Engine blocks and strokers

#61

Racer

Thread Starter

Join Date: Oct 2005

Location: middle of nowhere, USA

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

Where would I have to go to find more information on these? Do they press in and mount only at the bottom like the factory bores? Do they require or can they be used with deck plates?

#62

Racer

Thread Starter

Join Date: Oct 2005

Location: middle of nowhere, USA

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

http://www.darton-international.com/main_fr.htm

Found it! In the press release section it mentions the Porsche 900 series as part of their patent for the design. If Carl or anyone who has used or seen these is listening I would LOVE to hear more details!!

Found it! In the press release section it mentions the Porsche 900 series as part of their patent for the design. If Carl or anyone who has used or seen these is listening I would LOVE to hear more details!!

#63

Addict

Rennlist Member

Rennlist Member

There are three separate types of sleeves we are talking about here.

1. Dry sleeves for repairing cylinder bore surface

These can be divided into two categories, alusil and steel. Alusil is available from Kolbenschmidt. I don't know who sells steel sleeves in USA. In here there is one company that does them from Valmet tractor diesel engine cylinder liners. Cost is very reasonable.

On both styles wall thickness is only about 2mm. If sleeve is done right it will have couple of mm ledge at the top to lock it between block and head gasket like described in Kolbenschmidt brochure. In reality this is just safety measure as sleeve is inserted into block when it's cooled about 200 celsius below block temperature. When machining tolerances are correct this results very tight installation. When block and sleeve heats up at similar rate it doesn't matter that different materials have different expansion ratio. Installation difference is greater than that and sleeve can't move because it's pushing against cylinder wall.

On both versions there must be enough material left in original block to support sleeve. How much is enough I don't know. 6.xx mm minimum thickness for original alusil walls minus 2mm wall thickness of the dry sleeve is very thin in my opinion. Probably this means these sleeves can not be safely used to make bore any bigger than conventional boring. Then methods only real benefits are possibility to fix bad stock bores and convert block to steel walled allowing usage of normal non coated pistons.

