32V cam gears into 16V?

#17

Nordschleife Master

Thinking about jp's point here. Even though the distributor is driven by the cam, if it's checked against the crank any error or adjustment in cam-to-crank position is taken out. One thing is to always re-check the timing after an adjustment. At least for those of us who's K-Jet engines work that way. Don't L and LH use a pick-up on the flywheel?

#18

Nordschleife Master

(Going off track a bit)

I searched for worldpac and looked in their catalog. I've been to four or five websites with that same system, except that there are prices on the parts. Guess that explains it. Those operations just set prices, make retail sales and, I'll wager, have everything drop shipped.

I searched for worldpac and looked in their catalog. I've been to four or five websites with that same system, except that there are prices on the parts. Guess that explains it. Those operations just set prices, make retail sales and, I'll wager, have everything drop shipped.

#19

Addict

Rennlist Member

Rennlist Member

L-injection ignition is set up the same way as K. That is the Distributor operates off left cam. Advancing the cam won't effect the ignition timing. Just readjust using timing light. LH uses a crank sensor off the flywheel.

#21

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Norm,

I looked at the V-dubya gears, they are smaller in diameter and width. The Franco centrifugal advance gear is a cool idea, but I don't know if you could get our two cams to advance at the exact same rate.

The 'spider' is DR (Dave Roberts, 928 Specialists) term for the 'Timing Gear Hub' to which the 32V cam gear mounts to.

I had assumed this whole time that the spider or hub was part of the 32V camshaft, and this is why I pursued the whole idler business.

...

jpitman2,

As DR suggested, there needs to be an accessory piece to go along with the 32V parts in order to have a fixed reference to the woodruff key.

A thin plate that mounts between the hub and the gear with a protusion which reaches up to the cam tower pointer. There could be degree marks to aid in setting up the timing.

...

toofast928,

You'll need the 32V gears. I suppose you could machine the back of your existing gears flat, but I think it would be cheaper and more reliable to go with the factory setup.

For this reason I don't think I will try making an early gear conversion. Easy enough to get used HTD crank and oil pump gears.

...

GlenL,

WorldPAC is the super suplier behind most of the drop-ship sites you see on the web. Each site charges a different percentage, but they all ship from one of (three?) giant warehouses. Shops can order directly from them.

I looked at the V-dubya gears, they are smaller in diameter and width. The Franco centrifugal advance gear is a cool idea, but I don't know if you could get our two cams to advance at the exact same rate.

The 'spider' is DR (Dave Roberts, 928 Specialists) term for the 'Timing Gear Hub' to which the 32V cam gear mounts to.

I had assumed this whole time that the spider or hub was part of the 32V camshaft, and this is why I pursued the whole idler business.

...

jpitman2,

As DR suggested, there needs to be an accessory piece to go along with the 32V parts in order to have a fixed reference to the woodruff key.

A thin plate that mounts between the hub and the gear with a protusion which reaches up to the cam tower pointer. There could be degree marks to aid in setting up the timing.

...

toofast928,

You'll need the 32V gears. I suppose you could machine the back of your existing gears flat, but I think it would be cheaper and more reliable to go with the factory setup.

For this reason I don't think I will try making an early gear conversion. Easy enough to get used HTD crank and oil pump gears.

...

GlenL,

WorldPAC is the super suplier behind most of the drop-ship sites you see on the web. Each site charges a different percentage, but they all ship from one of (three?) giant warehouses. Shops can order directly from them.

#22

Rennlist Member

Porken,

If you lay a 32V wheel over a 16V wheel, with timing marker notches in sync (assuming they are the same marks), the spread of the 32V keyway over the 16V should (might?) tell you something about the range of timing available. eg, if the centre of the 16V keyway is just say, 90degrees away from the timing mark, and the centre of the 32V is the same, the marks mean the same. Then, if the 32v keyway is, say, 8mm wide, the key can be +/- 2mm off centre. Work out what this means in terms of degrees from timing mark, you have the advance/retard range. If we knew the shaft diameter and keyway width we could calculate this now. Wonder if the change for the 32V timing was in response to the difficulty of getting the pax side cam timed exactly right on 16V cars? Everybody seems to get it. Reading manual yesterday, it actually says that if you cant get the belt to match with the marks aligned, rotate cam CCW, which is retarding it??

