Diagnosis? Retarded Ignition Timing - Slipped / Moved Timing Ring on Flywheel?

#16

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,226

Received 442 Likes

on

244 Posts

Åke

#18

Instructor

Thread Starter

Imoo - all cylinders are firing. The leak down was done on a completely cold engine . A year ago when I did it on a warm engine the readings were between five and 10%

Greg I'm going to remove the crank sensor and see if I can find the tooth gap while rotating the motor and see what the degree reading is on the damper. Since my timing is some 25° off my diagnosis will be confirmed if the tooth gap occurs somewhere near the 45° Mark on the damper if the factory is at 68 1/2°

Greg I'm going to remove the crank sensor and see if I can find the tooth gap while rotating the motor and see what the degree reading is on the damper. Since my timing is some 25° off my diagnosis will be confirmed if the tooth gap occurs somewhere near the 45° Mark on the damper if the factory is at 68 1/2°

#19

Team Owner

is it possible that you used the trigger ring to spin the engine,

IE using a screwdriver blade tip to pry the engine to turn?

or used the trigger ring to hold the flywheel from turning?

I was wondering how the ring could be moved in the first place

IE using a screwdriver blade tip to pry the engine to turn?

or used the trigger ring to hold the flywheel from turning?

I was wondering how the ring could be moved in the first place

#20

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Imoo - all cylinders are firing. The leak down was done on a completely cold engine . A year ago when I did it on a warm engine the readings were between five and 10%

Greg I'm going to remove the crank sensor and see if I can find the tooth gap while rotating the motor and see what the degree reading is on the damper. Since my timing is some 25° off my diagnosis will be confirmed if the tooth gap occurs somewhere near the 45° Mark on the damper if the factory is at 68 1/2°

Greg I'm going to remove the crank sensor and see if I can find the tooth gap while rotating the motor and see what the degree reading is on the damper. Since my timing is some 25° off my diagnosis will be confirmed if the tooth gap occurs somewhere near the 45° Mark on the damper if the factory is at 68 1/2°

And if everything you've tested and assumed are correct, there's not much else that could be wrong.

#21

Captain Obvious

Super User

Super User

Even on a cold engine the leakdown should be a mid to low single digit. Something is up with that cylinder.

#22

Rennlist

Basic Site Sponsor

Basic Site Sponsor

I don't think my Snap-on tester will read in the single digits.....on anything....ever. I've got an aircraft certified tester that reads way lower than that. And one other unit which is different than both of those.

Like compression gauges, you take 10 different ones and you are going to get 11 different readings.

I think his results tell us that he didn't melt a big hole in a piston from a set of generic chips that have a bunch of timing tossed in.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#23