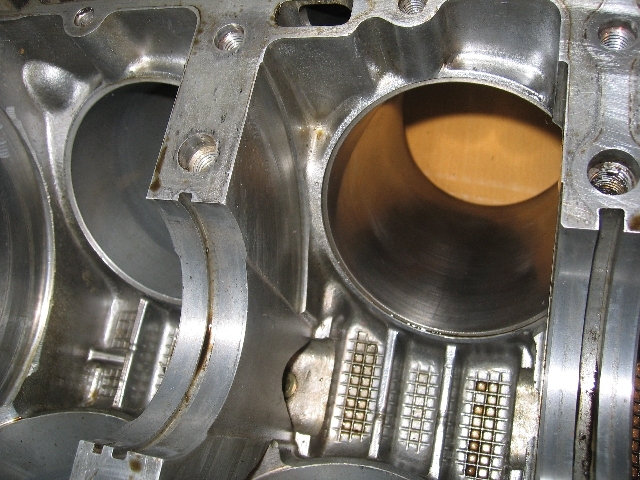

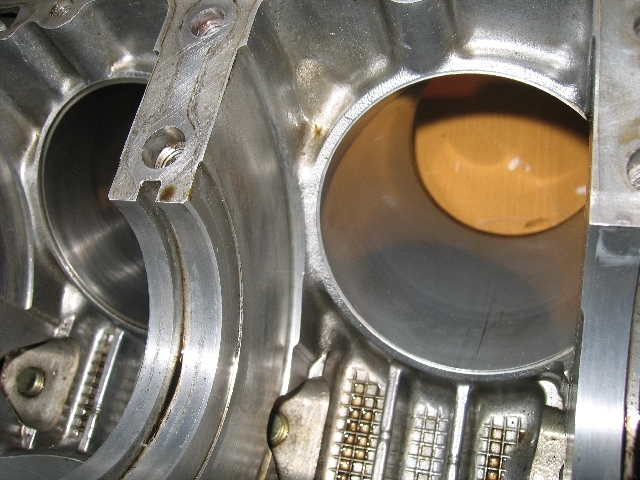

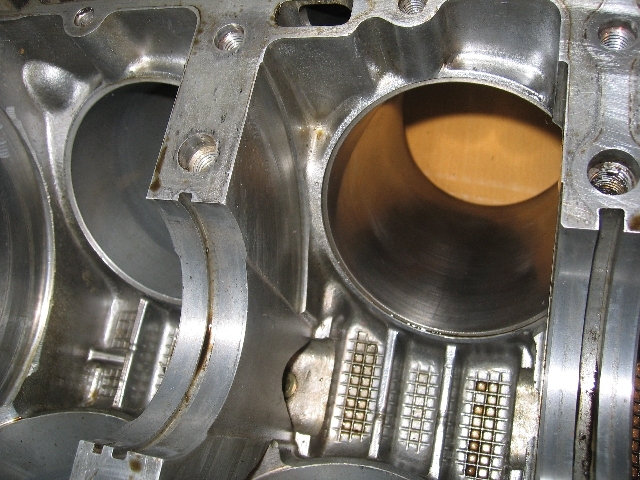

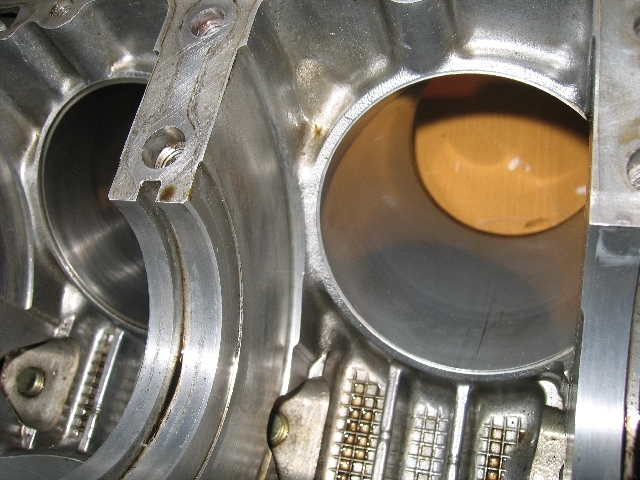

Just to give an example what dry sleeves look like in 928 block. These are in S4 engine. There are four sleeves all together, three alusil and one steel on cylinders 1 to 4. Needless to say it didn't work too well when pistons where original and designed for alusil. Two out of eight had lost coating from their skirts and the one that was in steel sleeved cylinder do not look pretty. Two cylinder towers have signs of welding on ouside. Apparently sleeves were attempt to resurface cracked block after cracks were welded. This butchery was done in Germany.

Original cylinder on left and alusil sleeved right

Alusil sleeve top left, steel right

Steel left, alusil right

Welded tower and steel sleeve at center, alusil sleeves on both sides

2. Wet sleeves for making totally new cylinder tower

I think at least one 928 engine has had it's cylinder towers machined out completely and new steel towers added. My only worry is how to seal water from oil at base of cylinders. Outside of sleeves can be made wavy which increases heat transfer. Also diameter can grow well beyond 104mm making cylinder head design limiting factor. IIRR in 951 forum there has been picture of custom wet sleeves where top of them was about 1/2" or wider and contained water channels for cooling. This should make very stable installation. On very heavy turbo use or such I would go this route and use cracked block as basis. They should be available practically free.

3. Outside support ring to cylinder towers

Somewhere in this forum archive there should be picture of these. Someone in USA made those and was selling them IIRR. I don't know how much original tower should be left. Little less than 6.xx mm perhaps but not much less before there are bound to be problems.

On both options 1. and 3. limiting factor is really how wide original tower is. There is no way in getting around this except option 2. That's what I would look if I were building boosted engine.

1. Dry sleeves for repairing cylinder bore surface

These can be divided into two categories, alusil and steel. Alusil is available from Kolbenschmidt. I don't know who sells steel sleeves in USA. In here there is one company that does them from Valmet tractor diesel engine cylinder liners. Cost is very reasonable.

On both styles wall thickness is only about 2mm. If sleeve is done right it will have couple of mm ledge at the top to lock it between block and head gasket like described in Kolbenschmidt brochure. In reality this is just safety measure as sleeve is inserted into block when it's cooled about 200 celsius below block temperature. When machining tolerances are correct this results very tight installation. When block and sleeve heats up at similar rate it doesn't matter that different materials have different expansion ratio. Installation difference is greater than that and sleeve can't move because it's pushing against cylinder wall.

