Help - Fuel Level Indication

#1

[SOLVED, see quoted responses to GregBBRD)

> New fuel level sender (from 928sRus)

> Gauge cluster contacts cleaned

> Tank filled until station nozzle kicks off twice

> Fuel visible mid-level in the filler neck

> No pinch in the neck vent hose that enters the frame to the L fitting on the tank

...yet gauge shows around 3/4 full. If I connect to my repaired OEM fuel level sender and hand-slide the float the needle travels the full range of motion. Air bubble in the tank? I don't want to undo the collar when there's fuel in the neck.

Ideas?

85.6 928S AT

> New fuel level sender (from 928sRus)

> Gauge cluster contacts cleaned

> Tank filled until station nozzle kicks off twice

> Fuel visible mid-level in the filler neck

> No pinch in the neck vent hose that enters the frame to the L fitting on the tank

...yet gauge shows around 3/4 full. If I connect to my repaired OEM fuel level sender and hand-slide the float the needle travels the full range of motion. Air bubble in the tank? I don't want to undo the collar when there's fuel in the neck.

Ideas?

85.6 928S AT

Last edited by Meatful; 12-13-2020 at 04:07 PM.

#2

Rennlist Member

My thought is that there is a vent line from the body of the tank inboard of the frame and to the smaller "gob" of tank outboard of the frame. The inboard part of the tank rises above the saddle between them. To allow the inboard part of the tank to fully fill there is a vent line that goes from the top of the inboard part down and through the frame and up into the neck of the tank which allows air to escape the inboard part of the tank when the level of fuel reaches the saddle and the air is then cut off from venting through the neck. If the vent line is kinked or crimped in some way or even if it might somehow be filled with fuel it will no longer let the air vent after the level reaches the saddle, when filing. That is probably about 3/4 tank. I suspect your vent line is plugged or full of fuel. Better minds than mine will suggest how best to clear the vent line; but my thought is to simply locate where the vent line comes into the neck of the fill port and try to blow air back through it with your compressor and a length of plastic tubing, or even with your lungs.

On the other hand, if your vent line is somehow kinked or crimped you still have the same problem but a much more complicated solution.

That's my $2 idea. I got past 2 cents a long time ago.

On the other hand, if your vent line is somehow kinked or crimped you still have the same problem but a much more complicated solution.

That's my $2 idea. I got past 2 cents a long time ago.

Last edited by Jerry Feather; 12-10-2020 at 10:48 AM.

#3

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Following on the excellent guidance from Jerry, you can look at the amount of fuel added to get an idea about blockage in that crossover vent hose. When it's blocked or kinked, the tank will only hold about 16 gals. If you fill from less than 1/2 indicated, you can guesstimate if the tank is actually holding 21 gals with liquid up in the filler neck.

The system includes an expansion bottle above and forward of the filler in the wheelhouse, with a liquid overflow from that section somewhat protected by a rollover valve, vents liquid to the center rear and vapor forward to the carbon canister. Not A Good Idea to fill into the neck if you can avoid it. I did that last fall before storage prep for my '89 car, and had a garage full of fuel fumes the next morning from expansion in the tank. Oregon has attendant-fill only, but I went to the second click as you did, after I talked the attendant into letting me fill it. I had to go drive some of the fuel out before the car moved to hibernation storage.

The system includes an expansion bottle above and forward of the filler in the wheelhouse, with a liquid overflow from that section somewhat protected by a rollover valve, vents liquid to the center rear and vapor forward to the carbon canister. Not A Good Idea to fill into the neck if you can avoid it. I did that last fall before storage prep for my '89 car, and had a garage full of fuel fumes the next morning from expansion in the tank. Oregon has attendant-fill only, but I went to the second click as you did, after I talked the attendant into letting me fill it. I had to go drive some of the fuel out before the car moved to hibernation storage.

#4

Rennlist Member

I have a vague memory that for whatever reason, there is a procedure for recalibrating the gauge on these cars. If I remember correctly, you have to have a specific amount of fuel in the tank (15 L?) and then do some stuff to get the needle to show the right level.

Like I said, it's a vague memory, but it has stuck with me and always indicated to me that there was more going on with the level display than just what the float/sender is outputting. I am sure that more experienced brains will chime in and set you straight.

