Rod Bearing replacement - or lack of : O

#1

Burning Brakes

Thread Starter

Join Date: Mar 2004

Location: Central Ohio

Posts: 891

Likes: 0

Received 0 Likes

on

0 Posts

Guys.

About to yank the rod caps and start replacing the bearings. Couple quick questions. (on a 1984 944 NA)

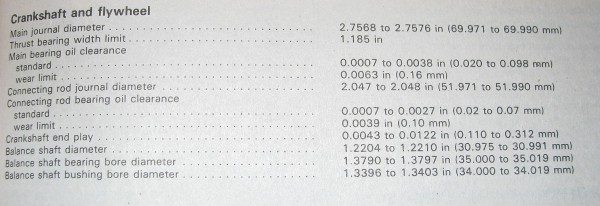

1. What is clearence supposed to be for oem rod to bearing? I'm planning to pick up some plasti gauges today, was curious what the gap is 'supposed to be.'

2. What's the torque spec for the rod nuts themselves? I have the new nuts so that's not a prob.

For the oil pan, I found these torque specs on clark's garage.

* Step 1 - Install bolts

* Step 2 - 4 Nm (3 ft-lbs)

* Step 3 - 8 Nm (6 ft-lbs)

Here's a few photos, I tried to remove / unbolt as little as possible to do this job.

Hoping tonight or tomorrow to get the lindsey baffle tig welded in.

Tom

About to yank the rod caps and start replacing the bearings. Couple quick questions. (on a 1984 944 NA)

1. What is clearence supposed to be for oem rod to bearing? I'm planning to pick up some plasti gauges today, was curious what the gap is 'supposed to be.'

2. What's the torque spec for the rod nuts themselves? I have the new nuts so that's not a prob.

For the oil pan, I found these torque specs on clark's garage.

* Step 1 - Install bolts

* Step 2 - 4 Nm (3 ft-lbs)

* Step 3 - 8 Nm (6 ft-lbs)

Here's a few photos, I tried to remove / unbolt as little as possible to do this job.

Hoping tonight or tomorrow to get the lindsey baffle tig welded in.

Tom

#2

i'm about to do mine again....(ugh headache. wish i had your lift)

plastigage 0.034-0.092 mm

rod nuts....search said 75Nm...i went by my haynes book...can't remember what ft lb was. i think 50 something

plastigage 0.034-0.092 mm

rod nuts....search said 75Nm...i went by my haynes book...can't remember what ft lb was. i think 50 something

#3

Got Nothin'

Rennlist Member

Rennlist Member

Wow...timely thread, about to do the oil pan gasket and look at the bearings while I am there.

Probably end up changing them.

Rate the job on a scale of 1-10, compared to a clutch job. (of which I have done twice).

Probably end up changing them.

Rate the job on a scale of 1-10, compared to a clutch job. (of which I have done twice).

#4

i've never done a proper clutch job (removing transaxle style) but once u either have the engine out on a stand or once the crossmember is out, it's pretty straight forward.

#6

Nordschleife Master

Clutch replacement i would rate in the 8-9 range (on my 951 atleast).. torque tube replacement is a 10 for sure just because its such a pain in the *** taking everything apart in the back..

.

.

Trending Topics

#8

Instructor

#10

Burning Brakes

Thread Starter

Join Date: Mar 2004

Location: Central Ohio

Posts: 891

Likes: 0

Received 0 Likes

on

0 Posts

SO fer the plastigauge, I just get it and pope between the bearing and crank and torque down and then take off and measure it for the change in width? NAPA told me they have two different size platigauges.

Course right now I am waiting on the local weld shop to call me back regarding my oil pan baffle.

Tom

Course right now I am waiting on the local weld shop to call me back regarding my oil pan baffle.

Tom

#11

clean off any oil from the journal and bearing surfaces. oil dissolves plastigage and makes it more mushy.

insert a strip of it across the surface of the journal. should be like inch and half or so. then put on the bearing and the cap. put the rod nut on and tighten it down to the torq spec. then loosen and remove the rod nut, remove the cap. the plastigage will be squished wide. use the plastigage gauge to measure how much squish there is.

insert a strip of it across the surface of the journal. should be like inch and half or so. then put on the bearing and the cap. put the rod nut on and tighten it down to the torq spec. then loosen and remove the rod nut, remove the cap. the plastigage will be squished wide. use the plastigage gauge to measure how much squish there is.

#13

Rennlist Member

Don't forget to use the old rod nuts when measuring. Rod nuts are good for only one torquing, so save the new ones for the final assembly.

And make sure the numbers on the rod cap match up with rod or the crank won't turn.

And make sure the numbers on the rod cap match up with rod or the crank won't turn.

#14

Burning Brakes

Thread Starter

Join Date: Mar 2004

Location: Central Ohio

Posts: 891

Likes: 0

Received 0 Likes

on

0 Posts

So I made some progress today. (baby steps.........)

Local weld shop tig'd in my lindsey trap door / baffle for me.

Grabbed some plasti-gauge and assembly lube after work.

Turns out the rod nuts were ribbed, meaning the bearings had been done so i likely didn't need to do them but oh well, I did em anyways.

Bearings looked in ok shape, i mean no streaks or nothing popping out at me so i saved em. One thing i liked was the fact they were OEM porsche and marked STD(standard bore)..

here's a few photos. I maybe was a little overboard on assembly lube(white crap) but i had a whole tube and only 4 rod bearings to do

maybe tomorrow night the pan will go back on after I cut some dental floss pieces

Oh wait, I still need to tack weld on this darn ring thing a ma jiggy to the oil pickup.

either way, i am bushed and its 11 and time to call it a night.

Tom

Local weld shop tig'd in my lindsey trap door / baffle for me.

Grabbed some plasti-gauge and assembly lube after work.

Turns out the rod nuts were ribbed, meaning the bearings had been done so i likely didn't need to do them but oh well, I did em anyways.

Bearings looked in ok shape, i mean no streaks or nothing popping out at me so i saved em. One thing i liked was the fact they were OEM porsche and marked STD(standard bore)..

here's a few photos. I maybe was a little overboard on assembly lube(white crap) but i had a whole tube and only 4 rod bearings to do

maybe tomorrow night the pan will go back on after I cut some dental floss pieces

Oh wait, I still need to tack weld on this darn ring thing a ma jiggy to the oil pickup.

either way, i am bushed and its 11 and time to call it a night.

Tom