2015 Nevada Open Road Challenge ORR

#16

Nordschleife Master

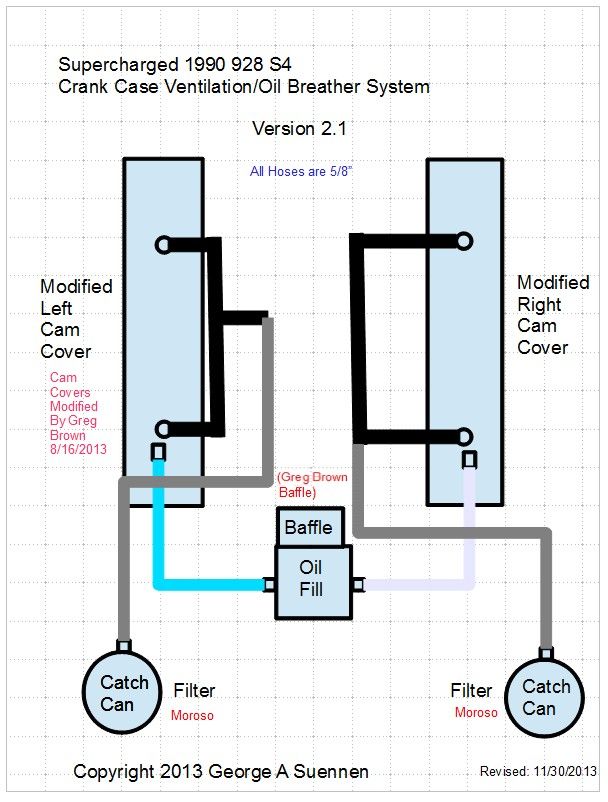

Can you explain to us in which direction are these hose expected to flow gas in this system? How is it intended to work under driving straight, cornering, accelerating, and decelerating?

#17

Addict

Rennlist Member

Rennlist Member

Thread Starter

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

#19

Addict

Rennlist Member

Rennlist Member

Thread Starter

Thanks Matt. I'll be racing the 928 and Bill will be in the tow vehicle, hopefully both will be running at the end of the event.

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

#20

Archive Gatekeeper

Rennlist Member

Rennlist Member

Be safe out there! It will be interesting to see whether there will be any difference in the volumes that end up in each catch-can, given the breathers are essentially symmetrical side-to side (is there still a hose at the base of the filler neck back to the passenger MAF intake elbow?, and if that gets plugged, then does all the air for idle come through the driver's side elbow? )

#21

Addict

Rennlist Member

Rennlist Member

Thread Starter

Be safe out there! It will be interesting to see whether there will be any difference in the volumes that end up in each catch-can, given the breathers are essentially symmetrical side-to side (is there still a hose at the base of the filler neck back to the passenger MAF intake elbow?, and if that gets plugged, then does all the air for idle come through the driver's side elbow? )

The ports at the base of the filler neck are plugged as is the port on the passenger side MAF boot, this was standard on a Murf supercharger kit (although I added the nozzle for the water injection into the plug on the MAF boot).

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

#22

Nordschleife Master

One thing that I'd be curious about is Which direction the gas flows in those hoses that connect the valve covers and the oil filler neck?

Another question that I have is What's the purpose of the baffle under the oil filler neck? It doesn't seem to be feeding anything that would need the oil separated. Perhaps it's just a left-over from the earlier setup?

#23

Addict

Rennlist Member

Rennlist Member

Thread Starter

I don't know what will happen. I have some guesses, of course, but they are just guesses. I am mostly just interested in learning whether this new setup works better than the old setup.

One thing that I'd be curious about is Which direction the gas flows in those hoses that connect the valve covers and the oil filler neck?

Another question that I have is What's the purpose of the baffle under the oil filler neck? It doesn't seem to be feeding anything that would need the oil separated. Perhaps it's just a left-over from the earlier setup?

One thing that I'd be curious about is Which direction the gas flows in those hoses that connect the valve covers and the oil filler neck?

Another question that I have is What's the purpose of the baffle under the oil filler neck? It doesn't seem to be feeding anything that would need the oil separated. Perhaps it's just a left-over from the earlier setup?

Another part of the solution is to keep the RPMs below 6,000. With my current set up I could go 200 mph at ~5,800 RPM. If I had more power, I was going to increase the diameter of the rear tires from 26.3" to 27.4". This would put me at 200 mph at about 5500 RPM. But since there's currently less power, I'm sticking with the old tire size.

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

Last edited by jorj7; 05-04-2015 at 08:23 PM. Reason: Add comment about RPM

#24

Nordschleife Master

One thing that I'd be curious about is Which direction the gas flows in those hoses that connect the valve covers and the oil filler neck?

Another question that I have is What's the purpose of the baffle under the oil filler neck? It doesn't seem to be feeding anything that would need the oil separated. Perhaps it's just a left-over from the earlier setup?