Good luck

Like I said, it's a vague memory, but it has stuck with me and always indicated to me that there was more going on with the level display than just what the float/sender is outputting. I am sure that more experienced brains will chime in and set you straight.

Good luck

#5

Rennlist Member

When the key is off where does the needle sit? Picture would be good.

#6

#7

Rennlist Member

When the fuel level has dropped to a safe level you could try removing the new sender and repeat the test you did with the OEM to prove it’s able to read full when the float is at the top? You’re then definately dealing with some kind of vent issue as above.

Trending Topics

#8

> New fuel level sender (from 928sRus)

> Gauge cluster contacts cleaned

> Tank filled until station nozzle kicks off twice

> Fuel visible mid-level in the filler neck

> No pinch in the neck vent hose that enters the frame to the L fitting on the tank

...yet gauge shows around 3/4 full. If I connect to my repaired OEM fuel level sender and hand-slide the float the needle travels the full range of motion. Air bubble in the tank? I don't want to undo the collar when there's fuel in the neck.

Ideas?

85.6 928S AT

> Gauge cluster contacts cleaned

> Tank filled until station nozzle kicks off twice

> Fuel visible mid-level in the filler neck

> No pinch in the neck vent hose that enters the frame to the L fitting on the tank

...yet gauge shows around 3/4 full. If I connect to my repaired OEM fuel level sender and hand-slide the float the needle travels the full range of motion. Air bubble in the tank? I don't want to undo the collar when there's fuel in the neck.

Ideas?

85.6 928S AT

#9

That's a great idea gazfish, appreciate it.

#10

Well that would be yet another new challenge...I'm going to try what gazfish suggested and if the new sender does report only 3/4 it may be time to chase that solder joint theory or return the unit to Roger. Seems more and more like venting methinks.

#11

Rennlist Member

My previously owned 86.5 had a similar issue. I ignored it until the odometer gear failed.

While I had the pod apart I made sure to have the tank full and I moved the needle to the full mark.

Problem solved.

While I had the pod apart I made sure to have the tank full and I moved the needle to the full mark.

Problem solved.

#12

Team Owner

NOTE did you remove the small metal float stop in the new sender?

this is a thin piece of wire placed into the side of the sender through a small hole it keeps the sender from going full travel.

NOTE I would also remove the plug on the other unused port of your new sender,

and put a piece of hose that is plugged and use clamps

NOTE that plug is not a secure way to stop fuel,

once the tank is hot and the pressure builds the plug could be pushed off,

then if the tank has enough fuel in it it will pour out. Or this will will happen when you fill the tank

Update IDK if the 944 sender also has this wire inserted I think it does.

That said it would be smart to plug the new sender in and turn it so the float goes to the top and see what the indication does before you install it into the tank.

Also it could be possible that the new sender is sealed so the float will only rise so far and thus an air bubble prevents the sender from topping out

this is a thin piece of wire placed into the side of the sender through a small hole it keeps the sender from going full travel.

NOTE I would also remove the plug on the other unused port of your new sender,

and put a piece of hose that is plugged and use clamps

NOTE that plug is not a secure way to stop fuel,

once the tank is hot and the pressure builds the plug could be pushed off,

then if the tank has enough fuel in it it will pour out. Or this will will happen when you fill the tank

Update IDK if the 944 sender also has this wire inserted I think it does.

That said it would be smart to plug the new sender in and turn it so the float goes to the top and see what the indication does before you install it into the tank.

Also it could be possible that the new sender is sealed so the float will only rise so far and thus an air bubble prevents the sender from topping out

Last edited by Mrmerlin; 12-11-2020 at 10:34 AM.

#13

NOTE did you remove the small metal float stop in the new sender?

this is a thin piece of wire placed into the side of the sender through a small hole it keeps the sender from going full travel.

NOTE I would also remove the plug on the other unused port of your new sender,

and put a piece of hose that is plugged and use clamps

NOTE that plug is not a secure way to stop fuel,

once the tank is hot and the pressure builds the plug could be pushed off,

then if the tank has enough fuel in it it will pour out. Or this will will happen when you fill the tank

this is a thin piece of wire placed into the side of the sender through a small hole it keeps the sender from going full travel.

NOTE I would also remove the plug on the other unused port of your new sender,

and put a piece of hose that is plugged and use clamps

NOTE that plug is not a secure way to stop fuel,

once the tank is hot and the pressure builds the plug could be pushed off,

then if the tank has enough fuel in it it will pour out. Or this will will happen when you fill the tank

Great point mrmerlin on capping the unused vent. I really appreciate that catch and will execute on your advice.