Instructor

Thread Starter

All

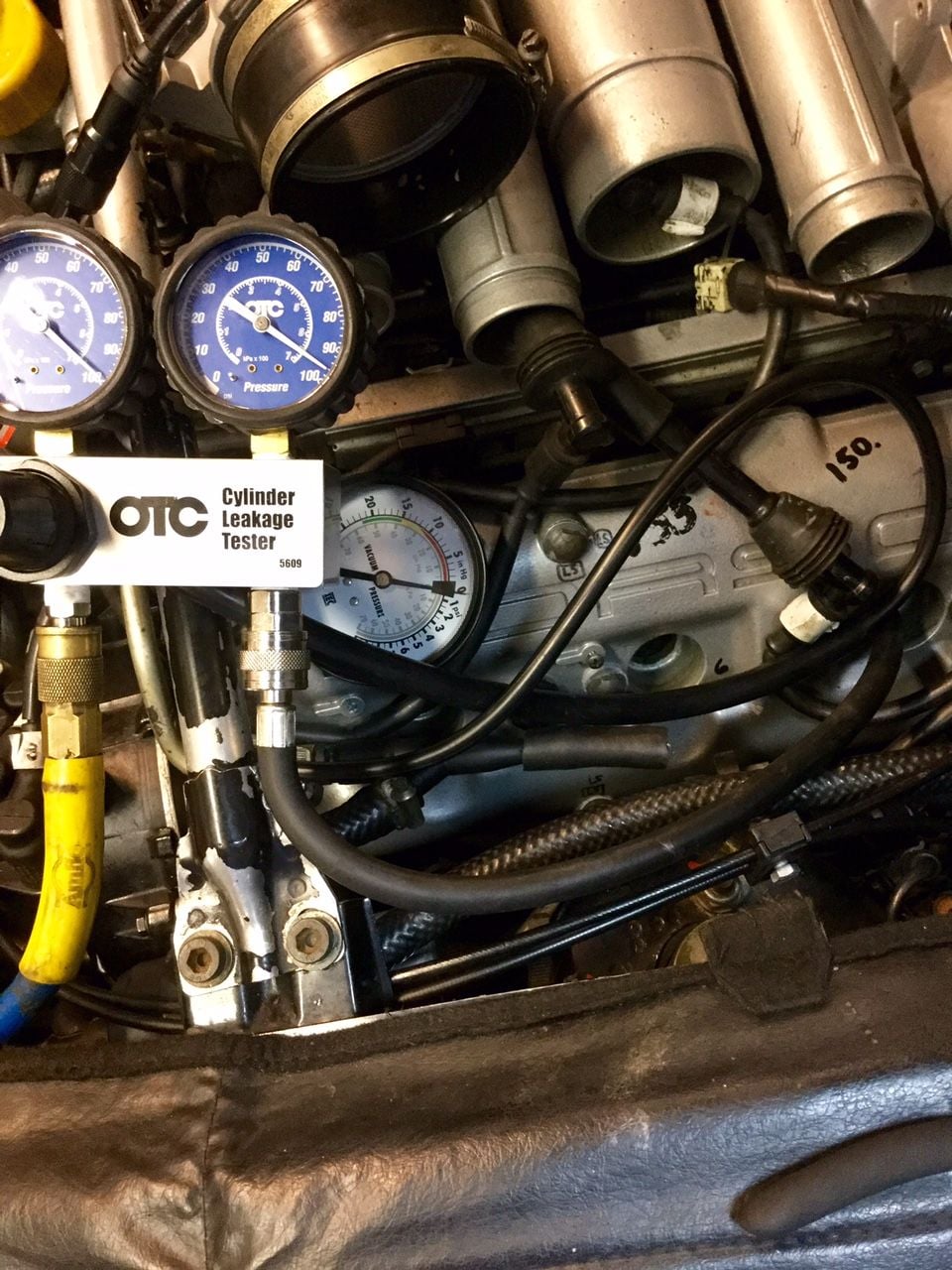

I removed the crank sensor, set my handy harbor freight digital screen in the crank sensor hole and rotated engine to the wider teeth gap on the trigger ring. With the trigger ring gap located at top of the flywheel, the damper is at 45 degrees BTC. See photo below. If the correct orientation of the ring gear is at circa 68 degrees, then the 23 +|- degree delta in initial timing is explained (my car is running at 12 to 15 degrees ATDC at idle). I am presuming that will correct the low vacuum and drivability problems

Does anybody have a way to rotate a motor and confirm where the degree reading is on the damper when the ring gear gap is at top directly under crank sensor? That way I will be sure. (note car is 86 US 5 speed)

Also, I got a new leak down tester. Retested all cylinders today. Worst cylinder when tested at 100 PSI was 96 PSI or 4%. The engine is mechanically sound

Also if correct diagnosis, who in Valley region of LA would you trust to do a removal of the clutch and install new flywheel? SHould I buy anew flywheel?Can I get the old one repaired?.

Photo of the ring gear from 2003 clutch job attached as well

[ATTACH][ATTACH]

[/ATTACH][/ATTACH]

[/ATTACH][/ATTACH]

I removed the crank sensor, set my handy harbor freight digital screen in the crank sensor hole and rotated engine to the wider teeth gap on the trigger ring. With the trigger ring gap located at top of the flywheel, the damper is at 45 degrees BTC. See photo below. If the correct orientation of the ring gear is at circa 68 degrees, then the 23 +|- degree delta in initial timing is explained (my car is running at 12 to 15 degrees ATDC at idle). I am presuming that will correct the low vacuum and drivability problems

Does anybody have a way to rotate a motor and confirm where the degree reading is on the damper when the ring gear gap is at top directly under crank sensor? That way I will be sure. (note car is 86 US 5 speed)

Also, I got a new leak down tester. Retested all cylinders today. Worst cylinder when tested at 100 PSI was 96 PSI or 4%. The engine is mechanically sound

Also if correct diagnosis, who in Valley region of LA would you trust to do a removal of the clutch and install new flywheel? SHould I buy anew flywheel?Can I get the old one repaired?.