Another question that I have is What's the purpose of the baffle under the oil filler neck? It doesn't seem to be feeding anything that would need the oil separated. Perhaps it's just a left-over from the earlier setup?

There is a lot of oil that gets ejected from the fill neck, the baffle is there to limit this, though it won't stop it.

The gas flow can go either direction, there are no check valves, but I think mostly it will flow from the crankcase to the cam covers from the fill neck and out through the cam covers to the vented catch cans.

Of course the pulses could balance out and net negligible gas flow. If I could, I'd run larger diameter hoses to decrease the speed of the gas, and thus decrease the chance of oil escaping, but that's not easy given the limitation of space and time.

Another part of the solution is to keep the RPMs below 6,000. With my current set up I could go 200 mph at ~5,800 RPM. If I had more power, I was going to increase the diameter of the rear tires from 26.3" to 27.4". This would put me at 200 mph at about 5500 RPM. But since there's currently less power, I'm sticking with the old tire size.

The gas flow can go either direction, there are no check valves, but I think mostly it will flow from the crankcase to the cam covers from the fill neck and out through the cam covers to the vented catch cans.

Of course the pulses could balance out and net negligible gas flow. If I could, I'd run larger diameter hoses to decrease the speed of the gas, and thus decrease the chance of oil escaping, but that's not easy given the limitation of space and time.

Another part of the solution is to keep the RPMs below 6,000. With my current set up I could go 200 mph at ~5,800 RPM. If I had more power, I was going to increase the diameter of the rear tires from 26.3" to 27.4". This would put me at 200 mph at about 5500 RPM. But since there's currently less power, I'm sticking with the old tire size.

If interpret your response correctly, you anticipate that the crankcase air will flow up the oil filler neck, then from the oil filler neck to the valve cover, and then from the valve cover to the catch can. If that happens (in net anyway), it's probably going to work.

If however the gas (in net) flows from the crankcase up the oil drains into the valve covers and from the valve covers into the oil filler neck and then again into the crankcase, then the connection between valve covers and the oil filler neck is counterproductive at least by my reasoning. It'll still probably work, so maybe this is hair splitting.

The above is basically why I'd be interested in the learning about the flow direction in those hoses that connect the valve cover and the oil filler neck.

---

Making more power at lower rpms would make everything easier. I assume you're knock limited? With methanol banned, do you have any other ways of increasing the fuel octane number? Also, how's your intercooling? Do you have an ice-water tank in the trunk? That might give you a little bit more room for additional spark advance or more boost if the compressor can deliver. Finally, where are you on the compressor map?

#25

Addict

Rennlist Member

Rennlist Member

Thread Starter

I am maybe dense, or not reading your diagram correctly. My understanding is that there's no direct link from the oil filler neck into the catch cans. Instead, the oil filler neck is only connected to the valve covers. If so, why do you need the baffle under the oil filler neck to stop oil from flowing into the hoses that go into the valve covers? In the words of Hillary Clinton, "What difference does it make?"

If interpret your response correctly, you anticipate that the crankcase air will flow up the oil filler neck, then from the oil filler neck to the valve cover, and then from the valve cover to the catch can. If that happens (in net anyway), it's probably going to work.

If however the gas (in net) flows from the crankcase up the oil drains into the valve covers and from the valve covers into the oil filler neck and then again into the crankcase, then the connection between valve covers and the oil filler neck is counterproductive at least by my reasoning. It'll still probably work, so maybe this is hair splitting.

The above is basically why I'd be interested in the learning about the flow direction in those hoses that connect the valve cover and the oil filler neck.

---

Making more power at lower rpms would make everything easier. I assume you're knock limited? With methanol banned, do you have any other ways of increasing the fuel octane number? Also, how's your intercooling? Do you have an ice-water tank in the trunk? That might give you a little bit more room for additional spark advance or more boost if the compressor can deliver. Finally, where are you on the compressor map?

If interpret your response correctly, you anticipate that the crankcase air will flow up the oil filler neck, then from the oil filler neck to the valve cover, and then from the valve cover to the catch can. If that happens (in net anyway), it's probably going to work.

If however the gas (in net) flows from the crankcase up the oil drains into the valve covers and from the valve covers into the oil filler neck and then again into the crankcase, then the connection between valve covers and the oil filler neck is counterproductive at least by my reasoning. It'll still probably work, so maybe this is hair splitting.

The above is basically why I'd be interested in the learning about the flow direction in those hoses that connect the valve cover and the oil filler neck.

---

Making more power at lower rpms would make everything easier. I assume you're knock limited? With methanol banned, do you have any other ways of increasing the fuel octane number? Also, how's your intercooling? Do you have an ice-water tank in the trunk? That might give you a little bit more room for additional spark advance or more boost if the compressor can deliver. Finally, where are you on the compressor map?

