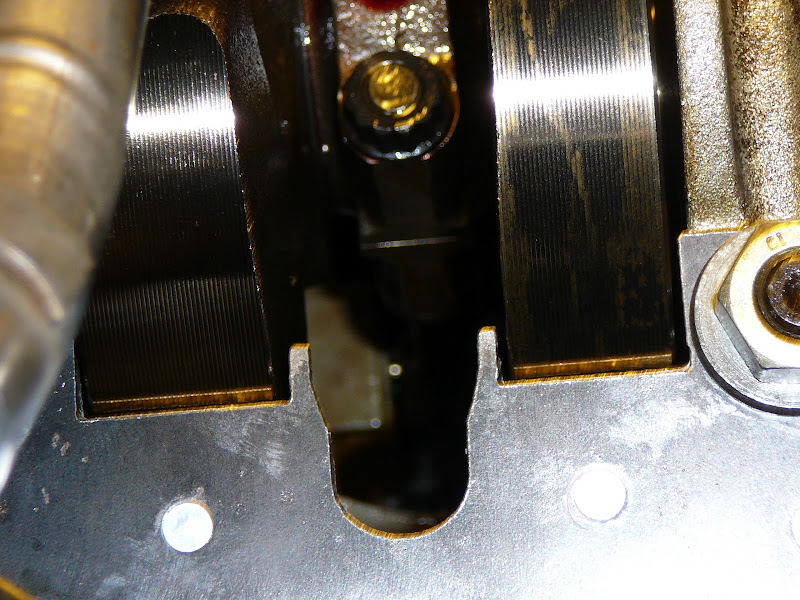

Rod bearings replacement and crank scraper installation completed.

#1

Rennlist Member

Thread Starter

My car turned 100,000 miles at the end of last year and I decided to check/replace the rod bearings to have some peace of mind for the near future track seasons. I have been only tracking the car for the last 10,000 miles and I know that this "maintenance" had not been done on the car before. I also decided to use the opportunity to install a crank scraper as well.

I have to admit that I was pleasantly surprised when I had the old rod bearings removed - they show almost no signs of wear to make one concerned. I was able to accomplish the job mostly due to my friend's (Jay) knowledge. He did a really good job cleaning all the parts while everything was apart.

I have to admit that I was pleasantly surprised when I had the old rod bearings removed - they show almost no signs of wear to make one concerned. I was able to accomplish the job mostly due to my friend's (Jay) knowledge. He did a really good job cleaning all the parts while everything was apart.

#3

Rennlist Member

Thread Starter

#5

Rennlist Member

Thread Starter

I'd recommend leaving the steering rack on the cross member and just disconnect the line going to the cooler and the one connected to the pump. You will have to take your time. Dropping the cross member is a tedious process but nothing special. I had to disconnect the motor mounts from the ENGINE support and leave them attached to the cross member. It did not work the other way even though it is easier and looks that it could work.

#6

Dimi,

I installed the teflon version in my turbo a few years back - noticed 1 bar better oil pressure at all operating temps - let us know how the standard scraper works for you. I'm mainly interested in HOT idle pressure. I want to know if the oil de-aeration was due to more oil in the sump, or if the windage tray was mostly the reason.

I installed the teflon version in my turbo a few years back - noticed 1 bar better oil pressure at all operating temps - let us know how the standard scraper works for you. I'm mainly interested in HOT idle pressure. I want to know if the oil de-aeration was due to more oil in the sump, or if the windage tray was mostly the reason.

#7

Rennlist Member

Dimi -

It looks like you used one of those HF engine supports from above then dropped the front cross member completely? If so, where did you attach the support chains to the block?

About how much time would you say it took to replace the bearings? I'm doing my pan seal and thinking about replacing the bearings while I'm at it.

It looks like you used one of those HF engine supports from above then dropped the front cross member completely? If so, where did you attach the support chains to the block?

About how much time would you say it took to replace the bearings? I'm doing my pan seal and thinking about replacing the bearings while I'm at it.

Trending Topics

#9

Rennlist Member

Hey Justin - thanks, I didn't know that. One less thing to buy. I wasn't planning to install a crank scraper on this go, but I did want to check #2 rod bearing and replace all if necessary. I've never driven this car, just got it a few months ago and working my way through stuff. Since I was putting in new motor mounts I had to drop the front cross member anyway and thought I'd do the pan gasket, one thing led to another and I thought of the rod bearings. "While you're in there" just keeps getting bigger the deeper I get into the car. I've got the entire drive train out now, I should have just pulled the engine too and have done with it...

#10

Three Wheelin'

Hey Justin - thanks, I didn't know that. One less thing to buy. I wasn't planning to install a crank scraper on this go, but I did want to check #2 rod bearing and replace all if necessary. I've never driven this car, just got it a few months ago and working my way through stuff. Since I was putting in new motor mounts I had to drop the front cross member anyway and thought I'd do the pan gasket, one thing led to another and I thought of the rod bearings. "While you're in there" just keeps getting bigger the deeper I get into the car. I've got the entire drive train out now, I should have just pulled the engine too and have done with it...