On both versions there must be enough material left in original block to support sleeve. How much is enough I don't know. 6.xx mm minimum thickness for original alusil walls minus 2mm wall thickness of the dry sleeve is very thin in my opinion. Probably this means these sleeves can not be safely used to make bore any bigger than conventional boring. Then methods only real benefits are possibility to fix bad stock bores and convert block to steel walled allowing usage of normal non coated pistons.

Just to give an example what dry sleeves look like in 928 block. These are in S4 engine. There are four sleeves all together, three alusil and one steel on cylinders 1 to 4. Needless to say it didn't work too well when pistons where original and designed for alusil. Two out of eight had lost coating from their skirts and the one that was in steel sleeved cylinder do not look pretty. Two cylinder towers have signs of welding on ouside. Apparently sleeves were attempt to resurface cracked block after cracks were welded. This butchery was done in Germany.

Original cylinder on left and alusil sleeved right

Alusil sleeve top left, steel right

Steel left, alusil right

Welded tower and steel sleeve at center, alusil sleeves on both sides

2. Wet sleeves for making totally new cylinder tower

I think at least one 928 engine has had it's cylinder towers machined out completely and new steel towers added. My only worry is how to seal water from oil at base of cylinders. Outside of sleeves can be made wavy which increases heat transfer. Also diameter can grow well beyond 104mm making cylinder head design limiting factor. IIRR in 951 forum there has been picture of custom wet sleeves where top of them was about 1/2" or wider and contained water channels for cooling. This should make very stable installation. On very heavy turbo use or such I would go this route and use cracked block as basis. They should be available practically free.

3. Outside support ring to cylinder towers

Somewhere in this forum archive there should be picture of these. Someone in USA made those and was selling them IIRR. I don't know how much original tower should be left. Little less than 6.xx mm perhaps but not much less before there are bound to be problems.

On both options 1. and 3. limiting factor is really how wide original tower is. There is no way in getting around this except option 2. That's what I would look if I were building boosted engine.

#64

Racer

Thread Starter

Join Date: Oct 2005

Location: middle of nowhere, USA

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

So if wet sleeves were used, how big can the bore get before the Cylinder head design stops us?

Sealing the sleeve should not be a real big problem as the wet sleeve design has been used for years in heavy industrial, agricultural and heavy truck engines. I have no small amount of personal experience with them in those applications. In the heavy diesel role leakage is almost never an issue, and truthfully never has in my experience. Erosion or pitting of the cylinder walls through electrolysis from improperly treated water becomes the biggest issue over the life of the engines. Also, unintentionally unseating the sleeves if the heads are removed for other work can be a concern.

So if the bore thickness issue was totally eliminated by the use of wet sleeves, which blocks are the best candidates? I would agree that there should be a fair supply of "junk" blocks that would be best suited for this task, I don't see any reason to destroy a good block to insert sleeves when you could use one that has damaged cylinder bores. Its not like we can go get brand new blocks) Were there oiling improvements other than the "squirter" blocks? I have heard lots of mixed opinions about the squirters, is there something more than the windage issue to be concerned about with them? Weren't there oil pickup changes? Any cooling system changes? Timing belt mount and drive changes? I believe there are some interchangeability issues with timing belt tentioners between euro and us blocks, is that also true of different year US blocks? Do European blocks have any advantages over US blocks? Do all 16v and 32v blocks share the same mounting bosses for intakes or does my block selection become somewhat dictated by head and intake selection?

Then there is the age old debate about bore vs stroke. If the bore size limitation was relaxed by the use of the sleeves, I would really have the choice to go with 108mm bores and the 95mm stroke, or would I be better off going with 106mm bores and 99mm stroke? I know there are a great many issues for each, how much room we really have for additional stroke, and a larger bore further taxes the airflow requirements of the heads and induction. Longer stroke typically results in improved torque but does create new issues of rod length and then rod angle and the reduction in piston height involved with lengthening the rods. Given that I am trying to build longevity and reliability in as much as possible my inclination is to use the larger bore and stay with the more commonly used 95mm or 3.75in stroke unless there are clear cut advantages to keeping the bore and stroke figures closer together. I don't want to build a monster (well I do want to build a monster but in a different sense of the word) here that cannot comfortably be driven, or requires constant maintenance and frequent tear downs like a full out race motor. I know a lot of this bore vs stroke math is rather "basic" but not all engines react to bore and stroke changes the same so again I am hoping to draw upon the experience of those who have done it with these Porshce V8s.