As always, you have more questions then I have answers. If I knew all the answers I probably would be in a different line of work and not a weekend hobbyist. But I'll try a few:

The idea is to keep the oil in the engine. If it's in the hoses, it's not in the engine. Plus if there's a lot of oil in the hoses, it might disrupt the flow of air.

I use the stock LH and EZK with knock sensors, Bill just tweeks the time and retard amounts.

No ice-water tank. That works for drag races, but not for long distance high speed stuff in the desert. I have two intercooler heat exchangers, one before entering the intercooler and one after but before it enters the reservoir (3 gallons). I just want to keep the air temps reasonable, which it does except when I'm making the high speed (200+) run at the trap (45 miles in). After I cruise a few miles at 170 mph and the water temps drop again.

As for octane boosters, I was going to see how just water worked this run, then adjust as I find the results. I've tried running race fuel, but that's problematic for me (especially when I was driving the car to and from the events). There are additives that could be used, but I'll wait to see it that's necessary.

The pulleys were size to give optimum output at 6000 RPM by people that do this stuff on a more regular basis. So I just leave it like that. I have had Tim/Todd rebuild the supercharger and use better internal bearings to help with reliability and heat resistance.

The goal of this kind of event is sustain a high speed average, the top speed run is just for bragging rights, so is of secondary interest. If all goes well, and I think the car (and I) can take it, I'll go for a higher average in the future.

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

#26

Nordschleife Master

No ice-water tank. That works for drag races, but not for long distance high speed stuff in the desert. I have two intercooler heat exchangers, one before entering the intercooler and one after but before it enters the reservoir (3 gallons). I just want to keep the air temps reasonable, which it does except when I'm making the high speed (200+) run at the trap (45 miles in). After I cruise a few miles at 170 mph and the water temps drop again.

At 200 mph, there's a lot of air flow available to cool the heat exchangers. Do you have photos of your ducting of air into the heat exchangers?

Is the problem during the 200mph + stint the air temperature in the intake manifold only or also the water temperature in the cooling reservoir? If it's the water temperature also, then better heat exchangers and/or better ducting can help. Also, a larger water reservoir will also help for a period of time.

If it's the intake air temperature only (while the water temperature stays reasonable) then you'd probably need a bigger intercooler core or alternative cooling methods. I think there are a number of ways to improve intercooling for that short stint at 200mph+ Are you allowed to spray water on the intercoolers? Evaporating water has high cooling capacity, both inside the intake manifold as well as on the outside surface of the water-to-air intercooler. At 200 mph, the water won't stay long enough on the surface of a well-ducted heat exchanger.

#27

Addict

Rennlist Member

Rennlist Member

Thread Starter

That's interesting. I've thought about intercooling recently.

At 200 mph, there's a lot of air flow available to cool the heat exchangers. Do you have photos of your ducting of air into the heat exchangers?

Is the problem during the 200mph + stint the air temperature in the intake manifold only or also the water temperature in the cooling reservoir? If it's the water temperature also, then better heat exchangers and/or better ducting can help. Also, a larger water reservoir will also help for a period of time.

If it's the intake air temperature only (while the water temperature stays reasonable) then you'd probably need a bigger intercooler core or alternative cooling methods. I think there are a number of ways to improve intercooling for that short stint at 200mph+ Are you allowed to spray water on the intercoolers? Evaporating water has high cooling capacity, both inside the intake manifold as well as on the outside surface of the water-to-air intercooler. At 200 mph, the water won't stay long enough on the surface of a well-ducted heat exchanger.

At 200 mph, there's a lot of air flow available to cool the heat exchangers. Do you have photos of your ducting of air into the heat exchangers?

Is the problem during the 200mph + stint the air temperature in the intake manifold only or also the water temperature in the cooling reservoir? If it's the water temperature also, then better heat exchangers and/or better ducting can help. Also, a larger water reservoir will also help for a period of time.

If it's the intake air temperature only (while the water temperature stays reasonable) then you'd probably need a bigger intercooler core or alternative cooling methods. I think there are a number of ways to improve intercooling for that short stint at 200mph+ Are you allowed to spray water on the intercoolers? Evaporating water has high cooling capacity, both inside the intake manifold as well as on the outside surface of the water-to-air intercooler. At 200 mph, the water won't stay long enough on the surface of a well-ducted heat exchanger.

http://928.jorj7.com/intercooler/

I have a few ideas on what/how to upgrade the intercooler functionality on the car. I'm planning to add vents on the top of the fenders after the heat exchangers to aid air flow. I also want to increase the size of the heat exchangers, but have to figure out how to get rid of the exist headlights and replace them with something that takes up less space in the front fender.

If I can keep the water temps down, but the air temps stay high, then I would look at replacing the intercooler core (although my air temp sensor on the intercooler broke, so I'm looking for a new air temp sensor with a 1/8" NTP fitting).