jp 83 Euro S AT 47k

If you lay a 32V wheel over a 16V wheel, with timing marker notches in sync (assuming they are the same marks), the spread of the 32V keyway over the 16V should (might?) tell you something about the range of timing available. eg, if the centre of the 16V keyway is just say, 90degrees away from the timing mark, and the centre of the 32V is the same, the marks mean the same. Then, if the 32v keyway is, say, 8mm wide, the key can be +/- 2mm off centre. Work out what this means in terms of degrees from timing mark, you have the advance/retard range. If we knew the shaft diameter and keyway width we could calculate this now. Wonder if the change for the 32V timing was in response to the difficulty of getting the pax side cam timed exactly right on 16V cars? Everybody seems to get it. Reading manual yesterday, it actually says that if you cant get the belt to match with the marks aligned, rotate cam CCW, which is retarding it??

jp 83 Euro S AT 47k

#23

Rennlist Member

Back again. If the camshaft shaft for the wheel is anywhere around 25mm dia, we are looking at timing changes of ~4 degrees per mm of movement in the keyway - gets bigger as diameter goes down. 25 * Pi =78.54; 360/ 78.54 = 4.58 degrees. I would guess the 32V wheel keyway is probably only 6mm wide. The beauty of this arrangement would seem to be that its easy to change the timing by just pulling the top covers, slackening the main bolt and 3 smaller bolts, adjust the relationship, bolt it all up again? Is that wrong? Quantifying the adjustment may be another thing entirely....

jp 83 Euro S AT 47k

jp 83 Euro S AT 47k

#24

Inventor

Rennlist Member

Rennlist Member

Thread Starter

jpitman2,

IIRC, it was posted a while back that there was a 6 degree movement on the 32V gear. Besides the keyway, the 3 bolt slots in the gear will serve to limit the travel.

The cam diameter is 23mm, the diameter of the gear is 144mm, and the key is 4mm. I would guess that the keyway is 6mm too.

"it's easy to change the timing by just pulling the top covers, slackening the main bolt and 3 smaller bolts, adjust the relationship, bolt it all up again"

Yep, all you left out was having to rotate the crank back or forward slightly. It will be even easier for me, since I left the covers off, cuz it looks cool (and they all fell apart).

...

For a 78-82 (flat tooth belt), going by 928 Intl's web store, assuming hubs are ~$25 each, it looks to be about ~$200 for a 32V gear swap, with all used parts. 83-84 already have the HTD (round tooth belt) crank and oil pump gears, so it's only ~$130 used!

If all you wanted to do was align the cams for 83-84, all you'd need is a 32V gear and hub for the right (US passenger) cam.

IIRC, it was posted a while back that there was a 6 degree movement on the 32V gear. Besides the keyway, the 3 bolt slots in the gear will serve to limit the travel.

The cam diameter is 23mm, the diameter of the gear is 144mm, and the key is 4mm. I would guess that the keyway is 6mm too.

"it's easy to change the timing by just pulling the top covers, slackening the main bolt and 3 smaller bolts, adjust the relationship, bolt it all up again"

Yep, all you left out was having to rotate the crank back or forward slightly. It will be even easier for me, since I left the covers off, cuz it looks cool (and they all fell apart).

...

For a 78-82 (flat tooth belt), going by 928 Intl's web store, assuming hubs are ~$25 each, it looks to be about ~$200 for a 32V gear swap, with all used parts. 83-84 already have the HTD (round tooth belt) crank and oil pump gears, so it's only ~$130 used!

If all you wanted to do was align the cams for 83-84, all you'd need is a 32V gear and hub for the right (US passenger) cam.

Last edited by PorKen; 04-11-2004 at 01:39 AM.

#25

Inventor

Rennlist Member

Rennlist Member

Thread Starter

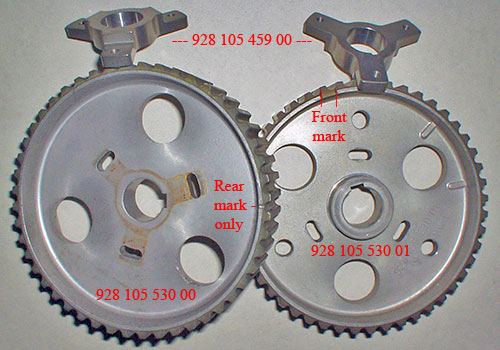

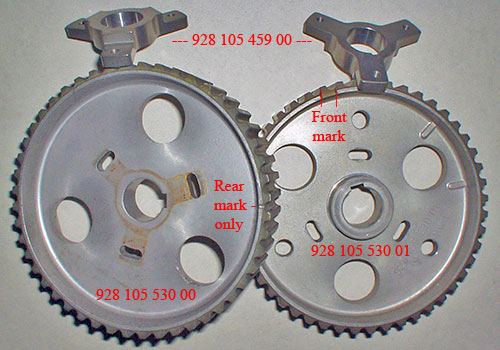

32V cam gears and hubs (spiders):

The gear on the right supercedes the original sprocket (gear).

