MAF conversion maybe easier then we thought

#16

Addict

Rennlist Member

Rennlist Member

Originally Posted by Zero10

A situation like this should only arise when the MAF used is too small for the application.

Remember, if there was no difference in signal reported between the airflow at 5000rpm vs the airflow at 7000rpm, it wouldn't have worked very well on the car it came from.

I wonder, if somebody like FRWilk might be able to help out in the development of a cheap(er) MAF kit. He seems very knowledgeable with the Bosh Motronic system, and very able to burn chips. Then again, the chips might be just as expensive as his power prom's.

A friend of mine has an EEPROM burner, I'll give him a shout, perhaps he might be able to help in the chips department.

If somebody was able to read/write the chips, and knew at least a little about the functionality of everything inside the DME, there is a good chance I could lend a hand on the computer side of things. I'm in the midst of several low-level programming and I/O courses right now.

Remember, if there was no difference in signal reported between the airflow at 5000rpm vs the airflow at 7000rpm, it wouldn't have worked very well on the car it came from.

I wonder, if somebody like FRWilk might be able to help out in the development of a cheap(er) MAF kit. He seems very knowledgeable with the Bosh Motronic system, and very able to burn chips. Then again, the chips might be just as expensive as his power prom's.

A friend of mine has an EEPROM burner, I'll give him a shout, perhaps he might be able to help in the chips department.

If somebody was able to read/write the chips, and knew at least a little about the functionality of everything inside the DME, there is a good chance I could lend a hand on the computer side of things. I'm in the midst of several low-level programming and I/O courses right now.

No what hes saying is differences in airflow at those RPMS between say a 944 Turbo and the original car, which could be say some 4 cyl N/A car. If that car sucks in X amount of car at 5000RPM, and our car sucks in 2X at 5000RPM for double the amount, the reading will be twice as high. Same RPM, but because a 951 engine puts out more power and thus uses more air than the original car did and thus what the MAF is calibrated for, then thats the problem, and THAT cant be solved by a microcontroller.

That is because the microcontoller can only "massage" a signal when it gets something to use. If the MAF hits its limit and pumps out a solid 5 volt signal, then you cant massage that because ultimatly you still know dont know how much air is flowing in, so ultimatly the signal is useless anyway once it hits 5 volts out from the MAF itself.

Edit: Fixed some stuff at the end... I was on something o_O

Last edited by theedge; 11-30-2004 at 09:53 PM.

#17

Race Director

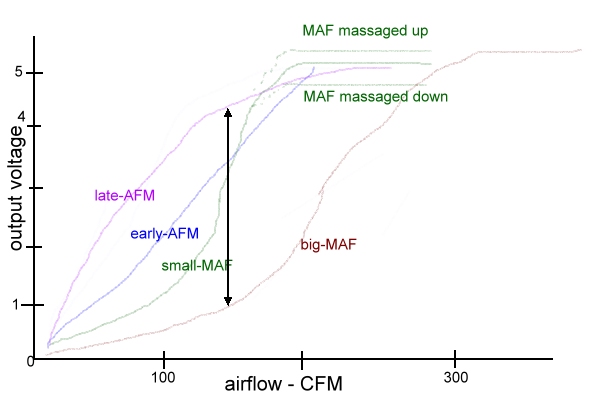

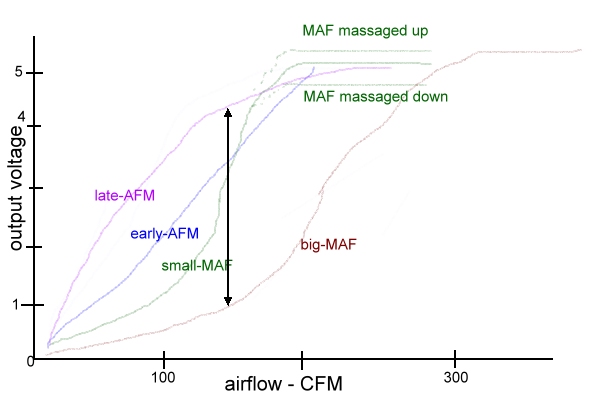

Brian, you're the only one that got it. Here's a picture of what I'm talking about (quick & dirty freehand-style since I'm not at home with my CAD tools):

Let's take the case of signal-massaging a maxed-out signal first (green line). As you can see, a flat-lined 5v input with a +/- 10% adjustment will ONLY result in a flat-lined 4.5v or 5.5v signal. This is a limitation of straight volt-in --> volt-out massaging. With 3D mapping with RPM x LOAD reference points on a 3D grid, you MAY be able to take that signal and adjust it by different amounts based upon RPM (at 100%x5000rpm=+5%, 100%x6000rpm=+10%, 100%x7000rpm=+15%). But this is fixing the symptoms of a problem, not the problem itself (too small a MAF). We have to get a MAF that's not going to max out before the max-flow CFM.

