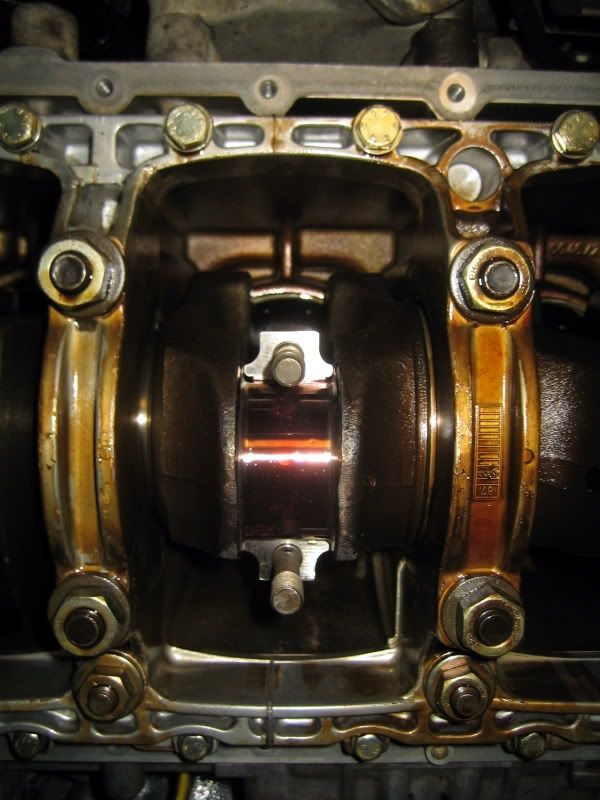

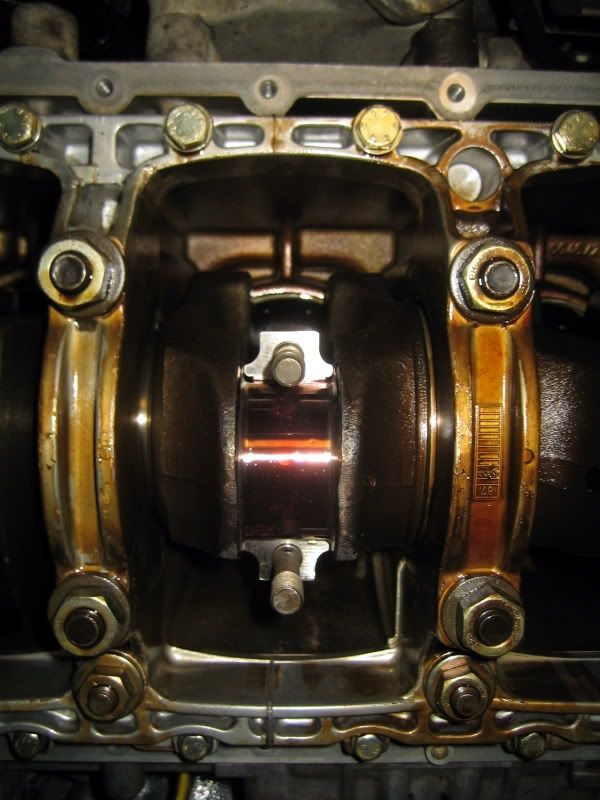

Intalling new rod bearings

#1

Rennlist Member

Thread Starter

Never done this before so I'm confused by step#56 in the replacement instructions from Pelican Parts site.

It reads:

56. Coat the new bearings with engine oil, and then place a large drop of assembly lube (penny sized) in the center of the inside of the bearing. Smooth the assembly lube with a CLEAN finger, insuring that nothing but oil and assembly lube are on the bearing.

I would only want to put oil on the inside of the bearing where the assembly lube also goes correct? Or does the film of oil coat the entire surface before it goes in the journals?

Holy **** I'll be glad when this is done. Long list of while you are at it parts is dragging this project out a bit. Also installed the LR oil pan baffle and oil pickup extension while I'm at it.

Thanks,

Brian

It reads:

56. Coat the new bearings with engine oil, and then place a large drop of assembly lube (penny sized) in the center of the inside of the bearing. Smooth the assembly lube with a CLEAN finger, insuring that nothing but oil and assembly lube are on the bearing.

I would only want to put oil on the inside of the bearing where the assembly lube also goes correct? Or does the film of oil coat the entire surface before it goes in the journals?

Holy **** I'll be glad when this is done. Long list of while you are at it parts is dragging this project out a bit. Also installed the LR oil pan baffle and oil pickup extension while I'm at it.

Thanks,

Brian

#2

Nordschleife Master

The bearing side that seats in the rod should be clean and installed dry. The side that faces the journal of the crank should just get a liberal amount of assembly lube.. just spread it out evenly with your finger, you cant over do it. I also give the journal a coating of assembly lube. I read the same thing when i did my rod bearings, not sure why they recommend oil and assembly lube.. seems redundant to me.

#5

Rennlist Member

well, I was going to start a thread about this... but I figure, if there is one, why not just jump in? I think it's relevant enough that I'm not hijacking...

I'll be doing this too rather soon, and a buddy of mine keeps telling me that I need to pull the rods and crank out and take them to a machine shop to have them re-sized or I will run serious risk of spinning a bearing...

I'm stuck here... on the one hand, I've not seen any mention of that being a requirement in the procedures and threads (thanks Jon) I've read detailing this job, and I don't hear much about spun bearings here either... on the other hand, my buddy is pretty damn knowledgeable and experienced when it comes to cars and repairs, albeit, not necessarily with the 944/951...

Is there something different about the 944/951 that makes it unnecessary to re-size the rods and journals, is it a good idea to have them re-sized? Is my buddy being paranoid? What do you think?

I'll be doing this too rather soon, and a buddy of mine keeps telling me that I need to pull the rods and crank out and take them to a machine shop to have them re-sized or I will run serious risk of spinning a bearing...

I'm stuck here... on the one hand, I've not seen any mention of that being a requirement in the procedures and threads (thanks Jon) I've read detailing this job, and I don't hear much about spun bearings here either... on the other hand, my buddy is pretty damn knowledgeable and experienced when it comes to cars and repairs, albeit, not necessarily with the 944/951...

Is there something different about the 944/951 that makes it unnecessary to re-size the rods and journals, is it a good idea to have them re-sized? Is my buddy being paranoid? What do you think?

#6

u should get some plastigauge (avail at napa/oreilly/whatever) and check the clearances between the bearing surface and the crank journal. if the crank journal is worn out of spec or out of round, it could go bad again very quickly.

if it is out of spec, going oversized bearings (expensive) and remachining the crank might be your option. or getting a good used crank to get back to spec

if it is out of spec, going oversized bearings (expensive) and remachining the crank might be your option. or getting a good used crank to get back to spec

#7

Nordschleife Master

BF951, definitely not the same person.

ihaza944t, probably just the difference between brands. As long as it says specifically it is engine assembly lube it should be fine. The stuff i used is made by Crane Cams, picked it up at a local speed shop. I know ARP makes some stuff called fastener assembly lube.. not sure what color it is but make sure its not that!

ihaza944t, probably just the difference between brands. As long as it says specifically it is engine assembly lube it should be fine. The stuff i used is made by Crane Cams, picked it up at a local speed shop. I know ARP makes some stuff called fastener assembly lube.. not sure what color it is but make sure its not that!