Photo of the ring gear from 2003 clutch job attached as well

[ATTACH][ATTACH]

[/ATTACH][/ATTACH]

[/ATTACH][/ATTACH]

#25

Instructor

Thread Starter

Mrmerlin - Never used ring gear to rotate or hold the motor. I am the only person who has worked on this car except for alignments since 1992 so I am pretty sure

The ring seems to have slipped on the third run of a dyno run- that is when the car began to run flat and has remained that way to this day for two years. The first two runs the car pulled 300 + RWHP and ran very strong.

Hopefully I have a direction to go now to fix the darn thing - then I am going to sell it

The ring seems to have slipped on the third run of a dyno run- that is when the car began to run flat and has remained that way to this day for two years. The first two runs the car pulled 300 + RWHP and ran very strong.

Hopefully I have a direction to go now to fix the darn thing - then I am going to sell it

#26

Developer

I did have a crank trigger ring move on me once, but in very peculiar circumstances.

Greg is right, the timing ring is heated up and dropped onto a chilled flywheel, and that's that. It never moves - when your flywheel is steel and the timing ring is steel they all expand and contract at the same rate.

In my case, the timing ring was mounted on to an aluminum flywheel, and "locked in place" with several screw-in pinsets. It worked great all summer with no issues. But when I was practicing for Pikes Peak 2009, it was 36 degrees F at 4:00 in the morning when I started the race car to back it out of the trailer. She started right up, but as usual, the alternator was not charging and it was my norm to just blip the throttle to wake the alternator up. I did. When I blipped the throttle (we learned later) the timing ring spun on the flywheel. The engine sputtered and stopped.

We tore our hair out for the rest of that day and 2 more days after trying to figure out what had happened before we found it, then pinned the trigger ring in place much more aggressively. Correctly positioned, she started right up and I was able to race Pikes Peak on Sunday, having had no practice at all. Won 3rd place in the Open division with a 13-minute run!

What happened was: the unusually cold ambient temp had reduced the diameter of the flywheel, then when I rapidly acceled/decelled the motor, we spun the ring. It hadn't happened before this because we normally don't run in temps that cold. Once the engine warms up, the flywheel expands and grips the timing ring tight. I really don't thing you will have had this issue, but it isn't impossible.

I know (because I have done it) that you can have a guy lay across the fender and pear down into the bore that the Hall sensor sits in. A second guy puts a wrench on the crank to turn it, and a third guy watches and reads the degree wheel on the harmonic balancer.

You want to confirm that the missing tooth (the space) is located 11 teeth before TDC. Ours was a 16v motor, so we put the harmonic balance to TDC, then turned the engine backwards while the guy peering down the Hall sensor bore counted teeth go by. It has to be 11 teeth before TDC when the gap occurs.

With a 32v motor, and not wanting to turn the crank backwards, you'd have to go the other way and count a lot of teeth but you could. It's just a way to see if the space is out of place before you do a lot of other work.

Greg is right, the timing ring is heated up and dropped onto a chilled flywheel, and that's that. It never moves - when your flywheel is steel and the timing ring is steel they all expand and contract at the same rate.

In my case, the timing ring was mounted on to an aluminum flywheel, and "locked in place" with several screw-in pinsets. It worked great all summer with no issues. But when I was practicing for Pikes Peak 2009, it was 36 degrees F at 4:00 in the morning when I started the race car to back it out of the trailer. She started right up, but as usual, the alternator was not charging and it was my norm to just blip the throttle to wake the alternator up. I did. When I blipped the throttle (we learned later) the timing ring spun on the flywheel. The engine sputtered and stopped.

We tore our hair out for the rest of that day and 2 more days after trying to figure out what had happened before we found it, then pinned the trigger ring in place much more aggressively. Correctly positioned, she started right up and I was able to race Pikes Peak on Sunday, having had no practice at all. Won 3rd place in the Open division with a 13-minute run!

What happened was: the unusually cold ambient temp had reduced the diameter of the flywheel, then when I rapidly acceled/decelled the motor, we spun the ring. It hadn't happened before this because we normally don't run in temps that cold. Once the engine warms up, the flywheel expands and grips the timing ring tight. I really don't thing you will have had this issue, but it isn't impossible.

I know (because I have done it) that you can have a guy lay across the fender and pear down into the bore that the Hall sensor sits in. A second guy puts a wrench on the crank to turn it, and a third guy watches and reads the degree wheel on the harmonic balancer.