The other problem comes in at all output-voltages BEFORE max-CFM. You can see the differences between the early and late AFM curves. The MAFs tend to be even further away. At every CFM flow, both the small and large MAFs tend to output lower voltages than the stock AFM. And when you size a MAF properly to flow the increased CFM from increased boost, the differences between the MAF and stock AFM becomes even greater.

The only way around this is to properly program a chip with the proper fuel-values for that MAF. Check out the software from Bonneville Motorwerks. It's based upon the early BMW software written by Jim Conforti. It will let you program in fuel & igntion values, but doesn't know anything about boost-related functions.

Let's take the case of signal-massaging a maxed-out signal first (green line). As you can see, a flat-lined 5v input with a +/- 10% adjustment will ONLY result in a flat-lined 4.5v or 5.5v signal. This is a limitation of straight volt-in --> volt-out massaging. With 3D mapping with RPM x LOAD reference points on a 3D grid, you MAY be able to take that signal and adjust it by different amounts based upon RPM (at 100%x5000rpm=+5%, 100%x6000rpm=+10%, 100%x7000rpm=+15%). But this is fixing the symptoms of a problem, not the problem itself (too small a MAF). We have to get a MAF that's not going to max out before the max-flow CFM.

The other problem comes in at all output-voltages BEFORE max-CFM. You can see the differences between the early and late AFM curves. The MAFs tend to be even further away. At every CFM flow, both the small and large MAFs tend to output lower voltages than the stock AFM. And when you size a MAF properly to flow the increased CFM from increased boost, the differences between the MAF and stock AFM becomes even greater.

The only way around this is to properly program a chip with the proper fuel-values for that MAF. Check out the software from Bonneville Motorwerks. It's based upon the early BMW software written by Jim Conforti. It will let you program in fuel & igntion values, but doesn't know anything about boost-related functions.

#18

Race Car

Okay, so what was wrong with my statement of 'that should only happen with too small of a MAF'??

Seems to me that's exactly what you guys just said!

Yep, the curves are completely different on a MAF signal from either AFM signal. The easiest solution is a table, this will work on smaller microcontrollers, but requires more memory. Although, I'm sure some math major could make a nice function to map one onto the other, I think it would be too processor-intensive to be worthwhile. I'm thinking with a microcontroller, with a couple of A-D converters, perhaps it could be modified to read DME temp senders, O2 sensor, etc, perhaps do some useful logging?... I guess that depends on the chip.

The website microchip.com has a bunch of prototyping boards, and things like that, but they're pretty expensive, although, on the up side, they come with a nice windows-based programming utility.

Seems to me that's exactly what you guys just said!

Yep, the curves are completely different on a MAF signal from either AFM signal. The easiest solution is a table, this will work on smaller microcontrollers, but requires more memory. Although, I'm sure some math major could make a nice function to map one onto the other, I think it would be too processor-intensive to be worthwhile. I'm thinking with a microcontroller, with a couple of A-D converters, perhaps it could be modified to read DME temp senders, O2 sensor, etc, perhaps do some useful logging?... I guess that depends on the chip.

The website microchip.com has a bunch of prototyping boards, and things like that, but they're pretty expensive, although, on the up side, they come with a nice windows-based programming utility.

#19

Race Director

"Okay, so what was wrong with my statement of 'that should only happen with too small of a MAF'??

Seems to me that's exactly what you guys just said!"

Nothing wrong with that, there's two issues we're discussing here:

1. clipped AFM & MAF signal: no amount of signal-massaging can fix. This occurs if people try to get a MAF that's calibrated similarly to the stock AFM.