Sealing the sleeve should not be a real big problem as the wet sleeve design has been used for years in heavy industrial, agricultural and heavy truck engines. I have no small amount of personal experience with them in those applications. In the heavy diesel role leakage is almost never an issue, and truthfully never has in my experience. Erosion or pitting of the cylinder walls through electrolysis from improperly treated water becomes the biggest issue over the life of the engines. Also, unintentionally unseating the sleeves if the heads are removed for other work can be a concern.

So if the bore thickness issue was totally eliminated by the use of wet sleeves, which blocks are the best candidates? I would agree that there should be a fair supply of "junk" blocks that would be best suited for this task, I don't see any reason to destroy a good block to insert sleeves when you could use one that has damaged cylinder bores. Its not like we can go get brand new blocks) Were there oiling improvements other than the "squirter" blocks? I have heard lots of mixed opinions about the squirters, is there something more than the windage issue to be concerned about with them? Weren't there oil pickup changes? Any cooling system changes? Timing belt mount and drive changes? I believe there are some interchangeability issues with timing belt tentioners between euro and us blocks, is that also true of different year US blocks? Do European blocks have any advantages over US blocks? Do all 16v and 32v blocks share the same mounting bosses for intakes or does my block selection become somewhat dictated by head and intake selection?

Then there is the age old debate about bore vs stroke. If the bore size limitation was relaxed by the use of the sleeves, I would really have the choice to go with 108mm bores and the 95mm stroke, or would I be better off going with 106mm bores and 99mm stroke? I know there are a great many issues for each, how much room we really have for additional stroke, and a larger bore further taxes the airflow requirements of the heads and induction. Longer stroke typically results in improved torque but does create new issues of rod length and then rod angle and the reduction in piston height involved with lengthening the rods. Given that I am trying to build longevity and reliability in as much as possible my inclination is to use the larger bore and stay with the more commonly used 95mm or 3.75in stroke unless there are clear cut advantages to keeping the bore and stroke figures closer together. I don't want to build a monster (well I do want to build a monster but in a different sense of the word) here that cannot comfortably be driven, or requires constant maintenance and frequent tear downs like a full out race motor. I know a lot of this bore vs stroke math is rather "basic" but not all engines react to bore and stroke changes the same so again I am hoping to draw upon the experience of those who have done it with these Porshce V8s.

#65

Addict

Rennlist Member

Rennlist Member

Just about any block will do with wet sleeves. There were some changes done to oil pump area at early eighties and GTS blocks have better air passages at crank chamber. Old blocks have intake mounting points but they can be easily grind away. Nothing to gain or lose in ROW blocks either. '87 squirter blocks would obviously be best for boosted application. I don't know if squirters had any serious issues that lead factory to drop them or was it just cost cuting measure. Scrapers should take care of the windage problems.

#66

Racer

Thread Starter

Join Date: Oct 2005

Location: middle of nowhere, USA

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

Are the squirters integrated into the block or a bolt in item? I saw somewhere that they only come in at higher RPM, how are they controlled? Can the be disabled if they proved to be a problem? These were on 87 only?

What is the limit to cylinder bore dictated by the heads? Is this measurement different for 16v and 32v heads?

What is the limit to cylinder bore dictated by the heads? Is this measurement different for 16v and 32v heads?

#67

Addict

Rennlist Member

Rennlist Member

Squirters are basically pressure valves that open when oil pressure is above 4 bars. They can be drilled out from the block if needed. And yes, they were '87 model year only or possibly were used on some early '88 MY engines or were not used on last '87's. There might not be clear cut which VIN they were deleted as it can be possible blocks went into cars randomly.

I think limiting factor in heads is water passager. If bore is increased too much they will come "in line of fire" and this could crack a head. Since 16V head is same as 8V in 944 which has 100mm bore 16V should be able to take 100 without any problems. Since 32V is basically same as 944 S2 and 968 104mm shouldn't be and is not a problem as we have seen. How much more these can take is questionable.

I think limiting factor in heads is water passager. If bore is increased too much they will come "in line of fire" and this could crack a head. Since 16V head is same as 8V in 944 which has 100mm bore 16V should be able to take 100 without any problems. Since 32V is basically same as 944 S2 and 968 104mm shouldn't be and is not a problem as we have seen. How much more these can take is questionable.