#11

Rennlist Member

I've talked to a lot of people who've checked and replaced the rod bearings at 150,000 only to find they were fine, but once you're in there you may as well replace them. I've never done the 944 so I thought I'd ask Dimi about how much extra work it is. My background with rod bearings is all on a bench, no idea really what the procedures are for doing them "in vivo" so to speak. If I hadn't stumbled on this thread I never would have thought it was possible.

As it turns out I already have the front cross member back in, but I've hit a snag that may cause me to take it back out again. I was changing the engine mounts, putting in semi-solid "SuperMounts" since the old ones had 125K+ on them and the passenger side was shot.

I used the lift from the bottom approach, everything went smoothly but the engine shifted while it was up and now I need to figure out how to winch it back into position so I can drop it on to the new mounts. It's moved forward and down about an inch on the right (passenger side). I've stopped for today but need to get back on it tomorrow.

I'm thinking about using a ratcheting cargo strap looped around the front cross member and the bottom of the oil pan to pull it back in position. Anyone else faced this?

#12

Rennlist Member

Sorry, the engine moved towards the rear of the car and down about an inch in both dimensions on the passenger side. I was standing under the lift looking at it from behind the engine (clutch side) and thought "forward" as in "towards me"

It's really off to the rear.

I'm thinking about one of those Harbor Freight engine "lifts' to fix it since I can't get my hoist into the front of the bay the car is in. I little bad planning on my part...

It's really off to the rear.

I'm thinking about one of those Harbor Freight engine "lifts' to fix it since I can't get my hoist into the front of the bay the car is in. I little bad planning on my part...

#13

Rennlist Member

Besides, it was a long day and I'll talk about rod bearings with anyone willing. God knows I can't get my wife or my dog interested. The way I did it didn't use that HF engine brace and my bet is I wouldn't be able to replace the oil pan gasket and tod bearings without it since I have the engine up on the oil pan.

The original question was about where to set the brace/lift/support, whatever you call it. HF has them for 79 bucks and I'm thinking of going for it since I can't get my hoist in, but I can't figure out how you'd use it since the lift points on the engine are on the diagonal and that brace goes straight over the struts.

The original question was about where to set the brace/lift/support, whatever you call it. HF has them for 79 bucks and I'm thinking of going for it since I can't get my hoist in, but I can't figure out how you'd use it since the lift points on the engine are on the diagonal and that brace goes straight over the struts.

Last edited by Otto Mechanic; 03-21-2015 at 08:26 AM.

#14

Three Wheelin'

Besides, it was a long day and I'll talk about rod bearings with anyone willing. God knows I can't get my wife or my dog interested. The way I did it didn't use that HF engine brace and my bet is I wouldn't e able to do the oil pan and bearings without it since I have the engine up on the pan.

The original question was about where to set the brace/lift/support, whatever you call it. HF has them for 79 bucks and I'm thinking of going for it since I can't get my hoist in, but I can't figure out how you'd use it since the lift points on the engine are on the diagonal and that brace goes straight over the struts.

The original question was about where to set the brace/lift/support, whatever you call it. HF has them for 79 bucks and I'm thinking of going for it since I can't get my hoist in, but I can't figure out how you'd use it since the lift points on the engine are on the diagonal and that brace goes straight over the struts.

#15

Rennlist Member

I lifted it using a jack and wood block under the pan, I don't know why it shifted on me either. It's on a lift with a hydraulic jack on a jack tray. The clutch and driveshaft are out, nothing else worth mentioning I don't think. When I took it up it tilted towards the passenger side of the car and moved back (towards the rear) about an inch.

I couldn't change the oil pan seal using this lash up anyway since I'm lifting the engine with a jack under the oil pan, so I was thinking of getting the HF support but couldn't figure how it would work. So you just lift on the front hard point? I thought you'd need two points just to lift? Isn't it out of balance on a single point?

I've only used my hoist before and it has a separate load leveler, I've never tried one of the HF or OTC supports but they'd be perfect in this case since I can't get the hoist in. Can't may be too strong a word; I can't do it easily, which is a bit different than can't I suppose

I couldn't change the oil pan seal using this lash up anyway since I'm lifting the engine with a jack under the oil pan, so I was thinking of getting the HF support but couldn't figure how it would work. So you just lift on the front hard point? I thought you'd need two points just to lift? Isn't it out of balance on a single point?

I've only used my hoist before and it has a separate load leveler, I've never tried one of the HF or OTC supports but they'd be perfect in this case since I can't get the hoist in. Can't may be too strong a word; I can't do it easily, which is a bit different than can't I suppose

Last edited by Otto Mechanic; 03-21-2015 at 08:33 AM.