#14

Hi, just starting out posting on this great forum. I also have the same exact issue as @Meatful . Good idea on capping the unused vent, I didn't do that, but likely will. I didn't see anything to remove from the new sender needed to allow for full float movement. I verified that the tank is filling to capacity (21 ish gallons), so there maybe something else going on.

Look forward to your what you find @Meatful , I'll pull the sender again this weekend to investigate.

Look forward to your what you find @Meatful , I'll pull the sender again this weekend to investigate.

#15

NOTE did you remove the small metal float stop in the new sender?

this is a thin piece of wire placed into the side of the sender through a small hole it keeps the sender from going full travel.

NOTE I would also remove the plug on the other unused port of your new sender,

and put a piece of hose that is plugged and use clamps

NOTE that plug is not a secure way to stop fuel,

once the tank is hot and the pressure builds the plug could be pushed off,

then if the tank has enough fuel in it it will pour out. Or this will will happen when you fill the tank

Update IDK if the 944 sender also has this wire inserted I think it does.

That said it would be smart to plug the new sender in and turn it so the float goes to the top and see what the indication does before you install it into the tank.

Also it could be possible that the new sender is sealed so the float will only rise so far and thus an air bubble prevents the sender from topping out

this is a thin piece of wire placed into the side of the sender through a small hole it keeps the sender from going full travel.

NOTE I would also remove the plug on the other unused port of your new sender,

and put a piece of hose that is plugged and use clamps

NOTE that plug is not a secure way to stop fuel,

once the tank is hot and the pressure builds the plug could be pushed off,

then if the tank has enough fuel in it it will pour out. Or this will will happen when you fill the tank

Update IDK if the 944 sender also has this wire inserted I think it does.

That said it would be smart to plug the new sender in and turn it so the float goes to the top and see what the indication does before you install it into the tank.

Also it could be possible that the new sender is sealed so the float will only rise so far and thus an air bubble prevents the sender from topping out

> Full range of motion on float, gauge indicates through full range of motion.

Disconnected, rotated to vertical, gently set on side and reconnected (shows R). Rotated to vertical, needle swings evenly (shows 4/4).

> Inspected breather hole from inside tank, no obvious blockage.

Used mirror to see breather hole on filler side of tank

> Pulled hose connecting compensation tank to goose neck,, no blockage observed.

Bore scope aimed into T fitting at the top of the filler goose neck, no obstructions observed

> Flexible sheathed wire fished into T and through breather hose, no obstructions felt.

> Shop air blown into filler neck T (from compensation tank hose barb end) and tank observed swelling. If the fitting end is quickly plugged (with a finger), tank holds air.

Compressed air blown into T fitting from compensation tank side in the direction of the tank breather hose which runs through frame

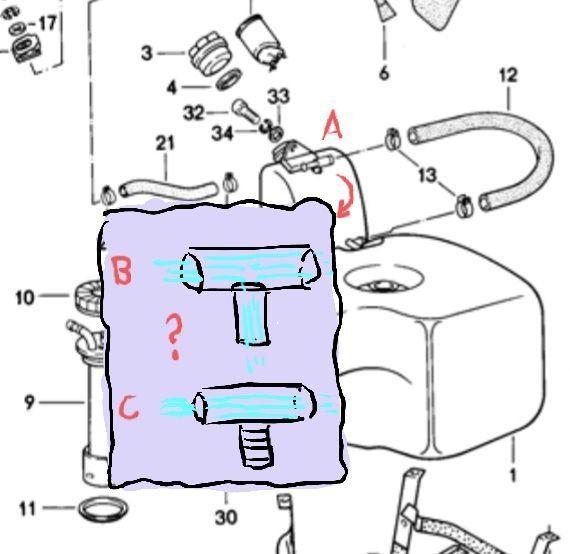

QUESTION 1: Does the T fitting (A) have three openings (B) or two (C)?

Is the T a two or three path channel?

> Applied shop into compensation tank hose (21) and felt back pressure. NOTE: the air may have triggered the rollover valve.