#68

Racer

Thread Starter

Join Date: Oct 2005

Location: middle of nowhere, USA

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

Here is the information I got from Darton Sleeves

We currently have a Porsche 928 V8 block here that we are doing R&D on. As far as we know it is very similar to the Porsche 968 3.0L block. The sleeve we will be making for the 928 will be an MID style sleeve which will make the block a closed deck and is like the one we currently use in the 968 and 944 blocks. As far as sizes we are not sure what the block will be able to withstand until we machine it out. The MID sleeve is one that we have been using on all our Honda, Ecotec, Nissan 350z, GM LS-1/2/6, Ford 4.6L and 5.4L blocks. In order to aid in slowing the deterioration of the sleeve we recommend the use of Evan Coolant when using our MID kit. www.evanscooling.com for more information. As far as warranty our sleeves carry a lifetime guarantee against manufacturer defects. As for pricing we will not know until we get the product closer to being made. Generally we have a 6-8 week lead time for our custom sleeves. We do have discounts for shops ordering multiple kits. We are not sure exactly how much longer it will be until we get the kit completed but I will see how far we are with our shop and let you know.

Let me know if you have any more questions.

Thanx,

John

Size Does MATTER!

John Catapang

National Sales Manager Darton International, Inc.

2380 Camino Vida Roble Bldg. K

Carlsbad, CA. 92011

sales@DARTON-international.com tel:

tel2:

fax: 800-713-2786

760-603-9895

760-603-9629

We currently have a Porsche 928 V8 block here that we are doing R&D on. As far as we know it is very similar to the Porsche 968 3.0L block. The sleeve we will be making for the 928 will be an MID style sleeve which will make the block a closed deck and is like the one we currently use in the 968 and 944 blocks. As far as sizes we are not sure what the block will be able to withstand until we machine it out. The MID sleeve is one that we have been using on all our Honda, Ecotec, Nissan 350z, GM LS-1/2/6, Ford 4.6L and 5.4L blocks. In order to aid in slowing the deterioration of the sleeve we recommend the use of Evan Coolant when using our MID kit. www.evanscooling.com for more information. As far as warranty our sleeves carry a lifetime guarantee against manufacturer defects. As for pricing we will not know until we get the product closer to being made. Generally we have a 6-8 week lead time for our custom sleeves. We do have discounts for shops ordering multiple kits. We are not sure exactly how much longer it will be until we get the kit completed but I will see how far we are with our shop and let you know.

Let me know if you have any more questions.

Thanx,

John

Size Does MATTER!

John Catapang

National Sales Manager Darton International, Inc.

2380 Camino Vida Roble Bldg. K

Carlsbad, CA. 92011

sales@DARTON-international.com tel:

tel2:

fax: 800-713-2786

760-603-9895

760-603-9629

#69

Racer

Thread Starter

Join Date: Oct 2005

Location: middle of nowhere, USA

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

Sterling:

What model Fluidampr was used as the starting point for the one on your engine? Was this model chosen because it could be adapted easiest of their units or was it chosen specifically for its ability to be used for the external balance correction? What all had to be done to make it work?

What model Fluidampr was used as the starting point for the one on your engine? Was this model chosen because it could be adapted easiest of their units or was it chosen specifically for its ability to be used for the external balance correction? What all had to be done to make it work?

#70

Racer

Join Date: Jan 2003

Location: Berkshire. 'Old' England. U.K.

Posts: 465

Received 0 Likes

on

0 Posts

There's a hot rodder in Ca.(IIRC) who has fitted 928 32v heads to a BBC block (IIRC Mark A supplied them)

So .... with bore sizes up to 117 mm (4.6 in.) & 10 ltrs with off the shelf parts........ a new race block is $2500 & weighs 270 Ilb (10 Ilb more than a 928's ?)............. who would know what was beneath your 928 heads

& 10 ltrs with off the shelf parts........ a new race block is $2500 & weighs 270 Ilb (10 Ilb more than a 928's ?)............. who would know what was beneath your 928 heads

So .... with bore sizes up to 117 mm (4.6 in.)

