (blocks on the side of TO?) or rotating the bearing to correct orientation. When everything goes in, the TO should be correctly oriented by the PP and the release arm. The release arm can move up and down and side to side until you get it onto the pivot ball.

Q2: no idea

Q2: no idea

#53

Supercharged

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 60 Likes

on

34 Posts

Originally Posted by FlyingDog

Q1: huh? I don't understand what you mean by pivot points (blocks on the side of TO?) or rotating the bearing to correct orientation. When everything goes in, the TO should be correctly oriented by the PP and the release arm. The release arm can move up and down and side to side until you get it onto the pivot ball.

Q2: no idea

Q2: no idea

On the GTS TO bearing the blocks on the sides of the bearing are triangle shaped with the point being a pivot. Based on how the old one came out (with the release arm loose as you describe), I thought I would be able to position the bearing correctly after I installed it. No dice.

Looks like I'll build a PP compressor and reposition. Thanks.

#54

Addict

Rennlist Member

Rennlist Member

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,442

Received 1,609 Likes

on

1,050 Posts

Originally Posted by Andrew Olson

On the GTS TO bearing the blocks on the sides of the bearing are triangle shaped with the point being a pivot. Based on how the old one came out (with the release arm loose as you describe), I thought I would be able to position the bearing correctly after I installed it.

Make any sense?

#55

Supercharged

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 60 Likes

on

34 Posts

Yes... unfortunately it does. When I was putting the TO bearing in, I couldn't get enough clearance to get the snap ring in with the tabs alligned - so I turned them thinking I could orientate them back after the fact.  I'll get some stuff to make a press to get it sorted out. I saw some pics in a different thread that make sense now.

I'll get some stuff to make a press to get it sorted out. I saw some pics in a different thread that make sense now.

I'll get some stuff to make a press to get it sorted out. I saw some pics in a different thread that make sense now.

I'll get some stuff to make a press to get it sorted out. I saw some pics in a different thread that make sense now.

#57

Supercharged

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 60 Likes

on

34 Posts

First, Thanks to all for their help. The WSM do not have a good writeuo on how to disassemble the S4 and up clutch. It took me the better part of a month to get the thing done (probably a total of 12 hours), but if I had to do it again, 4 hours tops! Although that damn retaining c-clip... what a major PITA!  . But it's done now and I have BWaaaaaa! I was expecting the clutch to feel heavier since I upgraded to the GTS clutch, but it feels about the same. The clutch engages much earlier now, which is klind of nice. I tried laying down some rubber, and whereas before I would smoke the clutch... today I smoked the tires!

. But it's done now and I have BWaaaaaa! I was expecting the clutch to feel heavier since I upgraded to the GTS clutch, but it feels about the same. The clutch engages much earlier now, which is klind of nice. I tried laying down some rubber, and whereas before I would smoke the clutch... today I smoked the tires!  I thought the VW commercial about "My Fast" was cute, and it is, just not fast - I know, because I now have very FAST!

I thought the VW commercial about "My Fast" was cute, and it is, just not fast - I know, because I now have very FAST!

Thanks again to the list and all who helped out! Next up, clear 5MPH bumperettes.

. But it's done now and I have BWaaaaaa! I was expecting the clutch to feel heavier since I upgraded to the GTS clutch, but it feels about the same. The clutch engages much earlier now, which is klind of nice. I tried laying down some rubber, and whereas before I would smoke the clutch... today I smoked the tires!

. But it's done now and I have BWaaaaaa! I was expecting the clutch to feel heavier since I upgraded to the GTS clutch, but it feels about the same. The clutch engages much earlier now, which is klind of nice. I tried laying down some rubber, and whereas before I would smoke the clutch... today I smoked the tires!  I thought the VW commercial about "My Fast" was cute, and it is, just not fast - I know, because I now have very FAST!

I thought the VW commercial about "My Fast" was cute, and it is, just not fast - I know, because I now have very FAST!Thanks again to the list and all who helped out! Next up, clear 5MPH bumperettes.

#59

Supercharged

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 60 Likes

on

34 Posts

Both the new one and the old one looked like that one in the picture. Probably not the answer you were looking for. I had to construct a press in order to get that damn thing on there. It wasn't pretty, but it got the job done. My neighbor owns a transmission shop. Next time I'll go use his press.

#60

Archive Gatekeeper

Rennlist Member

Rennlist Member

The release arm part number is (as you can see in the pic above) 928 116 832 07.

... which is... wait for it.... originally for 1984 - 1986 MY 928.

928 116 832 08 is the correct P/N for a '87 through '91.

But 07 is superseded by the 08 and 09. And 08 by 09.

... which is... wait for it.... originally for 1984 - 1986 MY 928.

928 116 832 08 is the correct P/N for a '87 through '91.

But 07 is superseded by the 08 and 09. And 08 by 09.

So I got into my clutch housing last night, to find an 07 arm. Per records, my clutch was re-done in 1997, 60K miles ago. Some slippage now under WOT, so WIAAT.......

They replaced:

clutch plate 928.116.013.23

pressure plate 928.116.004.12

clutch release bearing 928.116.085.08

clutch lever bushing 928-116-145-03 928.116.145.03

pilot bearing 928-102-111-02 928.102.111.02

guide tube 928-116-087-16 928.116.087.16

But no arm.

So 1990-91GT's either came with an 07 arm or both Andrew and I had cheapskates R&R'ing our clutches ~10 years ago....