It has a large timing mark on the front, plus larger and extra lightening holes.

The steel hubs are drilled offset on two of the legs to limit the movement in the slots to the size of the keyway in the gears.

I'm working on a degree marked 'pointer' to go on the back of the hub for easier setup, so I can't install them just yet.

928 Intl. sells used hubs for $10, used gears for $40, if they have them.

(Thanks very much to Dave and Jeanie at 928 Specialists for my new hubs.)

The gear on the right supercedes the original sprocket (gear).

It has a large timing mark on the front, plus larger and extra lightening holes.

The steel hubs are drilled offset on two of the legs to limit the movement in the slots to the size of the keyway in the gears.

I'm working on a degree marked 'pointer' to go on the back of the hub for easier setup, so I can't install them just yet.

928 Intl. sells used hubs for $10, used gears for $40, if they have them.

(Thanks very much to Dave and Jeanie at 928 Specialists for my new hubs.)

#26

Inventor

Rennlist Member

Rennlist Member

Thread Starter

After doing some rough measurements it appears that there's actually one tooth movement plus or minus!

That's 7.5 degrees advance or retard (15 at the crank). A little filing would easily add a few degrees if necessary.

By the rust marks on the used gears, the gears I have were set right on the center mark. Also, the front mark on the later gear only shows part of the possible movement.

...

On my 16V engine, I need ~2.5 degrees advance on the right cam gear to synchronize the cam marks. Then another 3 degrees advance for the fat torque. That still leaves another 2 degrees!

That's 7.5 degrees advance or retard (15 at the crank). A little filing would easily add a few degrees if necessary.

By the rust marks on the used gears, the gears I have were set right on the center mark. Also, the front mark on the later gear only shows part of the possible movement.

...

On my 16V engine, I need ~2.5 degrees advance on the right cam gear to synchronize the cam marks. Then another 3 degrees advance for the fat torque. That still leaves another 2 degrees!

#27

Inventor

Rennlist Member

Rennlist Member

Thread Starter

The back spacing is different between the 16V and 32V sprockets! (The 16V has 4mm backspacing, whereas the 32V has less than .5mm.)

If you look at used sprockets, the belt usually rides right near the front. There is about 3mm unused in the back. In order to have the maximum amount of hub on the key, I am going to move the sprocket forward 1mm, so only a 3mm backspace. (The hub is 12mm deep, I am going to machine it to 9mm, so it will use ~7mm of the 16mm cam key.) The cam bolt can be reused as the total depth will be less than 1mm deeper than the 16V sprocket.

There was no way that I could think of to make a degreed wheel or pointer that would have any real accuracy. There were too many places for slop to be introduced in the available mounting points.

I've designed a 'pointer' tool that shows the position of the cam key, not the gear, to set the advance/retard relative to the crankshaft damper marks. While adjusting, the pointer tool is bolted on the front of the sprocket, through to the hub, and is removed when the cam bolt is tightened.

If you look at used sprockets, the belt usually rides right near the front. There is about 3mm unused in the back. In order to have the maximum amount of hub on the key, I am going to move the sprocket forward 1mm, so only a 3mm backspace. (The hub is 12mm deep, I am going to machine it to 9mm, so it will use ~7mm of the 16mm cam key.) The cam bolt can be reused as the total depth will be less than 1mm deeper than the 16V sprocket.

There was no way that I could think of to make a degreed wheel or pointer that would have any real accuracy. There were too many places for slop to be introduced in the available mounting points.

I've designed a 'pointer' tool that shows the position of the cam key, not the gear, to set the advance/retard relative to the crankshaft damper marks. While adjusting, the pointer tool is bolted on the front of the sprocket, through to the hub, and is removed when the cam bolt is tightened.

#28

Drifting

porken, did you post any close up pics for your light upgrade?

with respect to the cam timing, as stock how far out are the two banks relative to each other and is correcting this significant to performance?

with respect to the cam timing, as stock how far out are the two banks relative to each other and is correcting this significant to performance?

