Help me repair my 951 transaxle

#16

Race Car

That diff has been worked on before.

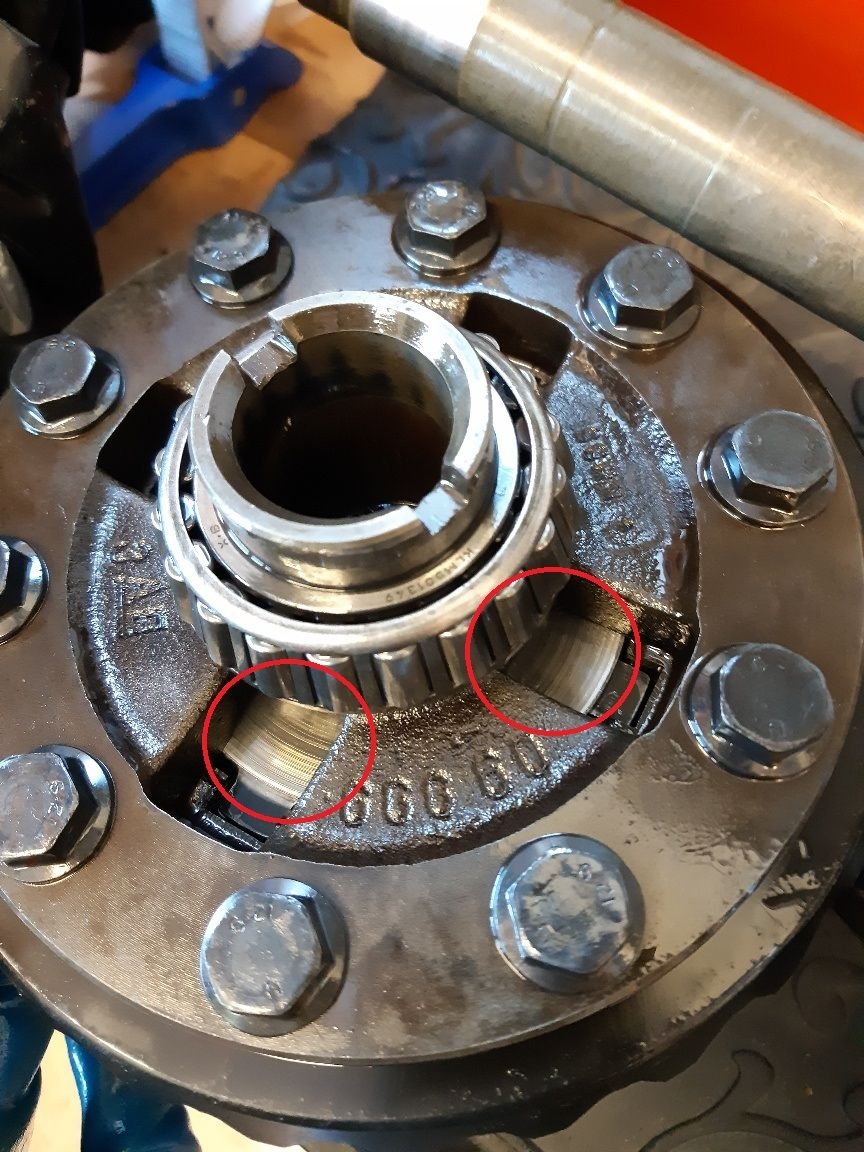

In your 1st picture, post #14, the view you have through the rectangular windows at the bottom of the external splined (4 prongs) show rotational wear that is impossible to occur since that plate is at one with the diff housing.

The only way this wear pattern can occur is if the plate was previously flipped, facing an internally splined (clutch) disc, which is normal since the discs "slip" while clamped due to the pressure of the diaphragm conical pressure plate.

Unless the picture is deceiving and that is the cup spring I am seeing but if it is, it should just look like gray metal, like the one in your last pic next to the broken washer.

There were two cupped spring plates right...?

One on each end....?

Can you snap a shot of the steel plates (4 prong) and the clutch discs....?

There is some damage to the diff housing, probably from a previous failure which warranted the fix attempt when they flipped the steels.

Lets see them.

The amount of the measurement (total depth of housing minus stack of new discs with thrust rings) that clamps the plates via compression of the cup spring (diaphragm conical plate) is not very much, (1.2mm from memory - could be wrong on that).

I'd also like to know for sure there is no noise when you run the engine with clutch released.

Not convinced your clutch disc drive isn't damaged.

The diff is easy to restore to like new condition, as long as the plates with the outer tangs don't hang in the housing due to damage to the tang slots.