2. mis-matched MAF-signal to chip-mapping: Compare both of the MAF signals above with the stock AFM. While you CAN use a microcontroller with a look-up table to convert the MAF signal into something that looks similar to the AFM, you end up with the problem in #1. Let's say the tick-marks on the CFM axis is 100, 200, 300CFM. If you get a MAF with a continuously-variable signal from 0-300CFM, like the large-MAF above, then you condition its signal to match the AFM, you'll max out at 5v around 200CFM. You then have no way to measuring air-flow between 200-300CFM because your microcontroller will be output a fixed 5v signal to the DME starting at 200CFM.

So your conversion table may look something like this:

The problem with converting the MAF signal into the AFM one is that you end up with the same high-flow clipped signal as the AFM if you try to flow more than stock volumes of air.

Seems to me that's exactly what you guys just said!"

Nothing wrong with that, there's two issues we're discussing here:

1. clipped AFM & MAF signal: no amount of signal-massaging can fix. This occurs if people try to get a MAF that's calibrated similarly to the stock AFM.

2. mis-matched MAF-signal to chip-mapping: Compare both of the MAF signals above with the stock AFM. While you CAN use a microcontroller with a look-up table to convert the MAF signal into something that looks similar to the AFM, you end up with the problem in #1. Let's say the tick-marks on the CFM axis is 100, 200, 300CFM. If you get a MAF with a continuously-variable signal from 0-300CFM, like the large-MAF above, then you condition its signal to match the AFM, you'll max out at 5v around 200CFM. You then have no way to measuring air-flow between 200-300CFM because your microcontroller will be output a fixed 5v signal to the DME starting at 200CFM.

So your conversion table may look something like this:

Code:

CFM AFM MAF MAF-massaged ------------------------- 50 2.0 0.3 2.0 100 3.2 0.5 3.2 150 4.0 0.8 4.0 200 4.8 1.7 4.8 250 5.0 3.5 5.0 300 5.0 5.0 5.0

#20

Three Wheelin'

Join Date: Jun 2001

Location: Winterville, NC

Posts: 1,688

Likes: 0

Received 0 Likes

on

0 Posts

So it really sounds like the only way to really do a proper MAF conversion is to have

Chips with the code and tables modified for the MAF and not use AFM chips with

a piggyback type controller.

Chips with the code and tables modified for the MAF and not use AFM chips with

a piggyback type controller.

#21

Race Director

Exactly! Due to the time involved with flow-benching a MAF and programming that particular voltage-calibration into the chips you end up spending more than buying an off-the-shelf MAF kit. The properly-matched chip to MAF is key here and that's why I think the APE MAF kits are the best. The genuine APE ones, not the copies off eBay. The chips are precisely matched to the MAF, so no signal massaging necessary and the precise accuracy of the MAF is preserved.

#22

Race Car

I was not aware that our engines could out-flow our AFM's. That presents a problem.

Like I said, I have a friend with an EEPROM burner, perhaps I can try modifying the stock maps, in that case, I might as well program it to read a MAF sensor while I'm in there. I'll talk to him about it.

Like I said, I have a friend with an EEPROM burner, perhaps I can try modifying the stock maps, in that case, I might as well program it to read a MAF sensor while I'm in there. I'll talk to him about it.

#23

Out-flowing the AFM isn't hard to believe but is this correct?

I find it hard to believe the ceiling for airflow is this low; Porsche over-engineered every other aspect of the 951 so why cut it so close on the AFM's capabilities?

Originally Posted by Danno

At 250rwhp when the AFM maxes out

#26

Race Car

Good, the AFM doesn't max out, I was under the impression that the same AFM was used on the turbo's, and I couldn't understand how the AFM would max out on the N/A, if it worked for the turbo. Then I started thinking about the TPS, being infinately variable on the turbo's instead of 3-position on the N/'A's, having a KLR to monitor boost pressure, etc, it was all of a sudden getting very complex.

If the AFM doesn't max out, the entire swap is rather straight-forward. However, I did have a thought (I know, a whole thought!!), I would still like to re-program some chips, then the MAF coule be used without a converter, and it would also allow for frequency-variable MAF's, and maybe open the door to MAP sensors, but as the guy who wrote that page that is linked at the top mentioned, the manifold pressure simply isn't stable enough for a MAP.

If the AFM doesn't max out, the entire swap is rather straight-forward. However, I did have a thought (I know, a whole thought!!), I would still like to re-program some chips, then the MAF coule be used without a converter, and it would also allow for frequency-variable MAF's, and maybe open the door to MAP sensors, but as the guy who wrote that page that is linked at the top mentioned, the manifold pressure simply isn't stable enough for a MAP.