Tubular front end

#16

I believe this is a good way to mock up the new front end. In the final product, the stiffness is enhanced by welding such as eliminating the flanges and bolts on the triangulation from shock tower to horizontal member bolted to rails. You can weld fabricated plates to shock tower to distribute the load on the thinner sheat metal and then weld round tubing to it (allows for more weld heat). You can triangulate tubing to the extended rails, might need to bend for tire clearance. Need to stiffen each shock tower to avoid deflection under braking or cornering. A cross tie of the two shock towers does not add sufficient structural rigidity

#17

I appreciate all the constructive feedback.

This is the first fabrication project I've undertaken, so I'm learning as I go. I know additional stiffness needs to be added (and I plan to add some), but I also want to retain the ability to remove the front section to improve serviceability.

This is the first fabrication project I've undertaken, so I'm learning as I go. I know additional stiffness needs to be added (and I plan to add some), but I also want to retain the ability to remove the front section to improve serviceability.

#18

I appreciate all the constructive feedback.

This is the first fabrication project I've undertaken, so I'm learning as I go. I know additional stiffness needs to be added (and I plan to add some), but I also want to retain the ability to remove the front section to improve serviceability.

This is the first fabrication project I've undertaken, so I'm learning as I go. I know additional stiffness needs to be added (and I plan to add some), but I also want to retain the ability to remove the front section to improve serviceability.

#19

#21

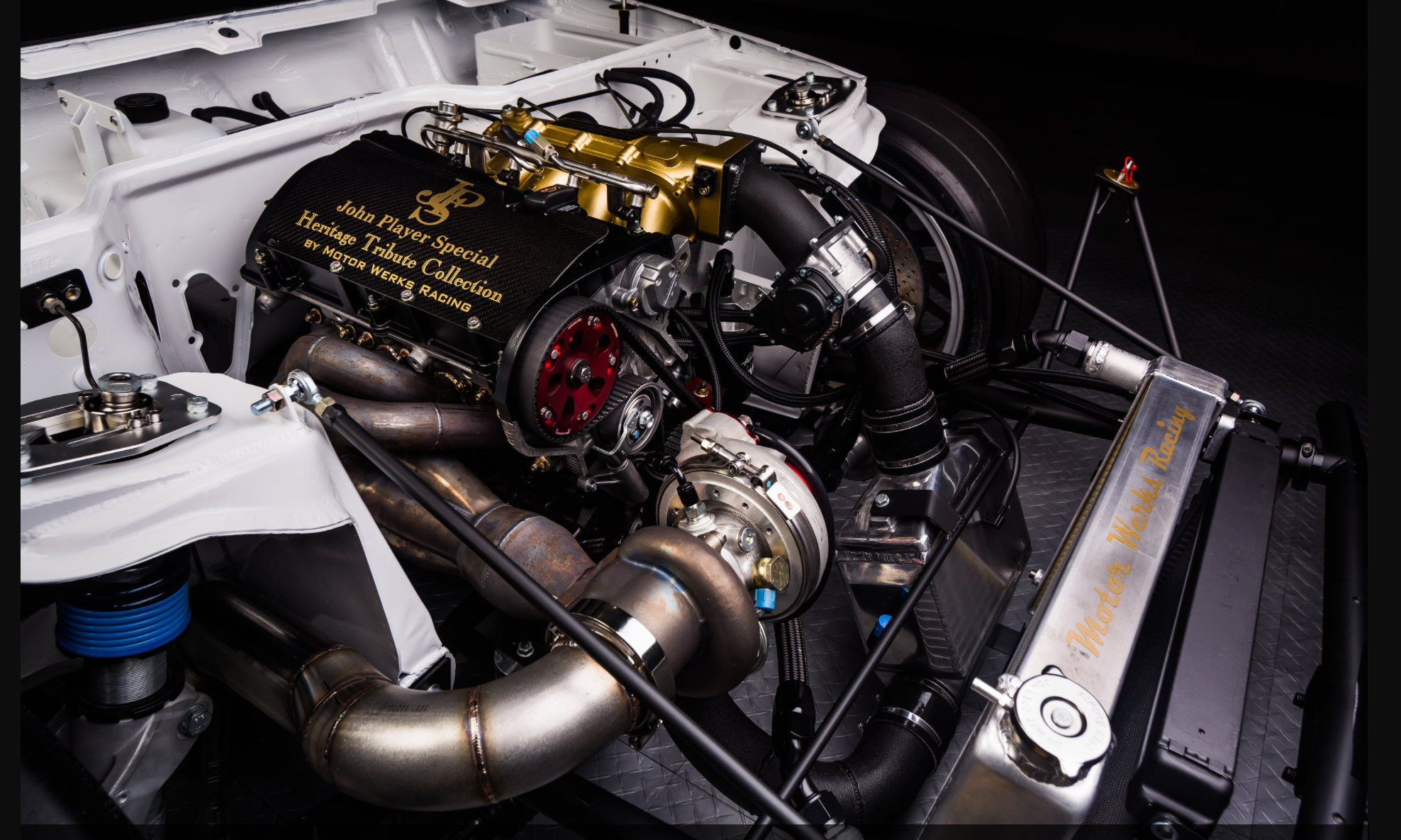

They sure look pretty... but I'm not convinced that the sheet metal supporting the corners aren't wobbly wobbly. I'm not an engineer, but the tubes in front of the cut line in the motorwerks cars don't look like they control the upper shock mount very much and instead are primarily to hang the body work and heat exchangers from.

The following users liked this post:

Jay Wellwood (05-19-2021)

#22

They sure look pretty... but I'm not convinced that the sheet metal supporting the corners aren't wobbly wobbly. I'm not an engineer, but the tubes in front of the cut line in the motorwerks cars don't look like they control the upper shock mount very much and instead are primarily to hang the body work and heat exchangers from.

#23

I'm thinking that in addition to a traditional strut tower brace, I'll brace the towers to the firewall, or even tie into the eventual roll cage.

As I've stated before, this is a learning project for me, and what I've done is nowhere close to the finished project. I also appreciate all the feedback.

As I've stated before, this is a learning project for me, and what I've done is nowhere close to the finished project. I also appreciate all the feedback.

#25

#27

They sure look pretty... but I'm not convinced that the sheet metal supporting the corners aren't wobbly wobbly. I'm not an engineer, but the tubes in front of the cut line in the motorwerks cars don't look like they control the upper shock mount very much and instead are primarily to hang the body work and heat exchangers from.

#28

You could incorporate the strut tower brace to the firewall with a delta going to the firewall..some American cars did this as well. All bolted in to ease removal for in-depth engine work.

#29

If a cage is being installed, interface the strut-to-firewall tubes to meet the horizontal roll-cage tubes that flow into door-bars, for added stiffness & safety.

I don't know if the roles allow, but I suspect they do allow for firewall bolted flanges... this was a miserably experience to weld. For this area, I'd weld flanges to the kick panel tubes & strut tubes & bolt both sides at firewall personally.

I don't know if the roles allow, but I suspect they do allow for firewall bolted flanges... this was a miserably experience to weld. For this area, I'd weld flanges to the kick panel tubes & strut tubes & bolt both sides at firewall personally.

Last edited by Noahs944; 05-24-2021 at 04:47 PM.

#30

Or better yet, make it 1 bar through a hole in the firewall from strut to A-pillar, but that would require some radical bends. mock it up with coat hanger wire.

Last edited by Noahs944; 05-24-2021 at 08:59 PM.