& 10 ltrs with off the shelf parts........ a new race block is $2500 & weighs 270 Ilb (10 Ilb more than a 928's ?)............. who would know what was beneath your 928 heads

& 10 ltrs with off the shelf parts........ a new race block is $2500 & weighs 270 Ilb (10 Ilb more than a 928's ?)............. who would know what was beneath your 928 heads

#71

Advanced

Join Date: Dec 2003

Location: Lyle-Land, Wa. (65mi. East of Portland, Or.)

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

One thing that might be interesting to see is how effective changing the intake might be without altering the displacment. Some of the supercharger guys are getting some good numbers with their "compressors" and the few working strokers who've done intake mods. have found the hp increases to be very significant. It follows that the factory intake seems to be one of the major limiting factors. The three racing strokers who've changed intakes have seen substantial increases in power using essentially the same lower components as before...I know Joe Fan and Mark Anderson gained big hp when they changed their racers to the Phil Threshie intakes, and my stroker motor went from around 420 at the wheels (with a factory style Throttle body on a cleaned up intake, etc) to 575 using Louis Ott's individual throttle body intake prototype. Given, we did some things slightly different below the intake on this motor, and changed the engine managment...but no changes that would account for a hundred and fifty hp increase..I think Joe F. and Mark A. also saw BIG improvments with just the intake changes and not much else..Given..my motor hasn't run on the track yet..but the HP figures at the dyno seem to indicate a lot more power than before with a stock style intake. Someone try it..

Don Hanson

Don Hanson

#72

Road Warrior

Rennlist Member

Rennlist Member

spacers seemed to help w/the torque on the intake.... love to mess w/louies ITB's, but I'm going to have enough trouble w/my license as it is.... gotta check into a diplomatic status....

#73

Rennlist Member

Don,

Keep in mind that I made over 500 rwhp with a stock intake with some pleneum spacers. You have my individual TB setup on your car, which is larger than what Louis and I tested originally developed when we did the develoment. My system was designed for 600 rwhp, and since I did your heads and you now have my intake, you should be able to tune to the 600 rwhp level.

The pleneum spacers have little to no value at stock displacements based on my dyno testing.

My modeling with DEVEK B1 cams and my next intake, should provide close to a 75 hp gain over stock. We will see soon.

Keep in mind that I made over 500 rwhp with a stock intake with some pleneum spacers. You have my individual TB setup on your car, which is larger than what Louis and I tested originally developed when we did the develoment. My system was designed for 600 rwhp, and since I did your heads and you now have my intake, you should be able to tune to the 600 rwhp level.

The pleneum spacers have little to no value at stock displacements based on my dyno testing.

My modeling with DEVEK B1 cams and my next intake, should provide close to a 75 hp gain over stock. We will see soon.

#74

Rennlist Member

Building a 7.0 is not a problem. It has been done before and our technology has improved quite a bit since then and they can be made to last. We now know why both 7.0 engines broke cranks, now we use 8 CW cranks

Those 7's were for racing with little regards for longevity. They were targeting 600-700 crank hp and were focused on power band range. Due to the tech used

EB238 - what is your name? Are you the same person who keeps calling me about the 7 liter engine info?

Regards,

Marc

Those 7's were for racing with little regards for longevity. They were targeting 600-700 crank hp and were focused on power band range. Due to the tech used

EB238 - what is your name? Are you the same person who keeps calling me about the 7 liter engine info?

Regards,

Marc

#75

Racer

Thread Starter

Join Date: Oct 2005

Location: middle of nowhere, USA

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

Marc:

No, I have not called you. I have emailed a couple times but not about building a 7.0 I have been planning to though to discuss your stroker crank setups, camshafts as well as induction and ignition options and so on and so fourth How did you go about the 7.0? What bore and stroke did you go with? I was hopeful you would get in on this thread at some point so I could hear your point of view on my 7.0 project.

How did you go about the 7.0? What bore and stroke did you go with? I was hopeful you would get in on this thread at some point so I could hear your point of view on my 7.0 project.

No, I have not called you. I have emailed a couple times but not about building a 7.0 I have been planning to though to discuss your stroker crank setups, camshafts as well as induction and ignition options and so on and so fourth

How did you go about the 7.0? What bore and stroke did you go with? I was hopeful you would get in on this thread at some point so I could hear your point of view on my 7.0 project.

How did you go about the 7.0? What bore and stroke did you go with? I was hopeful you would get in on this thread at some point so I could hear your point of view on my 7.0 project.