You want to confirm that the missing tooth (the space) is located 11 teeth before TDC. Ours was a 16v motor, so we put the harmonic balance to TDC, then turned the engine backwards while the guy peering down the Hall sensor bore counted teeth go by. It has to be 11 teeth before TDC when the gap occurs.

With a 32v motor, and not wanting to turn the crank backwards, you'd have to go the other way and count a lot of teeth but you could. It's just a way to see if the space is out of place before you do a lot of other work.

#27

Developer

Here is a pic of a typical timing ring on our aluminum flywheel.

Since our 2009 Pikes Peak experience, we re-engineered the locking method we use to hold the timing ring in place just in case any of our aluminum flywheel customers live in cold climates, and these rings are very well held in place.

As usual, experience is a great teacher!

Since our 2009 Pikes Peak experience, we re-engineered the locking method we use to hold the timing ring in place just in case any of our aluminum flywheel customers live in cold climates, and these rings are very well held in place.

As usual, experience is a great teacher!

#28

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Pete--

I've been known to print a paper "timing tape" to wrap around the balancer. Easy if you know the circumference of the balancer. I do it in Autocad since I can array the marks at specific spacing. Then print actual size (no scaling). You can do similar in Excel by setting row spacing and printing lines and numbers.

Unfortunately I haven't needed to do it for a 928 or I'd share the files with you to print locally. But you get the idea. It's also easy to add "event" markers on the tape to show where specific valves open and close or particular cylinders are at TDC, for instance.

I've been known to print a paper "timing tape" to wrap around the balancer. Easy if you know the circumference of the balancer. I do it in Autocad since I can array the marks at specific spacing. Then print actual size (no scaling). You can do similar in Excel by setting row spacing and printing lines and numbers.

Unfortunately I haven't needed to do it for a 928 or I'd share the files with you to print locally. But you get the idea. It's also easy to add "event" markers on the tape to show where specific valves open and close or particular cylinders are at TDC, for instance.

#29

Instructor

Thread Starter

Carl

Thanks for the response and taking my call today.

So with a 100 tooth flywheel, I need to count 18.3 teeth to the gap in the ring from TDC. This equates to 66 degrees (60 tooth ring gear x 11 teeth = 66 degrees). The 100 tooth flywheel will be 3.6 degrees per tooth so looks like 18 teeth is the correct count. I'll give this a shot by counting 82 teeth from TDC by rotating engine clockwise from TDC.

Based on what I did yesterday and with damper at 45 degrees BTDC means I am 45 / 3.6 degrees or 12.5 teeth count from TDC to gap on a 100 tooth wheel - not the correct 18.3 teeth; that is if my back of the envelope math is correct. Thus, I will probably count 88 teeth instead of 82 from zero degrees to the gap

If the gap in the toothed ring gear were correct orientation @ 18.3 teeth from TDC, the mark on the damper would have to be right of the 45 degree mark on the damper, (see my photo above) at circa 66 degrees.

Sure looks like this ring gear moved .

Thanks for the response and taking my call today.

So with a 100 tooth flywheel, I need to count 18.3 teeth to the gap in the ring from TDC. This equates to 66 degrees (60 tooth ring gear x 11 teeth = 66 degrees). The 100 tooth flywheel will be 3.6 degrees per tooth so looks like 18 teeth is the correct count. I'll give this a shot by counting 82 teeth from TDC by rotating engine clockwise from TDC.

Based on what I did yesterday and with damper at 45 degrees BTDC means I am 45 / 3.6 degrees or 12.5 teeth count from TDC to gap on a 100 tooth wheel - not the correct 18.3 teeth; that is if my back of the envelope math is correct. Thus, I will probably count 88 teeth instead of 82 from zero degrees to the gap

If the gap in the toothed ring gear were correct orientation @ 18.3 teeth from TDC, the mark on the damper would have to be right of the 45 degree mark on the damper, (see my photo above) at circa 66 degrees.

Sure looks like this ring gear moved .

#30

Rennlist

Basic Site Sponsor

Basic Site Sponsor

With the belt tension anywhere near correct and a stock tensioner, you can turn a 32 valve engine backwards, without any issues.

Actually, I have no idea why that warning is in the workshop manual..... it is a "non issue."

I wouldn't try this with a Porken tensioner.....and I'd really not try it with a Porken tensioner and no lower roller/rollers.

Actually, I have no idea why that warning is in the workshop manual..... it is a "non issue."

I wouldn't try this with a Porken tensioner.....and I'd really not try it with a Porken tensioner and no lower roller/rollers.