Pretty much stuck with original parts for sourcing and for what the are, the price per plate is pretty high.

I will walk you through the diff refurb.

T

In your 1st picture, post #14, the view you have through the rectangular windows at the bottom of the external splined (4 prongs) show rotational wear that is impossible to occur since that plate is at one with the diff housing.

The only way this wear pattern can occur is if the plate was previously flipped, facing an internally splined (clutch) disc, which is normal since the discs "slip" while clamped due to the pressure of the diaphragm conical pressure plate.

Unless the picture is deceiving and that is the cup spring I am seeing but if it is, it should just look like gray metal, like the one in your last pic next to the broken washer.

There were two cupped spring plates right...?

One on each end....?

Can you snap a shot of the steel plates (4 prong) and the clutch discs....?

There is some damage to the diff housing, probably from a previous failure which warranted the fix attempt when they flipped the steels.

Lets see them.

The amount of the measurement (total depth of housing minus stack of new discs with thrust rings) that clamps the plates via compression of the cup spring (diaphragm conical plate) is not very much, (1.2mm from memory - could be wrong on that).

I'd also like to know for sure there is no noise when you run the engine with clutch released.

Not convinced your clutch disc drive isn't damaged.

The diff is easy to restore to like new condition, as long as the plates with the outer tangs don't hang in the housing due to damage to the tang slots.

Pretty much stuck with original parts for sourcing and for what the are, the price per plate is pretty high.

I will walk you through the diff refurb.

T

#17

Race Car

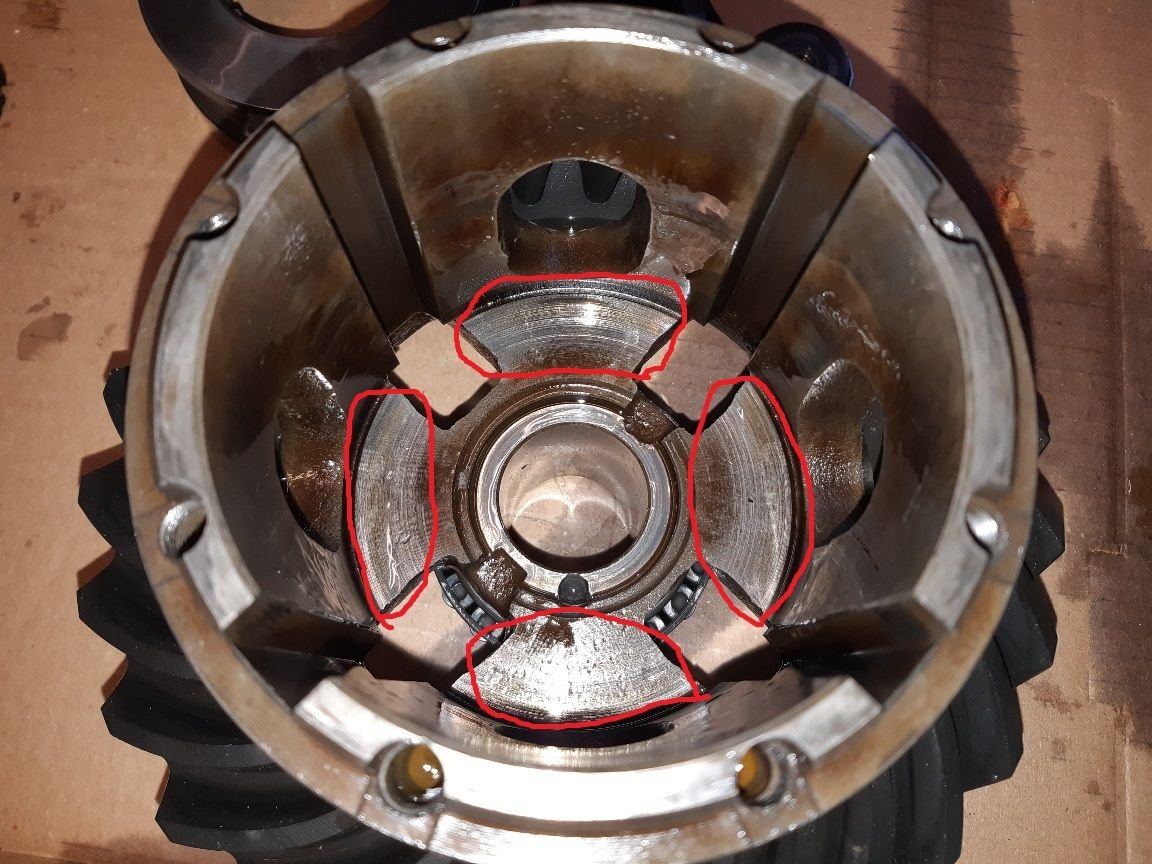

Kevin, what do you make out of the damage to the ID of the housing itself at the 1 o'clock spot, to the right of the window...?