#29

Rennlist Member

Porken, does your last post mean the camshaft noses are different from 16V to 32 v cams? I was wondering about that. Also, part of the WSM addressing the adjustment using the hub and extra M5 bolts is very unclear to me - I seem to recall Wally posting a clarification on it once but I cant find it now. So, your plan is to shave one face of the hub, so it and the 32V wheel will fit on a 16V cam nose? Is there enough space to rotate the cam wrt the wheel with it all mounted? We dont have the luxury of moving the cam via a hex on it with cam cover off like the 32V guys.

Is there any reason one could not leave the 3 M5 bolts in place, as well as the main central bolt, once the timing was adjusted? The WSM says to remove after tightening centre bolt, but why?

jp 83 Euro S AT 47k Whiteout

Is there any reason one could not leave the 3 M5 bolts in place, as well as the main central bolt, once the timing was adjusted? The WSM says to remove after tightening centre bolt, but why?

jp 83 Euro S AT 47k Whiteout

#30

Inventor

Rennlist Member

Rennlist Member

Thread Starter

drnick,

Here's how she looks today:

If you'd like a particular closeup of the lights, just PM me.

The amount varies between cars. On mine the right cam was about 2.5 degree retarded, the left was .5 degree advanced. It's been posted that people have as much as 1/2 tooth off, or 3.75 degrees.

I found with my advance idler that just a few degrees advance of both cams made a noticeable difference in torque.

After adjusting to line up the cam sprocket marks, so that both banks are 3 degrees advanced, I have more torque, at lower rpms, it idles better, and even though I was able to raise the fuel pressure up to 3bar, I have gained a conservative 1.5 MPG average reduction in fuel consumption in city driving.

On the dyno, maximum horsepower did not increase but the torque peak is more like a plateau, it comes on earlier and stays flat for ~1200rpm. However, if the cams were retarded instead of advanced, there should be a horsepower jump, with some torque loss. I would guess that a supercharged engine would do well with some retard.

...

jpitman2,

The 32V camshaft nose is longer, and the cam is set back further. Fortunately, the diameter is the same, 23mm, and the parallel key is also the same on the early 32V cams, 4mm wide x 16mm long. After machining, the face of my 32V sprockets will be 1mm farther forward (which should center the belt better), but the 16V bolt I'm reusing will only be ~.6mm farther out.

The M5 bolt procedure perplexed me for a bit too, but then I realized that the 32V distributor rotor bolts to the hub when the covers are on. I am going to use 5mm x 20 studs, red Locktite'd to the hubs and nuts with washers, and I will leave them in place once they are adjusted.

You can't reach the cam with the assembly mounted, so I will have to tighten the sprocket to the hub, rotate the cam, then loosen and readjust. I used the same trial and error method setting up the idler pulleys that I have now.

Here's how she looks today:

If you'd like a particular closeup of the lights, just PM me.

The amount varies between cars. On mine the right cam was about 2.5 degree retarded, the left was .5 degree advanced. It's been posted that people have as much as 1/2 tooth off, or 3.75 degrees.

I found with my advance idler that just a few degrees advance of both cams made a noticeable difference in torque.

After adjusting to line up the cam sprocket marks, so that both banks are 3 degrees advanced, I have more torque, at lower rpms, it idles better, and even though I was able to raise the fuel pressure up to 3bar, I have gained a conservative 1.5 MPG average reduction in fuel consumption in city driving.

On the dyno, maximum horsepower did not increase but the torque peak is more like a plateau, it comes on earlier and stays flat for ~1200rpm. However, if the cams were retarded instead of advanced, there should be a horsepower jump, with some torque loss. I would guess that a supercharged engine would do well with some retard.

...

jpitman2,

The 32V camshaft nose is longer, and the cam is set back further. Fortunately, the diameter is the same, 23mm, and the parallel key is also the same on the early 32V cams, 4mm wide x 16mm long. After machining, the face of my 32V sprockets will be 1mm farther forward (which should center the belt better), but the 16V bolt I'm reusing will only be ~.6mm farther out.

The M5 bolt procedure perplexed me for a bit too, but then I realized that the 32V distributor rotor bolts to the hub when the covers are on. I am going to use 5mm x 20 studs, red Locktite'd to the hubs and nuts with washers, and I will leave them in place once they are adjusted.

You can't reach the cam with the assembly mounted, so I will have to tighten the sprocket to the hub, rotate the cam, then loosen and readjust. I used the same trial and error method setting up the idler pulleys that I have now.

Last edited by PorKen; 04-30-2004 at 08:28 PM.