Air injected into compensation (expansion) tank hose

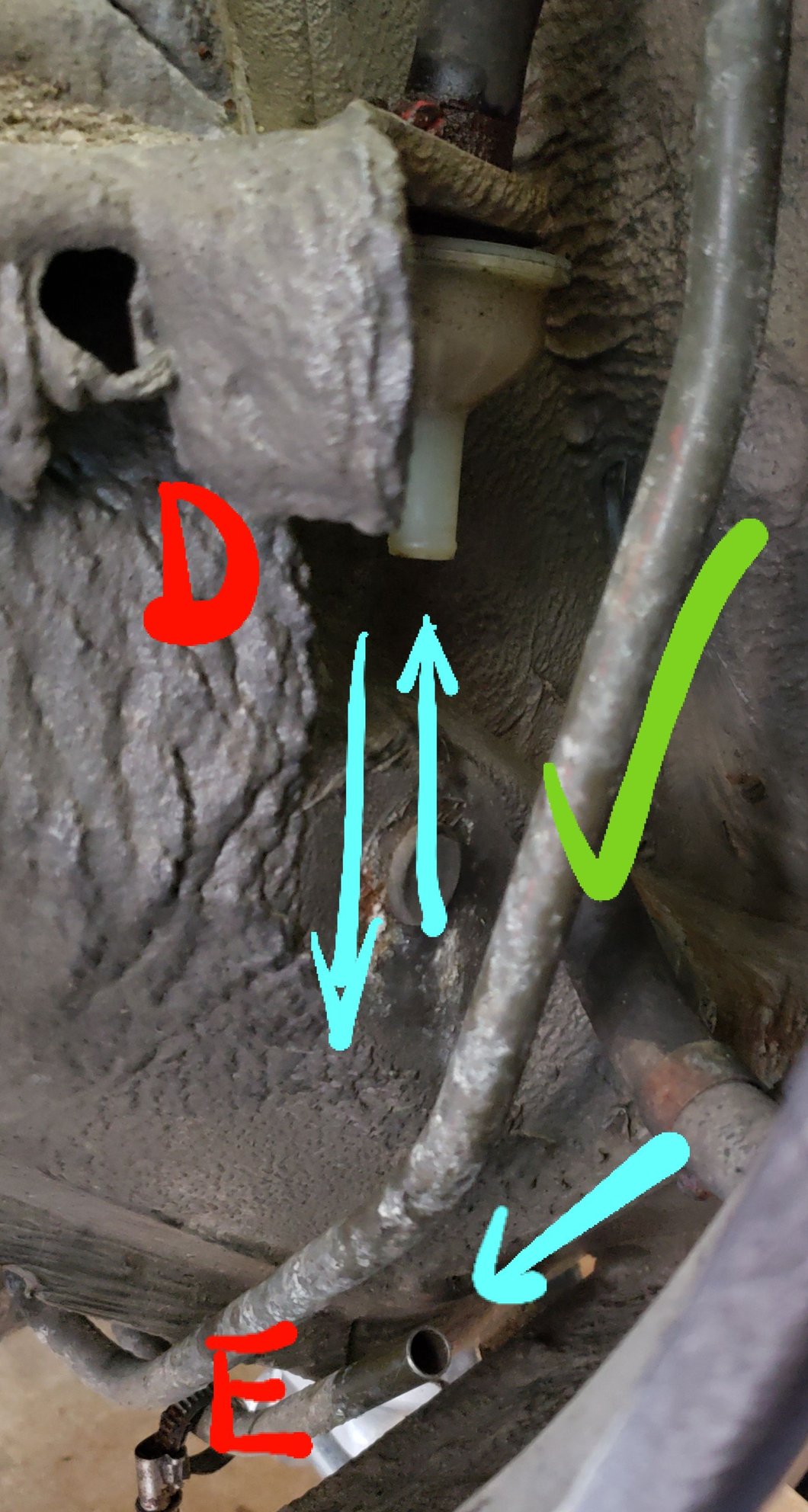

> Pulled hose (D) from the rollover valve, confirmed air can flow bidirectionally (by drawing and blowing breaths into the hose which connects the hardline to the valve, not shown).

> Applied shop air into hardline (E), observed light resistance and observed vapor escaping from aft vent between tank and bumper (the one with the conical/fluted fitting).

Inside wheel well showing vent valve and hardline connection with hose removed

> Reinstalled everything, went to two different gas stations (in hopes of perhaps blowing out any obstructions) but still could not fill tank to even 3/4 mark indicated.