Previous failure...?

T

Previous failure...?

T

#18

Advanced

Thread Starter

Probably not the root issue. The broken thrust washer is a common occurrence: its pressed-in tab is a stress riser and design mistake. (Guard did something a little different in their LSD to avoid this.) This part is NLA from Porsche. Check the other thrust washer carefully for a crack propagating from the pressed-in tab.

The cup washer is installed "backwards" in some LSDs, from the factory intentionally. They mark these LSDs with a yellow paint dot on the LSD case, and with age the dot may look more brown than yellow.

The cup washer is installed "backwards" in some LSDs, from the factory intentionally. They mark these LSDs with a yellow paint dot on the LSD case, and with age the dot may look more brown than yellow.

That diff has been worked on before. In your 1st picture, post #14, the view you have through the rectangular windows at the bottom of the external splined (4 prongs) show rotational wear that is impossible to occur since that plate is at one with the diff housing.

...

Unless the picture is deceiving and that is the cup spring I am seeing but if it is, it should just look like gray metal, like the one in your last pic next to the broken washer.

...

Unless the picture is deceiving and that is the cup spring I am seeing but if it is, it should just look like gray metal, like the one in your last pic next to the broken washer.

And the spring washer itself (those spots are just marks in the oil, not dents)

There were two cupped spring plates right...?

One on each end....?

Can you snap a shot of the steel plates (4 prong) and the clutch discs....?

There is some damage to the diff housing, probably from a previous failure which warranted the fix attempt when they flipped the steels.

Lets see them.

One on each end....?

Can you snap a shot of the steel plates (4 prong) and the clutch discs....?

There is some damage to the diff housing, probably from a previous failure which warranted the fix attempt when they flipped the steels.

Lets see them.

The diff is easy to restore to like new condition, as long as the plates with the outer tangs don't hang in the housing due to damage to the tang slots.

Pretty much stuck with original parts for sourcing and for what the are, the price per plate is pretty high.

I will walk you through the diff refurb.

Pretty much stuck with original parts for sourcing and for what the are, the price per plate is pretty high.

I will walk you through the diff refurb.

#19

Race Car

Ok, yeah, that's what I was asking.

The picture was deceiving in that it looked like there was an outer splined plate against the diff housing with no cup spring on that side.

People will "flip" those plates and install so the side never contacted by the clutch disc faces opposite when installing new discs.

Fine if they measure in spec and are not warped.

You need to mic the thickness of the clutch discs (inner splined) to tell which of the thickness options you have, you can bring this diff up to Turbo S spec with the thicker, more robust clutches if you have access to a machine shop that can reface the pressure ring (thick part with 4 tangs) to precisely set your clearance.

When you have to replace the ring and pinion or the case, you need to accurately measure the diff carrier center line to the face of the installed pinion gear.

When neither of these items requires replacement, you can replace the bearings without the complication.

Especially in a case like yours, only surface pitting of the races due to metal contamination from the oil running through them, you can carefully press these off and accurately measure the sum of the bearing + race with a depth gauge on a metal table or surface. Then you do the same with your new replacement bearing.

When you see that the new and old bearing is identical in this fashion, you can safely restore the transmission to it's original settings.

You will need a hydraulic press, a bearing splitter and a thin jaw puller at a minimum.

Most of the puller and pusher tools I have are self fabricated from differing steel tubing diameters, etc.

I may have some of the diff thrust washers in good condition if you can't source one.

The front pinion bearing was in scarce supply last time I needed one but if you get the trans code off top of bell housing, you can verify that one is available.

I'll keep an eye out on your progress but we are prepping a 968 for the NOLA race this weekend, then at the track from Friday-Sunday.

I'll be in Nashville for work the following week but will have some free time during hotel boredom to help you if I can.

T

The picture was deceiving in that it looked like there was an outer splined plate against the diff housing with no cup spring on that side.

People will "flip" those plates and install so the side never contacted by the clutch disc faces opposite when installing new discs.

Fine if they measure in spec and are not warped.

You need to mic the thickness of the clutch discs (inner splined) to tell which of the thickness options you have, you can bring this diff up to Turbo S spec with the thicker, more robust clutches if you have access to a machine shop that can reface the pressure ring (thick part with 4 tangs) to precisely set your clearance.