Oh it's not just a few seconds at 200+, it's about 10 miles (~2 1/2 minutes). If I do decide to go up in speed class, this time/distance will increase, so I will need to address this by then.

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

#28

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Since I've done a bunch of testing in these engines about oil and windage, I might be able to add some thoughts.

"Stock" ventilated 928 engines will frequently loose more than 2 quarts of oil during this particular style "race" event. Combine that with several quarts of oil pumped into and sitting in the cylinder heads, a quart or so suspended in crankcase windage, and there's not much oil left around the oil pick-up....a seriously dangerous situation at 200mph!

At higher rpms, the oil filler neck area is a real mess. Tremenous amounts of air mixed with tremendous amounts of oil. A baffle there does some good. A well engineered oil/air separator does better. A combination of both does even more. George is using one of my latest design oil/air separators, combined with the stock baffle (I hope.)

The balance of the crankcase vapors from this area are them vented into the valve covers, for additional separation.

The added vents in the valve cover help this dramatically....right up to the point where the oil volume in the valve covers overcomes the ability for the drains to deal with.

Far from a perfect solution, these items are designed to help in a situation where a dry sump system should be incorporated, but is not, for a variety of reasons. (Like when multiple used engines can be purchased, for the price of a correct dry sump system.....disregarding the potential costs/results of having an engine "explode" at 200mph.)

"Stock" ventilated 928 engines will frequently loose more than 2 quarts of oil during this particular style "race" event. Combine that with several quarts of oil pumped into and sitting in the cylinder heads, a quart or so suspended in crankcase windage, and there's not much oil left around the oil pick-up....a seriously dangerous situation at 200mph!

At higher rpms, the oil filler neck area is a real mess. Tremenous amounts of air mixed with tremendous amounts of oil. A baffle there does some good. A well engineered oil/air separator does better. A combination of both does even more. George is using one of my latest design oil/air separators, combined with the stock baffle (I hope.)

The balance of the crankcase vapors from this area are them vented into the valve covers, for additional separation.

The added vents in the valve cover help this dramatically....right up to the point where the oil volume in the valve covers overcomes the ability for the drains to deal with.

Far from a perfect solution, these items are designed to help in a situation where a dry sump system should be incorporated, but is not, for a variety of reasons. (Like when multiple used engines can be purchased, for the price of a correct dry sump system.....disregarding the potential costs/results of having an engine "explode" at 200mph.)

#29

Nordschleife Master

Here is a page with the current heat exchanger set up:

http://928.jorj7.com/intercooler/

I have a few ideas on what/how to upgrade the intercooler functionality on the car. I'm planning to add vents on the top of the fenders after the heat exchangers to aid air flow. I also want to increase the size of the heat exchangers, but have to figure out how to get rid of the exist headlights and replace them with something that takes up less space in the front fender.

If I can keep the water temps down, but the air temps stay high, then I would look at replacing the intercooler core (although my air temp sensor on the intercooler broke, so I'm looking for a new air temp sensor with a 1/8" NTP fitting).

Oh it's not just a few seconds at 200+, it's about 10 miles (~2 1/2 minutes). If I do decide to go up in speed class, this time/distance will increase, so I will need to address this by then.

http://928.jorj7.com/intercooler/

I have a few ideas on what/how to upgrade the intercooler functionality on the car. I'm planning to add vents on the top of the fenders after the heat exchangers to aid air flow. I also want to increase the size of the heat exchangers, but have to figure out how to get rid of the exist headlights and replace them with something that takes up less space in the front fender.

If I can keep the water temps down, but the air temps stay high, then I would look at replacing the intercooler core (although my air temp sensor on the intercooler broke, so I'm looking for a new air temp sensor with a 1/8" NTP fitting).

Oh it's not just a few seconds at 200+, it's about 10 miles (~2 1/2 minutes). If I do decide to go up in speed class, this time/distance will increase, so I will need to address this by then.

In terms of the heat exchangers, the 928 fenders fit absolutely massive liquid-to-air heat exchangers with the headlights fully operational. The largest core volume that fits on both sides is 10"x10"x6" per side. That's absolutely massive. A smoothly diffusing duct from the front bumper will feed that 10"x10" area the best. If you put one of those on each side, they'll flow so much air with so much surface area that the system should have not problem whatsoever keeping the water temperatures stable.

The fans start hurting at relatively low speeds. At above 100 mph, you'd almost certainly cool better without any fans if the air ducting is correct.

#30

Drifting

Thanks Matt. I'll be racing the 928 and Bill will be in the tow vehicle, hopefully both will be running at the end of the event.

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

__________________

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

What tire are you running and how do you inspect them before racing?

Last edited by The Fixer; 05-05-2015 at 05:19 PM.