When you have to replace the ring and pinion or the case, you need to accurately measure the diff carrier center line to the face of the installed pinion gear.

When neither of these items requires replacement, you can replace the bearings without the complication.

Especially in a case like yours, only surface pitting of the races due to metal contamination from the oil running through them, you can carefully press these off and accurately measure the sum of the bearing + race with a depth gauge on a metal table or surface. Then you do the same with your new replacement bearing.

When you see that the new and old bearing is identical in this fashion, you can safely restore the transmission to it's original settings.

You will need a hydraulic press, a bearing splitter and a thin jaw puller at a minimum.

Most of the puller and pusher tools I have are self fabricated from differing steel tubing diameters, etc.

I may have some of the diff thrust washers in good condition if you can't source one.

The front pinion bearing was in scarce supply last time I needed one but if you get the trans code off top of bell housing, you can verify that one is available.

I'll keep an eye out on your progress but we are prepping a 968 for the NOLA race this weekend, then at the track from Friday-Sunday.

I'll be in Nashville for work the following week but will have some free time during hotel boredom to help you if I can.

T

#20

Race Car

BTW - listen close to the bell housing (front) area with car running, or better yet, you get under there and have someone depress and release clutch multiple times while you are listening close.

There is a strange noise.

This can be transmitted through the shaft to the rear but it sounds like the metal drive potion of your disc is cracked or broken.

T

There is a strange noise.

This can be transmitted through the shaft to the rear but it sounds like the metal drive potion of your disc is cracked or broken.

T

#21

Advanced

Thread Starter

BTW - listen close to the bell housing (front) area with car running, or better yet, you get under there and have someone depress and release clutch multiple times while you are listening close.

There is a strange noise.

This can be transmitted through the shaft to the rear but it sounds like the metal drive potion of your disc is cracked or broken.

T

There is a strange noise.

This can be transmitted through the shaft to the rear but it sounds like the metal drive potion of your disc is cracked or broken.

T

If anyone has a 951 transaxle for sale please send me a message.

#22

Rennlist Member

That diff has been worked on before.

In your 1st picture, post #14, the view you have through the rectangular windows at the bottom of the external splined (4 prongs) show rotational wear that is impossible to occur since that plate is at one with the diff housing.

The only way this wear pattern can occur is if the plate was previously flipped, facing an internally splined (clutch) disc, which is normal since the discs "slip" while clamped due to the pressure of the diaphragm conical pressure plate.

Unless the picture is deceiving and that is the cup spring I am seeing but if it is, it should just look like gray metal, like the one in your last pic next to the broken washer.

In your 1st picture, post #14, the view you have through the rectangular windows at the bottom of the external splined (4 prongs) show rotational wear that is impossible to occur since that plate is at one with the diff housing.

The only way this wear pattern can occur is if the plate was previously flipped, facing an internally splined (clutch) disc, which is normal since the discs "slip" while clamped due to the pressure of the diaphragm conical pressure plate.

Unless the picture is deceiving and that is the cup spring I am seeing but if it is, it should just look like gray metal, like the one in your last pic next to the broken washer.

I have to confess that I don't get to see "normal" as much as I'd like to. Many of the transmissions sent to me are being rebuilt by new-to-them racers / owners after a lifetime of passive abuse by someone else. So they are a mess. Bless all my clients who do take care of their transmissions! I did just walk into the shop and take a peak at the LSD going into a transmission for a new client, which LSD came out of a race 944 whose original transmission grenaded. As a point of comparison, he was lucky, no debris ingested, no scoring of any kind, and the case ends and cup springs are clean and smooth.

You need to mic the thickness of the clutch discs (inner splined) to tell which of the thickness options you have, you can bring this diff up to Turbo S spec with the thicker, more robust clutches if you have access to a machine shop that can reface the pressure ring (thick part with 4 tangs) to precisely set your clearance.

For a street-only car, I really don't think the AOR upgrade is needed. Except maybe the input shaft with its hardened 1st and 2nd gear teeth. It's inexpensive and really worth it.

The front pinion bearing was in scarce supply last time I needed one but if you get the trans code off top of bell housing, you can verify that one is available.

I'll keep an eye out on your progress but we are prepping a 968 for the NOLA race this weekend, then at the track from Friday-Sunday.

I'll keep an eye out on your progress but we are prepping a 968 for the NOLA race this weekend, then at the track from Friday-Sunday.

Last edited by KevinGross; 02-20-2019 at 07:25 PM.